Professional Documents

Culture Documents

ACI Mix-Design Summary Sheet

Uploaded by

Abu Zafor0 ratings0% found this document useful (0 votes)

66 views3 pagesACI Mix Design - Summary Sheet calculates the required cement content Based on water / cement ratio and the aggregate size. The coarse aggregate will occupy: ACI Mix Design equations Step 8. Estimation of fine aggregate content by the absolute volume method.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentACI Mix Design - Summary Sheet calculates the required cement content Based on water / cement ratio and the aggregate size. The coarse aggregate will occupy: ACI Mix Design equations Step 8. Estimation of fine aggregate content by the absolute volume method.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

66 views3 pagesACI Mix-Design Summary Sheet

Uploaded by

Abu ZaforACI Mix Design - Summary Sheet calculates the required cement content Based on water / cement ratio and the aggregate size. The coarse aggregate will occupy: ACI Mix Design equations Step 8. Estimation of fine aggregate content by the absolute volume method.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

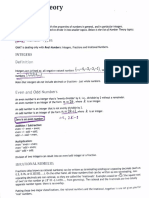

CIVL 1112

ACI Mix Design - Summary Sheet

1/3

ACI Mix Design Equations

Step 1. Required material information (already given). Step 2. Choice of slump. The slump is given, consistent with Table 1.

ACI Mix Design Equations

Step 4. Estimation of mixing water and air content.

Maximum aggregate size (in) Slump(in) 1 to 2 3 to 4 6 to 7 Air Content Mild Moderate Extreme 4.5% 6.0% 7.5% 4.0% 5.5% 7.0% 3.5% 5.0% 6.0% 3.0% 4.5% 6.0% 2.5% 4.5% 5.5% 2.0% 4.0% 5.0% 1.5% 3.5% 4.5% 1.0% 3.0% 4.0% 0.375 305 340 365 0.5 295 325 345 0.75 280 305 325 1 270 295 310 1.5 250 275 290 2 240 265 280 3 225 250 270 6 180 200 -

Step 3. Maximum aggregate size. Given: inches

ACI Mix Design Equations

Step 4. If the concrete were non air entrained then you would use the following table to estimate the mixing water.

Maximum aggregate size (in) Slump(in) 1 to 2 3 to 4 6 to 7 Air Content 0.375 350 385 410 3.0% 0.5 335 365 385 2.5% 0.75 315 340 360 2.0% 1 300 325 340 1.5% 1.5 275 300 315 1.0% 2 260 285 300 0.5% 3 220 245 270 0.3% 6 190 210 0.2%

ACI Mix Design Equations

Step 5. Water/cement ratio.

28-day Compressive Non-AE g (p ) Strength (psi) 2,000 3,000 4,000 5,000 6,000 7,000 0.82 0.68 0.57 0.48 0.41 0.33

AE 0.74 0.59 0.48 0.40 0.32 ---

ACI Mix Design Equations

Step 6. Calculation of cement content. Based on steps 4 and 5, the required cement content is:

ACI Mix Design Equations

Step 7. Estimation of coarse aggregate content.

Fineness Modulus Max Aggregate (in) 2.4 0.50 0.59 0 59 0.66 0.71 0.75 0.78 0.82 0.87 2.5 0.49 0.58 0 58 0.65 0.70 0.74 0.77 0.81 0.86 2.6 0.48 0.57 0 57 0.64 0.69 0.73 0.76 0.80 0.85 2.7 0.47 0.56 0 56 0.63 0.68 0.72 0.75 0.79 0.84 2.8 0.46 0.55 0 55 0.62 0.67 0.71 0.74 0.78 0.83 2.9 0.45 0.54 0 54 0.61 0.66 0.70 0.73 0.77 0.82 3 0.44 0.53 0 53 0.60 0.65 0.69 0.72 0.76 0.81

weight of cement

weight of water w /c

0.375 0.500 0 500 0.750 1.000 1.500 2.000 3.000 6.000

CIVL 1112

ACI Mix Design - Summary Sheet

2/3

ACI Mix Design Equations

The coarse aggregate will occupy:

ACI Mix Design Equations

Step 8. Estimation of fine aggregate content by the absolute volume method.

