Professional Documents

Culture Documents

Mathcad - 5

Uploaded by

Desejo SozinandoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathcad - 5

Uploaded by

Desejo SozinandoCopyright:

Available Formats

HYDRAULIC MACHINES III PUMP PERFORMANCE AND

CHARACTERISTIC CURVES

Solution by DF Sozinando, Mechanical Eng.

student at Vaal University of Technology

4- The characteristic of a pump in terms of dimensionless coeffci ents may approximated to K

H

240 2 K

Q

21 K

Q

2

= .

Such a pump having an impeller of 0.4m and running at 145 rev/min operates against a system characteristic represeted

by H

sys

5 300 Q

2

+ = . Use Q=0, 0.1, 0.2, 0.3, 0.4, and 0.5m

3

/s to plot the original pump curve and system curce.

a) Obtem the volume flow rate delivered and the pump operating head for the original pump from your graph?

b) Obtem the volume flow rate delivered and the pump operating head for a similar pump with an impeller diameter of

0.39m in the dame system operating at 220rev/min from your graph?

Solution:

Q

pump_145

0

0.1

0.2

0.3

0.4

0.5

|

\

|

|

|

|

|

|

|

.

m

3

s

:= d

1

0.4m := N

1

145rpm := d

2

0.39m := N

2

220rpm := z

145

5m :=

k

pump_145

300

s

2

m

5

:=

H

sys

z

145

k

pump_145

Q

pump_145

( )

2

+ := H

sys

5

8

17

32

53

80

|

\

|

|

|

|

|

|

|

.

m =

K

Q

Q

N d

3

= , K

H

g H

N

2

d

2

=

FROM AFFINITY

LAWS

K

H

240 2 K

Q

21 K

Q

2

=

g H

N

2

d

2

240 2

Q

N d

3

21

Q

N d

3

\

|

|

.

2

=

gH 240 N

2

d

2

( )

2 N

2

d

2

( )

N d

3

Q 21

N

2

d

2

N

2

d

6

\

|

|

|

.

Q

2

=

H 240

N

2

g 60 60

d 2

N

60 g d

Q

21

g d

4

Q

2

=

25

HYDRAULIC MACHINES III PUMP PERFORMANCE AND

CHARACTERISTIC CURVES

Solution by DF Sozinando, Mechanical Eng.

student at Vaal University of Technology

H

pump_145

22.861 1.232Q

pump_145

83.62 Q

pump_145

( )

2

=

H

pump_145

22.861m 1.232

s

m

2

Q

pump_145

83.62

s

2

m

5

Q

pump_145

( )

2

:= H

pump_145

22.861

21.902

19.27

14.966

8.989

1.34

|

\

|

|

|

|

|

|

|

.

m =

H

pump_220

50.028 1.917 Q

pump_220

92.532 Q

pump_220

( )

2

=

H

pump_220

50.028m 1.917

s

m

2

Q

pump_145

92.532

s

2

m

5

Q

pump_145

( )

2

:= H

pump_220

50.028

48.911

45.943

41.125

34.456

25.936

|

\

|

|

|

|

|

|

|

.

m =

NB: Always use the operation flow rate to calcul ate any system head, pump

head and to plot the graph.

Q

pump_220

Q

pump_145

N

2

d

2

3

N

1

d

1

3

:= Q

pump_220

0

0.141

0.281

0.422

0.563

0.703

|

\

|

|

|

|

|

|

|

.

m

3

s

=

Q

pump_145

N

1

d

1

3

Q

pump_220

N

2

d

2

3

=

FROM AFFINITY

LAWS

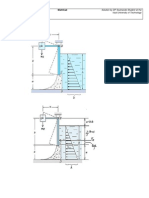

0 0.1 0.2 0.3 0.4 0.5

0

20

40

60

80

System Curve

Pump Curve at 145 rpm

Pump Curve at 220 rpm

Flow rate

H

e

a

d

Readings taken from the graph

Q

145

0.214

m

3

s

:= H

145

18.8m :=

Q

220

0.333

m

3

s

:= H

220

38.3m :=

26

HYDRAULIC MACHINES III PUMP PERFORMANCE AND

CHARACTERISTIC CURVES

Solution by DF Sozinando, Mechanical Eng.

student at Vaal University of Technology

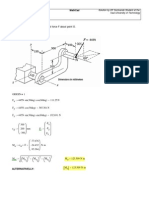

5- For the system in Question4, water at 15 (=9.81kN/m

3

, P

vap

=1.7kPa flows from a closed thank through a 50cm

diameter suction pipe (f=0.02) whose length is 2km. The pressure above the water in the sealed tank is 10kPa below

atmospheric. The similar pump for the Question1 is placed 4m below the surface of the water in the thank, the pipe

connection to the thank is square edged and there are two 90 elbows (f

T

=0.017, Le/D=30). Take atmospheric pressure

as 100.5kPa. Sketch the system. Calculate the net positive suction head available to this similar pump.

