Professional Documents

Culture Documents

HP Regulators v2

Uploaded by

Danny SánchezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HP Regulators v2

Uploaded by

Danny SánchezCopyright:

Available Formats

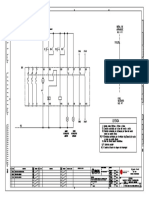

HIGH PRESSURE REGULATORS

Models HPMV

Instruction Manual: IME1HPMVREG

Sense Line Protector

Supply gas Regulator

30 HPG Pilot

INTRODUCTION: SCOPE:

150 PG Pilot High Pressure Motor Valve

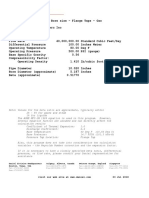

SPECIFICATIONS: Normal Service: Features:

Connection Size: Body Style: Connection Type: Actuation: Control: Temperature:

This instruction manual includes installation, operation, and parts information for the Kimray Pilot operated High Pressure Regulators. Refer to separate manuals for instructions covering actuators, controllers, maintenance, and accessories. Only trained and qualified individuals should attempt to install, operate, or maintain any Kimray products or accessories. The following instructions should be reviewed and completely understood before attempting any installation, operation, or maintenance. If you have any concerns or questions about these instructions, contact your Kimray sales office before proceeding.

Liquid* or Gas

1 thru 8 DN 25 thru DN 200 Through or Angle NPT, Flanged, or RTJ Pressure Open or Pressure Closed Upstream or Downstream -20f to 200f -29c to 93c 5 psig - 2500 psig .34 bar - 172 bar Pre-piped pilot supply Filter drip pot Reduced trim capacity Trim material Elastomer material Quick exhaust slam-shut device Electro-pneumatic control Actuator spring ranges Adjustable actuator Non-freeze body

DESCRIPTION:

Kimray pilot operated high pressure regulators are used for liquids, natural gas, air, or other non-corrosive gas applications and include a High Pressure Motor Valve, 12 SGR supply gas regulator, High pressure pilot, and sense line protector were applicable. The High Pressure Regulator will control set point at upstream or downstream of the valve depending on configuration. A name tag is attached to the upper bonnet housing on each Thermostat. The name tag lists the serial number, model number, and pressure rating. When servicing valves, always use only Kimray replacement parts. For specific model numbers, part numbers, and repair kit numbers, refer to the Kimray Catalog, Section H1, or to the packing slip which is enclosed with each valve.

Range:

Options:

* Do not use in Liquid service with pulsations in pressure

HIGH PRESSURE REGULATORS

Models HPMV

AVAILABLE MODELS: Typical Configurations

Pressure Reducing Regulator with 30 hpg pilot Control Pressure: 5 - 300 psig Operating Pressure: 0 - 1000 psig * 1000 psig with sense line protector

Pressure Reducing Regulator with PG pilot Control Pressure: 75 - 2500 psig Operating Pressure: 0 - 4000 psig * 4000 psig with sense line protector

Back Pressure Regulator with 30 hpg pilot Control Pressure: 5 - 300 psig Operating Pressure: 0 - 1000 psig * 1000 psig with sense line protector

Back Pressure Regulator with PG Pilot Control Pressure: 75 - 2500 psig Operating Pressure: 0 - 4000 psig * 4000 psig with sense line protector

HIGH PRESSURE REGULATORS

Models HPMV

Hi-Lo Regulator with PG Pilots Control Pressure: 75 - 2500 psig Operating Pressure: 75 - 2500 psig

Hi-Lo Regulator with 30 HPG Pilots Control Pressure: 10 - 300 psig Operating Pressure: 10 - 1000 psig * 1000 psig with sense line protector

Upstream Gap Control Regulator with PG Pilots Control Pressure: 75 - 2500 psig Operating Pressure: 75 - 2500 psig

Downstream Gap Control Regulator with 30 HPG Pilots Control Pressure: 10 - 300 psig Operating Pressure: 10 - 1000 psig * 1000 psig with sense line protector

