Professional Documents

Culture Documents

Mathcad - 4

Uploaded by

Desejo SozinandoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathcad - 4

Uploaded by

Desejo SozinandoCopyright:

Available Formats

HYDRAULIC MACHINES III

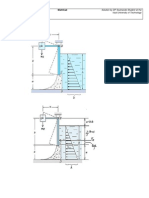

PUMP PERFORMANCE AND CHARACTERISTIC CURVES

Solution by DF Sozinando, Mechanical Eng. student at Vaal University of Technology

3- The characteristic of a centrifugal pump handling water are given as:

m s

3

Q(

0.01 9.5 65

0.014 8.7 81

0.017 7.4 78

0.019 6.1 68

0.024 0.9 12

H( m) (%)

The system consists of 840m of 15cm diameter pipes with absolutes roughness 6x10-6m joining two reservoirs, the difference between water levels being 3m. Neglecting all losses except frictions. Determine the rate of flow between two reservoirs at the operation point and the power consumed by the pump. Take absolute viscosity of water as =1.14x10 Pa.s and =1000

-3

kg m

3

solution:

0.01 0.014 m3 Q Pump := 0.017 0.019 s 0.024

%1

:= 6 10

-6

9.5 8.7 HPump := 7.4 m 6.1 0.9

:= 1.14 10

-3

65 81 78 % 68 12 :=

7

for the reason of scale, efficiency I used reduction scale 1:7, that's why divided all efficiencies by 7

L := 840m

d := 15cm

z := 3m

Pa s

:= 1000

kg m

3

In the given data there no pipe friction factor, to get the system equation is needed, in t his case is necessary the interaction in order to get acceptable pipe friction factor

Interact pipe friction factor start by 0.01

2

f1 := 0.01

HSys f , L, Q Pump , d := z +

8 f L Q Pump g d

2 5

R( , Q , , d) :=

4 Q

d

f ( , d , R) :=

0.25

log + 5.74 3.7 d 0.9 R

HSys1 := z +

8 f1 L Q Pump g d

2 5

3.914 4.792 HSys1 = 5.642 m 6.301 8.266

head and flow rate form the graph at f1 = 0.01 H1 := 6.25m Q 1 := 0.018834 m s

3

22

HYDRAULIC MACHINES III

PUMP PERFORMANCE AND CHARACTERISTIC CURVES

Solution by DF Sozinando, Mechanical Eng. student at Vaal University of Technology

After getting the system equation always plot it to find the head and flow rate and then use it to calculate Reynolds number and new friction factor until getting the right one as show below: R2 := 4 Q 1

d

R2 = 140235.05

f2 :=

0.25

log + 5.74 3.7 d R2 0.9 4.551 6.039 HSys2 = 7.481 m 8.597 11.931

f3 :=

f2 = 0.017

HSys2 := z +

8 f2 L Q Pump g d

2 5

head and flow rate form the graph at f2 = 0.017 H2 := 7.4211m Q 2 := 0.016897 m s

3

R3 :=

4 Q 2

d

R3 = 125812.448

0.25

log + 5.74 3.7 d R3 0.9 4.583 6.102 HSys3 = 7.574 m 8.714 12.117

f4 :=

f3 = 0.0173

HSys3 := z +

8 f3 L Q Pump g d

2 5

head and flow rate form the graph at f3 = 0.0173 H3 := 7.4605m Q 3 := 0.016985 m s

3

R4 :=

4 Q 3

d

R4 = 126467.682

0.25

log + 5.74 3.7 d R4 0.9

3 := ( 11.143 ) ( 7) = 78.001 %

f4 = 0.0173

HSys.Ideal := HSys3

I multiply by 7 because of the scale that I used for efficiency

After getting the ideal pipe friction factor the one of the system3, m ean that the head, flow rate and efficiency of two reservoir is also from system 3, now we are able to calculate the power consum ed as show below

