Professional Documents

Culture Documents

Insulation

Uploaded by

Brinto VargheseCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Insulation

Uploaded by

Brinto VargheseCopyright:

Available Formats

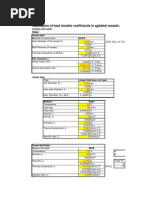

Economic Insulation Thickness calculation

Length of Pipe (L) = Pipe diameter (d) = Ambient temperature (Ta) = Desired temperature (Tc) = Pipe Wall temperature (Th) = Insulation Material =

Thermal Conductivity of insulation = (take value from table) Calculated Thickness of Thickness= Thickness of the Insullation=

(Select as per Manufacters Data)

2.1 1200 30 64 250

Mineral Wool

m mm

o o o

take

157 oC

0

Thermal Conductivity

(W/m2 K)

Thermal Conductivity Insulation Temperature(oC) Mineral Wool

C C C

400 o

>

0.04 49.0 50.0

W/m2oc mm mm

100 200 300 400 700 1000

0.04 0.06 0.08 0.11 0 0

Solution

Heat Transfer Coefficient Of Hot Bare Surface, h = SurfaceHeat Transfer Coefficient After insulation, h' = Thermal Resistance Rth = Thickness of Insulation t = 14.2 4.8 1.14 49.01 W/m2 oc W/m2 oc m2 oc/W mm

Outer radius of insulation, r2 = Insulated Pipe area, A = Bare Pipe surface area, A =

650.00 8.58 7.92

mm m2 m2

Total heat lossfromBare surface , Q = Total heat lossfromInsulated surface , Q= Power saved by providing insulation, P=

24.73 1.40

KW KW

23.33

KW

Annual working hours, n= Energy Saving After providing Insullation, (E = P*n) =

8400 195992

Hrs Kwh/year

400

400

157

Mineral Wool 100 0.04 200 0.06 300 0.08 400 0.11 700 0 1000 0

100 200 300 400 700 1000

0.04 0.06 0.08 0.11 0 0

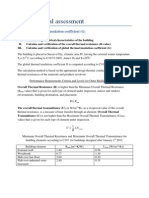

Economics

Steam Cost = Heat energy cost, p = Cost of insulation(material+Labor) =

Discount factor for calculating Net present value(NPV) of Cost of energy loss =

0.7 1.85 2000 15

Rs/kg Rs/kWh Rs/m %

Solution Annual Monetary Saving (S=E*p) = Total Cost of insulation= Annual cost of energy loss=

NPV of annual cost of Energy loss for 5 years =

362586 4200 21751 72913

Rs Rs Rs / Year Rs

TOTAL COST = Rs 77113

195992.43

2.1 1.4 8400 21751 18914.11 21751 16447.05 21751 14301.78 21751 12436.33 21751 10814.2 72913.47

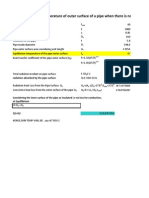

flat surface heat loss calculation Economic Insulation Thickness calculation

Surface Length (L) = Pipe diameter (d) = Ambient temperature (Ta) = Desired temperature (Tc) = Pipe Wall temperature (Th) = Insulation Material =

Thermal Conductivity of insulation = (take value from table) Calculated Thickness of Thickness= Thickness of the Insullation=

(Select as per Manufacters Data)

0

0

400

400

2.1 1.2 30 64 400

Mineral Wool

m m

o o o

take

232 oC

Thermal Conductivity Insulation Temperature(oC)

Thermal Conductivity

(W/m2 K)

C C C

400 o

Mineral Wool

232 0.04 0.06 0.08 0.11 0 0

>

0.07 144.1 150.0

W/m2oc mm mm

100 200 300 400 700 1000

Solution

Heat Transfer Coefficient Of Hot Bare Surface, h = SurfaceHeat Transfer Coefficient After insulation, h' = Thermal Resistance Rth = Thickness of Insulation t = 21.7 4.8 2.06 144.12 W/m2 oc W/m2 oc m2 oc/W mm

Mineral Wool 100 0.04 200 0.06 300 0.08 400 0.11 700 0 1000 0

Insulated Pipe area, A = Bare Pipe surface area, A =

2.52 2.52

m2 m2

100 200 300 400 700 1000

0.04 0.06 0.08 0.11 0 0

Total heat lossfromBare surface , Q = Total heat lossfromInsulated surface , Q= Power saved by providing insulation, P=

