Professional Documents

Culture Documents

Hybrid Vehicles RUSHIKESH

Uploaded by

Vishal SinghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hybrid Vehicles RUSHIKESH

Uploaded by

Vishal SinghCopyright:

Available Formats

Hybrid vehicles The Mogen Configuration

A Seminar Report On

HYBRID VEHICLES

Submitted in partial fulfillment of the Requirement of the Third Year Diploma(Mechanical) By

MR. RUSHIKESH DILIP GHUGE

Roll No:- 11

Under the guidance of

PROF. ROY SIR Department of Mechanical Engg.

BHUJBAL KNOWLEDGE CITY

METS INSTITUTE OF TECHNOLOGY(POLY.), ADGAON NASIK-422003.

1

Hybrid vehicles The Mogen Configuration

Hybrid vehicles The Mogen Configuration

Index Sr. No

1. 2. 3. 4. 5. 6. 7. 8. 8.1 8.2 8.3 8.4 8.5 9. 10.

Title

Introduction Types of HEVs HEV Components Hybrid vehicle configurations HEV advantages HEV Economics Future of HEV The MOGEN Configuration Introduction Principle of operation Functioning applications Advantages Conclusion References

Page No.

2 2 4 5 6 6 7 8 8 9 10 12 12 13 13

Hybrid vehicles The Mogen Configuration

1. Introduction :Any vehicle is a hybrid when it combines two or more sources of power. In fact, many people have probably owned a hybrid vehicle at some point. For example, a mo-ped (a motorized pedal bike) is a type of hybrid because it combines the power of a gasoline engine with the pedal power of its rider. Hybrid vehicles are all around us. These include Giant mining trucks, Submarines, diesel-electric buses, locomotives etc. The gasoline-electric hybrid car is just that -- a cross between a gasolinepowered car and an electric car. Hybrid electric vehicles (HEVs) combine the internal combustion engine of a conventional vehicle with the battery and electric motor of an electric vehicle, resulting in twice the fuel economy of conventional vehicles. This combination offers the extended range and rapid refueling that consumers expect from a conventional vehicle, with a significant portion of the energy and environmental benefits of an electric vehicle. The practical benefits of HEVs include improved fuel economy and lower emissions compared to conventional vehicles. The inherent flexibility of HEVs will allow them to be used in a wide range of applications, from personal transportation to commercial hauling. The flexibility in the design of hybrid vehicles comes from the ability of the control strategy to manage how much power is flowing to or from each component. There are many (often conflicting) objectives desirable for HEVs, the primary ones being:

Maximize fuel economy Minimize emissions Minimize propulsion system cost to keep overall vehicle cost affordable to the consumer market

Do all of the above while maintaining or improving upon acceptable performance (acceleration, range, handling, noise, etc.)

2.0 Types of HEVs

Many configurations are possible for HEVs. Essentially, a hybrid combines an energy storage system, a power unit, and a vehicle propulsion system. The primary

Hybrid vehicles The Mogen Configuration

options for energy storage include batteries, ultra capacitors, and flywheels. Although batteries are by far the most common energy storage choice, research is still being done in other energy storage areas. Hybrid power unit options are spark ignition engines, compression ignition direct injection engines, gas turbines, and fuel cells. Propulsion can come entirely from an electric motor, such as in a series configuration, or the engine might provide direct mechanical input to the vehicle propulsion system in a parallel configuration system. There are several transmission options when it comes to HEVs as wellthe driver that determines which transmission to use is efficiency.

3.0 HEV components

A hybrid electric vehicle (HEV) is an optimized mix of various components. The vehicle drive train consists of:

Electric traction motors/controllers.

The electric motor on a hybrid car is very sophisticated. Advanced electronics allow it to act as a motor as well as a generator. For example, when it needs to, it can draw energy from the batteries to accelerate the car. But acting as a generator, it can slow the car down and return energy to the batteries.

Electric energy storage systems, such as batteries, ultra capacitors, and flywheels.

Desirable attributes of high-power batteries for HEV applications are highpeak and pulse-specific power, high specific energy at pulse power, a high

Hybrid vehicles The Mogen Configuration

charge acceptance to maximize regenerative braking utilization, and long calendar and cycle life. Various types of batteries include, Lead acid batteries, nickel-cadmium batteries, Nickel-metal hydride batteries, The lithium ion batteries, Lithium polymer batteries.

