Professional Documents

Culture Documents

Determination of HHV of Diesel Fuel

Uploaded by

Adrian Soriaga LontocOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determination of HHV of Diesel Fuel

Uploaded by

Adrian Soriaga LontocCopyright:

Available Formats

K.Sivaramakrishnan et al.

/ International Journal of Engineering Science and Technology (IJEST)

DETERMINATION OF HIGHER HEATING VALUE OF BIODIESELS

K.SIVARAMAKRISHNAN

Assistant Professor, Anjalai Ammal Engineering College, Kovilvenni-614403. Research scholar Anna University of Technology., Tiruchirappalli-24 Sivaporkodi2000@yahoo.co.in

Dr.P.RAVIKUMAR

Professor& Principal St.Joseph College of Engineering & Technology Thanjavur

ABSTRACT Biodiesel, an alternative fuel can be used in diesel engine as neat or blended with diesel. The physiochemical properties of fuel are important in design of fuel system for compression ignition engine run on diesel, biodiesel or biodiesel blend. The HHV is an important property which characterizes the energy content of a fuel such as solid, liquid and gaseous fuels. The biodiesels were characterized for their physical and main fuel properties including viscosity, density, flash point and higher heating value. The viscosities of biodiesels were much less than those of pure oils and their HHVs of approximately 42 MJ/kg were 10% less than those of petro diesel fuels. The HHVs of vegetable oils and their biodiesels were measured and correlated using linear least square regression analysis. An equation was developed relating HHV and thermal properties. The predicted higher heating values compare well with the measured Higher Heating Values. This work establishes the general dependence of higher heating value on thermal properties of biodiesel. Keywords: Biodiesel, Higher heating Value (HHV), Fuel Properties.

1. INTRODUCTION Biodiesel as an alternative fuel of diesel is described as fatty acid methyl or ethyl esters from vegetable oils or animal fats. One of the most important properties to characterize a fuel is its energy content. [1] The standard measure of the energy content of a fuel is its heating value (HHV) sometimes called the calorific value or heat of combustion. The heating value is obtained by the complete combustion of a unit quantity of solid fuel in oxygen bomb calorimeter under carefully defined conditions. The Gross Heat of Combustion or Higher Heating Value (GHC or HHV) is obtained by oxygen bomb calorimeter method as the latent heat of moisture in the combustion products is recovered. The higher heating value is one of the most important properties of a fuel. [2] Some researchers have attempted to estimate the HHV of the vegetable oils by using their physical properties such as: saponification and iodine data [3,4 ]Some researchers have attempted to estimate the HHV of the vegetable oils by using their Fatty acids composition [5]Fuel properties of vegetable oils were characterized by determining its viscosity, density, Cetane number, cloud and Pour points, distillation range, flash point, ash content, sulfur content, carbon residue, acid value, copper corrosion and HHV [6]. The flash point of biodiesel is higher than that of biodiesel fuel. Although flash point does not directly affect combustion, it makes biodiesel safer regarding the storage and transport [7, 8] Kinematic viscosity and density are the parameters required by biodiesel and diesel fuel standards because of being key fuel properties for diesel engines [9].The objective of this study was to estimate mathematical relationships between higher heating value (HHV) and viscosity, density or flash point measurement of various bio diesel fuels from various vegetable oils by transestrification method.

ISSN : 0975-5462

Vol. 3 No.11 November 2011

7981

K.Sivaramakrishnan et al. / International Journal of Engineering Science and Technology (IJEST)

2. EXPERIMENTAL PROCEDURE The vegetable oils were obtained from commercial sources and used without further purification. The samples were converted to methyl esters by alkali catalytic and non catalytic super critical methanol transestrification methods.

