Professional Documents

Culture Documents

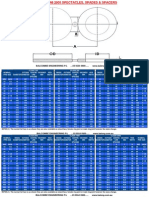

Spectacle Blinds (ANSI B 16-48)

Uploaded by

mikebo55Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spectacle Blinds (ANSI B 16-48)

Uploaded by

mikebo55Copyright:

Available Formats

0.

03937

NB

1

1

2

3

4

6

8

10

12

14

16

18

20

24

DIMENSIONS OF CLASS 150 FLANGES AS PER ANSI B 16.48

A

B

C

D

E

T1

15

48

14

60

26

20

57

21

70

32

25

67

27

79

38

40

86

41

98

52

50

105

52

120

20

64

80

137

78

152

20

86

100

175

103

190

20

114

150

222

154

241

22

148

200

279

203

298

22

188

250

340

254

362

26

154

300

410

303

432

26

190

350

451

343

476

30

208

400

515

394

540

30

176

450

550

445

578

33

188

500

605

495

635

33

162

600

720

597

749

36

194

NB

1

1

2

3

4

6

8

10

12

14

16

18

20

24

DIMENSIONS OF CLASS 300 FLANGES AS PER ANSI B 16.48

A

B

C

D

E

T1

15

54

14

66

30

20

67

21

83

36

25

73

27

89

42

40

95

41

114

58

50

111

52

127

20

68

80

149

78

168

22

96

100

181

103

200

22

118

150

251

154

270

22

112

200

308

203

330

26

138

250

362

254

387

30

118

300

422

303

451

33

138

350

486

343

514

33

124

400

540

394

571

36

140

450

595

445

628

36

126

500

655

495

686

36

140

600

775

597

813

42

168

NB

1

1

2

3

4

6

8

10

12

14

16

18

20

24

DIMENSIONS OF CLASS 600 FLANGES AS PER ANSI B 16.48

A

B

C

D

E

T1

15

54

14

66

30

20

67

21

82

36

25

73

27

89

42

40

95

41

114

58

50

111

52

127

20

68

80

149

78

168

22

96

100

194

103

216

26

126

150

267

154

292

30

116

200

321

203

349

33

140

250

400

254

432

36

128

300

457

303

489

36

114

350

492

343

527

39

122

400

565

394

603

42

144

450

613

445

654

45

155

500

682

495

724

45

140

600

790

597

838

52

164

T2

5

5

5

5

6

8

9

12

15

18

21

23

25

28

31

37

A

4

4

4

4

4

6

7

10

12

15

18

20

23

26

29

34

T2

5

5

5

7

8

11

13

18

23

27

32

35

39

44

49

58

A

4

4

4

5

6

8

10

15

19

24

28

33

37

42

47

56

T2

5

6

7

9

11

15

18

24

31

38

44

48

55

62

68

81

B

1.890

2.244

2.638

3.386

4.134

5.394

6.890

8.740

10.984

13.386

16.142

17.756

20.276

21.654

23.819

28.347

B

2.126

2.638

2.874

3.740

4.370

5.866

7.126

9.882

12.126

14.252

16.614

19.134

21.260

23.425

25.787

30.512

A

4

4

4

6

8

12

15

21

27

33

39

44

53

60

67

80

B

2.126

2.638

2.874

3.740

4.370

5.866

7.638

10.512

12.638

15.748

17.992

19.370

22.244

24.134

26.850

31.102

Inches

DIMENSIONS OF CLASS 150 FLANGES AS PER ANSI B 16.48

C

D

E

T1

T2

0.551

2.362

0.000

1.024

0.197

0.158

0.827

2.756

0.000

1.260

0.197

0.158

1.063

3.110

0.000

1.496

0.197

0.158

1.614

3.858

0.000

2.047

0.197

0.158

2.047

4.724

0.787

2.520

0.236

0.158

3.071

5.984

0.787

3.386

0.315

0.236

4.055

7.480

0.787

4.488

0.354

0.276

6.063

9.488

0.866

5.827

0.472

0.394

7.992

11.732

0.866

7.402

0.591

0.472

10.000

14.252

1.024

6.063

0.709

0.591

11.929

17.008

1.024

7.480

0.827

0.709

13.504

18.740

1.181

8.189

0.906

0.787

15.512

21.260

1.181

6.929

0.984

0.906

17.520

22.756

1.299

7.402

1.102

1.024

19.488

25.000