HIGH PRESSURE REGULATORS

Models HPMV

Redundant Regulators with PG Pilots Control Pressure: 75 - 2500 psig Operating Pressure: 0 - 4000 psig * 4000 psig with sense line protector

Worker Monitor Regulators with 30 HPG Pilots Control Pressure: 5 - 300 psig Operating Pressure: 0 - 1000 psig * 1000 psig with sense line protector

HIGH PRESSURE REGULATORS

Models HPMV

Body, Connections & Pressure Ratings Size

1 NPT 150 RF 300 RF 600 RF 900 RF 1500 RF 150 RTJ 300 RTJ 600 RTJ 1500 RTJ NPT 150 RF 300 RF 600 RF 900 RF 1500 RF 150 RTJ 300 RTJ 600 RTJ 900 RTJ 1500 RTJ 150 RF 300 RF 600 RF 600 RTJ 150 RF 300 RF 600 RF 150 RF 300 RF 600 RF 300 RF 600 RF 4000 psig 285 psig 740 psig 1480 psig 2220 psig 3705 psig 285 psig 740 psig 1480 psig 3705 psig 4000 psig 285 psig 740 psig 1480 psig 2220 psig 3705 psig 285 psig 740 psig 1480 psig 2220 psig 3705 psig 285 psig 740 psig 1480 psig 1480 psig 285 psig 740 psig 1480 psig 285 psig 740 psig 1480 psig 740 psig 1480 psig 96 bar 19 bar 51 bar 102 bar 153 bar 255 bar 19 bar 51 bar 102 bar 255 bar 96 bar 19 bar 51 bar 102 bar 153 bar 255 bar 19 bar 51 bar 102 bar 153 bar 255 bar 19 bar 51 bar 102 bar 102 bar 19 bar 51 bar 102 bar 19 bar 51 bar 102 bar 51 bar 102 bar

INSTALLATION:

BEFORE INSTALLATION: Be sure you fully understand the application, operation, and connection of the device before installing. WARNING: Only trained personnel should install or service a control valve. Control valves and other control devices should be installed, operated, and maintained in accordance with international codes and regulations, manufacturers instructions, and proven best practices. Personal injury, equipment damage, property damage, leakage, or bursting of pressure-containing parts may result if the valve is overpressured or installed where service conditions could exceed the limits given in the SPECIFICATIONS section. Overpressure protection should also be provided if the valve inlet pressure may exceed the safe working pressure of the equipment downstream. To avoid injury or damage, install pressure-relieving or pressure limiting devices to prevent service conditions from exceeding those limits. Consult the appropriate code, regulations, or standards. Consideration should be given to the potential risk of injury or property damage due to escaping fluid. To avoid such risks, install the regulator in a safe location. 1. Inspect the openings in the valve for foreign material and clean the pipe lines to remove scale, chips, and debris. 2. Install the valve with the arrow on the body pointing in the direction of flow. The arrow signifies that the device will operate properly in the direction of flow indicated and will not necessarily prevent flow in the opposite direction. The flow direction of the HPMV 1 and 2 with ball and cone trim is DOWN through the valve. If conditions indicate the possibility of backward flow you may wish to install check valves. The flow direction of the HPMV PB 2 thru 8 is UP through the valve. If conditions indicate the possibility of backward flow you may wish to install check valves. A person should never stand directly over or in front of a valve when the system is pressurized. Never look directly into a valve in a pressurized system. The valve could suddenly open, blowing gas, dirt, metal particles, or other debris into the persons face and eyes.

