Professional Documents

Culture Documents

Morrison GE Work Plan

Uploaded by

saukvalleynews0 ratings0% found this document useful (0 votes)

86 views29 pagesGeneral Electric (GE) Morrison Facility located in Morrison, illinois. This report was prepared pursuant to the provisions of Consent Order No. 04 CH 28.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGeneral Electric (GE) Morrison Facility located in Morrison, illinois. This report was prepared pursuant to the provisions of Consent Order No. 04 CH 28.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

86 views29 pagesMorrison GE Work Plan

Uploaded by

saukvalleynewsGeneral Electric (GE) Morrison Facility located in Morrison, illinois. This report was prepared pursuant to the provisions of Consent Order No. 04 CH 28.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 29

~¥7086 1950350004

Morceon) Werk

sun.oinss a BETTER woRLD Cota me petis

February 18, 2011 SE/fFecd

Mr, Andrew Frierdich

Project Manager

Remedial Project Management Section

Bureau of Land

inois Environmental Protection Agency

1€21 North Grand Avenue East

Springfield, IL 62702

Re: Work Plan

GE Morrison Facility, Morrison, Hinois

Consent Order No. 04 CH 28 0 R } 6) Ny :

IGINA

Dear. rich NAL

Please find enclosed three copies of the Work Plan for the General Electric (GE) Morrison

Fecility located in Morrison, Illinois. This report was prepared by MV/H Americas, Inc.

(WH) on behalf of GE Energy. This report was prepared pursuant to the provisions of

Consent Order No, 04 CH 28,

Please call Mr. Andrew Graham (GE Energy) at 518-385-3423 or mysef at 312-831-3432

wih any questions or comments

Sincerely,

MWH AMERICAS, INC. RECEIVED

Jus Pelee £822 20H

Projet Manger IEPABOL

Enclosures: Work Plan Consent Order 04 CH 28

cc: Paul Jagiello, lilinois Environmental Protection Agency (1 hard copy)

Gerald T. Karr, Office of Attorney General (1 hard copy)

Edward F. Jamison, GE Energy (1 electronic copy)

Andrew Graham, GE Energy (2 hard copies, 1 electronic copy)

H. Carl Horneman, Wyatt, Tarrant & Combs LLP (1 electronic copy)

Timothy J. Harrington, Hard Hat Services (1 electronic copy)

RELI

opr

0 10800-101069911010616 GE Monison'4.0 Execution (Project Dalivernbies) 4.2 Work Plan\Morison_ Transmit

Jetler_ Work Plan doo

Fax SH

14147056

1950350007

MORRISON WELL CONTAMINATION

SFITECH

GE MORRISON FACILITY

WORK PLAN

CONSENT ORDER NO. 04 CH 28

GENERAL ELECTRIC ENERGY

SCHENECTADY, NEW YORK

Prepared For:

GE Energy

Propared By:

MWH Americas, inc.

@® mw

sunDie a Berren wont RECEIVED

7 FEB 22 201

Project No. 1010616

{EPA/BOL

February 2011

RELEASABLE

FEB 24 29)

REVIEWER aap

SECTION

ACRONYMS AND ABBREVIATIONS...

1.0 INTRODUCTION.

2.0 PROJECT BACKGROUND.

24

22

3.0 FIELD PROCEDURES.

3.4

TABLE OF CONTENTS

SITE CONDITIONS ......

WORK PLAN REQUIREMENTS .

PRIVATE WELL SURVEY...

3.2 GROUNDWATER MONITORING WELL, INSTALLATION AND

SAMPLING...

3.3

34

35

3.6

4,0 REPORTING

5.0 SCHEDULE.

3.2.1 Monitoring Well Installation and Develogmen

3.2.2. Monitoring Well Sampling .. a

SOIL INVESTIGATION 7

DECONTAMINATION PROCEDURES........

INVESTIGATIVE DERIVED WASTE MANAGEMENT.

SAMPLING PARAMETERG.......

