Professional Documents

Culture Documents

Synthesis of Acetanilide and Its Purification Through Recrystallization

Uploaded by

Teresa SayloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Synthesis of Acetanilide and Its Purification Through Recrystallization

Uploaded by

Teresa SayloCopyright:

Available Formats

Organic Chemistry Laboratory CH 200L (2012 2013) 2B-Ph Group 9 Experiment 4

Synthesis of Acetanilide and its Purification through Recrystallization

Bianca Therese Rivera, Camille Aliana Rivera, Zarah Mae Roxas, Ma. Rosario Teresa Saylo, Jean Darlene Semilla and Adrian Yu Department of Pharmacy, Faculty of Pharmacy University of Santo Tomas, Espana Street, Manila 1008

Date Submitted: July 27, 2012 Abstract Acetylation of aniline was done in the experiment to synthesize acetanilide. The crude acetanilide was purified by recrystallization. A corn-grain amount of pure acetanilide was mixed with water, methanol and hexane separately to determine the appropriate recrystallizing solvent. The test showed that water was the most effective solvent. A mixture of aniline, distilled water and acetic anhydride was cool in an ice bath to hasten crystallization. The crude acetanilide obtained was dissolved in the water bath with the recrystallizing solvent and was filtered. The weight of the crystals collected is 0.21 grams and its melting o point reached 114-115 C.

_____________________________________________________________________________________

Introduction Recrystallization is the primary method for purifying solid organic compounds. Compounds obtained from natural sources or from reaction mixtures almost always contain impurities. The impurities may include some combination of insoluble, soluble, and colored impurities. Other techniques for purifying solids include sublimation, extraction and chromatography. Nevertheless, even when one of these alternative methods of purification has been used, the solid material thus isolated may still be recrystallized to achieve the highest possible state of purity. The process of recrystallization involves dissolution of the solid in an appropriate solvent at an elevated temperature and the subsequent reformation of the crystals upon cooling, so that any impurities remain in the solution. If the impurities present in the original solid mixture have dissolved and remain dissolved after the solution is cooled, isolation of the crystals that have formed should ideally provide pure material. Alternatively, the impurities may not dissolve at all in the hot solution and may be removed by filtration before the solution is cooled. The crystals that subsequently form should be purer than the original solid mixture. There are times even after a solid has been recrystallized, it may still not be pure. Thus, it is important to determine the purity of the sample, and one of the easiest methods to do this is by determining the melting point of the solid. The experiment aims to (1) synthesize acetanilide by the acetylation of aniline and (2) purify crude acetanilide product by recrystallization.

Methodology A. Choosing Solvent the Recrystallizing

Figure 1. Dissolving crude acetanilide and solvent mixture in water bath. While still hot, the solution was quickly filtered using a fluted filter paper. The filtrate was poured in a beaker containing tap water to be cooled. Formation of crystals occurred and these were collected and washed with distilled water. The crystals were dried by pressing these in-between filter papers. The pure acetanilide produced was weighed and the melting point was determined using an oil bath. The oil bath set-up is shown in Figure 2.

The best recrystallizing solvent for the experiment was determined by mixing in three separate test tubes a corn-grain amount of pure acetanilide and 1mL of the reagent to be tested, water, methanol and hexane. The test tubes were shook and placed in a warm water bath (37 - 40oC) for 1-5 minutes. The test tubes were cooled afterwards and observations were recorded. B. Synthesis of Acetanilide A certain amount (2 mL) of aniline was mixed with 20 mL of distilled water in an Erlenmeyer flask. The acetic anhydride (3 mL) was slowly added. The mixture was cooled in an ice bath to hasten crystallization. The mixture was filtered through a wet filter paper making the crude acetanilide as the residue. The crude acetanilide was made to dry and weighed. C. Purification of Crude Acetanilide The recrystallizing solvent (20 mL) was added to the crude acetanilide. This was heated in a water bath until the solid completely dissolved (Figure 1).