Water: Cement: Coarse Aggregate: Air: water/62.4 lb/ft3 cement/(3.15 62.4 cement/(3 15 x 62 4 lb/ft3) CAOD/(SGCA x 62.4 lb/ft3) air content x 27ft3/yd3

CA %coarse aggregate 27ft

Value from Table T bl 4

yd 3

The OD weight of the coarse aggregate

CA CA dry rodded lb OD

Dry-Rodded Unit Weight

ft

ACI Mix Design Equations

Therefore, the fine aggregate must occupy a volume of:

3 FA volume 27 ft volume

ACI Mix Design Equations

Step 9. Adjustment for moisture in the aggregate. Since the moisture level of the fine aggregate in our storage bins can vary, we will apply a simple rule to adjust the t th water required. i d Decrease the amount of water required by surface moisture content of the weight of the fine aggregate Increase the amount of aggregate by the amount equal to the surface moisture

The SSD weight of the fine aggregate is:

FA FA SGFA 62.4lb OD volume

Specific Gravity of Fine Aggregate

ft

Unit Weight of Water

ACI Mix Design Equations

Mix Design Procedures

9. Adjustment for moisture in the aggregate -- The water content of the concrete will be affected by the moisture content of the aggregate.

ACI Mix Design Equations

Mix Design Procedures

9. Adjustment for moisture in the aggregate -- The water content of the concrete will be affected by the moisture content of the aggregate.

AC

SM

Moisture content (MC ) AC SM

CIVL 1112

ACI Mix Design - Summary Sheet

3/3

ACI Mix Design Equations

Step 9. Stockpile adjustment for moisture in the aggregate. Stockpile fine aggregate required is:

ACI Mix Design Equations

Step 9. Adjustment of required water The water required is: Require water = water - FA

OD

SM = MC - AC

FA stockpile = FAOD (1 + MCFA)

(SM) CA

Moisture Content

OD

(SM)

Stockpile coarse aggregate required is:

CA stockpile = CAOD (1 + MCCA)

You might also like

- Bs Mix Design Doe MethodDocument22 pagesBs Mix Design Doe Methodsanthu25693% (27)

- Mix DesignDocument29 pagesMix Designshahhassa9No ratings yet

- Concrete Mix Design GuideDocument42 pagesConcrete Mix Design GuidesereneNo ratings yet

- Concrete Mix Design ProportionsDocument88 pagesConcrete Mix Design ProportionsjinshadNo ratings yet

- Conrete Mix Design ACI and JSCE Example. (20+33 Mpa)Document8 pagesConrete Mix Design ACI and JSCE Example. (20+33 Mpa)nirmaljoshi100% (1)

- Concret CementDocument29 pagesConcret CementKamal Hameed Al-taiy100% (1)

- Experimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Document6 pagesExperimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Siddhesh Kamat Mhamai100% (2)

- Mix Design ProcedujersDocument19 pagesMix Design ProcedujersAbinet AlemuNo ratings yet

- Fresh ConcreteDocument28 pagesFresh ConcreteAmar WadoodNo ratings yet

- Proportioning Concrete Mixtures With Graded AggregatesDocument86 pagesProportioning Concrete Mixtures With Graded AggregatesM HAFEEZ RAJA100% (1)

- Compressive Strength Test On Concrete CoreDocument4 pagesCompressive Strength Test On Concrete CoreSyed Mohd MehdiNo ratings yet

- MIX DESIGN PROCEDURE FLOW CHARTDocument33 pagesMIX DESIGN PROCEDURE FLOW CHARTLim Shwe WenNo ratings yet

- Quality Control and Monitoring CONSTRUCTIONDocument38 pagesQuality Control and Monitoring CONSTRUCTIONcosmin_b100% (1)

- Compaction Factor Test&Slump Test ReportDocument1 pageCompaction Factor Test&Slump Test ReportMUN SIM SOHNo ratings yet

- Is2720 Part09Document6 pagesIs2720 Part09anvesh_kumar_16No ratings yet

- Concrete TechnologyDocument36 pagesConcrete Technologyshalu R FNo ratings yet

- Testing Air Content in ConcreteDocument4 pagesTesting Air Content in ConcretePritha DasNo ratings yet

- Concrete Mix DesignDocument23 pagesConcrete Mix DesignSyahmi FadziNo ratings yet

- Mahmoud Khlifa Almoghazy Aliraqi 2 Civil Engineering Section 21Document119 pagesMahmoud Khlifa Almoghazy Aliraqi 2 Civil Engineering Section 21Nasir AlsalehNo ratings yet

- D1557 12 (Reapproved 2021)Document13 pagesD1557 12 (Reapproved 2021)jorgesilva84No ratings yet

- AggregateDocument65 pagesAggregateShawonNo ratings yet

- Fundamentals of ConcreteDocument53 pagesFundamentals of ConcreteAbsiye AdenNo ratings yet

- Hyper CreteDocument2 pagesHyper CretedjgiumixNo ratings yet

- HOT WEATHER CONCRETING TIPSDocument6 pagesHOT WEATHER CONCRETING TIPSMazharYasinNo ratings yet