:= 9.81

kN m

3

Specific Density of water

Pcons :=

H3 Q 3 3

100

Pcons = 1.594 kW

23

HYDRAULIC MACHINES III

PUMP PERFORMANCE AND CHARACTERISTIC CURVES

Solution by DF Sozinando, Mechanical Eng. student at Vaal University of Technology

12 10.8 9.6

Head & Efficiency

8.4 7.2 6 4.8 3.6 2.4 1.2 0 0.01

0.0115

0.013

0.0145

0.016

0.0175

0.019

0.0205

0.022

0.0235

0.025

Flow Rate Pump Curve System Curve 1 with f1 System Curve 2 with f2 System Ideal Curve 3 with f3 Efficiency Curve

24

You might also like

- 14 Jet Bit Nozzle Size SelectionDocument46 pages14 Jet Bit Nozzle Size Selectiontotos20100% (2)

- Tech Drilling JetBitNozzleDocument46 pagesTech Drilling JetBitNozzlealvarex007100% (1)

- Mathcad - 5Document4 pagesMathcad - 5Desejo SozinandoNo ratings yet

- Jet Bit Nozzle Size SelectionDocument46 pagesJet Bit Nozzle Size SelectionBharat BhattaraiNo ratings yet

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsFrom EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNo ratings yet

- CEE 345 Spring 2002 problem set solutions pump efficiency discharge headDocument10 pagesCEE 345 Spring 2002 problem set solutions pump efficiency discharge headAdrian Antonio TorresNo ratings yet

- Mathcad - 2Document4 pagesMathcad - 2Desejo SozinandoNo ratings yet

- Group-2: Che F312 Chemical Engineering Lab Experiment-5Document8 pagesGroup-2: Che F312 Chemical Engineering Lab Experiment-5Prateek MantriNo ratings yet

- Sizing CostingDocument39 pagesSizing CostingMarilynYunLingNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Psme QuizDocument9 pagesPsme QuizJerico LlovidoNo ratings yet

- Pyrhonen Squirrel Cage Motor Calculation Mathcad13Document35 pagesPyrhonen Squirrel Cage Motor Calculation Mathcad13Mutee Ullah KhanNo ratings yet

- Mathcad - Pond Hex - FinalDocument6 pagesMathcad - Pond Hex - FinalMohammed A IsaNo ratings yet

- Design of The Cross Flow Runner: ConstantsDocument8 pagesDesign of The Cross Flow Runner: ConstantshydraleyNo ratings yet

- Validation Report On The 2-Phase Line SizingDocument18 pagesValidation Report On The 2-Phase Line SizingEbby Onyekwe100% (1)

- The American University of MadabaDocument8 pagesThe American University of MadabaDia MujahedNo ratings yet

- T 2Document9 pagesT 2Amaterasu Susanoo TsukuyomiNo ratings yet

- Calculation ExampleDocument20 pagesCalculation Examplepavankumar0001No ratings yet

- Gas LooplinestptDocument64 pagesGas Looplinestptniyo7No ratings yet

- Student Surname: Student Name: Student IDDocument6 pagesStudent Surname: Student Name: Student IDKumail Al KhuraidahNo ratings yet

- Pelton TurbineDocument28 pagesPelton TurbineLemi ChalaNo ratings yet

- Drilling HydraulicDocument52 pagesDrilling HydraulicHeris Sitompul100% (1)

- Pelton TurbineDocument28 pagesPelton Turbinealejandro777_eNo ratings yet

- Final Round and ClincherDocument8 pagesFinal Round and Clincherponcatoera0% (2)

- Pelton TurbineDocument28 pagesPelton TurbineCésar SantosNo ratings yet

- Pressure Drop Calculation in Sieve Plate Distillation ColumnDocument15 pagesPressure Drop Calculation in Sieve Plate Distillation ColumnAnoop Kumar GuptaNo ratings yet

- UTM Flow Measurement Lab Report AnalysisDocument20 pagesUTM Flow Measurement Lab Report AnalysisKhairil IkramNo ratings yet