Ultra capacitors are higher specific energy and power versions of electrolytic capacitorsdevices that store energy as an electrostatic charge. They are electrochemical systems that store energy in a polarized liquid layer at the interface between an ionically conducting electrolyte and a conducting electrode.

Flywheels store kinetic energy within a rapidly spinning wheel-like rotor or disk. Modern flywheels employ a high-strength composite rotor, which rotates in a vacuum chamber to minimize aerodynamic losses. A motor/generator is mounted on the rotor's shaft both to spin the rotor up to speed (charging) and to convert the rotor's kinetic energy to electrical energy (discharging).

Hybrid power units such as spark ignition engines, compression ignition direct injection (diesel) engines, gas turbines, and fuel cells etc.

Both petrol and diesel engines have the advantage over other systems because of their century long development and low cost due to mass production. They also suffer due to disadvantages like more frictional losses, difficulty in meeting future stringent emission norms alone etc.

Gas turbines have got advantages of smooth running due to rotary motion, high efficiency as well as low emissions, whereas the disadvantages are, slow response to changing driving situations and the poor part load efficiency.

Fuel cells generate electricity through an electrochemical reaction that combines hydrogen with ambient air. Efficient, quiet, and reliable, fuel cells are predicted to demonstrate energy conversion efficiencies up to 50%. Te disadvantages being, required infrastructure, system accessories, efficiency, very high capital costs and large size.

Generators.

The generator is similar to an electric motor, but it acts only to produce electrical power. It is used mostly on series hybrids.

Fuel systems for hybrid power units.

Fuel systems are similar to conventional IC engine powered vehicles.

Transmissions. 6

Hybrid vehicles The Mogen Configuration

Hybrid electric vehicles (HEVs) can use a variety of transmissions, based on the system design of the vehicle. Some transmissions are more efficient than others; however, sometimes less efficient transmissions are used for a variety of reasons. The four types of transmissions used in HEVs are:

Continuously variable transmission Automated shifted manual transmission Manual transmission Traditional automatic transmission with torque converter

There are other key developments being made to help reduce emissions and improve the efficiency of HEVs:

Emission control systems Energy management and systems control Thermal management of components Light-weight and aerodynamic body/chassis Low rolling resistance (including tires) Reduction of accessory loads in the vehicle

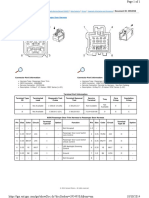

4.0 Hybrid vehicle configurations:There are two possible configurations for hybrid vehicles, 1. Series hybrid and 2. Parallel hybrid Series hybrid :In a series hybrid (Figure below) the gasoline engine turns a generator, and the generator can either charge the batteries or

power an electric motor that drives the transmission.

Thus, the gasoline engine never directly powers the vehicle. 7

Hybrid vehicles The Mogen Configuration

Parallel hybrid:A parallel hybrid has a fuel tank, which supplies gasoline to the engine. But it also has a set of batteries that supplies power to an electric motor. Both the engine and the electric motor can turn the transmission at the same time, and the transmission then turns the wheels.

5.0 HEV Advantages

HEVs have several advantages over conventional vehicles:

Regenerative braking capability helps minimize energy loss and recover the energy used to slow down or stop a vehicle.

Engines can be sized to accommodate average load, not peak load, which reduces the engine's weight.

Fuel efficiency is greatly increased (hybrids consume significantly less fuel than vehicles powered by gasoline alone).

Emissions are greatly decreased. HEVs can reduce dependency on fossil fuels because they can run on alternative fuels.

Special lightweight materials are used to reduce the overall vehicle weight of HEVs.

The HEVs available for sale are very cost competitive with similar conventional vehicles. Any cost premium that may be associated with HEVs of the future can be off-set by overall fuel savings and possible incentives.