20.23 0.41

KW KW

19.82

KW

Annual working hours, n= Energy Saving After providing Insullation, (E = P*n) =

8400 166503

Hrs Kwh/year

Page 5

economics1

Economics

Steam Cost = Heat energy cost, p = Cost of insulation(material+Labor) =

Discount factor for calculating Net present value(NPV) of Cost of energy loss =

0.7 1.85 2000 15

Rs/kg Rs/kWh Rs/m2 %

166503.25

Solution Annual Monetary Saving (S=E*p) = Total Cost of insulation= Annual cost of energy loss=

NPV of annual cost of Energy loss for 5 years =

308031 5040 6391 21424

Rs Rs Rs / Year Rs

2.52 0.41 8400 6391 6391 6391 6391 6391 5557.43 4832.55 4202.21 3654.1 3177.48 21423.77

TOTAL COST = Rs 26464

Page 6

You might also like

- Economic Thickness of InsulationDocument8 pagesEconomic Thickness of InsulationJunaid MazharNo ratings yet

- Pipe Insulation THK CalculationDocument3 pagesPipe Insulation THK Calculationnitin_bir67% (3)

- Insulation CalcDocument4 pagesInsulation Calcjacok22No ratings yet

- Insulation ThicknessDocument10 pagesInsulation ThicknessPratik Ray ChaudhuryNo ratings yet

- HX Design v1Document12 pagesHX Design v1mansourotaibiNo ratings yet

- Insulation ThicknessDocument29 pagesInsulation Thicknessrajachem100% (2)

- Insulation CalcDocument13 pagesInsulation CalczamijakaNo ratings yet

- Design Calculations - Insulation Thickness REV-1Document4 pagesDesign Calculations - Insulation Thickness REV-1delMAK100% (1)

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Document1 pageTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456No ratings yet

- Pipe Insulation THK CalculationDocument6 pagesPipe Insulation THK Calculationnitin_bir100% (2)

- Pipe Heat Loss CalculationDocument10 pagesPipe Heat Loss Calculationingemarquintero67% (3)

- Tank Heat CalculationDocument7 pagesTank Heat CalculationElton Situmeang100% (3)

- Insulated PipeDocument54 pagesInsulated Pipedeion29No ratings yet

- Sizing of Steam Coil of Insulated Tank Rev 3Document2 pagesSizing of Steam Coil of Insulated Tank Rev 3ypatels50% (2)

- Coil DesignDocument7 pagesCoil DesignSajal Kulshrestha100% (3)

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Shell and Tube Heat Exchanger1Document19 pagesShell and Tube Heat Exchanger1Lily NurdianaNo ratings yet

- Half Pipe CalculationDocument3 pagesHalf Pipe CalculationCaptainTonies0% (1)

- Atm Sto Tanks Venting Req API2000 2009 Rev1Document2 pagesAtm Sto Tanks Venting Req API2000 2009 Rev1fzhou100% (4)

- Insulation Thickness CalculationDocument2 pagesInsulation Thickness Calculationrajpal14667% (6)

- Shell Tube Heat Exchanger CalculationDocument20 pagesShell Tube Heat Exchanger CalculationĐoàn TrangNo ratings yet

- Heat Exchanger StageSizingDocument4 pagesHeat Exchanger StageSizingnilesh100% (1)

- Calculation of Heat and Mass BalanceDocument18 pagesCalculation of Heat and Mass BalanceJitendra Bhatia100% (3)

- Steam Coil SizingDocument21 pagesSteam Coil SizingMildogg100% (1)

- Steam Tracing CalculationDocument76 pagesSteam Tracing CalculationChristina Martin63% (8)

- Calculation Overall Heat TransferDocument4 pagesCalculation Overall Heat TransferDavid LambertNo ratings yet

- Heat Exchanger Rating Calc SheetDocument14 pagesHeat Exchanger Rating Calc SheetSatria 'igin' Girindra NugrahaNo ratings yet

- Heat Exchanger Calculation Version 2Document2 pagesHeat Exchanger Calculation Version 2huangjlNo ratings yet

- AST Heating Coil Design Calculation Rev 0Document3 pagesAST Heating Coil Design Calculation Rev 0Pieter Grendel100% (3)

- Steam Tracing CalculationDocument44 pagesSteam Tracing CalculationsafaldNo ratings yet

- PED (Design of Shell and Tube Heat Exchanger) 63Document5 pagesPED (Design of Shell and Tube Heat Exchanger) 63DineshNo ratings yet

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- Gas Line Capacity CalcDocument2 pagesGas Line Capacity CalcMario Mendoza100% (1)

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDocument2 pagesSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1No ratings yet

- Steam Pressure DropDocument8 pagesSteam Pressure DropDavid Muñoz CastroNo ratings yet