- Sprinkler Capacity 1Document22 pagesSprinkler Capacity 1Richelle DandoNo ratings yet

- Mechanical Engineering DepartmentDocument7 pagesMechanical Engineering Departmentحسين عمريNo ratings yet

- Chapter 6Document13 pagesChapter 6Marco Luigi100% (1)

- Steam Problem SetDocument20 pagesSteam Problem SetMavrix Agustin67% (3)

- Gas Compression IIDocument13 pagesGas Compression IIAnuraag MulpuriNo ratings yet

- Set of Answer of Fluid Mechanics II, UTHM. Based On Cengel 11th EditionDocument6 pagesSet of Answer of Fluid Mechanics II, UTHM. Based On Cengel 11th EditionIskandar BellNo ratings yet

- Exp 2 ME LAB 3Document14 pagesExp 2 ME LAB 3q234asdfasdfNo ratings yet

- Final Compilation of Assing 3 - Vignes ShanmuganathanDocument28 pagesFinal Compilation of Assing 3 - Vignes ShanmuganathanlibbissujessyNo ratings yet

- Saet 8 BDocument3 pagesSaet 8 BnaefmubarakNo ratings yet

- Ejercicios de Ecuaciones Diferenciales, Resueltos en MatlabDocument6 pagesEjercicios de Ecuaciones Diferenciales, Resueltos en MatlabCrezpo YzNo ratings yet

- Chemical Engineering DepartmentDocument18 pagesChemical Engineering Departmentiffat100% (1)

- Gas Pipeline Hydraulics CalculationsDocument20 pagesGas Pipeline Hydraulics CalculationsDavid MontoyaNo ratings yet

- Reporte 3Document7 pagesReporte 3حسين عمريNo ratings yet

- Addi Examples Pipe3Document10 pagesAddi Examples Pipe3Diego MorenoNo ratings yet

- RNZ Integrated (M) SDN BHD: Calculation SheetDocument14 pagesRNZ Integrated (M) SDN BHD: Calculation SheetNhantran VanNo ratings yet

- Fluid Mechanics: University of LeedsDocument16 pagesFluid Mechanics: University of LeedsHasitha MadusankaNo ratings yet

- Car crushing hydraulic circuit analysisDocument22 pagesCar crushing hydraulic circuit analysisphankhoa83100% (1)

- Single acting pump power and discharge calculationsDocument5 pagesSingle acting pump power and discharge calculationsAmaterasu Susanoo TsukuyomiNo ratings yet

- Fluid Mechanics Ii: ContentsDocument9 pagesFluid Mechanics Ii: ContentsMahmoudNo ratings yet

- CALCULATE GAS FLOW AND PRESSURE DROP IN PIPELINESDocument17 pagesCALCULATE GAS FLOW AND PRESSURE DROP IN PIPELINESsidharththerrothNo ratings yet

- Sewer Hydraulics Calculations Using Manning EquationDocument13 pagesSewer Hydraulics Calculations Using Manning EquationshamashergyNo ratings yet

- Civil Engineering Portal Provides Free Books, Papers and ResourcesDocument64 pagesCivil Engineering Portal Provides Free Books, Papers and ResourcesCiutac Ionut CristianNo ratings yet

- From Table We KnowDocument5 pagesFrom Table We KnowTaha ZakiNo ratings yet

- Chapter 7Document6 pagesChapter 7Marco LuigiNo ratings yet

- PUMP DESIGN OPTIMIZATIONDocument17 pagesPUMP DESIGN OPTIMIZATIONSamuel AnandNo ratings yet

- Fluid Mechanics d203 ReseniDocument90 pagesFluid Mechanics d203 ReseniDennys Fabricio Ramirez100% (1)

- Mathcad - Beam ProgrammingDocument1 pageMathcad - Beam ProgrammingDesejo SozinandoNo ratings yet

- Mathcad - Extra39Document1 pageMathcad - Extra39Desejo Sozinando100% (1)

