Professional Documents

Culture Documents

Mathcad - ASME I I VIII I Thickness Cylindrical Shell

Uploaded by

kurcekOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathcad - ASME I I VIII I Thickness Cylindrical Shell

Uploaded by

kurcekCopyright:

Available Formats

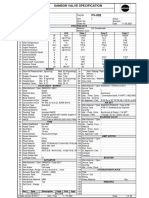

Pressure: P 130 10

5

Pa :=

Design temp: T 120 C :=

Amissible stress@temp: S 138

N

mm

2

:=

Welded joint efficiency: E 1 :=

t

a

50 mm :=

Actual thickness:

Corrosion allowance: C 0 mm :=

c

th

1.6 mm :=

tolerance on thickness:

Outside diameter: D

o

906 mm :=

Inside diameter: D

i

D

o

2 t

a

( )

:= D

i

806 mm =

Inside radius (corrected): R

i

D

i

2

C + c

th

+ := R

i

404.6 mm =

Temperature coeffiecient y 0.4 := - ASME I see note 6, PG-27.4

- for ASME VIII div 1 y = 0.4

prema UG-27(1)(2) za circumferential i longitudinal stresses:

BUL if t

a

R

i

2

<

|

\

|

|

P 0.385 S E < "koristi (1)" , "Greska" ,

(

(

:= BUL "koristi (1)" =

BUL if t

a

R

i

2

<

|

\

|

|

P 1.25 S E < "koristi (2)" , "Greska" ,

(

(

:= BUL "koristi (2)" =

t

P R

i

S E 1 y ( ) P

C + c

th

+ :=

(1)

t 41.998 mm =

ASME VIII div I UG27 (1)

t

2

P R

i

2 S E 0.4 P +

C + c

th

+ :=

(2)

t

2

20.305 mm =

ASME VIII div I UG27 (1)

t

1

P D

o

2 S E 2 y P +

C + c

th

+ :=

t

1

42.724 mm =

ASME I PG27.2.2

t

11

P R

i

c

th

( )

S E 1 y ( ) P

C + c

th

+ :=

t

11

41.838 mm =

BUL if t t

a

< "GOOD" , "NOT GOOD" ,

( )

:= BUL "GOOD" =

Maximum opening diameter for which compensation check according to PG-36 (see PG-32)

is not required:

factor

k

P D

i

1.82 S t

a

:= k 0.834 =

ouside diamter:

D

o

D

i

2 t

a

+ := D

o

906 mm =

in inches:

D

oi

D

o

25.4 mm

:=

D

oi

35.669 =

Actual thickness in inches:

t

ai

t

a

25.4 mm

:= t

ai

1.969 =

Maximum opening diameter: d

max_op

min 2.75 D

oi

t

ai

1 k ( )

1

3

8 ,

(

(

(

:=

d

max_op

6.231 =

d

max_op

d

max_op

25.4 mm :=

d

max_op

158.255 mm =

max. pressute for actual thickness

P

max

S E t

a

C c

th

( )

R

i

1 y ( ) t

a

C c

th

( )

+

:= P

max

154.026 10

5

Pa =

P

test

4.1 1.3 :=

P

test

5.33 =

You might also like

- WRC 107 WRC 297 Co MP PDFDocument11 pagesWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- Bolting-Up CalcDocument21 pagesBolting-Up CalcJayanth TSNo ratings yet

- Bleed Rings RTJDocument1 pageBleed Rings RTJAlessandro1975No ratings yet

- A869-6-44-0005 PMS For RevampDocument950 pagesA869-6-44-0005 PMS For RevampMastram HatheshNo ratings yet

- Girth Flange Load Calculation Using by FEA TechniquesDocument12 pagesGirth Flange Load Calculation Using by FEA TechniqueskingstonNo ratings yet

- 5th Effect Large Nozzle CalcsDocument5 pages5th Effect Large Nozzle CalcsPROTOTYPE TESTNo ratings yet

- Acme Thread External 29Document16 pagesAcme Thread External 29Dhanraj VasanthNo ratings yet