LIST OF TABLES

Table 1

Sample and Analysis Plan

LIST OF FIGURES

Figure 1 Site Location Map

Figure 2. Private Well Survey Locations

Figure 3 Proposed Monitoring Well Locations

Figure 4 Proposed Soil Boring Locations

APPENDICES

Appendix A Private Well Survey Questionnaire

Work Plan

‘Consant Order No. 04 CH 28 7

GE Morrison Facility

Morrison, tlinots

ASTM

bes

VOCs

DPT

EPA

FOC

FSI

GE

Geotrans

iDW

MS.

MSD

PCE

PDB

PID

PPE

PVC

ac

Site

TACO

TCE

g/t

Vvots

1,1-DCE"

1,1,1-TCA

Work Pian

ACRONYMS AND ABBREVIATIONS

American Society for Testing and Materials

Below ground surface

Chlorinated volatile organic compounds

Direct push technology

Environmental Protection Agency

Fraction organic carbon

Focused site investigation

General Electric Company

Geotrans, inc.

Investigative derived waste

Matrix spike

Matrix spike duplicate

Tetrachloroethene

Passive diffusion bag

Photo-ionization detector

Personal protective equipment

Polyvinyl! chloride

Quality control

GE Morrison Facility

Tiered Approach to Corrective Action Objectives

Trichloroethene

micrograms per liter

Volatile organic compounds

1,1-dichloroethene

1,1,1-trichloroethane

GE Morrison Facility

‘Consent Order No. 04 GH 28 7 Morrison, ilinois

4.0 INTRODUCTION

This Work Plan presents the field activities for a soil and groundwater investigation

at the GE Morrison Facility (Site) located in Morrison, Illinois (Figure 4). This Work

Plan is prepared in accordance with Consent Order No. 04 CH 28 between the State

of Iilinois and General Electric Company (GE), which was entered on December 23,

2010. The Illinois Environmental Protection Agency (EPA) is the administrative

agency for the State of Illinois.

Section C (Future Compliance) of the Consent Order mandates several components

of work that need to be completed at the site, under an approved Work Plan. The

Consent Order requires the following activities:

* Asurvey of the homes west of Heaton Street and south of Morris Avenue to

ascertain whether residents are using private wells.

© The installation and sampling of two new monitoring wells.

* Completion of soil borings and collection of soil samples near two former

degreaser units,

This Work Plan presents a summary of the project background, an outline of the field

sampling procedures, a description of the reporting and data evaluation

requirements for the project, and a schedule for completing the work,

Work Plan GE Mortison Facility

‘Consent Order HB 7 a ~ Morrison, Hinois

2.0 PROJECT BACKGROUND

2.1 SITE CONDITIONS

General Electric Company has operated a manufacturing facility in Monson, Illinois,

from the late 1940's until 2010. The facility manufactured components for motors

and motor control equipment that were assembled at other locations. Prior to 1994

GE used chlorinated organic solvents for removing oil from the components prior to

subassembly into units for installation in the final product. The degreasing

‘operations occurred in the Main Building (Building No. 1) at two separate locations:

@ small immersion tank degreaser and at a larger continuous process line

degreaser.

|n 1986, chlorinated volatile organic compounds (CVOCs) were detected in the City

‘of Morrison water supply wells located near Rock Creek on the south side of

Morrison. in 1987 GE, under illinois EPA oversight, installed and sampled eight

groundwater monitoring wells in the unconfined aquifer in this area. CVOCs were

detected in groundwater samples collected from three of the eight monitoring wells.

Concentrations of | tricholorethene (TCE), _—tetrachlorothene (PCE),

1,1,1-etrachloroethane (1,1,1-TCA) and 1,1-dichlorosthene (1,1-DCE) exceeded

Illinois EPA Tier 1 Groundwater Standards in the groundwater sample collected from

G105D. The water supply wells are screened in a deeper con‘ined aquifer that is

separated from the unconfined aquifer by the 350-foot thick Maquoketa Shale Layer.