- Gyrops 22 08 2016Document7 pagesGyrops 22 08 2016Desejo SozinandoNo ratings yet

- Hydraulic Machines IIIDocument73 pagesHydraulic Machines IIIDesejo SozinandoNo ratings yet

- Mathcad - Extra38Document2 pagesMathcad - Extra38Desejo Sozinando0% (1)

- Mathcad - Extra44Document1 pageMathcad - Extra44Desejo SozinandoNo ratings yet

- Mathcad - Test 1Document3 pagesMathcad - Test 1Desejo SozinandoNo ratings yet

- Mathcad - Test 2Document2 pagesMathcad - Test 2Desejo SozinandoNo ratings yet

- Mathcad - Extra30Document2 pagesMathcad - Extra30Desejo Sozinando50% (2)

- Mathcad - Extra43Document1 pageMathcad - Extra43Desejo SozinandoNo ratings yet

- Mathcad - Proramming Spot2Document2 pagesMathcad - Proramming Spot2Desejo Sozinando100% (1)

- Mathcad - Extra37Document2 pagesMathcad - Extra37Desejo Sozinando0% (1)

- Mathcad - Spot Questions1Document5 pagesMathcad - Spot Questions1Desejo SozinandoNo ratings yet

- Mathcad - ProgrammDocument1 pageMathcad - ProgrammDesejo SozinandoNo ratings yet

- Mathcad - Extra42Document2 pagesMathcad - Extra42Desejo SozinandoNo ratings yet

- Mathcad - Extra41Document2 pagesMathcad - Extra41Desejo SozinandoNo ratings yet

- Mathcad - Extra33Document1 pageMathcad - Extra33Desejo Sozinando50% (2)

- Mathcad - Extra40Document1 pageMathcad - Extra40Desejo SozinandoNo ratings yet

- Mathcad - Extra31Document1 pageMathcad - Extra31Desejo SozinandoNo ratings yet

- Mathcad - Extra32Document2 pagesMathcad - Extra32Desejo SozinandoNo ratings yet

- Mathcad - Extra35Document2 pagesMathcad - Extra35Desejo SozinandoNo ratings yet

- Mathcad - Extra36Document2 pagesMathcad - Extra36Desejo SozinandoNo ratings yet

- Mathcad - Extra34Document1 pageMathcad - Extra34Desejo SozinandoNo ratings yet

- Mathcad - Extra29Document1 pageMathcad - Extra29Desejo SozinandoNo ratings yet

- Mathcad - Extra27Document2 pagesMathcad - Extra27Desejo SozinandoNo ratings yet

- Mathcad - Extra28Document3 pagesMathcad - Extra28Desejo SozinandoNo ratings yet

- Mathcad - Extra26Document1 pageMathcad - Extra26Desejo SozinandoNo ratings yet

- Mathcad - Extra24Document2 pagesMathcad - Extra24Desejo SozinandoNo ratings yet

- Mathcad - Extra25Document1 pageMathcad - Extra25Desejo Sozinando0% (1)

- Mathcad - Extra23Document2 pagesMathcad - Extra23Desejo SozinandoNo ratings yet

- Top Brand Story Bar Supervisor Jobs Chennai Apply Now Latest Fresher Experienced Bar Supervisor Jobs in Various Location July 18 2021Document1 pageTop Brand Story Bar Supervisor Jobs Chennai Apply Now Latest Fresher Experienced Bar Supervisor Jobs in Various Location July 18 2021Surya JamesNo ratings yet

- PNB - Recruitment For The Post of Chief Security OfficerDocument3 pagesPNB - Recruitment For The Post of Chief Security OfficerCareerNotifications.comNo ratings yet

- Usa Easa 145Document31 pagesUsa Easa 145Surya VenkatNo ratings yet

- 13-07-01 Declaration in Support of Skyhook Motion To CompelDocument217 pages13-07-01 Declaration in Support of Skyhook Motion To CompelFlorian MuellerNo ratings yet