Hybrid vehicles The Mogen Configuration

6.0 Some economics about hybrid vehicles:As per current prices in the US the hybrid vehicles from various companies start from around $19000 whereas conventional vehicles with similar performance can be purchased for around $13000-$14000 thus putting an extra cost of about $5000 to $6000 But these extra costs are partially offset by tax incentives offered by various countries to promote use of hybrid vehicles, for example the US government offers a tax deduction of around $2000 for hybrid vehicle owners. Also there is a lot of saving in the fuel costs due to higher fuel efficiency of hybrid vehicles. The warranties for hybrid vehicle Maintenance are also high. Both the Honda and the Toyota have long warranties on the hybrid systems. The Insight has an eightyear/80,000-mile warranty on most of the power train, including batteries, and a three-year/36,000-mile warranty on the rest of the car. The Prius has an eightyear/100,000-mile warranty on the battery and hybrid systems and a threeyear/36,000-mile warranty on everything else. Along with all these there is a priceless pride of doing your part in helping the global cause of pollution reduction as well as helping your country in saving precious foreign exchange spent for buying petroleum fuels.

7.0 Future of HEVs

HEVs are now at the forefront of transportation technology development. Hybrids have the potential to allow continued growth in the automotive sector, while also reducing critical resource consumption, dependence on foreign oil, air pollution, and traffic congestion. A few examples are listed here to give a flavor of some possibilities:

The car could be warmed up or cooled down while it's still in the garage (based on a timer) to make the first few minutes of commute more enjoyable and energy efficient.

Hybrid vehicles The Mogen Configuration

For "lead-foot" drivers, the control strategy could always keep batteries as close to fully charged as possible to allow maximum power for hard accelerations and keep the APU running continuously to have full power available on demand.

For people who drive their cars with maximum fuel economy in mind, the vehicles would use their onboard components in such a way that they would be operating in their highest efficiency regions as much of the time as possible.

For people who normally drive long commutes, the vehicle could turn on the APU before batteries get depleted in anticipation of extra on-board power being needed.

For those who have a short, repeatable commute, the vehicle could delay turning on the APU to allow the commuter to use only "wall charged" electric energy except when driving longer trips.

8.0 THE MOGEN CONFIGURATION FOR HAVs 8.1 Introduction

The word MOGEN stands for THE MOTOR GENERATOR. This device utilizes internal combustion, like conventional engines, only it is unique in that the primary motion is purely linear. There are no crankshafts, flywheels, timing belts, or other rotary devices to reduce engine efficiency. In addition, the deletion of these devices makes for a lighter weight, and thus, a more fuel efficient vehicle. This system is developed by Red Barn Engg., Caledonia, U.S. There is no need for rotating components in the MOGEN because there is no mechanical output; the power generated is in the form of alternating current, the frequency of which is determined by the constant operating speed of the device. For example, at 3600 cycles per minute the MOGEN produces standard 60 Hertz alternating which current for

many

standard

electrical control devices are readily available. 10

Hybrid vehicles The Mogen Configuration

Expanding gases propel a piston, rigidly attached to a "armature coil" which, in turn, moves through a larger "field coil". The motion is reciprocal and produces as alternating current (AC) in the "armature coil". o Classic internal combustion engines have inefficiencies. o Their linear motion (force) must be converted to rotary motion (torque). o Since the basic motion of combustion engine is linear......and since the motion of a coil past a coil is linear.......then why go through a rotary stage? o Let the linear motion of an engine drive the coils past each other! o Combine this with the "coil through a coil" concept to maximum efficiency. o Thus...... The linear motor generator...... The "Mogen".

8.2 Principles of Operation

The Principles Of This Invention Are Based On Well Known Theories Of Electromotive Force And Magnetism. When a conductor is moved through a magnetic field, a current is produced in the conductor. In conventional generators (and electric motors), the conductor and the generator of the magnetic field take the form of coils of wire. These are referred to as the "field coils" and the "armature coils".

Fields Around Coils

In a conventional generator, a "armature coil" moves past a "field coil" to produce a current in the "armature coil". By theory and experimentation, it has been shown that the magnetic field of a circular coil is the most intense on the coil's interior side. Therefore, it would be much more efficient to move the "armature

coil" through the inside of the "field coil".

