Professional Documents

Culture Documents

Natural Drive Mechanisms

Uploaded by

Waleed EjazOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Natural Drive Mechanisms

Uploaded by

Waleed EjazCopyright:

Available Formats

Natural Drive Mechanisms

The production of oil and gas is possible only because of potential energy stored in the compressed fluids and rock of the reservoir or because of energy added to the reservoir. Reservoir energy is released when a pressure difference is imposed between the wellbore and the reservoir, and a well is produced. While this pressure differential is maintained, fluids will flow from high- to low-pressure. If the pressure at the wellbore is sufficient to lift the column of fluid, the well will flow; if not, it must be artificially lifted. Energy sources in a reservoir vary and this largely determines the efficiency of oil and gas recovery. The sources of energy for oil production are listed in Table 1(below) . The dominant type of energy determines the type of "drive" mechanism attributed to a given reservoir. These mechanisms are listed in Table 2 (below). Reservoir energy sources: Gas dissolved in oil Free gas under pressure

gas reservoir oil reservoir w/free gas cap Fluid pressure

hydrostatic-hydrodynamic compressed water, gas, oil Elastically compressed rock Gravity Combinations of the above Table 1 (above) Reservoir drive mechanisms: Solution-gas drive gas dissolved in oil Cas-cap drive free gap cap under pressure Water drive hydrostatic/hydrodynamic pressure and compressed water Gravity drainage density differences of fluids Table 2 (above)

A reservoirs overall means of production is usually a result of some combination of two or more of the drive mechanisms shown in Table 2. In general, water drive reservoirs have the highest primary oil recoveries, while solution has drive reservoirs have the lowest. Typical recovery ranges are 12 to 37 percent for solution gas drive (median 20 percent), 15 to 60 percent for has cap drive (median 33 percent), and 28-84 percent for water drive (median 51 percent).

1. Solution Gas Drive Reservoirs

Production Mechanism A solution gas drive reservoir is one in which the principal drive mechanism is the expansion of the oil, the expansion of the gas dissolved in the oil, and the expansion of the rock with its associated water. Two phases of production may occur in such reservoirs. The first phase is that in which the pressure is above the bubble-point value. During this period, no free gas phase exists and the reservoir oil is undersaturated. The second phase occurs when the pres sure falls below bubble-point and a free gas phase exists.

2. Gas Cap Drive Reservoirs

Production Mechanism The same theoretical methods for computing recovery from solution gas drive reservoirs may be applied to gas cap drive reservoirs. The assumptions are (1) that no gravity segregation of the gas liberated from the oil occurs, and (2) that the gas cap gas diffuses through the oil to supply additional expansion energy, while the location of the gas-oil contact remains at its original position. In reality, the gas-oil contact moves downward, although en gineers attempt to maintain the gas cap movement at a uniform level for optimum recovery. If the gas cap shows definite ex pansion as indicated by a high level of reservoir pressure, and the producing wells remain at low gas-oil ratio, gravity is maintaining a uniform movement of the gas cap. The low produced gas-oil ratio continues until the gas cap reaches the wells, at which point a sizeable increase in the produced gas-oil ratio occurs. Recovery in such cases is greatly dependent on the completion intervals and well locations.

3. Water Drive Reservoirs

Production Mechanism

When speaking of a water drive reservoir, we mean natural water drive as opposed to artificial water injection. Water moves into the reservoir from the aquifer in response to a pressure drop that causes the water and the rock in the aquifer to expand. If the aquifer is small, one may assume that the pressure drop is instantaneously trans mitted throughout the reservoir.