- Pressure Vessel Design Old (Eugyene F Megysey)Document31 pagesPressure Vessel Design Old (Eugyene F Megysey)David FonsecaNo ratings yet

- B.16.5 Interpretation PDFDocument68 pagesB.16.5 Interpretation PDFmohdluthfiNo ratings yet

- ASME Formula DerivationDocument1 pageASME Formula Derivationvm153748763No ratings yet

- B16 Case 12Document2 pagesB16 Case 12InaamNo ratings yet

- Samson Valve Specification: Process DataDocument49 pagesSamson Valve Specification: Process DataMuhammed TamerNo ratings yet

- Technical DataDocument48 pagesTechnical Datashekhar2681No ratings yet

- PV Newsletter April2021Document32 pagesPV Newsletter April2021Tushar MangratiNo ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionSung Woong MoonNo ratings yet

- Stress Analysis of Cross Country PipingDocument3 pagesStress Analysis of Cross Country PipingSharon LambertNo ratings yet

- Raccordi A Inserto Forgiato PDFDocument3 pagesRaccordi A Inserto Forgiato PDFpeppino di capriNo ratings yet

- Torque-Tension Chart For A307 Gr5 Gr8 Gr9Document1 pageTorque-Tension Chart For A307 Gr5 Gr8 Gr9Krish DoodnauthNo ratings yet

- Flow Calculation: II. Constants I. Flow EquationDocument1 pageFlow Calculation: II. Constants I. Flow EquationAndrey Pachón FrancoNo ratings yet

- Stress Young Modulus and Thermal Expansion Coefficients of SteelsDocument51 pagesStress Young Modulus and Thermal Expansion Coefficients of Steelswili_ab8040No ratings yet

- Cylindrical Shell of Pressure Vessel CalculationDocument24 pagesCylindrical Shell of Pressure Vessel CalculationTinBáoNo ratings yet

- IMPGas GRI 207 - PDFDocument141 pagesIMPGas GRI 207 - PDFJorge Vásquez100% (1)

- Calcs 4Document19 pagesCalcs 4Syariful Maliki NejstaršíNo ratings yet

- Mean Metal Temperature For Fixed Heat Exchanger - Intergraph CADWorx & AnalysisDocument3 pagesMean Metal Temperature For Fixed Heat Exchanger - Intergraph CADWorx & Analysisisrar khanNo ratings yet

- Design and Analysis of Industrial Ball Valve Using Computational Fluid DynamicsDocument7 pagesDesign and Analysis of Industrial Ball Valve Using Computational Fluid DynamicsPradeep AdsareNo ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument1 pageAS4041 ASME B31 - 3 Pipe Wall ThicknesselleNo ratings yet

- DNV OS-H102 Marine Operations Design and Fabrication 2012-01Document12 pagesDNV OS-H102 Marine Operations Design and Fabrication 2012-01Marios DiasNo ratings yet

- Ancor Flanges Asme Viii PDFDocument3 pagesAncor Flanges Asme Viii PDFLizbeth Fiallos AvilaNo ratings yet

- Manu Cal 6-Modified Rev 01Document43 pagesManu Cal 6-Modified Rev 01jeeva100% (1)

- Matl Specn.: Matl Temp - in Deg.fDocument15 pagesMatl Specn.: Matl Temp - in Deg.fpandiangvNo ratings yet

- The Definitive O Ring Design GuideDocument31 pagesThe Definitive O Ring Design GuideChezNo ratings yet

- PADT ANSYS Fastener Simulation Part1Document22 pagesPADT ANSYS Fastener Simulation Part1isma_nashNo ratings yet

- ASME B16.5 2013 FlangeRating 1.0Document4 pagesASME B16.5 2013 FlangeRating 1.0sanjaysyNo ratings yet

- DNV Spec For Calculation PDFDocument15 pagesDNV Spec For Calculation PDFXiangchuzeNo ratings yet

- EPM-GL-PI-CLC-0004 - Rev 0 - Slug Flow Force CalculationDocument4 pagesEPM-GL-PI-CLC-0004 - Rev 0 - Slug Flow Force CalculationHernán DazaNo ratings yet