NB: The pressure in the thank always must be absolute pressure and do not

consider the suction after the pump, consider only the suction before the pump.

9.81

kN

m

3

:= p

vap

1.7kPa := d 50cm := f 0.02 := L 2km := p

g

10 kPa :=

f

T

0.017 :=

L

e

d

e

30 = p

at

100.5kPa := Q 0.333

m

3

s

:= from Question4

h

s

4m :=

NPSH

A

p

2

v

2

2

2 g

+

|

\

|

|

|

.

h

vap

= h

sp

h

s

+ h

L

h

vap

=

TO AVOID CAVITATION

NPSH

A

NPSH

R

>

p

sp

p

g

p

at

+ := p

sp

90.5 kPa = abs ( )

NPSH

A

1.10NPSH

R

=

h

sp

p

sp

:= h

sp

9.225 m =

h

L

entre friction + 2elbows + =

NPSH

A

h

sp

h

s

+

8 f L Q

2

2

g d

5

2 f

T

30 ( )

8 Q

2

2

g d

4

(

(

(

p

vap

:= NPSH

A

1.171 m =

27

HYDRAULIC MACHINES III PUMP PERFORMANCE AND

CHARACTERISTIC CURVES

Solution by DF Sozinando, Mechanical Eng.

student at Vaal University of Technology

DISCUSSION:

Many pumps are too large to be tested in a laboratory therefore it is essential to be able to test small geometrically

similar ones and then scale the results up to the required size.

If a centrifugal pump operates in conjunction with a pipe system the two must handle the same volume and at the

same time, the head generated by the pump must be equal to the system energy requirement at that flow rate.

The point at which the system curve and the pump rating curve intercepts is the true operating point of the pump

in the system. At operating point, the pump head and system head the are equal ( H

pump

H

system

= ).

An important characteristic of the head flow curve is the best efficiency point, at this point, the pump operates

most cost-effectively in term of both energy, effi ciency and mai ntenance.

The performance of the centrifugal pumps is typically described by graph plotting the pressure head generated by

the pump over a range of flow rates.

Vapour bubbles are formed in the fluid in a manner similar to boling. If the suction pressure of pump inlet is too low.

The propety that determines the conditions under which vapour bubbles from is h

s

vapour pressure ( p

vap

). It is very

important to compute the net positive suction head available( NPSH

A

) to the pump in order to avoid cavitations.

The value of NPSH

A

depends on the vapour pressure of the flowing fluid, energy losses in the suction pipe, the

location of the fluid reservoir and the pressure applied to the fluid in reservoir.

28

You might also like

- Mathcad - 2Document4 pagesMathcad - 2Desejo SozinandoNo ratings yet

- Hydraulic Machines ChapterDocument15 pagesHydraulic Machines Chapterحيدر محمدNo ratings yet

- Mathcad - 3Document3 pagesMathcad - 3Desejo SozinandoNo ratings yet

- Pumps and Compressors: Week 7Document20 pagesPumps and Compressors: Week 7ednsmnNo ratings yet

- Flu Mach Paper 2Document11 pagesFlu Mach Paper 2NAPOLEON QUENo ratings yet

- CEE 345 Spring 2002 problem set solutions pump efficiency discharge headDocument10 pagesCEE 345 Spring 2002 problem set solutions pump efficiency discharge headAdrian Antonio TorresNo ratings yet

- Mathcad - 3B - Tut - 2 - PumpsDocument2 pagesMathcad - 3B - Tut - 2 - PumpsFabrizio NEBESSENo ratings yet

- Centrifugal PumpDocument42 pagesCentrifugal PumpKautilyaChennaNo ratings yet

- Tech Drilling SurgeSwabPressDocument40 pagesTech Drilling SurgeSwabPressdaongocha108No ratings yet

- Mathcad - 4Document3 pagesMathcad - 4Desejo SozinandoNo ratings yet

- Jet Bit Nozzle Size SelectionDocument46 pagesJet Bit Nozzle Size SelectionBharat BhattaraiNo ratings yet