- Concrete Mix DesignDocument25 pagesConcrete Mix DesigngauravrediffmailNo ratings yet

- Self-Compacting Concrete SeminarDocument16 pagesSelf-Compacting Concrete SeminarAnubhab GhoshNo ratings yet

- Projectmodified Mix Design For ConcreteDocument32 pagesProjectmodified Mix Design For ConcreteSagarNo ratings yet

- Ultra Span CS Brochure BookletDocument19 pagesUltra Span CS Brochure BookletZarko LazicNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix Designadil271No ratings yet

- Monitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewDocument8 pagesMonitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewAmit Sharma IPS AcademyNo ratings yet

- C685C685M 14Document9 pagesC685C685M 14Alvin BaraNo ratings yet

- Technical Report TR 5 Conc Mix DesignDocument18 pagesTechnical Report TR 5 Conc Mix DesignSunil ReddyNo ratings yet

- Concrete Mix Design Examples for Target Strength and Restricted Water-Cement RatioDocument8 pagesConcrete Mix Design Examples for Target Strength and Restricted Water-Cement Ratioعابد خواجہNo ratings yet

- Astm 1579Document7 pagesAstm 1579Paolita Zubieta BelloNo ratings yet

- Optimal Mix Design For Pervious ConcreteDocument9 pagesOptimal Mix Design For Pervious ConcretejanakarajNo ratings yet

- Self Compacting Concrete & Pre Placed ConcreteDocument33 pagesSelf Compacting Concrete & Pre Placed Concretesanthu256100% (2)

- Temperature problems in concretingDocument4 pagesTemperature problems in concretingMirosha NavaratnaNo ratings yet

- A Simple Guide To Concrete Cube TestingDocument4 pagesA Simple Guide To Concrete Cube TestingmsohaibazizNo ratings yet

- Assessment of In-Situ Compressive Strength in Concrete Structures, Methods and CharacteristicsDocument8 pagesAssessment of In-Situ Compressive Strength in Concrete Structures, Methods and CharacteristicsAnonymous ELujOV3No ratings yet

- Final PDF of Standard SpecificationDocument179 pagesFinal PDF of Standard SpecificationabualamalNo ratings yet

- Factors Affecting Workability of ConcreteDocument7 pagesFactors Affecting Workability of ConcreteNeseth Eleuterio Badato100% (1)

- Curing of ConcreteDocument46 pagesCuring of Concretepmonica0850% (2)

- Normal Concrete Mix DesignDocument4 pagesNormal Concrete Mix Designmurnal0% (1)

- Concrete Mix Design Optimized ApproachDocument8 pagesConcrete Mix Design Optimized ApproachHerman MwakoiNo ratings yet

- Concrete Mix DesignDocument20 pagesConcrete Mix DesignRony BaloyiNo ratings yet

- Factors Affecting Workability of ConcreteDocument6 pagesFactors Affecting Workability of ConcreteNick GeneseNo ratings yet

- ACI 304.6R-91 Guide For The Use of Volumetric-MeasuringDocument14 pagesACI 304.6R-91 Guide For The Use of Volumetric-MeasuringMihai BanateanuNo ratings yet

- RMCDocument2 pagesRMCraju_mantripragadaNo ratings yet

- Handbook for Clerks of Works: Greater London Council Department of Architecture and Civic DesignFrom EverandHandbook for Clerks of Works: Greater London Council Department of Architecture and Civic DesignNo ratings yet

- AttachmentDocument23 pagesAttachmentayeshakynaNo ratings yet

- Concrete Mix DesignDocument6 pagesConcrete Mix DesignKarnalPreethNo ratings yet

- Mix-Design Lecture Notes PDFDocument6 pagesMix-Design Lecture Notes PDFEngr RakNo ratings yet

- ACI Mix Design PDFDocument9 pagesACI Mix Design PDFHanniel MadramootooNo ratings yet

- Mix DesignDocument52 pagesMix DesignsorowareNo ratings yet

- Concrete Mix Design FormulaDocument6 pagesConcrete Mix Design FormulaMichaelScofieldNo ratings yet

- Concrete Mix DesignDocument5 pagesConcrete Mix DesignMichaelScofieldNo ratings yet

- ACI 211.1 - Mix Deisgn of ConcreteDocument7 pagesACI 211.1 - Mix Deisgn of ConcreteleorNo ratings yet

- ACI Concrete Design Mix ProcedureDocument4 pagesACI Concrete Design Mix ProcedureLan CorpuzNo ratings yet

- GW Report Final Peer ReviewedDocument42 pagesGW Report Final Peer ReviewedAbu ZaforNo ratings yet

