Professional Documents

Culture Documents

AMS - R&D - Global SMT-interview

Uploaded by

sshaffer_90 ratings0% found this document useful (0 votes)

183 views2 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

183 views2 pagesAMS - R&D - Global SMT-interview

Uploaded by

sshaffer_9Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

26 - Global SMT & Packaging ~ Dacember 2008

dering,

Founded in 1996 to support the vapor reflow market, R&D Techni-

cal Services is thi

Technical

including S

leading source of vapor phase equipment. RED

swvices’ vapor phase systems are used in numerous markets

T solder reflow, selective component rework, lead free sol

ing, drying, mechanical attachment, plastic package testing

and more. Trevor Galbraith, Global SMT & Packaging’s editorinchief,

recently spoke with R&D Technical Services president David Suihkonen

about the renewed interest in vapor phase technology.

(Over the past year, R&D Technical Services has been

focused on two front. First, we have been workin

closely with some of our high-volume customers t0

enhance our inline capability for reflow. This work:

led ust the ewlution of the RD32 inline vapor phase

reflow oven, which won a few industry award cariers

this year. With adjustable pin chain conveyors, contin

‘ous throughpur, multistage preheat and easyeoae

controls this machine san excellent replacement for

the traditional convection evens, making vapor phase a

superior choice forthe inline reflow process

Second, we have been very focused on bringing the

advantages of va

phase to the s

rework environment. This development proved succes

tive component

ful in solving many of the ues now facing the rework

ofthe industry

“The ViWorks 24 rework station brings a number of

benefits tothe

ik environment. One ofthe bigs

abi

temperature seen by the bo

cd and component.

Because the maximum reflow temperature i tied to

the boiling point of che fluid, iis impossible to over

heat the proxluct Le’ say yo

melts at 221°C. ¥

older that

‘would simply use a fluid with

230°C for rfl effectively closing the

ane window ta 9°C, This isthe same reason

that vapor phase reflow i gaining ground in the reflow

industy-the ability to limie the maximum temperature

‘STVIISLYH SHY

801S-Z22-998

‘while stil attaining perfect reflow on all

sections ofthe produc

(Other key elements ae the uniformity

and repeatability of vapor phase and the

‘way it transfers heat. No longer ae you

required to deliver excessive amounts of

heat through IR or hor arto ger all portions

‘of the component to heat evenly, There i

no shadowing, reflection or deflection of

Inet in the vapor phase process.

Some ofthe isis facing the rework

industey today include excessive heat,

uneven heat and the migration ofthe heat

to other areas ofthe circuit board. Vapor

phase rework effectively solves these issues

Why is R&D Technical Services so

important tothe current electronics

industry? What do you provide that

competitors cannot?

‘Aside from the fat thae vapor phase is

‘product whose time has come, I think

RSD Technical Srvices has been successful

fora several reasons, namely quality, valve

and customer support. Ir stats by working

to build only the highest quality equipment

‘using only che highest quality material,

‘We then couple this with experience. Ray

‘Wille and Ihave mone than 50 years of

‘combined vapor phase experience-we

know what works.

Alter building a quality piece of

‘equipment, we eake our knowledge and

apply itto customer support treating every

‘eustomer with respect. We know a lange

portion of our busines ie from customer

referral and word of mouth, When your

name is on the product, you take your

reputation seriously. I think the reputation

‘of our pradits andl our company is wery

igh amonsst our customers fis oxe goal

AtRGD Technical

Services you've

gence of interest in

Toaedovan Mission Possible.

credit this revival?

A number of factors Versatility that beats compleaity.

have contributed,

Leadree solder hat

certainly played

role. The higher

melting points of

lead-free solder

have forced many

reflow methods

ico uncomfortably

high eomperarures.

Unable to transfer

het as effectively

and consistently as

vapor phase, they

are forced i some

instances to push,

‘maim temperse

rues to umaccepe

able level. They are

simply unable to

close the window

bewecn reflow and

‘peak temperatures

as efficiently a6

PHILIPS

Its not just a promise, its a fact!

Assembleon

vapor phase, which

can place reliability and consistency at rick,

would sey more difficule components

and board architecture also have played a

part, More densely populaed hoards and

‘mote demanding components lend

themselves to otch easier teow vsing

vapor phase and its condensation method

“This is the same reason that vapor

phase reflow is gaining ground in the

reflow industry—the ability to limit

the maximum temperature while still

attaining perfect reflow on all sections

of the product.”

to keep ie that way. At R&D Technical

Services, customer support isnot just tag

ling, ic 62 way of ie, and I think even in

today's world people take note ofthat.

cof beat transfer

‘Vapor phase ovens have evolved as well

with beter controls, beter containment,

higher quality construction and, quite

frankly, more interest by the industry in

taking an unbiased evaluation ofa mature

success proces.

feel all these factors have played a

part inthis vapor phase resurgence.

How docs the rest of 2008 and into 2009,

look for R&D Technical Services!