11

Hybrid vehicles The Mogen Configuration

8.3 Function

The invention consists of an internal combustion motor with a combustion chamber and one or more linear reciprocating pistons. The piston assembly includes a linear reciprocating armature coil (or coils) which move linearly through an annular magnet (field coil). The Internal Combustion Motor with Integral Electric Generator operates similar to conventional combustion engines. This design is unique due to the integration of an electrical generating system, and pure linear motion AS the motor drives the piston(s) linearly, the armature coil is passed through the field coil generating 60 Hertz current which, in automotive

applications powers the drive motors for the wheels. The electric

current produced by the MOGEN is generated by coils which inside are the This

integrated engine.

arrangement not only saves much of the space required by a separate engine and 12

Hybrid vehicles The Mogen Configuration

generator, but, also, the weight and cost of the mechanisms required to connect the two components. The additional weight savings of this compact power system makes for an even more fuel efficient vehicle. In its optimum form, the MOGEN utilizes two opposing pistons operating in a two-cycle manner (firing at the end of each stroke). Obviously, this configuration requires constant computer control to maintain reliability and optimum performance. Other configurations with springs, crankshafts, and multiple cylinder banks are also possible. Another innovative feature of the MOGEN is the action of the circular coils of wire that produce the electric current. The armature coil, attached to the piston rod, moves back and forth through the field coil. This reciprocal motion of a coil through a coil is much more efficient than conventional generators where the coils move past each other. "MOGEN" Configurations 1) BY STORING MECHANICAL ENERGY (SPRING/GAS):

2) BY A POWERED PISTON ON THE OPPISITE END:

3) BY CONNECTING TO A ROTARY DEVICE:

13

Hybrid vehicles The Mogen Configuration

8.4 Applications

Hybrid vehicles (fuel powered; electric drive) Remote generators (fuel powered) Power generation substations (stream or fuel powered) Locomotives (diesel powered)

8.5 The Advantages

The MOTOR/GENERATOR produces electric current. o Powerful (high energy output); lightweight; minimal moving parts; compact; no mechanical output. o Eliminates "rotary" components (cost + weight savings) like Flywheel, Block, Main Bearings, Camshaft, Armature & Shaft, Crankshaft, Timing Gears. o At 3600 RPM, provides standard 60 hertz current. o Can be tuned to a single speed; Minimum number of cylinders can be tuned for fuel efficiency. o The circular coils are more efficient and inexpensive than the "oblong" coils in standard generators. o Engine may be started by reversing coil current. . VEHICLE ADVANTAGES o Small efficient power plant could replace engine/transmission/differential in automobiles to create an electric/fuel (hybrid) vehicle. o Allow for highly flexible vehicle design configuration. o Vehicle would be lightweight and very fuel efficient. o Auxiliary devices may be electric motor driven (air conditioner, power steering, water pump, lube system).

14

Hybrid vehicles The Mogen Configuration

9.0 Conclusion

Any vehicle is a hybrid when it combines two or more sources of power. And by combining gasoline with electric power, hybrids will have the same or greater range than traditional combustion engines. The HEV is able to operate approximately two times more efficiently than conventional vehicles. More efficient cars can make a big difference to society in terms of environmental benefits. Hybrids will never be true zero-emission vehicles, however, because of their internal combustion engine. But the first hybrids on the market will cut emissions of global-warming pollutants by a third to a half, and later models may cut emissions by even more.

10.0 References

www.nrel.gov/international/china/pdfs/annex5/ introduction_of_hybrid_electric_vehicles.pdf http://www.howstuffworks.com/hybrid-car1.htm http://www.howstuffworks.com/hybrid-car2.htm http://www.ott.doe.gov/pdfs/drivehev_factsheet.pdf http://www.ott.doe.gov/pdfs/puthev_factsheet.pdf http://www.fueleconomy.gov/feg/hybridtech.shtml http://www.ott.doe.gov/hev/what.html http://www.ott.doe.gov/hev/components.html http://www.ott.doe.gov/hev/related.html http://www.fleets.doe.gov/fleet_tool.cgi?$$,benefits,1 http://www.ott.doe.gov/hev/faqs.html http://www.ott.doe.gov/pdfs/techhev_factsheet.pdf http://www.ott.doe.gov/pdfs/gmhev_factsheet.pdf http://www.fueleconomy.gov/feg/hybrid_sbs.shtml

15

You might also like

- AET Assignment C Kate ThomsonDocument12 pagesAET Assignment C Kate ThomsonaymenmoatazNo ratings yet

- Hybrid Electric VehiclesDocument6 pagesHybrid Electric VehiclesIslam FattouhNo ratings yet

- Hybrid Electric VehiclesDocument16 pagesHybrid Electric VehiclesmedNo ratings yet