1.299

6.378

1.221

1.142

23.504

29.488

1.417

7.638

1.457

1.339

DIMENSIONS OF CLASS 300 FLANGES AS PER ANSI B 16.48

C

D

E

T1

T2

0.551

2.598

0.000

1.181

0.197

0.158

0.827

3.268

0.000

1.417

0.197

0.158

1.063

3.504

0.000

1.654

0.197

0.158

1.614

4.488

0.000

2.284

0.276

0.197

2.047

5.000

0.787

2.677

0.315

0.236

3.071

6.614

0.866

3.780

0.433

0.315

4.055

7.874

0.866

4.646

0.512

0.394

6.063

10.630

0.866

4.409

0.709

0.591

7.992

12.992

1.024

5.433

0.906

0.748

10.000

15.236

1.181

4.646

1.063

0.945

11.929

17.756

1.299

5.433

1.260

1.102

13.504

20.236

1.299

4.882

1.378

1.299

15.512

22.480

1.417

5.512

1.535

1.457

17.520

24.724

1.417

4.961

1.732

1.654

19.488

27.008

1.417

5.512

1.929

1.850

23.504

32.008

1.654

6.614

2.284

2.205

DIMENSIONS OF CLASS 600 FLANGES AS PER ANSI B 16.48

C

D

E

T1

T2

0.551

2.598

0.000

1.181

0.197

0.158

0.827

3.228

0.000

1.417

0.236

0.158

1.063

3.504

0.000

1.654

0.276

0.158

1.614

4.488

0.000

2.284

0.354

0.236

2.047

5.000

0.787

2.677

0.433

0.315

3.071

6.614

0.866

3.780

0.591

0.472

4.055

8.504

1.024

4.961

0.709

0.591

6.063

11.496

1.181

4.567

0.945

0.827

7.992

13.740

1.299

5.512

1.221

1.063

10.000

17.008

1.417

5.039

1.496

1.299

11.929

19.252

1.417

4.488

1.732

1.535

13.504

20.748

1.535

4.803

1.890

1.732

15.512

23.740

1.654

5.669

2.165

2.087

17.520

25.748

1.772

6.102

2.441

2.362

19.488

28.504

1.772

5.512

2.677

2.638

23.504

32.992

2.047

6.457

3.189

3.150

All dimensions are in millimeters unless otherwise indicated.

General notes:

D = Hole size (where required) should be the same as the flange bolt hole. In practice, these dimensions have been rounded round off upwards.

T1 = Thickness Carbon Steel.

T2 = Thickness Stainless Steel.

W = Thickness of the web (or tie bar) should be 0.25 inch (6 mm) minimum, or equal to T1 and T2 if less than 0.25 inch (6 mm).

Spectacle Blinds should be made from a plate or forging specification, approved for use by ASME B31.3, of essentially the same chemical composition as the mating flanges

and piping involved.

Depending on a customer specification, the dimensions can be different from what on this page is defined.

You might also like

- ASME B16.5 Flange DimensionsDocument2 pagesASME B16.5 Flange Dimensionsbakelly100% (1)

- Table Asme b36.19Document1 pageTable Asme b36.19Alin TomozeiNo ratings yet

- Pipe Dimension Ansi VS Jis PDFDocument3 pagesPipe Dimension Ansi VS Jis PDFGalih Prianggodo100% (2)

- Pipe Schedule Segun ASME B36.1 PDFDocument1 pagePipe Schedule Segun ASME B36.1 PDFalberthf_1No ratings yet

- Ansi B 16-28 Codo 180º RCDocument1 pageAnsi B 16-28 Codo 180º RCmekoxxxNo ratings yet

- Tabel Corespondenta Duritati OtelDocument2 pagesTabel Corespondenta Duritati OtelReparatii CncNo ratings yet

- Ansi B16.9Document4 pagesAnsi B16.9hailay1983No ratings yet

- 150#RFWN 26-60 Asme b16.47 DimensionsDocument1 page150#RFWN 26-60 Asme b16.47 DimensionsHeymonth ChandraNo ratings yet

- ASME ANSI B 31.3 Pressure-Tables-E1Document3 pagesASME ANSI B 31.3 Pressure-Tables-E1Franklin JprstNo ratings yet

- Tabel ProfilDocument8 pagesTabel ProfilUcok DedyNo ratings yet

- Epaisseur Tube Acier & InoxDocument1 pageEpaisseur Tube Acier & InoxMaroiene100% (1)