Figure 2. Oil bath set-up

Results and Discussion In the determination which is the appropriate recrystallizing solvent between water, methanol and hexane, the results obtained after heating the

mixtures in a water bath are shown in Table 1. At room temp. + During heating + Upon cooling -

water methanol hexane

It is important to determine the purity of the substance obtained and this is done by determining the melting point of the substance. The melting point of the pure acetanilide obtained was verified by heating it in an oil bath with a thermometer. The melting point of the pure acetanilide based on the experiment is 114-115oC. This means that the product does not have impurities anymore since the melting point observed has no difference with the theoretical melting point of acetanilide which is 114.3oC. References [1] Bayquen A. et.al.(2009).Laboratory Manual in Organic Chemistry .Quezon City: C&E Publishing Inc. [2] http://www.chem.umass.edu/~samal/26 9/cryst1.pdf [3] http://www.chem.utoronto.ca/coursenote s/CHM249/Recrystallization.pdf [4] http://chem.chem.rochester.edu/~chem2 07/Recrystallization.pdf

Table 1. Solubility of Recrystallizing Solvents Based on the results on Table 1, the pure acetanilide when mixed with water is insoluble at room temperature and upon cooling but soluble during heating. On the other hand, it is soluble in methanol only at room temperature and it is insoluble in hexane. The results showed that water is the best recrystallizing solvent since a suitable solvent should have high solubility at high temperatures and low solubility at low temperatures. In the acetylation of aniline, the amount of crude acetanilide produced was 4.3 grams. After the recrystallization process, the amount of crystals collected which is the pure acetanilide was 0.21 grams. The percentage yield was computed after the weighing of the product. The formula for solving the percentage yield is:

% yield =

0.21 grams x 100 2.97 grams

% yield = 7.07 %

You might also like

- Organic Functional Group Analysis: International Series of Monographs on Analytical Chemistry, Volume 8From EverandOrganic Functional Group Analysis: International Series of Monographs on Analytical Chemistry, Volume 8No ratings yet

- AcetanilideDocument7 pagesAcetanilideepsonme101No ratings yet

- Synthesis of AcetanilideDocument4 pagesSynthesis of AcetanilideMich Tolentino50% (2)

- Recrystallization of Acetanilide (2EMT - Group 1, 2009)Document7 pagesRecrystallization of Acetanilide (2EMT - Group 1, 2009)Mary Christelle100% (2)

- Recrystallization of AcetanilideDocument2 pagesRecrystallization of Acetaniliderm_gabriel07No ratings yet

- Sythesization and Purification of Acetanilide by Acetylation and Re CrystallizationDocument4 pagesSythesization and Purification of Acetanilide by Acetylation and Re CrystallizationToni Sy EncinaresNo ratings yet

- Experiment 5 - : Preparation and Purification of AcetanilideDocument6 pagesExperiment 5 - : Preparation and Purification of AcetanilideFluoruro De PotasioNo ratings yet

- Obtaining Pure Acetanilide From Crude Acetanilide by Recrystallization ProcessDocument5 pagesObtaining Pure Acetanilide From Crude Acetanilide by Recrystallization ProcessCharlot NavarroNo ratings yet

- Classification Tests For Organic Halides Formal ReportDocument4 pagesClassification Tests For Organic Halides Formal ReportJessa Mateum VallangcaNo ratings yet

- Formal Report Synthesis of AspirinDocument4 pagesFormal Report Synthesis of AspirinEdrick Ramoran0% (1)

- Recrystallization and Aspirin (Full)Document32 pagesRecrystallization and Aspirin (Full)Yosita RahmawatiNo ratings yet

- Experiment 12 (Synthesis of Acetylsalicylic Acid)Document8 pagesExperiment 12 (Synthesis of Acetylsalicylic Acid)Cheng Bauzon100% (1)

- Isolation of Casein From Skimmed Milk and Seperation and Identification of Amino Acids by Paper ChromatographyDocument8 pagesIsolation of Casein From Skimmed Milk and Seperation and Identification of Amino Acids by Paper ChromatographyKc CalderonNo ratings yet

- Esterification Salicylic AcidDocument3 pagesEsterification Salicylic AcidBobbyGunarsoNo ratings yet

- Expt 2 BIOCHEMLABDocument5 pagesExpt 2 BIOCHEMLABEloisah Vin Santiago Ragodon100% (1)

