Professional Documents

Culture Documents

Par de Apriete en Bridas

Uploaded by

Jose Humberto Aranda0 ratings0% found this document useful (0 votes)

859 views1 pageTorque values for each bolt diameter are shown in Table 1. Torque values should be uniformly applied at each step.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTorque values for each bolt diameter are shown in Table 1. Torque values should be uniformly applied at each step.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

859 views1 pagePar de Apriete en Bridas

Uploaded by

Jose Humberto ArandaTorque values for each bolt diameter are shown in Table 1. Torque values should be uniformly applied at each step.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Página 1 de 1

De: Juan Montemuiño [jmontemuino@grupocobra.com]

Enviado: Jueves, 04 de Febrero de 2010 11:26

Para: ELADIO ANTONIO APABLAZA HERNANDEZ; ERWIN ANDRES HEVIA RETAMAL; HERNAN JOSE MENDEZ BERMUDEZ; JOSE

HUMBERTO ARANDA PERNIA; MARCO ANTONIO VERA GAMBOA; NILO ANDRES ARAYA GONZALEZ; PALEMON ARNOLDO PIZARRO

HUIDOBRO; PILAR SOFIA GIRON RAMIREZ; RICARDO ALFREDO CARVAJAL GONZALEZ; SERGIO ANDRES ARANCIBIA GARCIA

CC: 'Joaquin Romero'; 'Jesus Villar'; Andrea Ocaranza

Asunto: CTA-COBS-SALFA-048/10: TABLA PARES DE APRIETE PARA BOP

Importancia: Alta

Estimados,

Adjunto tabla de aprietes para los embridamientos del BOP.

Los valores aquí indicados son orientativos y es responsabilidad de Salfa el asegurar el correcto par de apriete que dependerá de las condiciones de montaje,

empaquetaduras empleadas, etc..

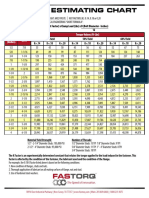

VI. INSTALLATION PROCEDURE

D. Bolt Tensioning Torque Requirements

b. The torque values should be uniformly applied at each step.

c. After achieving the required bolt stress, final tightening may be made at the required torque in a clockwise bolt-to-bolt sequence.

d. The procedure in steps a through c is to be used, in conjunction with instructions from the manufacturer of the torque wrench, for torquing

flanged joints. Torque values for each bolt diameter are shown in Table 1.

TABLE 1

Bolt Diameter Wrench Torque Bolt Load Bolt Diameter Wrench Torque Bolt Load

Inches Kg.m Kg Inches Kg.m Kg

3/4 26 7,535 1-3/4 381 49,398

7/8 41 10,454 1-7/8 507 57,481

1 63 13,747 2 558 66,162

1-1/8 90 18,163 2-1/4 806 85,397

1-1/4 127 23,177 2-1/2 1116 107,077

1-3/8 173 28,815 2-3/4 1501 131,202

1-1/2 203 35,052 3 1957 157,720

1-5/8 279 41,913

Notes for Table 1:

1. Table 1 shall be used for SA 193-B7, SA 193-B16 bolts, and flange material having the same thermal coefficient or expansion as the bolts.

2. Reduce bolt load and wrench torque specified in Table 1 by a factor of .44 for SA 193-B8 C1. 1 bolting.

3. Reduce bolt load and wrench torque specified in Table 1 by a factor of .80 for SA 453-GR 660 bolting.

4. Bolt load specified in Table 1 produces theoretical stress of about 3870 kg/cm2 in bolts which will result in actual stress of 3165 kg/cm2 due to frictional losses

and relaxation.

