Professional Documents

Culture Documents

Bicomponent Fiber

Uploaded by

Ashishn Thakur0 ratings0% found this document useful (0 votes)

161 views2 pagesBicomponent Fiber is comprised of two polymers of different chemical and / or physical properties extruded from the same spinneret. Most commercially available bicomponent fibers are configured in a sheath / core, side-by-side, or eccentric sheath/core arrangement.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBicomponent Fiber is comprised of two polymers of different chemical and / or physical properties extruded from the same spinneret. Most commercially available bicomponent fibers are configured in a sheath / core, side-by-side, or eccentric sheath/core arrangement.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

161 views2 pagesBicomponent Fiber

Uploaded by

Ashishn ThakurBicomponent Fiber is comprised of two polymers of different chemical and / or physical properties extruded from the same spinneret. Most commercially available bicomponent fibers are configured in a sheath / core, side-by-side, or eccentric sheath/core arrangement.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Bicomponent Fiber

Bicomponent Fiber

Current U.S. Bicomponent Fiber Producers: BASF Corporation; DuPont Company; Fiber Innovation Technology, Inc.;

KoSa; Solutia Inc.

Definition: Bicomponent fiber is comprised of two polymers of different chemical and / or physical properties extruded

from the same spinneret with both polymers within the same filament.

Bicomponent Fiber Capabilities

Bicomponents can provide:

● Thermal bonding

● Self bulking

● Very fine fibers

● Unique cross sections

● The functionality of special polymers or additives at reduced cost

Common Bicomponent Configurations

Most commercially available bicomponent fibers are configured in a sheath / core, side-by-side, or eccentric sheath / core

arrangement.

Sheath / Core Side by Side Eccentric Sheath / Core

Advantages of Bicomponent Thermal Binder Fibers

● Uniform distribution of adhesive

● Fiber remains a part of structure and adds integrity

● Customized sheath materials to bond various materials

● Wide range of bonding temperatures

● Cleaner, environmentally friendly (no effluent)

● Recyclable

● Lamination / molding / densification of composites.

Common Polymer Combinations in Bicomponent Thermal Binder Fibers

● Polyester Core (250C melt point) with Copolyester Sheath (melt

points of 110C to 220C)

● Polyester Core (250C melt point) with Polyethylene Sheath (130C

melt point)

● Polypropylene Core (175C melt point) with Polyethylene Sheath (130C

melt point)

Self Bulking Bicomponent Fibers

http://www.fibersource.com/f-tutor/bicomponent.htm (1 of 2) [14-03-2010 17:10:05]

Bicomponent Fiber

● Created most often with side-by-side or eccentric cross section

● Variation in orientation across the fiber causes crimping due to differential shrinkage or strain with applied heat or

relaxation.

top • home • map • feedback • fiber products • classroom

http://www.fibersource.com/f-tutor/bicomponent.htm (2 of 2) [14-03-2010 17:10:05]

You might also like

- Man Made FibereDocument57 pagesMan Made FibereSuraj RaghvNo ratings yet

- Bi ComponentDocument13 pagesBi ComponentA.K.M. Rashedul IslamNo ratings yet

- SpandexDocument56 pagesSpandexmonowar karimNo ratings yet

- Heat SettingDocument6 pagesHeat SettingHaco Chinedu ObasiNo ratings yet

- Polymer MorphologyDocument4 pagesPolymer Morphologyrehrifat2000No ratings yet

- SpandexDocument1 pageSpandexNavnath PingaleNo ratings yet

- Acrylic FiberDocument9 pagesAcrylic FiberNeeraj JainNo ratings yet

- Gel Spun PE FiberDocument35 pagesGel Spun PE FiberNimra GhafoorNo ratings yet

- Effect of First Heater Temperature Variations On The Polyester Yarn Properties of False Twist Texturing TechniquesDocument5 pagesEffect of First Heater Temperature Variations On The Polyester Yarn Properties of False Twist Texturing TechniquesIberê Cruz Freitas100% (1)

- Heat SettingDocument17 pagesHeat SettingSajib IglesiasNo ratings yet

- 2011 - Sage - Natural Fiber-Based Reinforcements in Epoxy Composites Processed by Filament WindingDocument9 pages2011 - Sage - Natural Fiber-Based Reinforcements in Epoxy Composites Processed by Filament WindingECE IV YearNo ratings yet