- Synthesis of Salicylic AcidDocument2 pagesSynthesis of Salicylic AcidHarly Kabut100% (1)

- Synthesis of Aspirin From Salicylic Acid and Acetic AnhydrideDocument6 pagesSynthesis of Aspirin From Salicylic Acid and Acetic AnhydrideChristine71% (7)

- Buffer Preparation and PH Measurement Using The Electrometric Method and Colorimetric MethodDocument2 pagesBuffer Preparation and PH Measurement Using The Electrometric Method and Colorimetric MethodArndrei CunananNo ratings yet

- Nucleophlic Acyl Substitution - The Synthesis of Ethyl ButanoateDocument5 pagesNucleophlic Acyl Substitution - The Synthesis of Ethyl ButanoateRuther Cabral67% (3)

- Synthesis of Aspirin (2EMT - Group 1, 2009)Document8 pagesSynthesis of Aspirin (2EMT - Group 1, 2009)Mary Christelle90% (10)

- 35 Exp 12Document4 pages35 Exp 12dubstepoNo ratings yet

- Experiment 9 Formal Laboratory ReportDocument5 pagesExperiment 9 Formal Laboratory ReportNathaniel Argelio Dimaano100% (1)

- Determination of PH of Common Solutions Using PH Paper and PH MeterDocument2 pagesDetermination of PH of Common Solutions Using PH Paper and PH MeterKeziah Casco CortadoNo ratings yet

- Aspirin SythesisDocument4 pagesAspirin Sythesiskramnuj92% (12)

- Synthesis of AspirinDocument4 pagesSynthesis of Aspirinホアキン 印33% (3)

- Lab Activity 5Document5 pagesLab Activity 5Jasmin CeciliaNo ratings yet

- Partially Miscible LiquidsDocument8 pagesPartially Miscible LiquidsRenz Roger Esteves Buendicho100% (1)

- CHEM 40.1 Expt. 11Document3 pagesCHEM 40.1 Expt. 11May Lacdao0% (1)

- PH Determination and Buffer Preparation FRDocument6 pagesPH Determination and Buffer Preparation FRFelipe VillanuevaNo ratings yet

- Nitration of Methyl BenzoateDocument7 pagesNitration of Methyl BenzoateJanel Pauline G. Chua100% (1)

- EXPERIMENT 5 Common Ion EffectDocument4 pagesEXPERIMENT 5 Common Ion EffectNat DabuétNo ratings yet

- Classification Tests For Carboxylic Acid and DerivativesDocument3 pagesClassification Tests For Carboxylic Acid and DerivativesJohn Emmanuel SyNo ratings yet

- Assay of Aspirin Tablets PDFDocument14 pagesAssay of Aspirin Tablets PDFTariq Al-shamiry71% (7)

- Synthesis of Aspirin-Formal ReportDocument6 pagesSynthesis of Aspirin-Formal ReportStephanie ButedNo ratings yet

- Activity 2Document6 pagesActivity 2MARKUS GERARD REYESNo ratings yet

- Experiment 8 The Preparation of AcetanlideDocument12 pagesExperiment 8 The Preparation of AcetanlideRadhwanNo ratings yet

- Classification Tests For Hydroxyl and Carbonyl Containing CompoundsDocument5 pagesClassification Tests For Hydroxyl and Carbonyl Containing CompoundsAcener Padua100% (1)

- Determination of Glucose by Titration With Fehling's ReagentDocument5 pagesDetermination of Glucose by Titration With Fehling's ReagentMohamed Abdelghni EmaraNo ratings yet

- Ester of Carboxylic AcidsDocument6 pagesEster of Carboxylic Acidsmaryam_m_chemNo ratings yet

- Solubility of Organic CompoundsDocument4 pagesSolubility of Organic CompoundsJeremy Noceda100% (1)

- Synthesis of AspirinDocument6 pagesSynthesis of AspirinVanessaOlgaJ.Dagondon100% (1)

- Qualitative Color Reaction For CaseinDocument4 pagesQualitative Color Reaction For CaseinDiane QuiambaoNo ratings yet