- Thermal InsulationDocument27 pagesThermal Insulationmkchy12No ratings yet

- Thermal Insulation Thickness Calculation (By James)Document1 pageThermal Insulation Thickness Calculation (By James)Ah BengNo ratings yet

- Heat Exchanger DesignDocument48 pagesHeat Exchanger DesignJose SotoNo ratings yet

- Pipe Size CalculationDocument28 pagesPipe Size CalculationAnonymous Iev5ggSR100% (1)

- Internal Coil CalculationDocument19 pagesInternal Coil CalculationMr Incognito100% (3)

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- Heat Loss /vesselDocument2 pagesHeat Loss /vesselSapariya Hitesh50% (2)

- Shell and Tube Heat Exchanger SpreadsheetDocument2 pagesShell and Tube Heat Exchanger SpreadsheetHernan Cardenas Franco100% (1)

- Liquid Line SizingDocument12 pagesLiquid Line Sizinglolofm25No ratings yet

- Calculation Flow and CalculatorDocument37 pagesCalculation Flow and CalculatorDavid LambertNo ratings yet

- Coil HeatDocument4 pagesCoil HeatTarmana Antt50% (2)

- Skin Temp of Pipe Exposed To SunDocument8 pagesSkin Temp of Pipe Exposed To SunDebasis PalNo ratings yet

- DimensionsDocument11 pagesDimensionsAsavela NotshwelekaNo ratings yet

- HMT 2marksDocument85 pagesHMT 2marksyogesh sNo ratings yet

- Calculation On RefrectoryDocument3 pagesCalculation On RefrectorymishtinilNo ratings yet

- Cost-Efficient Steam Pipe Insulation PDFDocument2 pagesCost-Efficient Steam Pipe Insulation PDFkryptNo ratings yet

- Lect - 5 Examples Steady Conduction in Slabs, Cylinders and Spheres - Critical Thickness of Insulation With SolutionDocument22 pagesLect - 5 Examples Steady Conduction in Slabs, Cylinders and Spheres - Critical Thickness of Insulation With SolutionVivaan Sharma33% (3)

- Big Qtns HT 1Document61 pagesBig Qtns HT 1Pranay TinkuNo ratings yet

- Heat Calculation Results: First Chamber Heat Calculation Material Data: Material Width Thermal ConductivityDocument4 pagesHeat Calculation Results: First Chamber Heat Calculation Material Data: Material Width Thermal ConductivityDavid LambertNo ratings yet

- Heat Transfer Fundamentals: Numerical ProblemsDocument14 pagesHeat Transfer Fundamentals: Numerical ProblemsRohail SarfrazNo ratings yet

- HMT University Solved ProblemsDocument69 pagesHMT University Solved ProblemsKendra Kaiser60% (5)

- CEMENTDocument4 pagesCEMENTEyael ShimleasNo ratings yet

- Chapter Five: Heating Load CalculationDocument18 pagesChapter Five: Heating Load CalculationSameerSaleemNo ratings yet

- Hygrothermal AssessmentDocument9 pagesHygrothermal AssessmentGeorge LazarNo ratings yet

- Heat and Mass TransferDocument107 pagesHeat and Mass Transferchandar munisamyNo ratings yet

- Gmail - Booking Confirmation On IRCTC, Train - 12432, 02-Jun-2019, 1A, NZM - TCRDocument2 pagesGmail - Booking Confirmation On IRCTC, Train - 12432, 02-Jun-2019, 1A, NZM - TCRBrinto VargheseNo ratings yet

- Sicca 150-600 GLC PDFDocument4 pagesSicca 150-600 GLC PDFBrinto VargheseNo ratings yet

- Receipt PDFDocument2 pagesReceipt PDFBrinto VargheseNo ratings yet

- Sicca 150-600 GLC Ag PDFDocument4 pagesSicca 150-600 GLC Ag PDFBrinto VargheseNo ratings yet

- Boarding PassDocument2 pagesBoarding PassBrinto VargheseNo ratings yet

- EMT41595000 Delhi-CochinDocument2 pagesEMT41595000 Delhi-CochinBrinto VargheseNo ratings yet

- Vasu PDFDocument2 pagesVasu PDFBrinto VargheseNo ratings yet

- Irctcs E Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E Ticketing Service Electronic Reservation Slip (Personal User)Brinto VargheseNo ratings yet

- Final Exam 259 Answer KeyDocument20 pagesFinal Exam 259 Answer KeyYasmeenNo ratings yet