Fig.1 Preparation of Laboratory Samples of Biodiesel

3. MATERIALS AND METHODS 3.1. Measurement of Different Fuels Properties Untreated oil is mixed with a mixture of anhydrous methanol and a catalyst (Methoxide) in proper proportion. The mixture is maintained at a temperature little below 65C (being the B.P. of methanol) and continuously stirred the mixture for around three hours. After completion of stirring, the mixture is allowed to settle down for 24 hours. The layer of glycerol settled at the bottom is carefully taken out and the upper layer is the ester of karanja oil which is tapped separately. The important physical and chemical properties of oil and biodiesel were determined by standard methods. In order to measure the properties of the oil diesel fuels, the test methods were used as follows. Density (ASTM D941), Viscosity (ASTM D445), Flash point (ASTM D93), higher heating value (ASTM D2015). The details about the apparatus is given in table1

Table 1. Measurement Methods

S.No 1 2 3

Parameters Viscosity @ 40C Density @ 27C Flash Point

Method of Analysis IS:1448:(P:25):1976 IS:1448:(P:32):1992 IS:1448:(P:21):1992

Instruments Used Redwood Viscometer Pycnometer Pensky Martens Apparatus [Closed Cup]

Calorific value

IS:1448:(P:33):1991

Bomb Calorimeter

3.1.1. Density Relative density otherwise known as the specific gravity refers to the ratio of the density of a fuel to the density of water at same temperature with its other properties could be judged. Density measurements were carried out using a pycnometer at a temperature of 311.5 + 0.05 k: the pycnometer of capacity about 25 ml being calibrated with water.

3.1.2. Flash Point Flash point is the lowest temperature corrected to a standard atmospheric condition at which application of a test flame Cause the vapour specimen to ignite under specific conditions of test, flash point of the samples were measured by Pensky martens apparatus.

ISSN : 0975-5462

Vol. 3 No.11 November 2011

7982

K.Sivaramakrishnan et al. / International Journal of Engineering Science and Technology (IJEST)

3.1.3. Viscosity The resistance to flow exhibited by fuel blends is expressed in various units of viscosity. It is a major factor of consequence in exhibiting their suitability for the mass transfer and metering requirements of engine operation. Higher the viscosity results low volatility and poor atomization of oil during injection in CI engine, that results in complete combustion and ultimately carbon deposit on injector nozzle as well as in the combustion chamber. The viscosities of oil as well as derived bio diesel are measured by red wood viscometer at 313 k. 3.1.4. Higher Heating Value Heating Value of a fuel is the thermal energy released per unit quantity of fuel when the fuel is burned completely and the products of combustion are cooled back to the initial temperature of the combustible mixtures. It measures the energy content in a fuel. The HHV, of the vegetable oils and their methyl esters were measured in a bomb calorimeter according to ASTM D2015 standard method. An oxygen bomb was pressurized to 3 Mpa with an oxygen container. The bomb was fired automatically after the jacket and a bucket temperature equilibrates to within acceptable accuracy of each other. 4. RESULTS AND DISCUSSION The viscosity density, flash point, and higher heating value (HHV) measurements of fourteen methyl esters of various vegetable oils are tabulated in Table 2, taken from the literature [1.]

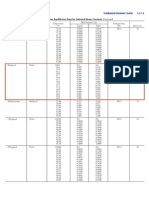

Table 2Viscosity Density, Flash Point, and Higher Heating Value (HHV) Measurements of Fourteen biodiesel

Vegetable Oils Cotton seeds Corn Crambe Hazelnut Linseed Mustard Olive Palm Rapeseed Safflower Sesame Soybean Sunflower Walnut

Viscosity (cst) 3.75 3.62 5.12 3.59 2.83 4.10 4.18 3.94 4.60 4.03 3.04 4.08 4.16 4.11

Density (g/L) 871 873 848 875 885 866 860 867 857 866 880 865 863 864

Flash Point (k) 455 427 463 425 415 442 447 434 453 440 418 441 439 443

HHV (MJ/kg) 41.18 41.14 41.98 41.12 40.84 41.30 41.35 41.24 41.55 41.26 40.90 41.28 41.33 41.32