The Maquoketa shale is a hydrogeologic barrier between the shallower and deeper

permeable formations’,

A video survey was conducted down-hole In the three City water supply wells near

Rock Creek in early 1988, The results showed a hole in the casing in one of the

wells and water entering the well from the unconfined aquifer and migrating down

'Bers, R.C., Kempton, J.P., and Stecyk, A.N., 1984. Geology for Planning in Boone and Winnebago

Counties. Ilinois Department of Energy and Natural Resources; prepared for State Geological Survey

Division, Circular 531, Page 11

Work Pian i GE Morrison Facility

28 a Morrison, tlinois

Consent Order Ni

the, casing to the confined aquifer. In response to this observation, GE

decommissioned two of the water supply wells (CW-1 and CW-2) in May 1988 to

eliminate the interconnection between the upper and lower aquifer systems. One of

the city.wells in the area, CW-3 was not abandoned, but an air stripper was installed

by GE in September 1988 to treat water extracted from it. Six additional monitoring

wells were installed by GE in the unconfined aquifer between the industrial area of

Morrison (the west side of Morrison) and Rock Creek. This system of monitoring

‘wells has been sampled on a regular basis and the results show a decreasing trend

in CVOC concentrations since 1988.

in 1989, a soil gas survey was conducted beneath the floor slab at the Morrison

Facility. Analysis of the soil gas samples indicated the presence of eight different

CVOGs. The most commonly detected CVOCs were 1,1-DCE, TCE, 1,1,1-TCA and

1,1-dichloroethane. 1,1-DCE was detected at concentrations above 10,000

micrograms per liter (ug/L) and TCE was detected at concentrations above 1,000

Hg/L. The results indicated CVOCs may be present in either the soil or groundwater

under the former western and eastern degreasers.

tn 2001, Geotrans, inc. (Geotrans), under contract to GE, reviewed the results of the

investigations conducted at the Site and the results from the groundwater

monitoring. Geotrans also performed a natural attenuation study and concluded that

residual VOCs in the unconfined aquifer between the west side industrial area of

Morrison and Rock Creek would continue to degrade to below Class | groundwater

standards over time. Geotrans recommended a groundwater management zone be

considered for the portion of the unconfined aquifer between the west side industrial

area and Rock Creek. Geotrans analysis of groundwater conditions indicated that

groundwater flowed directly south towards Rock Creek and recommended the

installation of two additional monitoring wells to complete the boundary of the

groundwater management zone.

Work Plan z GE Morrison Facility

Consent Order No. G4 CH 28 22 ‘Morrison, Hinois|

2.2 WORK PLAN REQUIREMENTS

This Work Plan outlines the investigation activities to be performed at the Site in

order to comply with the Consent Order. The investigation activities include:

* Conducting a private well survey to determine if residents of the homes west

of Heaton Street and south of Morris Avenue are utilizing private potable

wells,

* Installing two new downgradient monitoring wells and collecting and analyzing

groundwater samples for volatile organic compounds (VOCs) by USEPA

Method 8260.

+ Conducting a soil investigation beneath the two former degreaser areas by

drilling soil borings at these locations, collecting soil samples, and submitting

them for laboratory analysis for VOCs by USEPA Method 8260.

* Prepare a Focused Site Investigation (FS!) Report that summarizes the

results of the investigation activities described above,

Work Plan GE Morrison Facility.

‘Consent Order No. 04 GH 28 a ‘Morrison, ilinois

3.0 FIELD PROCEDURES

This section of the Work Plan presents the field procedures that will be used during

the private well survey, monitoring well installation, and soll and groundwater

sampling activities, and defines the laboratory and quality control procedures that

will be used during the investigation.

3.1. PRIVATE WELL SURVEY

The private well survey will be conducted to determine if residents of the homes

west of Heaton Street and south of Morris Avenue are utilizing private potable welis.

Approximate 82 properties are located within the search area (Figure 2). The

private well survey will be performed in the following manner:

1) A questionnaire will be mailed to each individual residen: in the survey area

with return stamped postcard reply;

2) Attempt to conduct a telephone interview with individual residents who have

not retumed the mailer; and,

3) Review City of Morrison Public Water Records to determine if a property of

interest receives a water bill.