- Prediction of Groundwater Trends For Irrigation in Northern BangladeshDocument19 pagesPrediction of Groundwater Trends For Irrigation in Northern BangladeshAbu ZaforNo ratings yet

- 2.bituminous Mix PDFDocument11 pages2.bituminous Mix PDFSuresh DevarajanNo ratings yet

- Advanced Transportation Engineering Web CourseDocument2 pagesAdvanced Transportation Engineering Web Courseirbasukirahardjoces0% (1)

- IeltsDocument3 pagesIeltsAbu ZaforNo ratings yet

- Journal of Hydrology 2007Document19 pagesJournal of Hydrology 2007Abu ZaforNo ratings yet

- General Training Writing Sample Task - Task 1Document1 pageGeneral Training Writing Sample Task - Task 1Phương MiNo ratings yet

- Math Number Theory PDFDocument2 pagesMath Number Theory PDFAbu ZaforNo ratings yet

- Surveying by Dr. RamachandraDocument338 pagesSurveying by Dr. Ramachandravrsec-rao84% (19)

- Landslide Susceptibility Mapping Using Frequency Ratio, Analytic Hierarchy Process, Logistic Regression, and Artficial Neural Network Methods at The Inje Area, Korea (15 - )Document23 pagesLandslide Susceptibility Mapping Using Frequency Ratio, Analytic Hierarchy Process, Logistic Regression, and Artficial Neural Network Methods at The Inje Area, Korea (15 - )Abu ZaforNo ratings yet

- Bournelli ExperimentDocument10 pagesBournelli ExperimentUsamaIjazNo ratings yet

- The Required MathematicsDocument299 pagesThe Required MathematicsMax Cedeño De LeónNo ratings yet

- Basic Noise CalculationsDocument15 pagesBasic Noise Calculationsapi-270822363No ratings yet

- 13 - Marshall Mix DesignDocument38 pages13 - Marshall Mix Designhasif21100% (1)

- As III Removal Using An Iron-ImpregnatedDocument7 pagesAs III Removal Using An Iron-ImpregnatedAbu ZaforNo ratings yet

- CE 453 Pavement Design Lecture - Rigid vs Flexible PavementsDocument35 pagesCE 453 Pavement Design Lecture - Rigid vs Flexible PavementsTarique Hasan Khan100% (1)

- As III Removal Using An Iron-ImpregnatedDocument7 pagesAs III Removal Using An Iron-ImpregnatedAbu ZaforNo ratings yet

- Calibrationorfice Venturimenterfinale 100604200306 Phpapp01Document6 pagesCalibrationorfice Venturimenterfinale 100604200306 Phpapp01Abu ZaforNo ratings yet

- As III Removal Using An Iron-ImpregnatedDocument7 pagesAs III Removal Using An Iron-ImpregnatedAbu ZaforNo ratings yet

- 2012retaining Wall DetailsDocument6 pages2012retaining Wall DetailsAbu ZaforNo ratings yet

- ARR Project 15 Subproject Report Buildings FinalDocument94 pagesARR Project 15 Subproject Report Buildings FinalAbu Zafor100% (1)

- Mixdesignpracticebituminousmixce 463 110830072917 Phpapp01Document85 pagesMixdesignpracticebituminousmixce 463 110830072917 Phpapp01Abu Zafor100% (1)

- Design of RC FootingDocument17 pagesDesign of RC FootingSwopnilOjhaNo ratings yet

- Assessment of Soil Erosion Using USLE Technique A Case Study of Mysore District, Karnataka, IndiaDocument8 pagesAssessment of Soil Erosion Using USLE Technique A Case Study of Mysore District, Karnataka, IndiaAbu ZaforNo ratings yet

- Curve Fitting TechniquesDocument14 pagesCurve Fitting TechniquesAveenNo ratings yet

- Floodplain Zoning Simulation by Using HEC RAS and CCHE2D Models in The - PDF 7393Document8 pagesFloodplain Zoning Simulation by Using HEC RAS and CCHE2D Models in The - PDF 7393Abu Zafor100% (1)

- Guide To BSC Numerical MethodsDocument223 pagesGuide To BSC Numerical Methodsbldfst12151878% (23)

- Jurnal Teknologi: A C A T S F M S F D H MDocument8 pagesJurnal Teknologi: A C A T S F M S F D H MAbu ZaforNo ratings yet

- SustainabilityDocument16 pagesSustainabilityAbu ZaforNo ratings yet

- 6 1 27Document6 pages6 1 27Abu ZaforNo ratings yet

- LUCY SwitchgearDocument8 pagesLUCY SwitchgearHillary McgowanNo ratings yet

- Friction Factor For Turbulent Pipe Flow: January 2006Document17 pagesFriction Factor For Turbulent Pipe Flow: January 2006John AnthoniNo ratings yet