Viscosity is a measure of the internal friction or resistance of an oil to flow. As the temperature of oil is increased, its viscosity decreases and it is therefore able to flow more readily. Viscosity is the most important property of biodiesel since it affects the operation of fuel injection equipment, particularly at low temperatures when the increase in viscosity affects the fluidity of the fuel. High viscosity leads to poorer atomization of the fuel spray to poorer atomization of the fuel spray and less accurate operation of the fuel injectors. The viscosity values of vegetables oils are between 27.2 and 53.6 mm2/s where as those of vegetable oils methyl esters are between 2.83 and 5.12 mm2/s. The viscosity values of vegetable oil methyl esters highly decreases sharply after transesterification process. The viscosity of Diesel fuel is 2.76 mm2/s at @40C. Compared to diesel fuels, all of the vegetable oil methyl esters are slightly viscous. Density is another important property of biodiesel. It is the weight of a unit volume of fluid. Specific gravity is the ratio of the density of a liquid to the density of water. Specific gravity of biodiesels ranges between 848 and 901 g/L. Fuel injection equipment operates on a volume metering system; hence a higher density for biodiesel results in the delivery of a slightly greater mass of fuel. An increase in density from 848 to 901 g/L for biodiesels for increases the viscosity from 3.6 and 5.1 mm2/s. and the increases are highly regular. The higher heating values (HHVs) of biodiesels are relatively high. The HHVs of biodiesel (39 to 43.33 MJ/kg) is slightly lower than that of diesel (49.65 MJ/kg). The oxygen content of biodiesel improves the

ISSN : 0975-5462

Vol. 3 No.11 November 2011

7983

K.Sivaramakrishnan et al. / International Journal of Engineering Science and Technology (IJEST)

combustion process and decreases its oxidation potential. The structural oxygen content of a fuel improves its combustion efficiency due to an increase in the homogeneity of oxygen with the fuel during combustion. Because of this the combustion efficiency of biodiesel is higher than that of petrodiesel and the combustion efficiency of methanol and ethanol is higher than that of diesel. The HHV is an important property defining the energy content and thereby efficiency of fuels. Fuel properties for the combustion analysis of biodiesel blends can be grouped conveniently into physical, chemical and thermal properties. Physical properties include viscosity, density, cloud point, pour point, flash point, boiling range, freezing point and refractive index. These exists a number of correlations for estimating the HHV of vegetables oils based upon its physical properties. The experimental data were correlated as a function of viscosity, density, flash point by empirical linear equation. These equations, obtained from regression analysis by using the measured values, were used for estimating the calorific value. The measured HHVs for each fuel are shows in table 3.

Table-3.The calculated and measured values of HHV biodiesel

Biodiesel Cotton seeds Corn Crambe Hazelnut Linseed Mustard Olive Palm Rapeseed Safflower Sesame Soybean Sunflower Walnut

Measured 41.18 41.14 41.98 41.12 40.84 41.30 41.35 41.24 41.55 41.26 40.90 41.28 41.33 41.32

K4 40.3667

K3 0.4527

K2 -0.0008

K1 -0.0003

R2 0.949

Calculated 41.14 41.09 41.78 41.07 40.72 41.31 41.36 41.23 41.54 41.27 40.82 41.30 41.34 41.31

Absolute Error 0.04 0.05 0.20 0.05 0.12 0.01 0.01 0.01 0.01 0.01 0.08 0.02 0.01 0.01

Error (%) 0.09 0.12 0.47 0.12 0.29 0.02 0.02 0.02 0.02 0.02 0.19 0.04 0.02 0.02

Formula (1) is obtained from physical properties of biodiesel D = K4 + K3 + K2 + K1FP ----- (1)

Where D is HHV (MJ/kg), is viscosity (CST), is density (g/L), FP is flash point (K), K1, K2, K3, and K4 are co-efficient. Table 3 shows the co-efficient R2 and the calculated HHVs from regression analysis, the measured HHV, the absolute and % error between the measured and calculated HHVs. HHV = 0.4527 0.0008 0.0003FP + 40.3667 (2)

The calculated HHVs from equation are validated by using the measured HHVs for all biodiesels. There is an excellent agreement between the measured and estimated values which is shown in fig2

ISSN : 0975-5462

Vol. 3 No.11 November 2011

7984

K.Sivaramakrishnan et al. / International Journal of Engineering Science and Technology (IJEST)

To check whether the equation is applicable for biodiesel and bioethanol blends, Karanja oil, ethanol is taken and properties were studied in the laboratory. The properties are given in table 4.