If it cannot be determined whether a resident is utilizing a private water well (using

the methods above) then an attempt will be made to meet the resident with the

following procedure’

* Attempt to contact by visiting a

weeknights;

\gle homeowner twice over two consecutive

* Attempt to contact by visiting the homeowner only during daylight hours:

+ Two personnel will be present at all times while contacting homeowners;

+ Personne! will not cross the threshold of homes or enter beckyards;

Work Plan fea

Consent Order No. 04 GH

GE Morrison Facility.

si Morrison, linois

The survey will not be performed if there exists (or is perceived) any threat or danger

to personnel from a resident, canine, or any other conditions {as deemed by the

opinion of the personnel conducting the survey). If a private well status cannot be

determined after attempting all the procedures listed above, that address will be

documented and reported to the Illinois EPA as undetermined for their consideration

3.2 GROUNDWATER MONITORING WELL INSTALLATION AND SAMPLING

3.2.1. Monitoring Well Installation and Development

Two new monitoring wells will be installed at the locations shown on Figure 3. Boart

Longyear will install the monitoring wells and a MWH field geologist will oversee the

drilling activities. The monitoring wells will be drilled using roto-sonic diling method

The boreholes will be logged by the field geologist using the United Soil

Classification System and the stratigraphy will be recorded on boring log forms. The

monitoring wells will be constructed of 2-inch inner diameter stainless steel with a

10-foot screen. The monitoring wells will be screened at the bottom of the

unconfined aquifer immediately above the bedrock surface in the sand and gravel

layer. The monitoring wells will be finished with a flush-mounted surface completion

and locking polyvinyl chloride (PVC) cap.

Each new monitoring well will be developed using.a submersible pump after 2

minimum waiting period of 24 hours after completing installation of the monitoring

well. Each well screen will be surged in an attempt to suspend and remove

sediments that have settled after well installation has been completed. The well will

be considered developed following the removal of at least three well volumes. Well

volumes will be calculated based on depth to water measurements and well

construction details.

Work Plan GE Mortison Facility

Consent Order No. 04 CH 28 ae Morrison, ifincis

3.2.2 Monitoring Well Sampling

Groundwater sampling of the two new monitoring wells will be completed during two

‘mobilizations to the Site. During the first visit, depth-to-groundwater measuremenis

will be collected and passive diffusion bag (PDB) samplers will be deployed. PDB

samplers will be allowed to remain in the wells for at least 14 days before the second

visit to remove and collect samples from the PDBs.

The following procedures will be used to deploy, recover, and collect groundwater

samples from the PDB samplers. A dedicated PDB sampler apparatus consisting of

stainless steel aircraft cable with clips for holding the PDB tethers (mesh sleeves in

which the bags are placed) and a stainless steel weight for lowering the PDB to the

screen midpoint will be placed in each new monitoring well

PDB Deployment

1, Fill the pre-assembled PDB samplers with laboratory grade de-ionized water

(approximately 200 milliliters). The sampler should be filled until water rises

and stands at least half way into the funnel. Remove excess bubbles from

the sampler and seal the PDB sampler. Laboratory prepared PDB samplers

will be used in lieu of filing PDB samplers in the field

2. Lower the weight, line, and PDB sampler down the welll until the weight rests

at the bottom and the line above the weight is taut. The PDB samplers should

now be positioned at the midpoint of the well screen.

3. Secure the assembly in this position using the locking well cap connected to

the line, Reattach the well cap.

4, Allow the system to remain undisturbed as the PDB samplers. equilibrate for a

minimum of 14 calendar days.

Work Plan GE Morrison Facility

‘Consent Order No. 04 CH 28 33) Morrison, Illinois

Groundwater Sample Collection

1. For sample collection, remove the PDB samplers from the well using the

attached line. Do not place the PDB sampler on the ground. Do not expose

the PDB sampler to ambient conditions for an extended time.

2. Detach and remove the PDB sampler from the weighted line. Remove the

‘excess liquid from the exterior of the bag with a clean towel to minimize the

potential for cross contamination.

3. Using the sampling straw provided with the PDB sampler, transfer the

groundwater to the sample containers (40 milliliter glass

vials, pre-preserved

with hydrochloric acid) provided by the laboratory

4, Monitoring well samples will be labeled GW-MDXX-20XX, where "MDXX" is

the monitoring well designation and “20XX" is the year in which the sample

was collected.

5. Place the filled sample containers in a cooler with ice for shipment to the

laboratory under chain of custody.