- Astm-F 1868Document8 pagesAstm-F 1868lizethbohorquez82No ratings yet

- Gelation and Fusion Process of PVC PlastisolDocument32 pagesGelation and Fusion Process of PVC Plastisolhost1000youtub100% (1)

- High Performance FibreDocument11 pagesHigh Performance FibreGgum LiNo ratings yet

- Rheological Study of The Plasticizer On Fusion Processes of PVC Plastisol PDFDocument8 pagesRheological Study of The Plasticizer On Fusion Processes of PVC Plastisol PDFvampireheart_soulNo ratings yet

- Manufacturing End Uses: Riaz-Ul-Haq 060820-054Document12 pagesManufacturing End Uses: Riaz-Ul-Haq 060820-054Kasra GolbanNo ratings yet

- Polyester Fibers: Fig.1: Production of Polyethylene TerephthalateDocument12 pagesPolyester Fibers: Fig.1: Production of Polyethylene TerephthalateShailendra Mishra100% (1)

- POY Spinning of Polyester - New Technologies To Improve ProductivityDocument8 pagesPOY Spinning of Polyester - New Technologies To Improve ProductivitySteve Jenkins100% (1)

- Textile CompositesDocument22 pagesTextile CompositesmalikengrNo ratings yet

- Study of Structure and Properties of Air Jet Textured YarnDocument15 pagesStudy of Structure and Properties of Air Jet Textured Yarnpraveen kumarNo ratings yet

- Processing of Elastomeric MaterialsDocument140 pagesProcessing of Elastomeric MaterialsNano MaxNo ratings yet

- Wet II Presentation Group 3 Antimicrobial FinishDocument29 pagesWet II Presentation Group 3 Antimicrobial FinishZillur Rahman SaykatNo ratings yet

- Textile Processing: Energy Saving Techniques in the Textile IndustryDocument165 pagesTextile Processing: Energy Saving Techniques in the Textile IndustryPurnesh JagadNo ratings yet

- Fabrication of Ceramic Matrix Composites by Liquid Phase InfiltrationDocument5 pagesFabrication of Ceramic Matrix Composites by Liquid Phase InfiltrationyoukahoNo ratings yet

- DesizingDocument4 pagesDesizingsyed asim najam100% (2)

- Pojet PPT 1Document39 pagesPojet PPT 1Tushar JainNo ratings yet

- Knitted Fabric DefectDocument171 pagesKnitted Fabric DefectsakthigurusamyNo ratings yet

- Static ElectricityDocument2 pagesStatic ElectricitytusharNo ratings yet

- Aramid FiberDocument22 pagesAramid FiberAsad Jamil RanaNo ratings yet

- By: Hemant Ghanghor & Patanjal KumarDocument15 pagesBy: Hemant Ghanghor & Patanjal KumarpatanjaliictNo ratings yet

- High Performance Fibers Hifza 1Document20 pagesHigh Performance Fibers Hifza 1Hifza khalidNo ratings yet

- Introduction To Sulfur DyesDocument24 pagesIntroduction To Sulfur Dyesnitin p100% (1)

- Mechanical Properties of Weft Knitted FabricsDocument6 pagesMechanical Properties of Weft Knitted FabricsAhmad SamerNo ratings yet

- Unit Ii: Count of The YarnDocument9 pagesUnit Ii: Count of The YarngowriNo ratings yet

- Bio-Based Composites Made From Agrowaste: Lucas Whale & Suviti ChariDocument38 pagesBio-Based Composites Made From Agrowaste: Lucas Whale & Suviti CharisuvicNo ratings yet

- Unit 1Document22 pagesUnit 1ShyamalaNo ratings yet

- Renewable Energy Resources: Textile ProcessingDocument17 pagesRenewable Energy Resources: Textile ProcessingrohithNo ratings yet

- Lecture Three Natural Bast FiberDocument46 pagesLecture Three Natural Bast FiberGemeda GebinoNo ratings yet

- Core Handling EquipmentDocument20 pagesCore Handling EquipmentAnjas HardiansyahNo ratings yet