Gravity Drainage Mechanism

Conditions Needed for Segregation Gravity drainage is one of the most efficient recovery mechanisms when conditions are favorable. Under the influence of gravity, water, oil, and gas separate according to their densities. Gravity drainage is a slow process. The rate of recovery from a reservoir influ enced solely by this mechanism is time-dependent, similar to the case of the water drive mechanism. Gravity drainage is most effective in thick reservoirs with high vertical fluid communication and continuity. It is also effective in thin reservoirs with an appreciable angle of dip (at least 10 to 15) and a favorable permeability to flow in the vertical direction. Reservoirs with shale stringers or laminations are not good candidates for gravity drainage. Conditions and parameters needed for effective gravity drainage are indicated by considering the following equation. The rate of segregation of gas in an oil reservoir is

(52) where: qs = rate of gravity segregation in RB/D A = cross-sectional area of the linear bed in ft2 = oil-specific gravity minus gas-specific gravity = angle of dip in degrees = gas viscosity in cp kg = gas, effective vertical permeability evaluated at So = 1 - Swc - Sgr , in md o = oil viscosity in cp ko = oil, effective vertical permeability evaluated at So = 1 - Swc - Sgr , in md Equation 52 shows that the factors favorable to gravity segregation are , the difference in specific gravity between the oil and the gas. The higher it is, the faster the segregation. high vertical ko and kg low o

a high dip angle a large cross-sectional area available to segregation. Recovery Factor As we stated, gravity drainage is the most efficient drive mechanism. When complete segregation (i.e, full gravity drainage) occurs, recovery may approach

If the initial oil saturation is 80% and Sor = 25%, recovery is 68% of the initial oil in place. In many reef reservoirs where vertical communication is good and the oil viscosity is low it is not uncommon to obtain recovery by gravity segregation in the range of 60%. The main disadvantage of gravity drainage is that it is a slow process. Therefore, one hardly ever takes full advantage of gravity drainage because the oil production rate is normally much higher than the segregation rate.

Improved Oil Recovery

The use of reservoir energy to produce oil and gas generally results in a recovery of less than 50% of the original oil in place. The primary recovery mechanisms of solution gas drive, gas cap drive and water drive, or a combination of one or more of these and gravity drainage, account for most of the world's oil production. Secondary recovery techniques, in which external energy is added to a reservoir to improve the efficiency of the primary recovery mechanisms, have been in use for many years. The injection of water to supplement natural water influx has become an economical and predictable recovery method and is applied worldwide. Less commonly, gas injection has been used to displace oil downdip in "attic" oil recovery projects or to maintain gas cap pressure. Still, both primary and secondary recovery techniques have only been effective in producing roughly one third of the oil discovered. The remaining two thirds, more than 300 billion barrels (4.7696 1010 m3) in the United States alone, is a target for more sophisticated processes. Such processes, developed to increase recovery from reservoirs considered depleted by primary mechanisms and secondary methods of water or gas injection, were historically termed tertiary recovery techniques. However, because some of these processes may be applied earlier in the life of a reservoir, perhaps even in the first day of production, the "tertiary" term is no longer appropriate here, and as a result, the term enhanced oil recovery methods has been introduced as the term to be used for all processes that attempt to alter the physical forces that control the movement of oil within the reservoir. Both conventional water and gas injection, and the more unconventional enhanced oil recovery methods can collectively be termed improved oil recovery methods.

You might also like

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Pro Tech 1 CH 2Document29 pagesPro Tech 1 CH 2weldsvNo ratings yet

- New and Novel Fracture Stimulation Technologies For The Revitalization of Existing Gas Storage Wells: Interim Project ResultsDocument87 pagesNew and Novel Fracture Stimulation Technologies For The Revitalization of Existing Gas Storage Wells: Interim Project ResultsPinkesh ShahNo ratings yet

- Microbial Enhancement of Oil Recovery - Recent AdvancesFrom EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesNo ratings yet

- Spe 135704 MS PDFDocument9 pagesSpe 135704 MS PDFKd FaNo ratings yet

- Key Issues in Multilateral Technolog 1668247705Document55 pagesKey Issues in Multilateral Technolog 1668247705Dhani de EngineurNo ratings yet

- SPE-57390-Underbalance or Extreme OverbalanceDocument10 pagesSPE-57390-Underbalance or Extreme Overbalancecv sabiraNo ratings yet

- SPE 126719 Matrix Acid Systems For Formations With High Clay ContentDocument15 pagesSPE 126719 Matrix Acid Systems For Formations With High Clay ContentJose Miguel GonzalezNo ratings yet

- Minor II Mid Review - FinalDocument10 pagesMinor II Mid Review - FinalArsh Attri100% (1)