Un saludo

Juan A. Montemuiño Ayaso

COBRA PLANTAS INDUSTRIALES

Supervisor de Construcción Mecánico

Móvil: (+34) 689189622

Móvil Chile: (+56) 989208893

e-mail: jmontemuino@grupocobra.com

12-10-2010

You might also like

- Thread Cutting, Taping and BroachingDocument111 pagesThread Cutting, Taping and BroachingKundan Patil100% (1)

- Wire Rope Sling Capacity Charts PDFDocument18 pagesWire Rope Sling Capacity Charts PDFRiko Bin Zulkifli100% (3)

- Mechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionFrom EverandMechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionA. SherryRating: 4 out of 5 stars4/5 (5)

- Cost BreakupDocument6 pagesCost Breakuppiyush sharma100% (1)

- Asme B 18.2.2 2015Document14 pagesAsme B 18.2.2 2015Plinio Pazos50% (2)

- Handbook - CalculationsDocument2 pagesHandbook - CalculationsMohammad AliNo ratings yet

- Illustrated Guide to Door Hardware: Design, Specification, SelectionFrom EverandIllustrated Guide to Door Hardware: Design, Specification, SelectionNo ratings yet

- Eg 640-365-168 WFLPMC Llii640.16.15.01j-00 20220726Document45 pagesEg 640-365-168 WFLPMC Llii640.16.15.01j-00 20220726ZakNo ratings yet

- Casting, Welding, Machine Tools, Material SC PDFDocument240 pagesCasting, Welding, Machine Tools, Material SC PDFSanjay Kajal0% (1)

- Crosby ShackleDocument1 pageCrosby ShacklevrandyNo ratings yet

- Powder Bushing Chart For MECReloadersDocument2 pagesPowder Bushing Chart For MECReloadersbowsniperx100% (1)

- DIN EN10084 - Case Hardening SteelsDocument40 pagesDIN EN10084 - Case Hardening SteelsNicole KeithNo ratings yet

- Weight Per Foot of Fillet Welds and Common Butt WeldsDocument1 pageWeight Per Foot of Fillet Welds and Common Butt WeldsDavid D'AgostinoNo ratings yet

- System 3R EMD Electrode Holder T-2389-E - EdmDocument108 pagesSystem 3R EMD Electrode Holder T-2389-E - EdmNamtien UsNo ratings yet

- Crosby G-450 Wire Rope Clips SpecsDocument2 pagesCrosby G-450 Wire Rope Clips SpecsUlises CastroNo ratings yet

- Demo in TleDocument47 pagesDemo in TleRose Amor Mercene-LacayNo ratings yet

- TOOLS and EQUIPMENTDocument22 pagesTOOLS and EQUIPMENTDrew Daniel SosaNo ratings yet

- MKT 001 Rev 02 Rotary Shoulder Handbook RS PDFDocument116 pagesMKT 001 Rev 02 Rotary Shoulder Handbook RS PDFKarla Hernandez0% (1)

- ANSI B 18.2.1 Screw-UnilokDocument2 pagesANSI B 18.2.1 Screw-Unilokssureshkar7699No ratings yet

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor Shacklesramy abazaNo ratings yet

- Wire Rope GripsDocument5 pagesWire Rope Gripsgeorge_zouridisNo ratings yet

- Chapter 3 - Wire Rope ClipsDocument6 pagesChapter 3 - Wire Rope ClipsSwajanSandesh BGBSNo ratings yet

- CA Round Swirl DiffuserDocument3 pagesCA Round Swirl DiffuserYapKJNo ratings yet

- CoreDocument1 pageCoreAlberto OrtizNo ratings yet

- 9 - Single Joint ElevatorDocument2 pages9 - Single Joint ElevatorleoNo ratings yet

- Flemish Eye Wire Rope SlingsDocument3 pagesFlemish Eye Wire Rope SlingsSalihNo ratings yet

- MM T Frame Maintenance ManualDocument9 pagesMM T Frame Maintenance Manualneomar BaptistaNo ratings yet

- Prevailing Torque Guide: Inch SizesDocument1 pagePrevailing Torque Guide: Inch Sizeskarthi.indya9274No ratings yet

- Operation Manual For TA ElevatorDocument7 pagesOperation Manual For TA ElevatortraidenNo ratings yet

- As SPT FS Sy EqrDocument2 pagesAs SPT FS Sy EqrAndreyNo ratings yet

- cROSBY LINKSDocument1 pagecROSBY LINKSTheo van der BergNo ratings yet

- FASTORQ-Torque-Estimating-Chart - Barra RoscadaDocument1 pageFASTORQ-Torque-Estimating-Chart - Barra RoscadaLucas RezendeNo ratings yet