- Pressure Vessel Selection, Sizing and Troubleshooting Kolmetz Handbook of Process Equipment DesignDocument26 pagesPressure Vessel Selection, Sizing and Troubleshooting Kolmetz Handbook of Process Equipment Designazmil hadyNo ratings yet

- StrainerDocument2 pagesStrainerRanjithNo ratings yet

- Mathcad - C02-C1Document5 pagesMathcad - C02-C1Krish ChandNo ratings yet

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNo ratings yet

- Flange Data: Bolt Reference Charts For ASME B16.5 FlangesDocument4 pagesFlange Data: Bolt Reference Charts For ASME B16.5 FlangesMilena Lemus FonsecaNo ratings yet

- PipestresDocument4 pagesPipestresRevankar B R ShetNo ratings yet

- Summary of Bolt TensioningDocument16 pagesSummary of Bolt Tensioningpedro ylarretaNo ratings yet

- Perforated PipesDocument1 pagePerforated PipeselcivilengNo ratings yet

- WRC, PV Elite, NozzlePro Sign ConventionsDocument13 pagesWRC, PV Elite, NozzlePro Sign ConventionsADHIRAJ KOLINo ratings yet

- 3D Stress CriteriaDocument5 pages3D Stress CriteriaFernando DiezNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- The Best Information in Your Pocket About Bottom Hole Assembly BHADocument8 pagesThe Best Information in Your Pocket About Bottom Hole Assembly BHAHezron Bryian ManurungNo ratings yet

- Flange Design Mmcobc 3.1 2010Document6 pagesFlange Design Mmcobc 3.1 2010bakellyNo ratings yet

- Anchor Force CalculationsDocument40 pagesAnchor Force CalculationsImmanuel SNo ratings yet

- High Pressure Flange Design 236313199Document133 pagesHigh Pressure Flange Design 236313199Karthikeyan VisvakNo ratings yet

- DC S3-1301 REV.0 OriginalDocument93 pagesDC S3-1301 REV.0 OriginalPeja JusohNo ratings yet

- Optimization Design of The U-Shaped Metal BellowsDocument5 pagesOptimization Design of The U-Shaped Metal BellowsdaymonNo ratings yet

- Examples Applying Fea Results With Caesar II Models Webinar PDFDocument36 pagesExamples Applying Fea Results With Caesar II Models Webinar PDFkorbelNo ratings yet

- TorquingDocument7 pagesTorquingVicky KumarNo ratings yet

- 2004A Rev 7Document78 pages2004A Rev 7Sri Dhar0% (1)

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965From EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerNo ratings yet

- Asme Viii CalcsDocument20 pagesAsme Viii CalcsSriram VjNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Axdopoo O.: Microstructural Observations of Arc Welded Boron-Aluminum CompositesDocument5 pagesAxdopoo O.: Microstructural Observations of Arc Welded Boron-Aluminum CompositeskurcekNo ratings yet

- En Proefexamen VOL VCA 1Document17 pagesEn Proefexamen VOL VCA 1kurcek100% (1)

- Innovage Jumbo Remote ManualDocument5 pagesInnovage Jumbo Remote ManualTilindinhoNo ratings yet

- Methods of Tube Expansion in Tube To TubDocument19 pagesMethods of Tube Expansion in Tube To Tubkurcek100% (1)

- Dimensions Concetric and Excetric Reducers ASME16.9Document3 pagesDimensions Concetric and Excetric Reducers ASME16.9kurcekNo ratings yet

- Flexibility Analysis of PipingDocument33 pagesFlexibility Analysis of PipingkurcekNo ratings yet

- Corrosion Under Insulation: Why Insulate?Document2 pagesCorrosion Under Insulation: Why Insulate?kurcekNo ratings yet

- Nozzle Loads Piping Stresses and The Effect of Piping On EquipmentDocument40 pagesNozzle Loads Piping Stresses and The Effect of Piping On Equipmentcaesar00100% (6)