6. The used PDB samplers will be contained in a plastic trash bag and disposed

of offsite as general refuse.

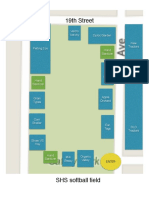

3.3. SOIL INVESTIGATION

Soil borings will be advanced and soil samples collected beneath the two former

degreaser areas. Ten soil borings will be completed to a depth of 20 feet below

ground surface (bgs) or to the water table (whichever is encountered first) near the

‘two former degreaser locations. One soil boring will be advanced in the center and

four soil borings will be advanced approximately 15 to 20 feet off-center (to bracket

the area) at each former degreaser location. Soil boring locations are shown on

Figure 4.

Work Plan ___GE Morrison Facility

Consent Order No. 04 CH 2B ae ‘Worrison, ilinols

PSA Environmental of Lee's Summit, Missouri wil perform the diiling activities, The

soil borings will be advanced using direct push technology (DP7). Soil borings will

be logged by a geologist and field screened with a photo-ionization detector (PID) for

VOCs. Two soil samples will be collected from each boring for VOC analysis by

USEPA Method 8260. One soil sample will be collected at the interval with the

highest PID reading and the other sample will be collected directly above the water

table or at the terminus end of the boring if groundwater is not encountered. if no

PID readings are observed, one soil sample will be collected at 5 feet bgs and the

other sample will be collected directly above the water table or atthe terminus end of

the boring if groundwater is not encountered.

Soil Sample Collection

1. Soil cores will be extracted in disposable acetate sleeves.

2. The acetate sieves will be cut and opened so the geologist can describe the

soils for the boring log and screen the core for VOCs.

3. The acetate sleeves will be sealed in clean tinfoil wrap to ensure VOCs do not

escape while the boring is completed to depth (maximum depth of 20 feet)

4. Following completion of the soil boring grab soil samples will be collected and

Placed into laboratory provided sample containers. Samples for VOC

analysis will be field preserved using a methanol field preservation sample kit,

5. Soil samples will be labeled SO-SBXX-YY, where “SBXX" is the soil boring

designation and "YY" is the depth from which the sample was collected.

6. Each sample will be piaced in a cooler with ice for shipment to the laboratory

under chain of custody.

7. The used acetate liners will be contained in a plastic trash bag and disposed

of offsite as general refuse.

Werk Plan ____GE Morrison Facility

Consent Order No. 04 CH 28 3 Mortison, ilinois

Up to four soil samples will be collected for physical characteristics and geotechnical

testing during the soil investigation. Sampling locations and depths for physical and

geotechnical characteristics will be determined in the field by the supervising

geologist. These samples will be submitted to the laboratory and placed on hold

pending the analytical results of the samples collected near the degreasers. If the

samples near the degreasers indicate the soils contain CVOCs above applicable

standards, then the samples for physical and geotechnical characteristics will be

analyzed. The samples for physical characteristics will be used to evaluate remedial

altematives and for use as inputs into soil and groundwater calculations (such as

Ieaching potential)

Four background soil samples will be collected for fraction organic carbon (FOC).

Background soil borings will be advanced at the locations illustrated on Figure 4.

Two soil borings will be advanced and two soil samples will be collected from each

boring for a total of four soil samples. One soil sample will be collected at 5 feet bgs

and the other sample will be collected directly above the water table or at the

terminus end of each boring if groundwater is not encountered. Additional sample

volume will be collected and analyzed for VOCs and semi-volatile organic

compounds (SVOCs) to confirm each sample is representative of actual background

FOC conditions and is not elevated by anthropogenic sources of organic carbon.

The soil sample will be considered representative of backgrourd soil conditions if

VOC concentrations are below the method detection limit and SVOG concentrations

are below the background soil concentrations for polynuclear aromatic hydrocarbons

listed in Part 742, Appenix A, Table H of the Tiered Approach to Corrective Action

Objectives (TACO). Following completion of the soil borings, the boreholes will be

backfilled with bentonite chips..