- SPE 29259 An Innovative Model For Drilling Fluid HydraulicsDocument17 pagesSPE 29259 An Innovative Model For Drilling Fluid HydraulicsmucoNo ratings yet

- Intro Well Engineering: Rotary Drilling, Directional Drilling & MoreDocument14 pagesIntro Well Engineering: Rotary Drilling, Directional Drilling & MoreHammed Lateef KennyNo ratings yet

- Dan 3Document14 pagesDan 3Adanenche Daniel EdohNo ratings yet

- Mitigation of Production ProblemsDocument16 pagesMitigation of Production ProblemsShubham GuptaNo ratings yet

- Application of Water Alaternating Gas (Wag) Injection For Heavy Oil Recovery in Niger DeltaDocument71 pagesApplication of Water Alaternating Gas (Wag) Injection For Heavy Oil Recovery in Niger DeltaNdifreke Nsima WilliamsNo ratings yet

- G Function Spe 60291Document9 pagesG Function Spe 60291José TimanáNo ratings yet

- Editing - Petrobowl Questions - FlashcardsDocument45 pagesEditing - Petrobowl Questions - FlashcardsManuel Marquez CequeaNo ratings yet

- An Integrated Wellbore Stability Study To Mitigate Expensive WellDocument164 pagesAn Integrated Wellbore Stability Study To Mitigate Expensive WellMangojak SiagianNo ratings yet

- EOR Methods GuideDocument109 pagesEOR Methods GuideKarwan DilmanyNo ratings yet

- Applications of Directional DrillingDocument11 pagesApplications of Directional Drillingkrsunil17No ratings yet

- Spe 090829 PDFDocument14 pagesSpe 090829 PDFdanielmcaeNo ratings yet

- Oilfield Services Companies Unsung Workhorses Oil Industry PDFDocument24 pagesOilfield Services Companies Unsung Workhorses Oil Industry PDFHanyNo ratings yet

- Trapped Gas, Relative Permeability and Residual Oil Saturation of An Oil-Wet SandstoneDocument15 pagesTrapped Gas, Relative Permeability and Residual Oil Saturation of An Oil-Wet Sandstoneari_si100% (3)

- SPE-124295-PP New Integrated Approach For Updating Pore-Pressure Predictions During DrillingDocument11 pagesSPE-124295-PP New Integrated Approach For Updating Pore-Pressure Predictions During DrillingMarcelo Ayllón RiberaNo ratings yet

- Kumar 2019Document25 pagesKumar 2019RishiNo ratings yet

- WT AssignmentDocument27 pagesWT Assignmentabdilrhman sulimanNo ratings yet

- Wellbore StabilityDocument39 pagesWellbore Stabilityashad100% (1)

- Density Log: DR Bijaya K BeheraDocument20 pagesDensity Log: DR Bijaya K BeheraSagar DadhichNo ratings yet

- Completion and Workover FluidsDocument2 pagesCompletion and Workover FluidsJit MukherheeNo ratings yet

- Software ADocument35 pagesSoftware Amelkady2020No ratings yet

- Understanding Unconventional Drilling TechnologiesDocument9 pagesUnderstanding Unconventional Drilling TechnologiesAmit Kumar SinghNo ratings yet

- SPE 160703 Simultaneous Well Stimulation and Scale Squeeze Treatments in Sandstone and Carbonate ReservoirsDocument21 pagesSPE 160703 Simultaneous Well Stimulation and Scale Squeeze Treatments in Sandstone and Carbonate ReservoirsJose Miguel GonzalezNo ratings yet

- Testing of Drilling Fluids: Mud DensityDocument9 pagesTesting of Drilling Fluids: Mud DensityMohammed Amin BenharkatNo ratings yet

- Multi Layer Testing: Theory and PracticeDocument7 pagesMulti Layer Testing: Theory and PracticeeckoNo ratings yet

- Understanding Source and Reservoir RocksDocument13 pagesUnderstanding Source and Reservoir RocksKhagen DoleyNo ratings yet

- Master Thesis - Jose Maria MoratallaDocument80 pagesMaster Thesis - Jose Maria MoratallaorlandoNo ratings yet