- Standardne Dimenzije Trof - MotoraDocument1 pageStandardne Dimenzije Trof - MotoraalesysNo ratings yet

- PAPER TARP For BirthdaysDocument12 pagesPAPER TARP For BirthdaysZechaina UdoNo ratings yet

- Ansi B 16-28 Codo 90º RCDocument1 pageAnsi B 16-28 Codo 90º RCAndres VelazquezNo ratings yet

- Ansi B16.5Document3 pagesAnsi B16.5rmnrajanNo ratings yet

- Book 1Document48 pagesBook 1Edgar BolotaoloNo ratings yet

- Revisi 2Document1 pageRevisi 2ridhabalataw84No ratings yet

- Is 1239Document1 pageIs 1239gopi_krishnan_29No ratings yet

- Section Armature CouranteDocument1 pageSection Armature CouranteFIDINIRIN'ARIMANANANo ratings yet

- HaubanageDocument12 pagesHaubanageRosemary GuerreroNo ratings yet

- Flambement Poteau Avec FlexionDocument117 pagesFlambement Poteau Avec FlexionasdhjshfdsjauildgfyhNo ratings yet

- Ansi c37.32-1996Document1 pageAnsi c37.32-1996Addin Ruano100% (1)

- Asme B16.48 2005 PDFDocument1 pageAsme B16.48 2005 PDFcristian_alex9885No ratings yet

- Astm B36.10Document4 pagesAstm B36.10RAVI1972No ratings yet

- Verification D'une Section A La Flexion + Effort TranchantDocument108 pagesVerification D'une Section A La Flexion + Effort TranchantasdhjshfdsjauildgfyhNo ratings yet

- Veenhuis PremiumDocument1 pageVeenhuis PremiumSantjin100% (1)

- 202 m55HJoxsaIepigel DIN933 - Bulon HexagonalDocument2 pages202 m55HJoxsaIepigel DIN933 - Bulon HexagonalIndian ChiefNo ratings yet

- Filtre 244Document7 pagesFiltre 244mbowNo ratings yet

- Documentation Simple Battant V2Document4 pagesDocumentation Simple Battant V2contactNo ratings yet

- Diametre (CM) Si Tipuri de BetonDocument1 pageDiametre (CM) Si Tipuri de BetonOctavian CicuNo ratings yet

- Ansi-Asme B16.47 B (Api 605)Document2 pagesAnsi-Asme B16.47 B (Api 605)aauppalNo ratings yet

- ASME B36 10M Tableau Des DimensionsDocument2 pagesASME B36 10M Tableau Des DimensionsMichel LupienNo ratings yet

- DIN en 1092 Dimensiuni Flanse PN 2.5Document3 pagesDIN en 1092 Dimensiuni Flanse PN 2.5obin04No ratings yet

- Catalogo TTCDocument4 pagesCatalogo TTCdaniloreaNo ratings yet

- Catalogo Donghua Cadenas VariasDocument46 pagesCatalogo Donghua Cadenas Variasj.arriolaNo ratings yet

- Wire TableDocument1 pageWire Tableqwerty_conan100% (13)

- 6in 50Ft PumpsetDocument2 pages6in 50Ft PumpsetPrashant PatilNo ratings yet

- Spidem Divina de LuxeDocument3 pagesSpidem Divina de LuxeiluyaaNo ratings yet

- Tabel ProfilDocument10 pagesTabel Profilyoi_123No ratings yet

- Calculation Sheet ETABSDocument17 pagesCalculation Sheet ETABSosama elmohandesNo ratings yet

- Demag CC 1800Document10 pagesDemag CC 1800mardini05No ratings yet

- Standart Abma Ansi 8.2Document6 pagesStandart Abma Ansi 8.2rogertecNo ratings yet

- Tabela de FiosDocument1 pageTabela de FiosElisa Peixoto MenezesNo ratings yet

- Calon Saham Bagger September 2022Document52 pagesCalon Saham Bagger September 2022Dokter Chandra WqinNo ratings yet

- Bảng hàng CT3Document2 pagesBảng hàng CT3Ngoc QuangNo ratings yet

- Tabla Bridas 600Document1 pageTabla Bridas 600prufino2No ratings yet

- ArmatureDocument1 pageArmatureMohamed EL Guennouni RichNo ratings yet

- Acn ModifDocument4 pagesAcn ModifYacine AnzarNo ratings yet

- Datasheet LR 1750Document14 pagesDatasheet LR 1750JITENDRA KUMAR SHARMANo ratings yet