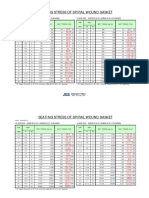

- #1. Torque Table - Spiral Wound Gasket (1) - 1Document6 pages#1. Torque Table - Spiral Wound Gasket (1) - 1jose del carmen rodriguez contrerasNo ratings yet

- Detention Lime Slaker: Series 85Document2 pagesDetention Lime Slaker: Series 85Marcelo GuarachiNo ratings yet

- Appendix A: Table A-I Drill Pipe Capacity and Displacement (English System)Document11 pagesAppendix A: Table A-I Drill Pipe Capacity and Displacement (English System)Hernan FNo ratings yet

- Revised GP-7033 Handbook - CoverDocument116 pagesRevised GP-7033 Handbook - CoverVali BazdagaNo ratings yet

- Astm f4844Document2 pagesAstm f4844Miguel AngelNo ratings yet

- Installation and Maintenance Instructions For Three Phase Induction MotorsDocument9 pagesInstallation and Maintenance Instructions For Three Phase Induction MotorsAnibal QuezadaNo ratings yet

- Normas ChavetasDocument5 pagesNormas ChavetasjofeluNo ratings yet

- Washers - Standard Flat WasherDocument1 pageWashers - Standard Flat WasherMohammed KhalidNo ratings yet

- MA - Spray Ball - 3A - V3 - EN-250726Document6 pagesMA - Spray Ball - 3A - V3 - EN-250726Hoàng Nguyễn VănNo ratings yet

- 6f2e58 0Document2 pages6f2e58 0Marcos QuequeNo ratings yet

- Thread Pitch ChartDocument1 pageThread Pitch Chartyu7468No ratings yet

- PMI-BA Tubing AnchorDocument5 pagesPMI-BA Tubing AnchorSajida QadeerNo ratings yet

- Handbook - Calculations 10 PDFDocument1 pageHandbook - Calculations 10 PDFSmith SivaNo ratings yet

- Ser & TSRDocument8 pagesSer & TSRSAMO THERMALNo ratings yet

- Sev Novec CylinderDocument1 pageSev Novec Cylindertribhuvan ShankarNo ratings yet

- PG-1028-T (HOS) General Data and Specifications: Table 5-3. Prestress Levels For HOSDocument4 pagesPG-1028-T (HOS) General Data and Specifications: Table 5-3. Prestress Levels For HOSAnkush SehgalNo ratings yet

- Aerial 15kVDocument1 pageAerial 15kVPrabhat RanjanNo ratings yet

- Line Pipe - Standard Weight, Threaded - Dimensional DataDocument1 pageLine Pipe - Standard Weight, Threaded - Dimensional Datatarno12No ratings yet

- MIL-PRF-32383 - 3 Battery, Rechargeable, Sealed, BB-2590Document9 pagesMIL-PRF-32383 - 3 Battery, Rechargeable, Sealed, BB-2590ismail suat özaydinNo ratings yet

- Fv-Cat-322-0316 Htaf PDFDocument2 pagesFv-Cat-322-0316 Htaf PDFTaylor RamirezNo ratings yet

- 0-Valvula - Unimizer 3 WaysDocument4 pages0-Valvula - Unimizer 3 WaysMuriloNo ratings yet

- TEL 02-2500-6206 FAX 02-2508-0398 ADD 9F., No.127, Sec. 2, Jianguo N. RD., Zhongshan Dist., Taipei City 104, Taiwan (R.O.C.)Document6 pagesTEL 02-2500-6206 FAX 02-2508-0398 ADD 9F., No.127, Sec. 2, Jianguo N. RD., Zhongshan Dist., Taipei City 104, Taiwan (R.O.C.)Ching HungNo ratings yet

- Filtro Temporario - ColtonDocument2 pagesFiltro Temporario - ColtonHernan Dario PereaNo ratings yet

- Flanged "Y" Strainers Steel / Stn. Stl. - 300YF Series: Ratings MaterialsDocument1 pageFlanged "Y" Strainers Steel / Stn. Stl. - 300YF Series: Ratings MaterialsNitin ZoreNo ratings yet