- Propellant-Assisted Perforating  - An Alternative ...Document15 pagesPropellant-Assisted Perforating  - An Alternative ...Konul AlizadehNo ratings yet

- Wet Combustion EOR-IORDocument10 pagesWet Combustion EOR-IORAbu ikhtiarNo ratings yet

- Hole Conditioning Before Running Casing or LinerDocument1 pageHole Conditioning Before Running Casing or LinerYougchu LuanNo ratings yet

- Well Placement FundamentalsDocument1 pageWell Placement FundamentalslolobsNo ratings yet

- Gas Well Testing HandbookDocument2 pagesGas Well Testing Handbookjose david CardozoNo ratings yet

- SPE-172549-MS Tandem ESP-Packer Dumpflood Completion - A Successful Alternative To Conventional Encapsulated ESP Systems - Field Case StudyDocument7 pagesSPE-172549-MS Tandem ESP-Packer Dumpflood Completion - A Successful Alternative To Conventional Encapsulated ESP Systems - Field Case StudyAhmed Ali AlsubaihNo ratings yet

- Fluid system roles and responsibilitiesDocument107 pagesFluid system roles and responsibilitiesEjaz ul Haq kakarNo ratings yet

- Well log analysis of borehole environmentDocument7 pagesWell log analysis of borehole environmentsalmanhalabjaiNo ratings yet

- Introduction To Formation EvaluationDocument2 pagesIntroduction To Formation EvaluationVince EspacioNo ratings yet

- HPHT CementingDocument2 pagesHPHT CementingOdesya SatyaNo ratings yet

- Managing Common Problems in Geothermal GenerationDocument12 pagesManaging Common Problems in Geothermal GenerationEM Rifqi Wilda PradanaNo ratings yet

- Reservoir Engineering CPG 2020 3 - 2Document120 pagesReservoir Engineering CPG 2020 3 - 2Chris ChijiokeNo ratings yet

- SPE 167698 Imbibition and Water Blockage in Unconventional Reservoirs: Well Management Implications During Flowback and Early ProductionDocument13 pagesSPE 167698 Imbibition and Water Blockage in Unconventional Reservoirs: Well Management Implications During Flowback and Early ProductionsouthliNo ratings yet

- CSUG HydraulicFrac BrochureDocument24 pagesCSUG HydraulicFrac BrochureNathan MoralesNo ratings yet

- 56 - Remedial Cleanup, Sand Control and Other Stimulation TreatmensDocument9 pages56 - Remedial Cleanup, Sand Control and Other Stimulation Treatmensrizal tri susiloNo ratings yet

- SPE-203872-MS - Multistage FracutringDocument24 pagesSPE-203872-MS - Multistage Fracutringzach100% (1)

- Experiment On Sand ContentDocument15 pagesExperiment On Sand ContentAnsell EwemeNo ratings yet

- 2015 ROP Enhancement in Shales Through Osmotic Processes SPE IADC 173138 MSDocument19 pages2015 ROP Enhancement in Shales Through Osmotic Processes SPE IADC 173138 MSSteven MarinoffNo ratings yet

- PetroSkills - Surface Production OperationsDocument2 pagesPetroSkills - Surface Production OperationsMausam GauravNo ratings yet

- Unit 1Document116 pagesUnit 1yash saragiyaNo ratings yet

- PGE 361 Lecture 6 Rock Compressibility (Compatibility Mode)Document39 pagesPGE 361 Lecture 6 Rock Compressibility (Compatibility Mode)Hermann MurielNo ratings yet

- Pinnacle - BD Overview EJD PDFDocument94 pagesPinnacle - BD Overview EJD PDFaliNo ratings yet

- Diagnosis of High Water CutDocument10 pagesDiagnosis of High Water CutLuis Alberto IzarraNo ratings yet

- Briefing N°8 - Chaperon-Method-in-Coning-at-Horizontal-Oil-WellsDocument4 pagesBriefing N°8 - Chaperon-Method-in-Coning-at-Horizontal-Oil-WellsANDREW LOJANo ratings yet