Table-4 . The properties of diesel, biodiesel (Karanja), ethanol and their blends

Fuel Diesel Biodiesel (Karanja) Ethanol B10 B20 B30 BE10 BE20 BE30

Viscosity @40C (cSt) 2.76 5.58 1.17 2.32 2.76 3.19 4.00 3.61 2.76

Density @ 20C (g/l) 828 901 783 833 835 850 886 876 869

Flash Point (k) 321 467 291 322 325 329 349 294 293

HHV (MJ/kg) 49.65 43.33 34.50 49.08 45.81 43.13 37.68 36.12 33.33

ISSN : 0975-5462

Vol. 3 No.11 November 2011

7985

K.Sivaramakrishnan et al. / International Journal of Engineering Science and Technology (IJEST)

Table-5.The calculated and measured values of HHV diesel, biodiesel (Karanja), ethanol and their blends

Fuel Diesel Karanja B10 B20 B30 BE10 BE20 BE30

Measured 49.65 43.33 49.08 45.81 43.13 37.68 36.12 33.33

Calculated 44.98 38.36 42.36 43.05 39.74 31.87 30.66 30.59

Absolute Error 4.67 4.97 6.72 2.76 3.39 5.81 5.46 2.74

Error (%) 9.4 11.47 13.69 6.02 7.85 15.42 15.11 8.22

Equation 2 was able to predict the HHV value with 0.94 accuracy. The calculated HHVs from equation are validated by using the measured HHVs for all biodiesels. There is an excellent agreement between the measured and estimated values which is shown in fig 3

Fig 3. Calculated and measured values of HHV

5. CONCLUSION

A new method of HHV estimation of vegetable oils, biodiesel is presented. The aim of this work is to show that it is possible to estimate the HHV of vegetable oils and biodiesel from viscosity, density and flash point. It is established that the physical properties of the bio-fuels has a predominate effect on the HHV of the bio diesel. From the results obtained it is found the HHV as affected by the physical properties. An equation was developed to predict the HHV based on physical properties and it was able to predict with 0.949 accuracy. The developed equation can effectively predict the HHV of the biodiesel based on its physical properties.

ISSN : 0975-5462 Vol. 3 No.11 November 2011 7986

K.Sivaramakrishnan et al. / International Journal of Engineering Science and Technology (IJEST)

REFERENCES

Ayhan Demirbas Relationships derived from physical properties of vegetable oil and biodiesel fuels-fuel 87 (2008) 1743-1748 Demirbas A. Biodiesel fuels from vegetable oils via catalytic and non- catalytic supercritical alcohol transesterifications and other methods: /a survey. Energy Convers Manage 2003;44:2093-109. [3] Demirbas A. Fuel properties and calculation of higher heating values of vegetable oils. Fuel 1998 [4] Anand K.Avishek R,Pramod SM.Estimating the viscosity of vegetable oil and biodiesel fuels.Energy Fuels 2010;24(1):664-72 [5] Wanignon Ferdinand Fassinou, Aboubakar Sako, Alhassane Fofana, Kamenan Blasie Koua-Energy 35(2010) 4949-4954 [6] Goering E, Schwab W, Daugherty J, Pryde H, Heakin J. Fuel properties of eleven vegetable oils. Trans ASAE 1982;25:1472-83 [7] Nagai K, Seko T. Trends of motor fuel quality in Japan. JSAE Rev 2000;21:457-62. [8] Bhatia S, Sang OY, Twaiq F, Zakaria R, Mohamed AR. Biofuel production from catalytic cracking of palm oil. Energy Source 2003;25:859-69. [9] Ertan Alptekin,Mustafa Canakci- Determination of the density and the viscosities of biodiesel- Diesel fuels blends-Renewable Energry 33(2008) 2623-2630 [10] Bhatia S, Sang OY, Twaiq F, Zakaria R, Mohamed AR. Biofuel production from catalytic cracking of palm oil. Energy Source 2003;25:859-69. [11] Zhenyi C, Xing J, Shuyuan L, Li L. Thermodynamics calculation of the pyrolysis of vegetable oils. Energy Source 2004;26:84956. [12] Lakshmi Narayanan Rao, A.S. Ramadass, Relationships among the physical and properties of biodiesel and engine fuel system design requirement, IJEE. [1] [2]

ISSN : 0975-5462

Vol. 3 No.11 November 2011

7987

You might also like

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerFrom EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNo ratings yet

- Fulltext - Study 207915 PDFDocument7 pagesFulltext - Study 207915 PDFVicente RamosNo ratings yet