- RDR 12Document3 pagesRDR 12Dione Gale NavalNo ratings yet

- FR 1 (E6)Document5 pagesFR 1 (E6)JR CastorNo ratings yet

- Extraction of Caffeine From Tea LeavesDocument8 pagesExtraction of Caffeine From Tea LeavesCesarah CabungcalNo ratings yet

- Chem 31.1 Experiment 1 Lab ReportDocument5 pagesChem 31.1 Experiment 1 Lab ReportMara Krista CooNo ratings yet

- Exp 16-FR 3 SudanDocument14 pagesExp 16-FR 3 Sudanherbie_wanNo ratings yet

- Experiment 3 - Determination of Mixed AlkaliDocument2 pagesExperiment 3 - Determination of Mixed AlkaliPeter BrayNo ratings yet

- Synthesis of Aspirin and Oil of WintergreenDocument5 pagesSynthesis of Aspirin and Oil of WintergreenJason Raquin Roque100% (4)

- Formal Report Synthesis of An Alkyl HalideDocument7 pagesFormal Report Synthesis of An Alkyl HalideFerdinand Tamayo Cayabyab Jr.No ratings yet

- Classification Tests For Hydroxyl and Carbonyl Containing Compounds AutosavedDocument9 pagesClassification Tests For Hydroxyl and Carbonyl Containing Compounds AutosavedCamille OngchuanNo ratings yet

- CHEM35.1 E5 Aldol Condensation: Synthesis of DibenzalacetoneDocument3 pagesCHEM35.1 E5 Aldol Condensation: Synthesis of DibenzalacetoneGlenn Vincent Tumimbang50% (2)

- Don't Trust MeDocument2 pagesDon't Trust Memark pascuaNo ratings yet

- Che21l - Experiment 2 - Complete Lab ReportDocument4 pagesChe21l - Experiment 2 - Complete Lab ReportMishel P. FerolinoNo ratings yet

- RecrystallizationDocument3 pagesRecrystallizationJeana GalinatoNo ratings yet

- Re CrystallizationDocument3 pagesRe CrystallizationKuia AllardeNo ratings yet

- Recrystallization of Acetanilide (Organic Chemistry)Document6 pagesRecrystallization of Acetanilide (Organic Chemistry)Earl Cedric DL Dalmacio78% (9)

- Re Crystallization of Acetanilide 1 ColDocument5 pagesRe Crystallization of Acetanilide 1 ColMediatrix SaraosNo ratings yet

- Formal ReportDocument5 pagesFormal ReportIvy Tan100% (1)

- Recrystallization: Mikee Melad and Alisson MangabatDocument4 pagesRecrystallization: Mikee Melad and Alisson MangabatMikee MeladNo ratings yet

- Botany LabDocument1 pageBotany LabTeresa SayloNo ratings yet

- Health Care StrategiesDocument7 pagesHealth Care StrategiesTeresa Saylo100% (1)

- Health Care StrategiesDocument7 pagesHealth Care StrategiesTeresa Saylo100% (1)

- PharCare1 Report Physical HealthDocument34 pagesPharCare1 Report Physical HealthTeresa SayloNo ratings yet

- Chapter 7 CapsulesDocument87 pagesChapter 7 CapsulesTeresa Saylo92% (26)

- Chapter 7 CapsulesDocument87 pagesChapter 7 CapsulesTeresa Saylo92% (26)

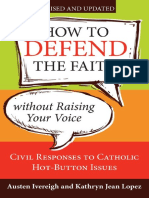

- How To Defend The Faith Without Raising Your VoiceDocument139 pagesHow To Defend The Faith Without Raising Your VoiceCleber De Souza Cunha100% (2)

- NIST Standard Reference Materials® 2023 CatalogDocument128 pagesNIST Standard Reference Materials® 2023 CatalogAbdul HaseebNo ratings yet

- Course Syllabus MGTP 31206 31207Document12 pagesCourse Syllabus MGTP 31206 31207NamitBhasinNo ratings yet

- FS011 Audit Plan Stage 2Document2 pagesFS011 Audit Plan Stage 2Ledo Houssien0% (1)

- Red Bank Squadron - 01/22/1942Document28 pagesRed Bank Squadron - 01/22/1942CAP History LibraryNo ratings yet