- 6.hybrid VehicleDocument12 pages6.hybrid VehicleawesomeyogeshwarNo ratings yet

- Hybrid Electric Vehicle: Classification of HevDocument4 pagesHybrid Electric Vehicle: Classification of HevAkhil UnnikrishnanNo ratings yet

- Ac 2007-429: An Innovative Hybrid-Electric Drivetrain Concept and Student ProjectDocument13 pagesAc 2007-429: An Innovative Hybrid-Electric Drivetrain Concept and Student ProjectAbdul HakeemNo ratings yet

- Lecture 35Document13 pagesLecture 35Keval ParmarNo ratings yet

- Hybrid Electric Vehicle: Classification Types of PowertrainDocument6 pagesHybrid Electric Vehicle: Classification Types of PowertrainarjunNo ratings yet

- Hybrid Electrical VehiclesDocument15 pagesHybrid Electrical VehiclesEmran MuftiNo ratings yet

- Review On Electrical VehicleDocument25 pagesReview On Electrical VehicleRavi Sankar MadineniNo ratings yet

- Synopsis G-BDocument15 pagesSynopsis G-Bashifsha930No ratings yet

- Hybrid Vehicle Technologies: Trends, Challenges and The FutureDocument10 pagesHybrid Vehicle Technologies: Trends, Challenges and The FutureV V DESIGANNo ratings yet

- Hybrid Vehicle1Document10 pagesHybrid Vehicle1Karthick K KanagarathinamNo ratings yet

- Hybrid Electric Vehical Dts ReportDocument13 pagesHybrid Electric Vehical Dts ReportSachin ChavanNo ratings yet

- Diesel Electric Hybrid VehiclesDocument8 pagesDiesel Electric Hybrid VehiclesLászló KovácsNo ratings yet

- An Overview of Electrical Vehicle and Hybrid Electrical Vehicle DrivesDocument5 pagesAn Overview of Electrical Vehicle and Hybrid Electrical Vehicle DrivesravigobiNo ratings yet

- Project On Multi Utility Hydrid VehicleDocument58 pagesProject On Multi Utility Hydrid VehicleChandrasekharPatnaniNo ratings yet

- Hybrid Electric VehicleDocument23 pagesHybrid Electric VehicleAhmed ShamakhNo ratings yet

- Final Hybrid Electric VehicleDocument23 pagesFinal Hybrid Electric VehicleshwetajhambNo ratings yet

- Hybrid Electric VehicleDocument23 pagesHybrid Electric VehicleshwetajhambNo ratings yet

- انظمه سيارات 2Document11 pagesانظمه سيارات 2ayman sweitiNo ratings yet

- Module 2Document59 pagesModule 2prashanth9.n.sNo ratings yet

- EV Powertrain Comp Deg Hybridization PDFDocument18 pagesEV Powertrain Comp Deg Hybridization PDFADITYA DAS 17BEE0267No ratings yet

- Hybrid Vehicles (SAISH GAONKAR)Document16 pagesHybrid Vehicles (SAISH GAONKAR)PrathameshNo ratings yet

- What Is A PowertrainDocument6 pagesWhat Is A Powertrainselenophile2719No ratings yet

- Hybrid Electric VehiclesDocument11 pagesHybrid Electric VehiclesRadoi Dinu-ValentinNo ratings yet

- M3 PDFDocument43 pagesM3 PDFNeacsu Florin-MariusNo ratings yet

- Hybrid Cars: Name-Kshitij Sharma ROLL NO-130106083 Class - Mechanical "A"Document26 pagesHybrid Cars: Name-Kshitij Sharma ROLL NO-130106083 Class - Mechanical "A"ksharma294No ratings yet

- ATC Trend Analysis - Range Extender TechnologyDocument23 pagesATC Trend Analysis - Range Extender TechnologyMaureen MossNo ratings yet

- Hybrid Electric VehicleDocument15 pagesHybrid Electric VehicletynanduNo ratings yet

- Understanding Micro, Mild, Full and Plug-In Hybrid Electric VehiclesDocument7 pagesUnderstanding Micro, Mild, Full and Plug-In Hybrid Electric VehiclesRui MendesNo ratings yet

- Hybrid Electric Vehicles: Ighlights P T SDocument6 pagesHybrid Electric Vehicles: Ighlights P T SkodumbuNo ratings yet