- 18-126 Fahrur Rozy Ahzen PENGARUH TEMPERATUR DAN KONSENTRASI BIODIESEL JARAK PAGAR TERHADAP PERFORMA MESIN DIESEL, Budi SatriawanDocument12 pages18-126 Fahrur Rozy Ahzen PENGARUH TEMPERATUR DAN KONSENTRASI BIODIESEL JARAK PAGAR TERHADAP PERFORMA MESIN DIESEL, Budi SatriawanFath RifaiNo ratings yet

- Determination of Physico-Chemical Properties of Castor Biodiesel A PotentialDocument7 pagesDetermination of Physico-Chemical Properties of Castor Biodiesel A PotentialIAEME PublicationNo ratings yet

- Selection of An Efficient Method of Biodiesel Production From Vegetable Oil Based On Fuel PropertiesDocument5 pagesSelection of An Efficient Method of Biodiesel Production From Vegetable Oil Based On Fuel PropertiesseventhsensegroupNo ratings yet

- J. Basic. Appl. Sci. Res. - 1 (12) 2717-2723 - 2011Document7 pagesJ. Basic. Appl. Sci. Res. - 1 (12) 2717-2723 - 2011Joko PrasetyoNo ratings yet

- Renewable Energy: Jerekias Gandure, Clever Ketlogetswe, Abraham TemuDocument7 pagesRenewable Energy: Jerekias Gandure, Clever Ketlogetswe, Abraham TemuLacramioara Iuliana VladulescuNo ratings yet

- Biodiesel EnthalpyDocument6 pagesBiodiesel EnthalpyJohn MaguireNo ratings yet

- Densities and Viscosities of Fatty Acid Ethyl EstersDocument10 pagesDensities and Viscosities of Fatty Acid Ethyl EstersNéia CostaNo ratings yet

- Analysis of The Physical and Chemical Characteristics of Vegetable Oils As FuelDocument10 pagesAnalysis of The Physical and Chemical Characteristics of Vegetable Oils As Fuelnaveed54No ratings yet

- Biodiesel Production From Waste Frying Oil and Determination of Fuel PropertiesDocument5 pagesBiodiesel Production From Waste Frying Oil and Determination of Fuel PropertiesMáximo Décimo MeridioNo ratings yet

- Biodiesel ProductionDocument8 pagesBiodiesel ProductionHosam Hasan Abd ElhadyNo ratings yet

- Physicochemical Properties On Non Edible Crude Oil With Its Performance Analysis On Base Fuel (Diesel Fuel)Document4 pagesPhysicochemical Properties On Non Edible Crude Oil With Its Performance Analysis On Base Fuel (Diesel Fuel)Shakeel RanaNo ratings yet

- Biodiseal Cooked OilDocument4 pagesBiodiseal Cooked OildineshlathiaNo ratings yet

- TugasDocument3 pagesTugasDary BahtiarNo ratings yet

- D.I Engne ManuscriptDocument12 pagesD.I Engne ManuscriptChandramanikandanNo ratings yet

- Transesterification of Neat and Used Frying Oil: Optimization For Biodiesel ProductionDocument8 pagesTransesterification of Neat and Used Frying Oil: Optimization For Biodiesel ProductionCristiNo ratings yet

- Biodiesel 005Document8 pagesBiodiesel 005Nakao SakurabaNo ratings yet

- Catalytic Esterification of Bio-Oil by Ion Exchange Resins (WANG Jin-Jiang, CHANG Jie, FAN Juan)Document5 pagesCatalytic Esterification of Bio-Oil by Ion Exchange Resins (WANG Jin-Jiang, CHANG Jie, FAN Juan)HappyNo ratings yet

- Performance and Emission Analysis of Compression Ignition Engine in Dual Fuel Mode Using Rice Bran Biodiesel and LPGDocument7 pagesPerformance and Emission Analysis of Compression Ignition Engine in Dual Fuel Mode Using Rice Bran Biodiesel and LPGAJER JOURNALNo ratings yet

- BiodieselDocument25 pagesBiodieselmano19me019No ratings yet

- Use Ofvegetable Oils As I.C. Engine Fuels-A ReviewDocument16 pagesUse Ofvegetable Oils As I.C. Engine Fuels-A ReviewMohit KulkarniNo ratings yet

- Biodiesel Density: Experimental Measurements and Prediction ModelsDocument8 pagesBiodiesel Density: Experimental Measurements and Prediction ModelsSofaiiSitthisukNo ratings yet