- Corruption in PakistanDocument15 pagesCorruption in PakistanklutzymeNo ratings yet

- Entrepreneurship WholeDocument20 pagesEntrepreneurship WholeKrizztian SiuaganNo ratings yet

- BA 9000 - NIJ CTP Body Armor Quality Management System RequirementsDocument6 pagesBA 9000 - NIJ CTP Body Armor Quality Management System RequirementsAlberto GarciaNo ratings yet

- CFEExam Prep CourseDocument28 pagesCFEExam Prep CourseM50% (4)

- Group 4 HR201 Last Case StudyDocument3 pagesGroup 4 HR201 Last Case StudyMatt Tejada100% (2)

- Benzon CaseDocument3 pagesBenzon Casejulieanne07100% (1)

- Milton Hershey's Sweet StoryDocument10 pagesMilton Hershey's Sweet Storysharlene sandovalNo ratings yet

- KSRTC BokingDocument2 pagesKSRTC BokingyogeshNo ratings yet

- Lister LRM & SRM 1-2-3 Manual and Parts List - Lister - Canal WorldDocument4 pagesLister LRM & SRM 1-2-3 Manual and Parts List - Lister - Canal Worldcountry boyNo ratings yet

- TEST BANK: Daft, Richard L. Management, 11th Ed. 2014 Chapter 16 Motivating EmplDocument37 pagesTEST BANK: Daft, Richard L. Management, 11th Ed. 2014 Chapter 16 Motivating Emplpolkadots939100% (1)

- Introduction To Elective DesignDocument30 pagesIntroduction To Elective Designabdullah 3mar abou reashaNo ratings yet

- Department of Ece Vjec 1Document29 pagesDepartment of Ece Vjec 1Surangma ParasharNo ratings yet

- The Human Resource Department of GIK InstituteDocument1 pageThe Human Resource Department of GIK InstitutexandercageNo ratings yet

- People vs. Ulip, G.R. No. L-3455Document1 pagePeople vs. Ulip, G.R. No. L-3455Grace GomezNo ratings yet

- Complaint Handling Policy and ProceduresDocument2 pagesComplaint Handling Policy and Proceduresjyoti singhNo ratings yet

- Overhead Door Closers and Hardware GuideDocument2 pagesOverhead Door Closers and Hardware GuideAndrea Joyce AngelesNo ratings yet

- Aptio ™ Text Setup Environment (TSE) User ManualDocument42 pagesAptio ™ Text Setup Environment (TSE) User Manualdhirender karkiNo ratings yet

- Gattu Madhuri's Resume for ECE GraduateDocument4 pagesGattu Madhuri's Resume for ECE Graduatedeepakk_alpineNo ratings yet

- Create A Gmail Account in Some Simple StepsDocument9 pagesCreate A Gmail Account in Some Simple Stepsptjain02No ratings yet

- Elaspeed Cold Shrink Splices 2010Document3 pagesElaspeed Cold Shrink Splices 2010moisesramosNo ratings yet

- Dwnload Full International Monetary Financial Economics 1st Edition Daniels Solutions Manual PDFDocument36 pagesDwnload Full International Monetary Financial Economics 1st Edition Daniels Solutions Manual PDFelegiastepauleturc7u100% (16)

- ADSLADSLADSLDocument83 pagesADSLADSLADSLKrishnan Unni GNo ratings yet

- 21st Century LiteraciesDocument27 pages21st Century LiteraciesYuki SeishiroNo ratings yet

- AKTA MERGER (FINAL) - MND 05 07 2020 FNLDocument19 pagesAKTA MERGER (FINAL) - MND 05 07 2020 FNLNicoleNo ratings yet

- 9IMJan 4477 1Document9 pages9IMJan 4477 1Upasana PadhiNo ratings yet

- Dissolved Oxygen Primary Prod Activity1Document7 pagesDissolved Oxygen Primary Prod Activity1api-235617848No ratings yet