- Shear and Bending Moment Diagrams - A ReviewDocument15 pagesShear and Bending Moment Diagrams - A ReviewNicole Ann PedriñaNo ratings yet

- Protocolo de Pruebas Ixsu-F51xxDocument41 pagesProtocolo de Pruebas Ixsu-F51xxMilagros Malpartida PeraunaNo ratings yet

- Automotive Steel Design Manual PDFDocument773 pagesAutomotive Steel Design Manual PDFLuis Hamilton Ramos Córdova100% (1)

- Introduction To SteelsDocument167 pagesIntroduction To Steelspaddiemaguire100% (1)

- Shear Wall Design Manual: IS 456:2000 and IS 13920:1993Document98 pagesShear Wall Design Manual: IS 456:2000 and IS 13920:1993soumyadeep194784250% (1)

- Chemicals Zetag DATA LDP Zetag 7875 FS 40 - 0410Document2 pagesChemicals Zetag DATA LDP Zetag 7875 FS 40 - 0410PromagEnviro.comNo ratings yet

- Gate 2018 Ce Set1 Madeeasy PDFDocument42 pagesGate 2018 Ce Set1 Madeeasy PDFShivangi MishraNo ratings yet

- Spectroscopic Techniques For Pharmaceutical and Biopharmaceutical Industries - Unit 9 - Week 8 PDFDocument1 pageSpectroscopic Techniques For Pharmaceutical and Biopharmaceutical Industries - Unit 9 - Week 8 PDFantony bevanNo ratings yet

- ASME Presentation Charpy Impact TestDocument118 pagesASME Presentation Charpy Impact TestYogi173No ratings yet

- Grey Iron A Unique MaterialDocument13 pagesGrey Iron A Unique MaterialmetkarthikNo ratings yet

- Konsep StressDocument26 pagesKonsep StressaliNo ratings yet

- Ncert Exemplar Solutions For Class 12 Physics Chapter 7Document9 pagesNcert Exemplar Solutions For Class 12 Physics Chapter 7getthef.ckfromshivashishNo ratings yet

- Water Properties Lab ReportDocument2 pagesWater Properties Lab Reportapi-454228134100% (2)

- 5 Cu-Zn SystemDocument30 pages5 Cu-Zn SystemfelipecastrocerdaNo ratings yet

- Seminar Presentation: Topic: Carbon Nano Tube Field Effect TransistorDocument12 pagesSeminar Presentation: Topic: Carbon Nano Tube Field Effect TransistormukulNo ratings yet

- Quantum Mechanics Course ZeemansplittingDocument29 pagesQuantum Mechanics Course ZeemansplittingjlbalbNo ratings yet

- Colloidal Dispersions 1Document20 pagesColloidal Dispersions 1محمد رائد رزاق إسماعيلNo ratings yet

- Monodisperse Magnetic Single-Crystal Ferrite MicrospheresDocument4 pagesMonodisperse Magnetic Single-Crystal Ferrite MicrospheresMahoo ShahNo ratings yet

- An Introduction To Interfaces Colloids The Bridge To Nanoscience by John C. BergDocument803 pagesAn Introduction To Interfaces Colloids The Bridge To Nanoscience by John C. BerganthonyNo ratings yet

- Manan and Gaurav - NDTDocument35 pagesManan and Gaurav - NDTManan Depala100% (1)

- Magnon Spintronics: Review ArticleDocument9 pagesMagnon Spintronics: Review Article許良兆No ratings yet

- Circular Tube End Plate Calculation PDFDocument4 pagesCircular Tube End Plate Calculation PDFALPHYL BALASABASNo ratings yet

- UNIT-2 Three Phase TransformerDocument24 pagesUNIT-2 Three Phase Transformerkaran nirmala gajanan shindeNo ratings yet

- Engineering Physics-Important Questions: Shorts UNIT - 1 (Units and Dimensions)Document4 pagesEngineering Physics-Important Questions: Shorts UNIT - 1 (Units and Dimensions)psatyasankarNo ratings yet

- Room-Including The Air and The Refrigerator (Or Fan)Document26 pagesRoom-Including The Air and The Refrigerator (Or Fan)denyNo ratings yet

- Non Ideal BehaviorDocument9 pagesNon Ideal BehaviorTushar DaveNo ratings yet

- HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudDocument16 pagesHKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudOMEGA CONSULTANT SERVICESNo ratings yet

- 3Cr2W8V PDFDocument2 pages3Cr2W8V PDFFARID MIFTAHUL ANWARNo ratings yet

- 7steel and Heat TreatmentDocument19 pages7steel and Heat TreatmentManoj BallaNo ratings yet