3.4 DECONTAMINATION PROCEDURES

Driling equipment used for monitoring well installation will be decontaminated before

and after drilling and between each borehole. Drilling equipment will be

decontaminated by steam cleaning on a decontamination pad that will be

Work Pian _ : GE Morrison Facility

Consent Order No. 04 GHB 36 ‘Morrison, ilinois

constructed to contain decontamination fluids. Downhole equiprent used for drilling

soil borings will be cleaned before beginning Site activities and between boring

locations using a non-phosphate wash (Alconox® or similar) and distilled water

rinse. The water level meter used for collection of groundwater elevations will be

decontaminated before and between each use using an Alconox® wash and distilled

water rinse, Groundwater sampling equipment is single use and is not transferred

between wells. The PDBs are disposable and the PDB tethers will be stored inside

the wells between sampling events. Sampling containers will be received from the

laboratory pre-cleaned and contaminant free.

3.5 INVESTIGATIVE DERIVED WASTE MANAGEMENT

Investigative derived waste (IDW) will consist of soil cuttings from monitoring well

installation and soil boring activities, purge water from monitoring well development

activities, decontamination water from drilling equipment, decontamination water

from the water level measurement device, excess water from ®DB sample bags,

personal protective equipment (PPE), puncturing tubes for the sampling, used PDB

sample bags, and used sample liners for soil sampling, The IDW will be handled

according to the waste stream characteristics as follows:

* Soil cuttings from well installation and soil boring activities will be contained in

55-gallon drums and stored on-site in a location designated by Site

personnel. The drums will be labeled with the date, contents, and Site name.

One composite sample will be collected at the end of the investigation

's from the soil IDW and submitted to the laboratory for analysis of

waste characterization parameters,

+ Liquid IDW consisting of decontamination water from driling equipment and

purge water from monitoring well development will be contained in 55-gallon

drums and stored on-site in a location designated by Site personnel. The

drums will be labeled with the date, contents, and Site name. One composite

sample will be collected at the end of the investigation activities from the

Work Pian = GE Morrison Factity

‘Consent Order No, 04 GH 28 37 Morrison, Hingis

liquid DW and submitted to the laboratory for analysis of waste

characterization parameters,

* Decontamination water will be generated in limited quantities during cleaning

of the water level meter, and minor amounts of excess groundwater may be

present in the PDB sample bags. This de minimus quantity of water will not

containerized with the development water.

* PPE will consist of nitrile gloves used during the soll and groundwater

sampling activities. PPE will be contained in plastic trash bags and disposed

offsite as general refuse.

* Puncturing tubes, used PDB sample bags, and used semple liners will be

Contained in plastic trash bags and disposed offsite with general refuse.

3.6 SAMPLING PARAMETERS

Groundwater samples will be analyzed for VOCs by USEPA SW-846 Method 82608.

Soil samples collected in the former degreaser areas will also be analyzed for VOCs.

by the same method. Soil samples collected for physical and geotechnical

characteristics will be analyzed for Atterberg limits by American Society for Testing

and Materials (ASTM) Method 04943, grain size (ASTM 01422), soil moisture

content (ASTM 02216), soil moisture retention (ASTM 02325), tctal porosity (ASTM

0854/2937), soil dry bulk density (ASTM 2937), and permeabilty (ASTM 02434)

Background soil samples will be analyzed for VOCs by USEPA SW-846 Method

8260B, SVOCs (USEPA SW-846 Method 8270C), and FOC (ASTM Method 2974).

Upon completion of the investigation activities, composite soil and water samples will

be collected from the drums of IDW and will be analyzed for waste characterization

Parameters for the purpose of determining proper disposal procedures. Composite

soil IDW samples will be analyzed for the following waste characterization

parameters:

Work Pian ee GE Morrison Facility

Consent Order No, 04 CH 28 38 ‘Morrison, ilinois

© TCLP VOCs (SW-846 82608);

* TCLP SVOCs (SW-846 8270C);

* TCLP Metals ~ RCRA List (SW-846 60108/SW7470A);

© Reactive Cyanide (ASTM D5049; and

* Reactive Sulfide (ASTM D4978).