- 2000.4 Saggf Et AlDocument34 pages2000.4 Saggf Et AlWaleed EjazNo ratings yet

- 4 3 Poststack-1Document7 pages4 3 Poststack-1Waleed EjazNo ratings yet

- Journal of Petroleum Science and Engineering: Hong Tang, Christopher D. WhiteDocument6 pagesJournal of Petroleum Science and Engineering: Hong Tang, Christopher D. WhiteWaleed EjazNo ratings yet

- Fundamentals of PoroelasticityDocument96 pagesFundamentals of PoroelasticitySimon-Nicolas RothNo ratings yet

- Chapter 17 Tawil Quaternary Aquifer System WebDocument17 pagesChapter 17 Tawil Quaternary Aquifer System WebWaleed EjazNo ratings yet

- SPE-152066-PA - Resource Evaluation For Shale Gas ReservoirsDocument12 pagesSPE-152066-PA - Resource Evaluation For Shale Gas ReservoirsLevinska PrimaveraNo ratings yet

- Induced OmanDocument295 pagesInduced OmanWaleed EjazNo ratings yet

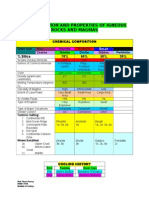

- UCS DolomiteDocument15 pagesUCS Dolomiteranjeevkumar100% (2)

- Well Design - PE 413: Chapter 1: Fracture PressureDocument44 pagesWell Design - PE 413: Chapter 1: Fracture PressureWeny AstutiNo ratings yet

- Rock Physics AnalysisDocument2 pagesRock Physics AnalysisWaleed EjazNo ratings yet

- SPE-152066-PA - Resource Evaluation For Shale Gas ReservoirsDocument12 pagesSPE-152066-PA - Resource Evaluation For Shale Gas ReservoirsLevinska PrimaveraNo ratings yet

- The Rock Physics Hand Book - Mavko Mukerji DvorkinDocument341 pagesThe Rock Physics Hand Book - Mavko Mukerji DvorkinWaleed EjazNo ratings yet

- The Mechanical Earth Model Concept and Its Application To High-Risk Well Construction ProjectsDocument13 pagesThe Mechanical Earth Model Concept and Its Application To High-Risk Well Construction ProjectsWaleed EjazNo ratings yet

- Petroleum Logs CharacteristicsDocument1 pagePetroleum Logs CharacteristicsWaleed EjazNo ratings yet

- Geology and Geophysics 303 Structural Geology Course NotesDocument10 pagesGeology and Geophysics 303 Structural Geology Course NotesWaleed EjazNo ratings yet

- Properties and classification of igneous rocks and magmasDocument2 pagesProperties and classification of igneous rocks and magmasWaleed EjazNo ratings yet

- Subsurface EnvironmentDocument8 pagesSubsurface EnvironmentWaleed EjazNo ratings yet

- Cglr3 PrimaryDocument8 pagesCglr3 PrimaryWaleed EjazNo ratings yet

- The Feldspar GroupDocument2 pagesThe Feldspar GroupWaleed EjazNo ratings yet

- Subsurface EnvironmentDocument8 pagesSubsurface EnvironmentWaleed EjazNo ratings yet

- Geological MapsDocument18 pagesGeological MapsWaleed EjazNo ratings yet

- NGA GroundwaterDocument2 pagesNGA GroundwaterWaleed EjazNo ratings yet

- Kelton Calculation DetailsDocument17 pagesKelton Calculation DetailsronziesNo ratings yet

- T132 Rocket GatlingDocument172 pagesT132 Rocket GatlingHosiah BlackfordNo ratings yet

- The Longest Prestressed Concrete Box Girder Span Bridge in ThailandDocument8 pagesThe Longest Prestressed Concrete Box Girder Span Bridge in ThailandsujupsNo ratings yet

- Chem Unit 3 Practice Exam PDFDocument6 pagesChem Unit 3 Practice Exam PDFJo PatrickNo ratings yet

- Nafta Nanofluidos-MainDocument13 pagesNafta Nanofluidos-MainNancy MorenoNo ratings yet