- SAN & ABS Polymers GuideDocument9 pagesSAN & ABS Polymers GuideSdkmega HhNo ratings yet

- Singeing: ND THDocument45 pagesSingeing: ND THSubham PalNo ratings yet

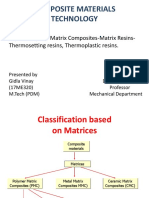

- Polymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic ResinsDocument27 pagesPolymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic Resinsgidlavinay100% (1)

- Unit 4-Cotton PDFDocument25 pagesUnit 4-Cotton PDFFuad HamidNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document2 pagesGujarat Technological University: W.E.F. AY 2018-19Rushi TannaNo ratings yet

- National Textile University: B.Sc. Textile Engineering Practical Lab Report / Fall-2018Document5 pagesNational Textile University: B.Sc. Textile Engineering Practical Lab Report / Fall-2018Faisal SaeedNo ratings yet

- Binders: 1. Compaction Behaviour of Organic Binders in Alumina Ceramics (PVA & PEG) General FactsDocument13 pagesBinders: 1. Compaction Behaviour of Organic Binders in Alumina Ceramics (PVA & PEG) General FactsPranav KumarNo ratings yet

- Textile Dyeing Introduction: Fiber Structure and Dyeing ProcessDocument10 pagesTextile Dyeing Introduction: Fiber Structure and Dyeing ProcessGanga DharanNo ratings yet

- Inspection 4 point fabric systemDocument1 pageInspection 4 point fabric systemtexcons6771No ratings yet

- Application of Polypropylene in Technical TextilesDocument11 pagesApplication of Polypropylene in Technical TextilesDr Muhammad Mushtaq Mangat100% (1)

- Studying Effects of Fabric Thickness, Loop Shape Factor, Fabric Tightness Factor and Aerial Weight On Thermal Conductivity of Plain Single Jersey Cotton Knitted Fabric Using Box Behnken DesignDocument8 pagesStudying Effects of Fabric Thickness, Loop Shape Factor, Fabric Tightness Factor and Aerial Weight On Thermal Conductivity of Plain Single Jersey Cotton Knitted Fabric Using Box Behnken DesignIJEACS UKNo ratings yet

- Thermal Properties: Chapter OutlineDocument4 pagesThermal Properties: Chapter OutlinehemontoNo ratings yet

- Filament Winding Process and ApplicationsDocument6 pagesFilament Winding Process and Applications林丽莹No ratings yet

- Quality On Yarn 1Document39 pagesQuality On Yarn 1Ashiq Khan100% (1)

- JBF Industries Ltd. Dalal Mott Mac DonaldDocument76 pagesJBF Industries Ltd. Dalal Mott Mac DonaldJimish PanchalNo ratings yet

- Mechanical FinishingDocument28 pagesMechanical FinishingRahulKumbhareNo ratings yet

- WPT 2Document141 pagesWPT 2SalimNo ratings yet

- Man Made Fiber Textile ProcessDocument39 pagesMan Made Fiber Textile ProcessGarmentLearnerNo ratings yet

- Revised List of Mechanics of Fibrous Structures (TET) 2k19Document35 pagesRevised List of Mechanics of Fibrous Structures (TET) 2k19RAZA Khn100% (1)

- Subject: Basic Technology Topic: Processing of Materials Sub-Topic: Plastic and Rubber Class: Jss 3Document34 pagesSubject: Basic Technology Topic: Processing of Materials Sub-Topic: Plastic and Rubber Class: Jss 3Abdulrahman IbrahimNo ratings yet

- Improving Degradation Resistance of Rubber CompoundsDocument1 pageImproving Degradation Resistance of Rubber CompoundsRivaldi JovianNo ratings yet

- Unspecified Toler. As Per 1503302-1 1996 E2: SCALE-5:1Document1 pageUnspecified Toler. As Per 1503302-1 1996 E2: SCALE-5:1kuraimundNo ratings yet

- PLASTICS Exercises (PROPERTIES, CLASSIFICATION) Rubén Martín 3ºE Azul (1) .OdtDocument3 pagesPLASTICS Exercises (PROPERTIES, CLASSIFICATION) Rubén Martín 3ºE Azul (1) .OdtJuan Carlos De la mataNo ratings yet