Composite liquid IDW samples will be analyzed for the following waste

characterization parameters:

* VOCs (SW-846 82608);

* SVOCs (SW-846 82700);

* Total Metals - RCRA List (SW-846 6010B/SW7470A);

* pH (SW-846 9040/9045);

‘+ Flashpoint (SW-846 1010);

* Total Cyanide (EPA 9012); and

* Total Sulfide (EPA 376.1).

Quality Control (QC) samples will be collected for soil and groundwater samples.

QC samples include field duplicates, matrix spike (MS), and matrix spike duplicate

(MSD). In addition, trip biank samples will be included with the groundwater

samples in the cooler and an equipment blank sample of the de-ionized water will be

analyzed for VOCs. A summary of the analytical methods, QC criteria, and number

of samples to be collected for each task associated with this Work Plan is provided

in Table 1.

Work Pian __GE Morrison Facility

‘Consent Order No. 04 CH 28 ao fee Morrison, tilinois

4.0 REPORTING

‘A Focused Site Investigation (FSI) Report will be prepared following completion of

field work. The report will summarize the results of the work conducted pursuant to

this Work Plan. The FSI Report will include a Tier 2 evaluation of soil concentrations

beneath the former degreasers. The FSI Report will be prepared in accordance with

the report guidelines provided in Exhibit B of the Consent Order.

Five Agency review copies of the FSI Report will be provided to the State of lilinois

distribution list defined in the Consent Order.

Work Plan zB GE Morrison Facility

‘Consent Order No. 04 GH 26 ei Morrison, ilinois

5.0 SCHEDULE

The investigation activities mandated in the Consent Order (1e. private well survey,

monitoring well installation and sampling, and soil investigation beneath the two

former degreaser areas) will be completed within 60 days of Hlinois EPA approval of

this Work Plan. The Agency review draft of the FSI Report summarizing these

investigation activities will be submitted to the illinois EPA within 180 days of Hlinois

EPA approval of this Work Plan.

JEBDPPPIDLOILMCIAKS

“s10800-101O89A 070616 GE Moreon\L0 Esecston Project OelvelsleyM.2 Work PliMorison Wok Fak Agony doe

Work Pian _ _GE Morrison Faclity

Consent Order No. 04 CH 2B a Morrison, ilinois

TABLE

FIGURES

auton

Fal

lSobeutace Sal Sorina —

[sae DEO

SaaS]

Seats soa W505

pst p2504

| sitions

Ai OBe4 27

‘ASTM Eze

swasigaive Deed Waste

MORRISON, ILLINOIS

FIGURE 1 - SITE LOCATION MAP.

GENERAL ELECTRIC ENERGY

709 WEST WALL STREET

LOCATION

SITE

ee

(

3

\

a

EES

i

COMI}

[

MAIN. BUILDING

FIRST FLOOR

ee

APPENDIX A

WATER WELL SURVEY QUESTIONNAIRE

1 Name:

2 Address:

Ee eee eee Egg LEELELEE

3. Telephone Number: pectin

4. How long have you lived at the above address?

5. Property owner if different than above i

6. _Is there a septic system installed and operating on your property?

j Yes No __ Unknown

7. Describe location and details of septic system.

| 8 Is here a well on the property?

Yes No Unknown, {if no or unknown stop here)

9. Is the well operable Yes No? (ifno, stop here.)

10, If the answer to Question 9 is Yes, what Is the well used for?

(Check ali that apply)

A) Domestic Use:

(a) Drinking Water

(b) Wash water

(c) Irrigation

{d) Other (Explain)

{8} Commercial/industriav/Agricultural Use

i {a) Animal Husbandry

\ {b) Irrigation

(6) Drinking

(8) Manufacturing

{e) Other (Explain)

11. How was the well constructed? Hand Dug __ Drilled Unknown

12, Weihead completion type?

Check: a) Below-ground pit ‘oF below-ground pitless adaptor

b) Depth of well casing or adaptor below ground

d ©) Other _

13. Do you have a water softener, iron filter, carbon filter, or other water treatment system installed?

a Yes ___No Unknown,

14. Well casing material

18. Well Depth?

16. Date well was instalied?

47. Drilling company and address (if known)

18. Tye of pump

eabainbareaseneseteeens sons aandatsnteanaatsnieasdat SanISeee SSISERS gC =]

submersible, jet puma)

18, Doyou have any additional comments regarding your water supply at this time?