- Tech Drilling JetBitNozzleDocument46 pagesTech Drilling JetBitNozzlealvarex007100% (1)

- 14 Jet Bit Nozzle Size SelectionDocument46 pages14 Jet Bit Nozzle Size Selectiontotos20100% (2)

- Set of Answer of Fluid Mechanics II, UTHM. Based On Cengel 11th EditionDocument6 pagesSet of Answer of Fluid Mechanics II, UTHM. Based On Cengel 11th EditionIskandar BellNo ratings yet

- LAB: TWO STAGE AIR COMPRESSOR TESTDocument4 pagesLAB: TWO STAGE AIR COMPRESSOR TESTAmit Singh DehuryNo ratings yet

- Core Ag Engineering Principles - Session 1Document101 pagesCore Ag Engineering Principles - Session 1peagricultureNo ratings yet

- Hydraulic MachineryDocument60 pagesHydraulic MachinerygetsweetNo ratings yet

- Sheet 4 New PDFDocument3 pagesSheet 4 New PDFMahmoud GaballaNo ratings yet

- Articol JmseDocument5 pagesArticol JmsepiticmicNo ratings yet

- Pump Practice ProblemsDocument16 pagesPump Practice ProblemsKhaled SolimanNo ratings yet

- Pump Hydraulic Calculation GuideDocument9 pagesPump Hydraulic Calculation Guidechem_taNo ratings yet

- Calculation ExampleDocument20 pagesCalculation Examplepavankumar0001No ratings yet

- Mee61 AssessmentDocument5 pagesMee61 AssessmentJoktanBelarminoNo ratings yet

- Francis ReportDocument24 pagesFrancis Reportantukara100% (3)

- Lecture On Affinity LawsDocument10 pagesLecture On Affinity LawsCyduck GuevarraNo ratings yet

- Pump characteristics and flow rate calculationDocument14 pagesPump characteristics and flow rate calculationBao PhanNo ratings yet

- 1 - Fluid Mechanics Takehome Project AssignmentDocument4 pages1 - Fluid Mechanics Takehome Project Assignmentazeem sheikhNo ratings yet

- CENTRIFUGAL PUMP EQUATIONSDocument38 pagesCENTRIFUGAL PUMP EQUATIONSRichard Manongsong100% (1)

- T 2Document9 pagesT 2Amaterasu Susanoo TsukuyomiNo ratings yet

- Fluid Mechanics II (Chapter 4)Document20 pagesFluid Mechanics II (Chapter 4)sarmadNo ratings yet

- Fluid System 04-Centrifugal PumpDocument46 pagesFluid System 04-Centrifugal PumpFuad AlhamidNo ratings yet

- Fluids Final ReqDocument17 pagesFluids Final ReqNAPOLEON QUENo ratings yet

- Addi Examples Pipe3Document10 pagesAddi Examples Pipe3Diego MorenoNo ratings yet

- Hydraulic EngineeringDocument4 pagesHydraulic Engineeringmmfauzi78No ratings yet

- Pipe Flow Problems-III: Example 1Document10 pagesPipe Flow Problems-III: Example 1Chaithanya Kumar DanduNo ratings yet

- Pitot Static TubeDocument4 pagesPitot Static TubeVrushiket PatilNo ratings yet

- Performance Test of Parallel Centrifugal Pump With Same CharacteristicDocument14 pagesPerformance Test of Parallel Centrifugal Pump With Same CharacteristicPrecious Gallardo DerainNo ratings yet

- Centrifugal Pump Report CompletedDocument24 pagesCentrifugal Pump Report CompletedMohamad Fareez Roslan100% (1)

- FLM3B0S Tutorial 2a TurbomachinesDocument3 pagesFLM3B0S Tutorial 2a TurbomachinesFabrizio NEBESSENo ratings yet

- Modification On The Design of A Drill Power PumpDocument7 pagesModification On The Design of A Drill Power PumpJohnson owoichoNo ratings yet

- ME2208 Fluid Mechanics and Machinery Lab ManualDocument54 pagesME2208 Fluid Mechanics and Machinery Lab ManualSenthil ArumugamNo ratings yet

- Venturi Meter Bernoulli Equation ExampleDocument4 pagesVenturi Meter Bernoulli Equation ExamplevackyvipinNo ratings yet

- Optimal Drill Bit Nozzle SizingDocument41 pagesOptimal Drill Bit Nozzle SizingJose Antonio Olvera JimenezNo ratings yet