- API 5L Grade X52 Pipe Chemical Composition and Mechanical PropertiesDocument1 pageAPI 5L Grade X52 Pipe Chemical Composition and Mechanical PropertiesMohamed HassanNo ratings yet

- 472Document35 pages472Nahida BanoNo ratings yet

- (2023) Design, Flow Characteristics and Performance Evaluation of Bioinspired Heat Exchangers Based On Triply Periodic Minimal SurfacesDocument13 pages(2023) Design, Flow Characteristics and Performance Evaluation of Bioinspired Heat Exchangers Based On Triply Periodic Minimal Surfaces오지윤No ratings yet

- Ballistics Science: Projectile Motion and Firearm ForensicsDocument17 pagesBallistics Science: Projectile Motion and Firearm ForensicsCinja ShidoujiNo ratings yet

- Antenna Datasheet Am 2 Freq CircDocument9 pagesAntenna Datasheet Am 2 Freq CircĐỗ Quang HuyNo ratings yet

- Wassce / Waec Chemistry Syllabus: 1. Structure of The AtomDocument30 pagesWassce / Waec Chemistry Syllabus: 1. Structure of The AtomJesse Lartey100% (1)

- Mardina A PDFDocument4 pagesMardina A PDFAdib YusofNo ratings yet

- 5 Analysis of of Gravity DamsDocument10 pages5 Analysis of of Gravity DamsBillie Ian. Salamante JrNo ratings yet

- Weather Station InstructionsDocument6 pagesWeather Station InstructionsCesar NavarroNo ratings yet

- Energy Loss and Straggling ConceptsDocument33 pagesEnergy Loss and Straggling ConceptsyounessinaNo ratings yet

- Understand Contacts - Midas NFX PDFDocument10 pagesUnderstand Contacts - Midas NFX PDFdzejziNo ratings yet

- Vibration Monitoring AnalysisDocument102 pagesVibration Monitoring AnalysisAlangghya Susatya Adigama100% (1)

- Comsol - Modeling of Three Dimensional Dye-SensitizedDocument6 pagesComsol - Modeling of Three Dimensional Dye-SensitizedEmma DNo ratings yet

- Duct Velocity D - 928 PDFDocument7 pagesDuct Velocity D - 928 PDFTeo Pei SanNo ratings yet

- Lectures On Quantum Mechanics For Mathematics Students Student Mathematical LibraryDocument124 pagesLectures On Quantum Mechanics For Mathematics Students Student Mathematical LibrarywillmateNo ratings yet

- 07 Theory of ShearingDocument33 pages07 Theory of ShearingSûhâs KS IyengarNo ratings yet

- Struc Ex Pro Rectangular Beam Design CalculationDocument1 pageStruc Ex Pro Rectangular Beam Design Calculationpobre3nga3bataNo ratings yet

- Atmospheric, Oceanic and Terrestrial Processes (Lec3)Document32 pagesAtmospheric, Oceanic and Terrestrial Processes (Lec3)kiedd_04100% (1)

- Amendment No 1 - IS 875 - Part 3Document7 pagesAmendment No 1 - IS 875 - Part 3Parthiban KandhasamyNo ratings yet

- Current Concepts: Biomechanics of Knee LigamentsDocument11 pagesCurrent Concepts: Biomechanics of Knee LigamentsBarbaraAndradeQuirozNo ratings yet

- Sound SummaryDocument2 pagesSound Summaryhweta173No ratings yet

- Chemistry Notes VtuDocument160 pagesChemistry Notes VtuNarayan S. Burbure67% (3)

- Corrosion PDFDocument73 pagesCorrosion PDFRajat VarshneyNo ratings yet

- Shear transfer coefficient, Γ: (ASTM E1300-09a eq. X11.5) (ASTM E1300-09a eq. X11.3)Document1 pageShear transfer coefficient, Γ: (ASTM E1300-09a eq. X11.5) (ASTM E1300-09a eq. X11.3)layaljamal2No ratings yet

- A Conceptual Hand Note On Chemical Engineering by Md. Towfiq Ahmed SakibDocument331 pagesA Conceptual Hand Note On Chemical Engineering by Md. Towfiq Ahmed SakibTowfiq AhmedNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)