20. If awell is present sketch the location of well relative to existing structures. Also sketch the location

of the septic system if present.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Reyes PetitionDocument1 pageReyes PetitionsaukvalleynewsNo ratings yet

- Erie Facilities Plan PresentationDocument55 pagesErie Facilities Plan PresentationsaukvalleynewsNo ratings yet

- Rock Falls Drug ConspiracyDocument7 pagesRock Falls Drug ConspiracysaukvalleynewsNo ratings yet

- Assistant Attorney General Matt Hartman's RulingDocument7 pagesAssistant Attorney General Matt Hartman's RulingsaukvalleynewsNo ratings yet

- Dixon CBA 2016 2020 FinalDocument48 pagesDixon CBA 2016 2020 FinalsaukvalleynewsNo ratings yet

- Erie CES1 4-26-16 Part III PDFDocument14 pagesErie CES1 4-26-16 Part III PDFsaukvalleynewsNo ratings yet

- Erie CES1 4-26-16 Part II PDFDocument12 pagesErie CES1 4-26-16 Part II PDFsaukvalleynewsNo ratings yet

- Notes From Charrette Map 2Document1 pageNotes From Charrette Map 2saukvalleynewsNo ratings yet

- Erie CES1 4-26-16 Part IDocument14 pagesErie CES1 4-26-16 Part IsaukvalleynewsNo ratings yet

- Potential: SolutionsDocument15 pagesPotential: SolutionssaukvalleynewsNo ratings yet

- 2016 Income Eligibility GuidelinesDocument1 page2016 Income Eligibility GuidelinessaukvalleynewsNo ratings yet

- Table 2Document1 pageTable 2saukvalleynewsNo ratings yet

- New Officer AgreementDocument2 pagesNew Officer AgreementsaukvalleynewsNo ratings yet

- Notes From Charrette Map 3Document1 pageNotes From Charrette Map 3saukvalleynewsNo ratings yet

- Notes From Charrette Map 1Document1 pageNotes From Charrette Map 1saukvalleynewsNo ratings yet

- AGclubflyer W LocationDocument1 pageAGclubflyer W LocationsaukvalleynewsNo ratings yet

- Notes From Charrette Map 2Document1 pageNotes From Charrette Map 2saukvalleynewsNo ratings yet

- Education Foundation Grant Program - Donald Hill-2016Document3 pagesEducation Foundation Grant Program - Donald Hill-2016saukvalleynewsNo ratings yet

- Notes From Charrette Map 3Document1 pageNotes From Charrette Map 3saukvalleynewsNo ratings yet

- Education Foundation Scholarhsip - 2016Document3 pagesEducation Foundation Scholarhsip - 2016saukvalleynewsNo ratings yet

- Notes From Charrette Map 1 3Document1 pageNotes From Charrette Map 1 3saukvalleynewsNo ratings yet

- Park Map For FarmapaloozaDocument1 pagePark Map For FarmapaloozasaukvalleynewsNo ratings yet

- Morrison Police Sergeant Job DescriptionDocument44 pagesMorrison Police Sergeant Job DescriptionsaukvalleynewsNo ratings yet

- MIA Tour BreakdownDocument5 pagesMIA Tour BreakdownsaukvalleynewsNo ratings yet

- Lee County Jail - PresentationDocument18 pagesLee County Jail - PresentationsaukvalleynewsNo ratings yet

- ICTM Regional CompetitionDocument6 pagesICTM Regional CompetitionsaukvalleynewsNo ratings yet

- City of Dixon Recovered FundsDocument1 pageCity of Dixon Recovered FundssaukvalleynewsNo ratings yet

- Allensworth & Easton (2007)Document68 pagesAllensworth & Easton (2007)saukvalleynewsNo ratings yet

- Doubles Pickleball Round Robin 031216 2Document2 pagesDoubles Pickleball Round Robin 031216 2saukvalleynewsNo ratings yet

- Exhibit BDocument19 pagesExhibit BsaukvalleynewsNo ratings yet