- Oil cooling system analysisDocument5 pagesOil cooling system analysisNora GuzmanNo ratings yet

- Drilling Hydraulics ADocument63 pagesDrilling Hydraulics Asryn89100% (3)

- FlowmeterDocument21 pagesFlowmeterHafizie ZainiNo ratings yet

- Some Aspects of Numerical Simulation of Control Valves For Steam TurbinesDocument1 pageSome Aspects of Numerical Simulation of Control Valves For Steam TurbinesSharat ChandraNo ratings yet

- Pump. Slurry Selection Typical WarmanDocument44 pagesPump. Slurry Selection Typical WarmanJuan Pablo Apaza100% (1)

- ME2135E Fluid Mechanics II Tutorial 1Document3 pagesME2135E Fluid Mechanics II Tutorial 1Law Zhan Hong0% (1)

- Computational Wind Engineering 1: Proceedings of the 1st International Symposium on Computational Wind Engineering (CWE 92) Tokyo, Japan, August 21-23, 1992From EverandComputational Wind Engineering 1: Proceedings of the 1st International Symposium on Computational Wind Engineering (CWE 92) Tokyo, Japan, August 21-23, 1992S. MurakamiNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Gyrops 22 08 2016Document7 pagesGyrops 22 08 2016Desejo SozinandoNo ratings yet

- Hydraulic Machines IIIDocument73 pagesHydraulic Machines IIIDesejo SozinandoNo ratings yet

- Mathcad - Proramming Spot2Document2 pagesMathcad - Proramming Spot2Desejo Sozinando100% (1)

- Mathcad - Extra43Document1 pageMathcad - Extra43Desejo SozinandoNo ratings yet

- Mathcad - Extra30Document2 pagesMathcad - Extra30Desejo Sozinando50% (2)

- Mathcad - Extra41Document2 pagesMathcad - Extra41Desejo SozinandoNo ratings yet

- Mathcad - Test 1Document3 pagesMathcad - Test 1Desejo SozinandoNo ratings yet

- Mathcad - Beam ProgrammingDocument1 pageMathcad - Beam ProgrammingDesejo SozinandoNo ratings yet

- Mathcad - Test 2Document2 pagesMathcad - Test 2Desejo SozinandoNo ratings yet

- Mathcad - Spot Questions1Document5 pagesMathcad - Spot Questions1Desejo SozinandoNo ratings yet

- Mathcad - Extra44Document1 pageMathcad - Extra44Desejo SozinandoNo ratings yet

- Mathcad - ProgrammDocument1 pageMathcad - ProgrammDesejo SozinandoNo ratings yet

- Mathcad - Extra40Document1 pageMathcad - Extra40Desejo SozinandoNo ratings yet

- Mathcad - Extra42Document2 pagesMathcad - Extra42Desejo SozinandoNo ratings yet

- Mathcad - Extra37Document2 pagesMathcad - Extra37Desejo Sozinando0% (1)

- Mathcad - Extra38Document2 pagesMathcad - Extra38Desejo Sozinando0% (1)

- Mathcad - Extra36Document2 pagesMathcad - Extra36Desejo SozinandoNo ratings yet

- Mathcad - Extra39Document1 pageMathcad - Extra39Desejo Sozinando100% (1)

- Mathcad - Extra35Document2 pagesMathcad - Extra35Desejo SozinandoNo ratings yet

- Mathcad - Extra34Document1 pageMathcad - Extra34Desejo SozinandoNo ratings yet

- Mathcad - Extra29Document1 pageMathcad - Extra29Desejo SozinandoNo ratings yet

- Mathcad - Extra33Document1 pageMathcad - Extra33Desejo Sozinando50% (2)

- Mathcad - Extra26Document1 pageMathcad - Extra26Desejo SozinandoNo ratings yet

- Mathcad - Extra32Document2 pagesMathcad - Extra32Desejo SozinandoNo ratings yet

- Mathcad - Extra28Document3 pagesMathcad - Extra28Desejo SozinandoNo ratings yet

- Mathcad - Extra23Document2 pagesMathcad - Extra23Desejo SozinandoNo ratings yet

- Mathcad - Extra31Document1 pageMathcad - Extra31Desejo SozinandoNo ratings yet

- Mathcad - Extra27Document2 pagesMathcad - Extra27Desejo SozinandoNo ratings yet

- Mathcad - Extra25Document1 pageMathcad - Extra25Desejo Sozinando0% (1)

- Mathcad - Extra24Document2 pagesMathcad - Extra24Desejo SozinandoNo ratings yet