- Introduction to Polyurethane ChemistryDocument31 pagesIntroduction to Polyurethane ChemistryMohammed ShaabanNo ratings yet

- Centrifugal CastingDocument4 pagesCentrifugal CastingaerovinuNo ratings yet

- Studi Pengaruh Jenis Kemasan Dan Ketebalan Plastik Terhadap KARAKTERISTIK MUTU REBUNG BAMBU TABAH (Gigantochloa Nigrociliata KURZ) KeringDocument10 pagesStudi Pengaruh Jenis Kemasan Dan Ketebalan Plastik Terhadap KARAKTERISTIK MUTU REBUNG BAMBU TABAH (Gigantochloa Nigrociliata KURZ) KeringlulalalaNo ratings yet

- Use of Plastics in Different Aspects of The Construction IndustryDocument7 pagesUse of Plastics in Different Aspects of The Construction Industryjanhavi28No ratings yet

- PS Catalogue Eng KKPCDocument2 pagesPS Catalogue Eng KKPCAyaan AnowarNo ratings yet

- Daban 8817 Super GundamDocument23 pagesDaban 8817 Super GundamVash HeroNo ratings yet

- Plastics, Wood Ad RubberDocument32 pagesPlastics, Wood Ad RubberPaul KagunyaNo ratings yet

- Thermoset Vs ThermoplasticDocument2 pagesThermoset Vs ThermoplasticMina Samy abd el zaherNo ratings yet

- Styrofoam - WikipediaDocument4 pagesStyrofoam - Wikipediakirthi83No ratings yet

- Chapter 3 Synthetic Fibres and Plastics: Samved SchoolDocument5 pagesChapter 3 Synthetic Fibres and Plastics: Samved SchoolAgent NorseNo ratings yet

- Polymer Processing HandoutDocument68 pagesPolymer Processing HandoutibraheemNo ratings yet

- Apollit 03Document18 pagesApollit 03Kostas FrantzikNo ratings yet

- Plastic RecyclingDocument7 pagesPlastic RecyclingindraNo ratings yet

- Puffer Riscaldamento Scheda TecDocument3 pagesPuffer Riscaldamento Scheda TecAlexander CiutiNo ratings yet

- Textile Fibres: Textile Engineering & Fibre ScienceDocument2 pagesTextile Fibres: Textile Engineering & Fibre ScienceSK RAJUNo ratings yet

- Rubber Product AhmedabadDocument33 pagesRubber Product AhmedabadKrupam Thetenders.comNo ratings yet

- PDL Handbook Series Guide to Plastics Engineering BooksDocument1 pagePDL Handbook Series Guide to Plastics Engineering BooksDaryl ChianNo ratings yet

- Biograde BL-FDocument3 pagesBiograde BL-FXuân Giang NguyễnNo ratings yet

- Moulds DesignDocument240 pagesMoulds DesignSree Raj92% (13)

- Adhesives Sealants FOR Panel AssemblyDocument2 pagesAdhesives Sealants FOR Panel AssemblyBhushan VermaNo ratings yet

- Yadr I ClassesDocument20 pagesYadr I ClassesRiya JaiswalNo ratings yet

- Polyethylene (PE) - Properties, Uses & ApplicationDocument19 pagesPolyethylene (PE) - Properties, Uses & ApplicationMagamba MirandaNo ratings yet

- Conveyor Belts For Aluminum Extrusion: The Megadyne GroupDocument8 pagesConveyor Belts For Aluminum Extrusion: The Megadyne GroupJuan Andrés Díaz RiveroNo ratings yet

- Lit-Std - Pars Ethylene Kish Polyethylene Pipe and Fitting StandardsDocument41 pagesLit-Std - Pars Ethylene Kish Polyethylene Pipe and Fitting Standardsbabakfun2000No ratings yet

- Placi Acrilice Clear, Opal, NegruDocument8 pagesPlaci Acrilice Clear, Opal, NegruPetre NicaNo ratings yet

- Atmer Anti-StaticDocument8 pagesAtmer Anti-Staticrp.qscplNo ratings yet