Professional Documents

Culture Documents

AMS - R&D Profile Page

Uploaded by

sshaffer_90 ratings0% found this document useful (0 votes)

124 views1 pageOriginal Title

AMS- R&D Profile page

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

124 views1 pageAMS - R&D Profile Page

Uploaded by

sshaffer_9Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

R&D Technical Services was formed in 1996 to support the Vapor Phase Reflow market and is

currently the leading source of Vapor Phase equipment

R&D Vapor Phase machines are being used everyday in a wide variety of markets such as, but

not limited to: SMT Solder Reflows, Lead Free Soldering, Curing, Drying, Mechanical Attachment

and Plastic Package Testing

Vapor Phase is the leader in Safe, Repeatable Heat Transfer with such advantages as:

+ Uniform Temperatures

+ Fast Even Heat Transfer Regardless of Product Size or Mass

+ Minimum Liquids Times

+ Absolute Limits to Maximum Temperatures

+ Low Oxygen Environment

+ Highly Repeatable

+ Easy to Use

+ Short Setup Time

‘Some Design Features of R&D Machines are as follows:

+ Programmable Logic Controls for more flexibility in operating systems.

+ Touch Screen Displays for ease of operation

+ Top and Bottom Ceramic Preheat Panels for thermal curve modification and reflow process

enhancement,

+ Working Fluid Auxi

fluid filtration.

+ Onboard Controls and Alarm Functions monitor all critical areas within the oven.

+ All R&D Vapor Phase modals are Single Vapor, meaning no need for a secondary fluid.

+ Inline and Batch Type models available.

Optional Features Include:

ry Tanks and Filter Systems facilitate routine maintenance and working

+ Limitless Oven Size and Working Envelope Variations

+ Convected and Nitrogen Ready Preheat Sections

+ Belt Conveyor Systems

‘Specialized Control Systems

+ Precise Mixing of Two Different Temperature Fluids to a Create Third Boiling Point Fluid

RAD Technical Services takes the time to completely test each piece of equipment before

shipment, R&D uses nothing but the highest quality materials. From our leading edge design to

‘exacting standards, the quality of the units is apparent throughout.

Contact R&D Technical Services today and let us show you how easily we can resolve you reflow

roblems when using @ Vapor Phase Oven fram R&D Technical Services.

‘STVIISLYH SAY

WP AFR ORT

801LS-ZL2-998

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AMS - SQL - CFC Naming ConventionDocument10 pagesAMS - SQL - CFC Naming Conventionsshaffer_9No ratings yet

- AMS - SQL - Refrigerant Ref TableDocument6 pagesAMS - SQL - Refrigerant Ref Tablesshaffer_9No ratings yet

- AMS - 3M - Fluorinert FC-3283Document4 pagesAMS - 3M - Fluorinert FC-3283sshaffer_9No ratings yet

- AMS - Bransonic General BrochureDocument8 pagesAMS - Bransonic General Brochuresshaffer_9No ratings yet

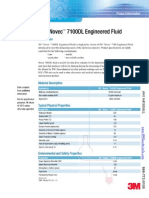

- AMS - 3M - Novec 7100DLDocument4 pagesAMS - 3M - Novec 7100DLsshaffer_9No ratings yet

- Ams - 3M - PF-5060-DLDocument6 pagesAms - 3M - PF-5060-DLsshaffer_9No ratings yet

- Ams - 3M - PF-5070Document4 pagesAms - 3M - PF-5070sshaffer_9No ratings yet

- AMS - 3M - Fluorinert FC-70Document4 pagesAMS - 3M - Fluorinert FC-70sshaffer_9No ratings yet

- Ams - 3M - PF-5060Document4 pagesAms - 3M - PF-5060sshaffer_9No ratings yet

- AMS - 3M - Fluorinert FC-3284Document4 pagesAMS - 3M - Fluorinert FC-3284sshaffer_9No ratings yet

- AMS - 3M - Cool Under FireDocument8 pagesAMS - 3M - Cool Under Firesshaffer_9No ratings yet

- Data Sheet HFE-7300Document4 pagesData Sheet HFE-7300sshaffer_9No ratings yet

- AMS - 3M - Novec 7000Document6 pagesAMS - 3M - Novec 7000sshaffer_9No ratings yet

- AMS - 3M - Boiling Enhancement CoatingDocument2 pagesAMS - 3M - Boiling Enhancement Coatingsshaffer_9No ratings yet

- AMS - VaporWorks - Rework 2011Document14 pagesAMS - VaporWorks - Rework 2011sshaffer_9No ratings yet

- AMS - Chemicals LRS FormulaDocument1 pageAMS - Chemicals LRS Formulasshaffer_9No ratings yet

- AMS - Branson - B252R TDSDocument2 pagesAMS - Branson - B252R TDSsshaffer_9No ratings yet

- AMS - Branson - CH Tanks TDSDocument2 pagesAMS - Branson - CH Tanks TDSsshaffer_9No ratings yet

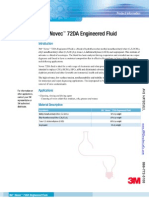

- Ams - 3M - TDS Hfe-72daDocument4 pagesAms - 3M - TDS Hfe-72dasshaffer_9No ratings yet

- AMS - Branson - B252R TDSDocument2 pagesAMS - Branson - B252R TDSsshaffer_9No ratings yet

- AMS - Branson - S-8500 Generator TDSDocument2 pagesAMS - Branson - S-8500 Generator TDSsshaffer_9No ratings yet

- AMS - Branson - OMNI 2000 1620 1620RI TDSDocument2 pagesAMS - Branson - OMNI 2000 1620 1620RI TDSsshaffer_9No ratings yet

- AMS - Branson - OMNI 2000 1012 TDSDocument2 pagesAMS - Branson - OMNI 2000 1012 TDSsshaffer_9No ratings yet