- 11 Ijmperdoct201711Document8 pages11 Ijmperdoct201711TJPRC PublicationsNo ratings yet

- Determination of Heat of Combustion of Biodiesel Using Bomb CalorimeterDocument3 pagesDetermination of Heat of Combustion of Biodiesel Using Bomb CalorimeterIsmail RahimNo ratings yet

- Ghid RO2019 RO WebDocument6 pagesGhid RO2019 RO WebAnonymous v5uipHNo ratings yet

- Characterization of Bio-Oils in Chemical Families: M.Garcia-Perez, A.Chaala, H.Pakdel, D.Kretschmer, C.RoyDocument21 pagesCharacterization of Bio-Oils in Chemical Families: M.Garcia-Perez, A.Chaala, H.Pakdel, D.Kretschmer, C.RoyyemresimsekNo ratings yet

- Synthesis and Characterization of Biodiesel From Nigerian Palm Kernel OilDocument3 pagesSynthesis and Characterization of Biodiesel From Nigerian Palm Kernel OilAJER JOURNALNo ratings yet

- Research PaperDocument4 pagesResearch PaperSiddharthBhatNo ratings yet

- Chapter 3: Hydrolysis of Vegetable Oils and Animal FatDocument27 pagesChapter 3: Hydrolysis of Vegetable Oils and Animal FatSamiNo ratings yet

- Preparation of Biodiesel From Soybean Oil Using Supercritical Methanol and CO2 As Co-SolventDocument4 pagesPreparation of Biodiesel From Soybean Oil Using Supercritical Methanol and CO2 As Co-SolventEmanuele TortoriciNo ratings yet

- A Second Order Kinetics of Palm Oil TransesterificationDocument6 pagesA Second Order Kinetics of Palm Oil Transesterificationmadadi moradNo ratings yet

- Jurnal EkstraksiDocument5 pagesJurnal EkstraksiLukman VyatrawanNo ratings yet

- Bio-Oil Yield and Quality Enhancement Through Fast Pyrolysis and Fractional Condensation ConceptsDocument11 pagesBio-Oil Yield and Quality Enhancement Through Fast Pyrolysis and Fractional Condensation ConceptsAri Adrianto100% (1)

- 4.studies On - FullDocument10 pages4.studies On - FullTJPRC PublicationsNo ratings yet

- Catalytic Cracking of Used Palm Oils: Dhundiraj P.Deshpande, S.V.Aneker and N.G.KanseDocument5 pagesCatalytic Cracking of Used Palm Oils: Dhundiraj P.Deshpande, S.V.Aneker and N.G.KanseFillipe DragoNo ratings yet

- Process Parameter Optimization and Performance Analysis of Raphanus Sativus Methyl Ester in Diesel EngineDocument3 pagesProcess Parameter Optimization and Performance Analysis of Raphanus Sativus Methyl Ester in Diesel EngineSivakumarNo ratings yet

- Biodiesel Production Using Second-Generation Feedstocks: A ReviewDocument18 pagesBiodiesel Production Using Second-Generation Feedstocks: A ReviewPadelisgiNo ratings yet

- Study of Viscosity Modifiers On Karanja OilDocument9 pagesStudy of Viscosity Modifiers On Karanja OilNithin A R NeoNo ratings yet

- IJETR021268Document5 pagesIJETR021268erpublicationNo ratings yet

- A Comparative Study of Combustion Performance and Emission of Biodiesel Blends and Diesel in An Experimental BoilerDocument8 pagesA Comparative Study of Combustion Performance and Emission of Biodiesel Blends and Diesel in An Experimental BoilerFitrye AniNo ratings yet

- Aspen ModelDocument4 pagesAspen ModelAlex MashegoNo ratings yet

- Energy ManagementDocument195 pagesEnergy ManagementKiran Alla100% (1)

- Rheological Characterization of Animal Fats andDocument8 pagesRheological Characterization of Animal Fats andnatyquimica100% (2)

- Case Study On Production of Bio-Diesel and Evaluation of Its Properties and Its Use in Diesel Engine Based Power PlantDocument5 pagesCase Study On Production of Bio-Diesel and Evaluation of Its Properties and Its Use in Diesel Engine Based Power PlantSr2152No ratings yet