- Fire BehaviourDocument4 pagesFire BehaviourFirezky CuNo ratings yet

- App Guide EntelliGuard - G 09 - 2020 AplicacionDocument100 pagesApp Guide EntelliGuard - G 09 - 2020 AplicacionjeorginagNo ratings yet

- Red Winemaking in Cool Climates: Belinda Kemp Karine PedneaultDocument10 pagesRed Winemaking in Cool Climates: Belinda Kemp Karine Pedneaultgjm126No ratings yet

- Sore Throat, Hoarseness and Otitis MediaDocument19 pagesSore Throat, Hoarseness and Otitis MediaainaNo ratings yet

- UntitledDocument18 pagesUntitledSpace HRNo ratings yet

- Unit 18: Calculating Food Costs, Selling Prices and Making A ProfitDocument4 pagesUnit 18: Calculating Food Costs, Selling Prices and Making A Profitkarupukamal100% (2)

- Esc200 12Document1 pageEsc200 12Anzad AzeezNo ratings yet

- Design and Fabrication of Floor Cleaning Machine - A ReviewDocument4 pagesDesign and Fabrication of Floor Cleaning Machine - A ReviewIJIERT-International Journal of Innovations in Engineering Research and Technology100% (1)

- Ideal Discharge Elderly PatientDocument3 pagesIdeal Discharge Elderly PatientFelicia Risca RyandiniNo ratings yet

- Director's Update Our StudentsDocument23 pagesDirector's Update Our StudentsAdrian MojicaNo ratings yet

- ACLS Post Test (Copy) 낱말 카드 - QuizletDocument18 pagesACLS Post Test (Copy) 낱말 카드 - Quizlet김민길No ratings yet

- Senior Cohousing - Sherry Cummings, Nancy P. KropfDocument86 pagesSenior Cohousing - Sherry Cummings, Nancy P. KropfAnastasia JoannaNo ratings yet

- Circulatory SystemDocument51 pagesCirculatory SystemTina TalmadgeNo ratings yet

- Electronic Fetal MonitoringDocument4 pagesElectronic Fetal MonitoringMauZungNo ratings yet

- Air MassesDocument22 pagesAir MassesPrince MpofuNo ratings yet

- The Importance of Early Childhood InterventionDocument11 pagesThe Importance of Early Childhood Interventionsilverlining0814100% (3)

- Pay Structure of Public Employees in PakistanDocument28 pagesPay Structure of Public Employees in PakistanAamir50% (10)

- Sasol Polymers PP HNR100Document3 pagesSasol Polymers PP HNR100Albert FortunatoNo ratings yet

- Ahsan Menu KolachiDocument12 pagesAhsan Menu Kolachisalman GtrNo ratings yet

- Bonsai TreesDocument19 pagesBonsai TreesMayur ChoudhariNo ratings yet

- Anatomy and Physiology Chapter 2Document28 pagesAnatomy and Physiology Chapter 2Marshalee FrancisNo ratings yet

- DM - BienAir - CHIROPRO 980 - EngDocument8 pagesDM - BienAir - CHIROPRO 980 - Engfomed_twNo ratings yet

- Sample Quantitative Descriptive Paper 1Document20 pagesSample Quantitative Descriptive Paper 1oishimontrevanNo ratings yet

- Cor Tzar 2018Document12 pagesCor Tzar 2018alejandraNo ratings yet

- 9 - 1 H Wood Cabinet Spec Options NelDocument8 pages9 - 1 H Wood Cabinet Spec Options NelinformalitybyusNo ratings yet

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 5 out of 5 stars5/5 (4)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideFrom EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (90)

- Phase Equilibria in Chemical EngineeringFrom EverandPhase Equilibria in Chemical EngineeringRating: 4 out of 5 stars4/5 (11)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)

- Taste: Surprising Stories and Science About Why Food Tastes GoodFrom EverandTaste: Surprising Stories and Science About Why Food Tastes GoodRating: 3 out of 5 stars3/5 (20)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Bioplastics: A Home Inventors HandbookFrom EverandBioplastics: A Home Inventors HandbookRating: 4 out of 5 stars4/5 (2)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsFrom EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNo ratings yet