- 07915a0207 - HevDocument22 pages07915a0207 - Hevvenky123456789No ratings yet

- Automotive: The Increasing Adoption of Hybrid and Electric VehiclesDocument4 pagesAutomotive: The Increasing Adoption of Hybrid and Electric Vehiclesabhinav anandNo ratings yet

- NGHV Unit 2Document28 pagesNGHV Unit 2PrabhaharMuthuswamyNo ratings yet

- Plug in Hyprid - Qutaiba.205248Document17 pagesPlug in Hyprid - Qutaiba.205248Qutaibq MahameedNo ratings yet

- Ajmer SinghhDocument53 pagesAjmer Singhhmd washiqeNo ratings yet

- Car Mini Projrct 1Document42 pagesCar Mini Projrct 1SanthoshNo ratings yet

- Seminar ReportDocument28 pagesSeminar ReportSwathi PrasadNo ratings yet

- Fuel Economy On Hybrid VehiclesDocument17 pagesFuel Economy On Hybrid Vehicleskienho88No ratings yet

- Hybrid VehicleDocument15 pagesHybrid VehiclemoulaNo ratings yet

- Plug-In Hybrid Conversion of A Series Hybrid Electric Vehicle and Simulation ComparisonDocument6 pagesPlug-In Hybrid Conversion of A Series Hybrid Electric Vehicle and Simulation ComparisonM VetriselviNo ratings yet

- Hybrid Electric VehicleDocument18 pagesHybrid Electric VehiclePrudhvi PrinceNo ratings yet

- Formula Hybrid ReportDocument4 pagesFormula Hybrid ReportSuthesh MNo ratings yet

- Electric VehiclesDocument5 pagesElectric Vehiclesaffiq danial 2001No ratings yet

- HEVTDocument9 pagesHEVTBhumika ThummaNo ratings yet

- Hybrid Electric Vehicles: M. R. Rahul Raj M. Nithin MohanDocument31 pagesHybrid Electric Vehicles: M. R. Rahul Raj M. Nithin MohanVarun VatsNo ratings yet

- HybridDocument4 pagesHybridVignesh AsokNo ratings yet

- Research Muneer LyatiDocument10 pagesResearch Muneer LyatiBedasa AbdisaNo ratings yet

- Hybrid Electric VehiclesDocument31 pagesHybrid Electric Vehiclesviper7887No ratings yet

- 2 Synopsis OF HEVDocument6 pages2 Synopsis OF HEVAshish GhadojeNo ratings yet

- Overview of Hybrid Electric Vehicle Trend: Articles You May Be Interested inDocument7 pagesOverview of Hybrid Electric Vehicle Trend: Articles You May Be Interested inRishikesh GunjalNo ratings yet

- Unit 6 QB For Transmission System in Hybrid Electric VehicleDocument16 pagesUnit 6 QB For Transmission System in Hybrid Electric VehicleBdhdhshNo ratings yet

- Harsh Kothari's Hybrid EVDocument7 pagesHarsh Kothari's Hybrid EVHARSH JAINNo ratings yet

- Hybrid Electric Vehicle: Rushikesh Trushar SoniDocument4 pagesHybrid Electric Vehicle: Rushikesh Trushar SoniPuttaraje GowdaNo ratings yet

- How Hybrids WorkDocument6 pagesHow Hybrids WorkmelesseNo ratings yet

- Two Marks-Nghv PDFDocument19 pagesTwo Marks-Nghv PDFSuriya Prakash.DNo ratings yet

- Hybrid Vehicle Drivetrain: Types by Drive Train StructureDocument15 pagesHybrid Vehicle Drivetrain: Types by Drive Train StructureCharyNo ratings yet

- Introduction to Hybrid Vehicle System Modeling and ControlFrom EverandIntroduction to Hybrid Vehicle System Modeling and ControlRating: 4 out of 5 stars4/5 (1)

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesFrom EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesNo ratings yet

- Rahul Metal Detector Full ReportDocument23 pagesRahul Metal Detector Full ReportVishal Singh56% (9)

- Trapazoidal CheckDocument1 pageTrapazoidal CheckVishal SinghNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentVishal SinghNo ratings yet

- Time TableDocument1 pageTime TableVishal SinghNo ratings yet

- Optical Fibre CommunicationDocument60 pagesOptical Fibre CommunicationN.ChanduNo ratings yet