- Bio-Hydrocarbons Through Catalytic Pyrolysis of Used Cooking Oils: Towards Sustainable Jet and Road FuelsDocument7 pagesBio-Hydrocarbons Through Catalytic Pyrolysis of Used Cooking Oils: Towards Sustainable Jet and Road Fuelsahmad zikriNo ratings yet

- Combustion of Vegetable Oils Under Optimized Conditions of Atomization and Granulometry in A Modified Fuel Oil BurnerDocument6 pagesCombustion of Vegetable Oils Under Optimized Conditions of Atomization and Granulometry in A Modified Fuel Oil BurnerThiago ValenteNo ratings yet

- Bio DieselDocument9 pagesBio DieselKIRAN G RNo ratings yet

- Analysis of Vegetable Liquid Insulating Medium For Applications in High Voltage TransformersDocument5 pagesAnalysis of Vegetable Liquid Insulating Medium For Applications in High Voltage TransformersSiva Sai MuruganNo ratings yet

- 17 909 PDFDocument6 pages17 909 PDFedison avvaiNo ratings yet

- Transesterification of Esterified Mixed Oil For Biodiesel ProductionDocument10 pagesTransesterification of Esterified Mixed Oil For Biodiesel ProductionyohannesNo ratings yet

- 1 s2.0 S1876107012000107 MainDocument7 pages1 s2.0 S1876107012000107 MainBUREAU VERITAS BLOQUESNo ratings yet

- 124 Ijmperdfeb2018124Document10 pages124 Ijmperdfeb2018124TJPRC PublicationsNo ratings yet

- 2 131 Acpi 2 (1) 2012 PDocument7 pages2 131 Acpi 2 (1) 2012 PBreKB MéndezNo ratings yet

- CFD Simulation of Fatty Acid Methyl Ester Production in Bubble Column ReactorDocument7 pagesCFD Simulation of Fatty Acid Methyl Ester Production in Bubble Column ReactorVenkatesh VenkyNo ratings yet

- 2012 BP Pattanaik Et Al. Performance & Emission Studies On A Single Cylinder DI Diesel Engine Fueled With Diesel and Rice Bran Oil Methyl Ester BlendsDocument9 pages2012 BP Pattanaik Et Al. Performance & Emission Studies On A Single Cylinder DI Diesel Engine Fueled With Diesel and Rice Bran Oil Methyl Ester BlendsBP PattanaikNo ratings yet

- Jurnal OkeDocument6 pagesJurnal OkeIlm NafsiNo ratings yet

- Production of Biodiesel From Waste Cooking OilDocument5 pagesProduction of Biodiesel From Waste Cooking OilIJMERNo ratings yet

- Ab 02417411746Document6 pagesAb 02417411746IJMERNo ratings yet

- Basic Properties of Palm Oil Biodiesel Diesel BlendsDocument7 pagesBasic Properties of Palm Oil Biodiesel Diesel BlendsRavindra_1202No ratings yet

- Air Duct CalculatorDocument1 pageAir Duct CalculatorgutmontNo ratings yet

- Pressure Relief Safety ValvesDocument52 pagesPressure Relief Safety Valveswah_ma100% (3)

- Last Man Dancing WEBDocument30 pagesLast Man Dancing WEBAdrian Soriaga LontocNo ratings yet

- Utility Engineer: Department: Public Works/Engineering Bargaining Unit: Seiu Salary Range: E79 Last Revision: April 1999Document4 pagesUtility Engineer: Department: Public Works/Engineering Bargaining Unit: Seiu Salary Range: E79 Last Revision: April 1999alan_campos2008No ratings yet

- WHO Dengue Guidelines 2013Document160 pagesWHO Dengue Guidelines 2013Jason MirasolNo ratings yet

- Firetube or WatertubeDocument3 pagesFiretube or WatertubeAdrian Soriaga LontocNo ratings yet

- Abstract Fuel BriquettesDocument1 pageAbstract Fuel BriquettesAdrian Soriaga LontocNo ratings yet

- Kurdistan Oil Gas Activity PDFDocument1 pageKurdistan Oil Gas Activity PDFJegr AbasNo ratings yet