Projections ate always part science, part

‘black magic and pare guess work. Right

‘pow, R&D Technical Services on tack

for 2008 tobe its best year eve. In the first,

half of 2008, we posted the best six-month

‘numbers in our [2-year history. With the

renewed interest in vapor phase, I expect

owt from 2009 as wll

‘Asa company, we will continue to

‘expand our reach, pushing into more

‘emerging economies and strengthening

‘our postion in regions where we are

already strong. We will continue to be the

leader in developing new approaches and

applications for vapor phase, and will work

to make our vapor phase rework station

an influential player inthe rework market

RED Technical Services will continue

to be the best at what we do from high:

‘quality, highwalue equipment to hands-on

‘customer support

‘SIVIAILYH SAY

Wer Hr Ary amr

801LS-ZL2-998

www.glabalemt.net

‘Global SMT & Packaging - December 2008 - 27

You might also like

- AMS - SQL - CFC Naming ConventionDocument10 pagesAMS - SQL - CFC Naming Conventionsshaffer_9No ratings yet

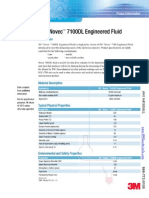

- AMS - 3M - Fluorinert FC-43Document4 pagesAMS - 3M - Fluorinert FC-43sshaffer_9No ratings yet

- AMS - V-Works 24 StandardDocument2 pagesAMS - V-Works 24 Standardsshaffer_9No ratings yet

- AMS - SQL - Refrigerant Ref TableDocument6 pagesAMS - SQL - Refrigerant Ref Tablesshaffer_9No ratings yet

- AMS - 3M - Fluorinert FC-3283Document4 pagesAMS - 3M - Fluorinert FC-3283sshaffer_9No ratings yet

- AMS - 3M - Cool Under FireDocument8 pagesAMS - 3M - Cool Under Firesshaffer_9No ratings yet

- AMS - 3M - Fluorinert FC-3284Document4 pagesAMS - 3M - Fluorinert FC-3284sshaffer_9No ratings yet

- AMS - 3M - VPS BrochureDocument4 pagesAMS - 3M - VPS Brochuresshaffer_9No ratings yet

- AMS - SQL - Eric Bank Quick GuideDocument6 pagesAMS - SQL - Eric Bank Quick Guidesshaffer_9No ratings yet

- Ams - 3M - PF-5060-DLDocument6 pagesAms - 3M - PF-5060-DLsshaffer_9No ratings yet

- AMS - Bransonic General BrochureDocument8 pagesAMS - Bransonic General Brochuresshaffer_9No ratings yet

- AMS - 3M - Fluorinert FC-70Document4 pagesAMS - 3M - Fluorinert FC-70sshaffer_9No ratings yet

- Data Sheet HFE-7300Document4 pagesData Sheet HFE-7300sshaffer_9No ratings yet

- Ams - 3M - PF-5070Document4 pagesAms - 3M - PF-5070sshaffer_9No ratings yet

- AMS - 3M - Novec 7000Document6 pagesAMS - 3M - Novec 7000sshaffer_9No ratings yet

- AMS - 3M - Novec MedicalDocument4 pagesAMS - 3M - Novec Medicalsshaffer_9No ratings yet

- Ams - 3M - PF-5060Document4 pagesAms - 3M - PF-5060sshaffer_9No ratings yet

- AMS - 3M - Novec 7100DLDocument4 pagesAMS - 3M - Novec 7100DLsshaffer_9No ratings yet

- AMS - 3M - Novec 7100DLDocument4 pagesAMS - 3M - Novec 7100DLsshaffer_9No ratings yet

- AMS - 3M - Novec 71DADocument4 pagesAMS - 3M - Novec 71DAsshaffer_9No ratings yet

- AMS - 3M - Novec 7300DLDocument4 pagesAMS - 3M - Novec 7300DLsshaffer_9No ratings yet

- AMS - 3M - Boiling Enhancement CoatingDocument2 pagesAMS - 3M - Boiling Enhancement Coatingsshaffer_9No ratings yet

- AMS - Chemicals BC FormulaDocument1 pageAMS - Chemicals BC Formulasshaffer_9No ratings yet

- AMS - 3M - Novec 7500Document8 pagesAMS - 3M - Novec 7500sshaffer_9No ratings yet

- 3M - Boiling Enhancement CoatingDocument2 pages3M - Boiling Enhancement Coatingsshaffer_9No ratings yet

- AMS - Chemicals EC FormulaDocument2 pagesAMS - Chemicals EC Formulasshaffer_9No ratings yet

- AMS - Chemcials GP FormulaDocument1 pageAMS - Chemcials GP Formulasshaffer_9No ratings yet

- AMS - Chemicals GP PowderDocument1 pageAMS - Chemicals GP Powdersshaffer_9No ratings yet

- AMS - Chemicals IS FormulaDocument1 pageAMS - Chemicals IS Formulasshaffer_9No ratings yet

- AMS - Chemicals LRS FormulaDocument1 pageAMS - Chemicals LRS Formulasshaffer_9No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)