- Advantages & Disadvantages CITWDocument5 pagesAdvantages & Disadvantages CITWSreePrakashNo ratings yet

- PDVSA Engineering Design Manual Volume 9–I Process AnalyzersDocument25 pagesPDVSA Engineering Design Manual Volume 9–I Process AnalyzersAlberto Enrique De Santa Anna CampderáNo ratings yet

- IEEE STD C37.30.1 Estandar de Requisitos para Interruptores de Aire de AV AC para Nivelesmayores A 1000VDocument104 pagesIEEE STD C37.30.1 Estandar de Requisitos para Interruptores de Aire de AV AC para Nivelesmayores A 1000Valex100% (4)

- Motion ReportDocument2 pagesMotion Reportmikeb-erau100% (2)

- Wacker Neuson-Dpu - 25 KNDocument3 pagesWacker Neuson-Dpu - 25 KNMilutin BožovićNo ratings yet

- A03_Grader_IRCD_InstructionsDocument2 pagesA03_Grader_IRCD_InstructionsClausulaLover24No ratings yet

- Vinay Quality ResumeDocument3 pagesVinay Quality Resumevinay kumarNo ratings yet

- Stress-Strain Behaviour of Steel-Fibre-Reinforced Recycled Aggregate Concrete Under Axial TensionDocument16 pagesStress-Strain Behaviour of Steel-Fibre-Reinforced Recycled Aggregate Concrete Under Axial TensionAndrucruz CruzNo ratings yet

- Usn LM2500 Asme Paper GT2010-22811 61410 JalDocument7 pagesUsn LM2500 Asme Paper GT2010-22811 61410 Jalferrerick0% (1)

- Ashrae - 2009 I-P - F09 - AddDocument2 pagesAshrae - 2009 I-P - F09 - AddSergio SemmNo ratings yet

- The Shand CCS Feasibility Study Public ReportDocument124 pagesThe Shand CCS Feasibility Study Public ReportSai RuthvikNo ratings yet

- Crompton Greaves LimitedDocument3 pagesCrompton Greaves LimitedNitish SinghNo ratings yet

- Applied Fluid Mechanics: Viscosity of FluidsDocument22 pagesApplied Fluid Mechanics: Viscosity of FluidsMaggie HepditchNo ratings yet

- AMS Thread Size ChartDocument4 pagesAMS Thread Size Chartarunvelu_1250% (2)

- An Algorithm For Minimax Solution of Overdetennined Systems of Non-Linear EquationsDocument8 pagesAn Algorithm For Minimax Solution of Overdetennined Systems of Non-Linear EquationsDewi FitriyaniNo ratings yet

- P1 Conservation and Dissipation of Energy Student Book AnswersDocument11 pagesP1 Conservation and Dissipation of Energy Student Book AnswersjoeNo ratings yet

- Department of Mechanical Engineering, Uet Lahore Refrigeration and Air Conditioning LaboratoryDocument7 pagesDepartment of Mechanical Engineering, Uet Lahore Refrigeration and Air Conditioning LaboratoryTauQeer ShahNo ratings yet

- Advanced Data Structures and ImplementationDocument56 pagesAdvanced Data Structures and ImplementationSyam Prasad Reddy BattulaNo ratings yet

- Bottom Ash HopperDocument8 pagesBottom Ash HopperBhargav ChaudhariNo ratings yet

- Resume of MD Saiful HyderDocument4 pagesResume of MD Saiful Hyderimtheboss*No ratings yet

- Beumer - Pipeconveyor TechnologyDocument51 pagesBeumer - Pipeconveyor TechnologyAli AlatasNo ratings yet

- Installing RegCM4.3rc Training Session IDocument11 pagesInstalling RegCM4.3rc Training Session Ijmatias765428100% (1)

- FAA Significant Regulatory DifferencesDocument3 pagesFAA Significant Regulatory DifferencesOpteron K.No ratings yet

- Feed Water and Boiler Water of Steam GeneratorsDocument2 pagesFeed Water and Boiler Water of Steam GeneratorsIvicaT0% (2)

- 83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsDocument12 pages83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsmaulikgadaraNo ratings yet

- January2016page1to36 Layout 1Document36 pagesJanuary2016page1to36 Layout 1c737No ratings yet

- Dow Corning (R) 200 Fluid, 50 Cst.Document11 pagesDow Corning (R) 200 Fluid, 50 Cst.Sergio Gonzalez GuzmanNo ratings yet