- Wire Rope Cutting ChartDocument8 pagesWire Rope Cutting ChartAkash SharmaNo ratings yet

- Appennx A: Table A-L Drill Pipe Capacity and Displacement (English System)Document9 pagesAppennx A: Table A-L Drill Pipe Capacity and Displacement (English System)moorpvrNo ratings yet

- Pages From Hilti BrochureDocument1 pagePages From Hilti BrochureCarlos Andres Santin OrtizNo ratings yet

- Dynabolt® Sleeve Anchors: Technical DataDocument1 pageDynabolt® Sleeve Anchors: Technical DataCoco Aryan TundyNo ratings yet

- SOCKOLETDocument1 pageSOCKOLETJOSE DIAZ HERNANDEZNo ratings yet

- Common Sucker Rod SpecificationsDocument1 pageCommon Sucker Rod SpecificationsMichelangeloTiberiiNo ratings yet

- Mechanical-Splice Wire Rope Sling: 115 IWRCDocument4 pagesMechanical-Splice Wire Rope Sling: 115 IWRCokifabianNo ratings yet

- Standard Cable SizesDocument3 pagesStandard Cable SizesNeal PaxtonNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Heat Input and Interpass Temperature During Welding PDFDocument6 pagesHeat Input and Interpass Temperature During Welding PDFVishal Sparkle QE3No ratings yet

- CNC ThesisDocument4 pagesCNC Thesisbkxk6fzf100% (2)

- Guillotine Assembly InstructionsDocument3 pagesGuillotine Assembly Instructions4U6ogj8b9snylkslkn3nNo ratings yet

- Brandix ReportDocument55 pagesBrandix ReportCharitha RanwalaNo ratings yet

- Test PDFDocument6 pagesTest PDFDr. L. Bhanuprakash Reddy100% (1)

- CATIA Apt CodeDocument24 pagesCATIA Apt CodeparipasuNo ratings yet

- Common G and M Codes For CNC MachinesDocument2 pagesCommon G and M Codes For CNC MachinesSiddhrajsinh ZalaNo ratings yet

- Mini La The Users GuideDocument9 pagesMini La The Users GuidepedjaNo ratings yet

- Socket Set Screw SizeDocument2 pagesSocket Set Screw Sizepavan_joshi_5No ratings yet

- 4 Eng Induction Welded Small Diameter TubeDocument22 pages4 Eng Induction Welded Small Diameter TubeDimitri PanagiotouNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 1430-0Document13 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 1430-0Yannick PinsonNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- Faculty of Mechanical Engineering Universiti Teknologi Mara (Uitm) Report FormDocument7 pagesFaculty of Mechanical Engineering Universiti Teknologi Mara (Uitm) Report Formafif lah100% (1)

- BS en 14399-7 2007Document24 pagesBS en 14399-7 2007Kristina KaskNo ratings yet

- Modco Closures: Operation, Maintenance & Welding InstructionsDocument7 pagesModco Closures: Operation, Maintenance & Welding InstructionsWijayanto BekasiNo ratings yet

- Kuliah 4 Pengencangan SambunganDocument24 pagesKuliah 4 Pengencangan SambunganAlifiaNo ratings yet

- Lab Manual: Department of Mechanical EngineeringDocument68 pagesLab Manual: Department of Mechanical EngineeringPrabhat Kumar SahuNo ratings yet

- AA County Deck - GuideDocument2 pagesAA County Deck - GuidegrahamsimmNo ratings yet

- ENG1 FastDocument5 pagesENG1 FastAlexNo ratings yet

- CNC MachinesDocument35 pagesCNC MachinesfitriarpNo ratings yet

- Hardinge Catalog 2351Document48 pagesHardinge Catalog 2351JoeGriffNo ratings yet

- Wall Ladder With BedDocument21 pagesWall Ladder With Bedcrashnburn4uNo ratings yet

- Printed CNC Brutus ManualDocument55 pagesPrinted CNC Brutus ManualGustavoGuevaraNo ratings yet