- Armare Zid de SprijinDocument1 pageArmare Zid de Sprijincr15tiNo ratings yet

- ARQUIVO IES STH8707-30.iesDocument1 pageARQUIVO IES STH8707-30.iesEduarda RochaNo ratings yet

- Annonces Maison A Louer ExerciceDocument1 pageAnnonces Maison A Louer ExerciceAlicia Margarita Sánchez MejoradoNo ratings yet

- Regle Installation ExtincteurDocument7 pagesRegle Installation ExtincteurbenoitrousierNo ratings yet

- DTU 13 - 3 DallageDocument26 pagesDTU 13 - 3 Dallageamadijob9527100% (6)

- Les Lisieres Plaquette PPE Digital 190429Document46 pagesLes Lisieres Plaquette PPE Digital 190429GuillaumeINo ratings yet

- Avis Technique 210-1410Document29 pagesAvis Technique 210-1410Touhami MimounNo ratings yet

- Terminologie Des Ouvrages D ArtDocument26 pagesTerminologie Des Ouvrages D ArtElvis AdivignonNo ratings yet

- Cinq Points de L'architecture Moderne - WikipédiaDocument8 pagesCinq Points de L'architecture Moderne - WikipédiaClaude KengneNo ratings yet

- Sanitaire08 Nicoll FranceDocument42 pagesSanitaire08 Nicoll FranceCarlos ChoqueNo ratings yet

- Tabela de Bitolas GerdauDocument3 pagesTabela de Bitolas GerdauVitor OgliariNo ratings yet

- Pont À VouteDocument8 pagesPont À VoutentgNo ratings yet

- 100 Logements Aadl A Tougourt WilayaDocument24 pages100 Logements Aadl A Tougourt WilayaBen Hakim Sohayb83% (6)

- RapportDocument139 pagesRapportbaddi_hNo ratings yet

- Terminologie Des Éléments DDocument4 pagesTerminologie Des Éléments DErcy Kakor NdiwaNo ratings yet

- Construire Soi Même Sa Piscine Béton Carrelée Comme Un Pro !Document8 pagesConstruire Soi Même Sa Piscine Béton Carrelée Comme Un Pro !Saber AbdelkafiNo ratings yet

- Dimensionnement FixationsDocument14 pagesDimensionnement FixationsNoel ChaneNo ratings yet

- Ecomed - Maison Kit BoisDocument2 pagesEcomed - Maison Kit BoissusCities100% (1)

- CATALOGO Armarios y Dormitorios ESENZIA BaixmodulsDocument41 pagesCATALOGO Armarios y Dormitorios ESENZIA Baixmodulscampa1973No ratings yet

- Guide de Pose Maxi Linteau Terreal 2017Document2 pagesGuide de Pose Maxi Linteau Terreal 2017maiducthoNo ratings yet

- CPT Chiali Tube AssainissementDocument8 pagesCPT Chiali Tube AssainissementHired MohamedNo ratings yet

- SIFAS CatalogueDocument155 pagesSIFAS CataloguetifonlineNo ratings yet

- Femmes Celebres FrancaisesDocument10 pagesFemmes Celebres FrancaisesorleanseliNo ratings yet

- Patrimoine LavandouDocument4 pagesPatrimoine LavandouPhilippe MiliotoNo ratings yet

- Conception Des PoutresDocument7 pagesConception Des PoutresKerby Pierre LouisNo ratings yet

- Camping-Cars HYMER 2010Document44 pagesCamping-Cars HYMER 2010Adelus Franck100% (1)

- Recherches Sur Les Monnaies Des Comtes de Hainaut / Par Rénier ChalonDocument279 pagesRecherches Sur Les Monnaies Des Comtes de Hainaut / Par Rénier ChalonDigital Library Numis (DLN)No ratings yet

- 564, Pp. 261-268Document8 pages564, Pp. 261-268Abdellah BoushabaNo ratings yet

- TP MDC AffaissementDocument12 pagesTP MDC AffaissementMiloudi Safou100% (5)

- Gare de Cavalaire - Maquettes ProspectivesDocument38 pagesGare de Cavalaire - Maquettes Prospectiveskval3rNo ratings yet

- Habito Mur Ultra ResistantDocument2 pagesHabito Mur Ultra ResistantKimiNo ratings yet

- Où Habites-TuDocument17 pagesOù Habites-TuSheadon Alexander100% (1)