- Firmware Upgrade To SP3 From SP2: 1. Download Necessary Drivers For The OMNIKEY 5427 CKDocument6 pagesFirmware Upgrade To SP3 From SP2: 1. Download Necessary Drivers For The OMNIKEY 5427 CKFilip Andru MorNo ratings yet

- E Rpms Portfolio Design 3 1Document52 pagesE Rpms Portfolio Design 3 1jebNo ratings yet

- Important Terms in ObliconDocument4 pagesImportant Terms in ObliconAriana Cristelle L. Pagdanganan100% (1)

- X606 PDFDocument1 pageX606 PDFDany OrioliNo ratings yet

- Future Generation Computer SystemsDocument18 pagesFuture Generation Computer SystemsEkoNo ratings yet

- Year Warranty: 1575 - 90 Ave Edmonton, AB Canada T6P 0E2Document2 pagesYear Warranty: 1575 - 90 Ave Edmonton, AB Canada T6P 0E2juanchingarNo ratings yet

- Galanz - Galaxy 7-9-12K - SPLIT PDFDocument42 pagesGalanz - Galaxy 7-9-12K - SPLIT PDFUbaldo BritoNo ratings yet

- Eastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateDocument6 pagesEastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateTasheen MahabubNo ratings yet

- LS Series Hand Crimping ToolsDocument4 pagesLS Series Hand Crimping ToolsbaolifengNo ratings yet

- Sage 200 Evolution Training JourneyDocument5 pagesSage 200 Evolution Training JourneysibaNo ratings yet

- BBI2002 SCL 7 WEEK 8 AdamDocument3 pagesBBI2002 SCL 7 WEEK 8 AdamAMIRUL RIDZLAN BIN RUSIHAN / UPMNo ratings yet

- MAS-02 Cost Terms, Concepts and BehaviorDocument4 pagesMAS-02 Cost Terms, Concepts and BehaviorMichael BaguyoNo ratings yet

- PDFDocument18 pagesPDFDental LabNo ratings yet

- Ab 1486 Developer Interest ListDocument84 pagesAb 1486 Developer Interest ListPrajwal DSNo ratings yet

- CH 3 Revision Worksheet 2 Class 6 CSDocument1 pageCH 3 Revision Worksheet 2 Class 6 CSShreyank SinghNo ratings yet

- Millets: Future of Food & FarmingDocument16 pagesMillets: Future of Food & FarmingKIRAN100% (2)

- Uporedna Tabela Addinol-Ovih UljaDocument4 pagesUporedna Tabela Addinol-Ovih UljaasimpeksNo ratings yet

- Unit 8 - Week 7: Assignment 7Document3 pagesUnit 8 - Week 7: Assignment 7Nitin MoreNo ratings yet

- AMCA 210-07 PreDocument10 pagesAMCA 210-07 PretiagocieloNo ratings yet

- 671 - BP Well Control Tool Kit 2002Document19 pages671 - BP Well Control Tool Kit 2002Ibama MirillaNo ratings yet

- Burberry Annual Report 2019-20 PDFDocument277 pagesBurberry Annual Report 2019-20 PDFSatya PhaneendraNo ratings yet

- 2 Players The One With Steam BaronsDocument1 page2 Players The One With Steam BaronsBrad RoseNo ratings yet

- ANNEX C LIST OF EXCEPTIONS (Non-Disslosure of Information)Document3 pagesANNEX C LIST OF EXCEPTIONS (Non-Disslosure of Information)ryujinxxcastorNo ratings yet

- 819-5917-April 2021-Domestic Warranty Policy ManualDocument46 pages819-5917-April 2021-Domestic Warranty Policy ManualDean KershnerNo ratings yet

- 25 - Marketing Channels - Value Networks.Document2 pages25 - Marketing Channels - Value Networks.zakavision100% (1)

- Scout Activities On The Indian Railways - Original Order: MC No. SubjectDocument4 pagesScout Activities On The Indian Railways - Original Order: MC No. SubjectVikasvijay SinghNo ratings yet

- Project Cost ContingencyDocument9 pagesProject Cost ContingencyniroshniroshNo ratings yet

- Application Form New - Erik WitiandikaDocument6 pagesApplication Form New - Erik Witiandikatimmy lauNo ratings yet