- Explosion Occurance in CFBC Boiler and Necessary OperationsDocument6 pagesExplosion Occurance in CFBC Boiler and Necessary OperationsAnudeep ChittluriNo ratings yet

- Pacu 02-Py100fa - 1,645 CFMDocument2 pagesPacu 02-Py100fa - 1,645 CFMAnonymous qOBFvINo ratings yet

- Abeba DebruDocument90 pagesAbeba Debruabera alemayehuNo ratings yet

- Thermodaynamics Lab 1Document11 pagesThermodaynamics Lab 1Kabo Busanang100% (2)

- NESC Diploma - MillwrightDocument2 pagesNESC Diploma - MillwrightjamesNo ratings yet

- Model: Puhy-P450Tka (-BS) : 14-Ton Outdoor VRF Heat Pump SystemDocument4 pagesModel: Puhy-P450Tka (-BS) : 14-Ton Outdoor VRF Heat Pump SystemJesus SacramentoNo ratings yet

- Problem Set 1Document2 pagesProblem Set 1Lovedeep SinghNo ratings yet

- Lorentz PS4000Document2 pagesLorentz PS4000SINES FranceNo ratings yet

- DuctulatorDocument44 pagesDuctulatorgeorgeNo ratings yet

- Grundfos CMB PTDocument2 pagesGrundfos CMB PTsara jamalNo ratings yet

- Crude CharacterizationDocument43 pagesCrude CharacterizationHussein100% (1)

- Model: AED2413ZHZ (CAE2417Z) : Technical Data SheetDocument3 pagesModel: AED2413ZHZ (CAE2417Z) : Technical Data SheetMarisol SaavedraNo ratings yet

- Lab # 2 Introduction To Steam BoilerDocument3 pagesLab # 2 Introduction To Steam Boilerjawad100% (2)

- Nuclear Marine PropulsionDocument106 pagesNuclear Marine PropulsionJosue Carpio100% (1)

- Electric Protection System in Thermal Power PlantsDocument17 pagesElectric Protection System in Thermal Power PlantsPriyatham GangapatnamNo ratings yet

- Vis BreakingDocument12 pagesVis BreakingMohit Arora100% (1)

- A1F8D3 - Appendix ICES-APL-003 (D) - Main Maintenance Tasks PDFDocument23 pagesA1F8D3 - Appendix ICES-APL-003 (D) - Main Maintenance Tasks PDFdj.amin07No ratings yet

- Submittal FCQ36MVJU - RZQ36MVJU 07-06 - DaikinDocument1 pageSubmittal FCQ36MVJU - RZQ36MVJU 07-06 - Daikinedward sabedraNo ratings yet

- Fcs 0104Document63 pagesFcs 0104OwaisNo ratings yet

- WEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDocument1 pageWEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDave CNo ratings yet

- Industrial Training Report on Suratgarh Super Thermal Power StationDocument39 pagesIndustrial Training Report on Suratgarh Super Thermal Power StationpriyaNo ratings yet

- Electrical Energy Storage Systems (MIET2131) : Session 3: PEM Electrolysers, Hydrogen Storage and SafetyDocument46 pagesElectrical Energy Storage Systems (MIET2131) : Session 3: PEM Electrolysers, Hydrogen Storage and SafetyAster J.No ratings yet

- Solar TrackingDocument14 pagesSolar TrackingPraveen RiderNo ratings yet

- Leaflet F LG Absorption ChillerDocument4 pagesLeaflet F LG Absorption ChillerSaad PathanNo ratings yet

- AspenIcarusPIDV11 RefDocument286 pagesAspenIcarusPIDV11 RefParth PatelNo ratings yet

- Lecture 3. Refrigeration Cycles 2Document37 pagesLecture 3. Refrigeration Cycles 2addisudagneNo ratings yet

- Abstract of Cooling Tower ProjectDocument8 pagesAbstract of Cooling Tower ProjectAWAL ADAMNo ratings yet

- Here UN Eets Ater: W S M WDocument37 pagesHere UN Eets Ater: W S M Wsandeep devabhaktuniNo ratings yet

- Steam Injector For Boiler Feed Water PDFDocument13 pagesSteam Injector For Boiler Feed Water PDFMuhammad Munir Ahmed100% (1)

- CUMMINS QSX15 Engine - Parts Catalog 79007291 27Document1 pageCUMMINS QSX15 Engine - Parts Catalog 79007291 27Bernard ApuritNo ratings yet