- Mvj19ae44 AP M-1 SyedDocument111 pagesMvj19ae44 AP M-1 SyedVinod Kumar sNo ratings yet

- Amm - 12 11 28 650 003 ADocument8 pagesAmm - 12 11 28 650 003 Araiday84No ratings yet

- Foam PumpsDocument4 pagesFoam Pumpskhalidwy6342No ratings yet

- Marine Gen Set Brochure 6-11 KWDocument2 pagesMarine Gen Set Brochure 6-11 KWIsmar EdgardoNo ratings yet

- Geothermal Comfort Systems: Frequently Asked Ques Tions Frequently Asked Ques Tions (Con' T)Document6 pagesGeothermal Comfort Systems: Frequently Asked Ques Tions Frequently Asked Ques Tions (Con' T)bzkizo_sbbNo ratings yet

- CHE 305 - Gas Power CycleDocument22 pagesCHE 305 - Gas Power Cycleannie bungisngisNo ratings yet

- Biofuels StudyDocument64 pagesBiofuels StudymerrytemesgenNo ratings yet

- VW T Cross Maintenance EngDocument112 pagesVW T Cross Maintenance EngPauloNo ratings yet

- 9650 STS 9750 STS Series Combines Filter Overview With Service Intervals and CapacitiesDocument2 pages9650 STS 9750 STS Series Combines Filter Overview With Service Intervals and CapacitiesAlejandro DhoNo ratings yet

- Analysis of Steam Vs Gas Failure: Boiler ExplosionDocument2 pagesAnalysis of Steam Vs Gas Failure: Boiler ExplosionSantosh KumarNo ratings yet

- Design and Analysis of Press Tool MachineDocument5 pagesDesign and Analysis of Press Tool MachineArun GsNo ratings yet

- SSP 507 Amarok 8 Speed Automatic Gearbox VW PDFDocument36 pagesSSP 507 Amarok 8 Speed Automatic Gearbox VW PDFFarid Mch0% (1)

- Experimental and Computational Studies On Oil Injected Twin-Screw CompressorDocument195 pagesExperimental and Computational Studies On Oil Injected Twin-Screw CompressorIhsan AhmedNo ratings yet

- Service Manual x2Document1,149 pagesService Manual x2jose94% (32)

- Fb-274 GB Paladin1200dDocument2 pagesFb-274 GB Paladin1200dchaudhasNo ratings yet

- 3748 PDFDocument53 pages3748 PDFFabian LopezNo ratings yet

- Natural Gas Generator Set QSK60 Series EngineDocument4 pagesNatural Gas Generator Set QSK60 Series Enginericva_rjNo ratings yet

- Part A (B) - Chemical Engineers Handbook, Perry Vol 1Document1 pagePart A (B) - Chemical Engineers Handbook, Perry Vol 1Jia Yuan ChngNo ratings yet

- Bio GasDocument20 pagesBio GasMajor Singh SidhuNo ratings yet

- Kamatsu Pc228us Uslc-3e0Document8 pagesKamatsu Pc228us Uslc-3e0Piotr Gabryś Hi-this100% (2)

- Me 303 CH9Document72 pagesMe 303 CH9Osman KutluNo ratings yet

- Bomag C766C Service Manual PDFDocument574 pagesBomag C766C Service Manual PDFDaveNo ratings yet

- 8000231-Metric and Inch (Sae) FastenersDocument11 pages8000231-Metric and Inch (Sae) FastenersFrancisco DiazNo ratings yet

- Chapter 3 ClinkerDocument179 pagesChapter 3 ClinkerAli Hüthüt100% (1)

- Airplane Turbofan Engine Operation and Malfunctions Basic Familiarization For Flight CrewsDocument38 pagesAirplane Turbofan Engine Operation and Malfunctions Basic Familiarization For Flight CrewstheevanraoNo ratings yet

- Engine Start Sys ShowDocument26 pagesEngine Start Sys ShowInterogator5No ratings yet

- Accent GS 2014Document45 pagesAccent GS 2014EDUARDO ALMARALES MARTINEZNo ratings yet

- Control de Nivel Mcdonnell Miller 263Document5 pagesControl de Nivel Mcdonnell Miller 263Genrry EchaccayaNo ratings yet

- Indigo NotesDocument189 pagesIndigo Notessyedhades sol100% (1)