Construction Materials:

Item Body Cage Stem Plug Seat Stuffing Box Bonnet Diaphragm O-rings Packing Standard A216-WCB AISI 12-L14 303 Stainless Chrome alloy D-2 Steel AISI 12-L14 ASTM-A395 Nitrile/Nylon Nitrile PTFE Viton Optional 316SS6 Stainless 316SS6 Stainless 316SS6 Stainless 316SS6 Stainless 316SS6 Stainless 316SS6 Stainless

3. Install the valve using good piping practice. For flanged bodies use a suitable gasket between the body and the pipeline flanges. For threaded (NPT) bodies, use TFE tape or pipe thread sealant on external pipe threads. The flange bodies are rated ANSI class. Do not install the valve in a system where the working pressure can exceed ANSI class rating. Kimrays HPMV regulators are self contained and no external connections are required unless an outside source of supply gas is required. 4. If an outside source of supply gas is required, connect supply gas to the drip pot with 1/4 connection or directly to pilot supply input if regulated. The maximum required instrument gas pressure is 45 psig (3bar).

HIGH PRESSURE REGULATORS

Models HPMV

START UP: BACK PRESSURE REGULATOR:

In a Back Pressure Regulator the sense line is connected upstream, and the valve is typically operated in a pressure closed (fail open) mode. The Back Pressure Regulator is fully self-contained with both supply and sense lines being connected to the valve. An instrument gas regulator is installed to cut the upstream pressure to the recommended pressure for the actuator (30 -35 psig). The drip pot is added to collect any liquid that might be in the upstream gas. 1. Make sure all block and vent valves are closed. 2. Back out the pilot adjusting screw. 3. Carefully open the following valves in this order: a. Pilot supply and control line valves, if applicable. b. Upstream block valve. c. Downstream block valve. 4. If a supply gas regulator is being used set to 35 psig at this time. 5. Adjust pilot until desired control pressure is achieved. Tighten adjustment bolt to increase upstream set point and loosen adjustment bolt to decrease upstream set point. 6. Once desired set point is achieved tighten lock nut on pilot adjust ment knob to lock pilot. 7. Check for any leaks around pilot or valve area at this time and cor rect if necessary.

4. If a supply gas regulator is being used set to 35 psig at this time. 5. Adjust pilot until desired control pressure is achieved. Tighten adjustment bolt to increase upstream set point or loosen adjustment bolt to decrease upstream set point. 6. Once desired set point is achieved tighten lock nut on pilot adjust ment knob to lock pilot. 7. Check for any leaks around pilot or valve area at this time and cor rect if necessary.

HI-LO REGULATOR:

In a Hi-Lo Regulator the sense line is connected downstream and and the vale is typically operated in a pressure open ( fail closed ) mode. The Hi-Lo Regulator is fully self-contained with both supply and sense lines being connected to the valve. An instrument gas regulator is installed to cut the upstream pressure to the recommended pressure for the actuator (30 - 35 psig). The drip pot is added to collect any liquid that might be in the upstream gas. The function of the Hi-Lo Regulator is to allow medium to flow through the valve within pilots controlled range. As long as the mediums pressure is between the regulators Hi set point and Low set point the valve will be open, if pressure falls or climbs outside this range the Regulator will close and a manual reset will be required. 1. Make sure all block and vent valves are closed. 2. Back out the pilot adjusting screw. 3. Carefully open the following valves in this order: a. Pilot supply and control line valves, if applicable. b. Upstream block valve. c. Downstream block valve.

PRESSURE REDUCING REGULATOR:

In a Pressure Reducing Regulator the sense line is connected downstream, and the valve is typically operated in a pressure open (fail closed) mode. The Pressure Reducing Regulator is fully self-contained with both supply and sense lines being connected to the valve. An instrument gas regulator is installed to cut the upstream pressure to the recommended pressure for the actuator (30 -35 psig). The drip pot is added to collect any liquid that might be in the upstream gas. 1. Make sure all block and vent valves are closed. 2. Back out the pilot adjusting screw. 3. Carefully open the following valves in this order: a. Pilot supply and control line valves, if applicable. b. Upstream block valve. C. Downstream block valve.

4. If a supply gas regulator is being used set to 35 psig at this time. 5. Adjust Hi set point pilot (indirect acting) to desired set point or shut off pressure by turning adjustment screw in. This can be determined by closing downstream block valve and observing downstream pressure when valve is closed. The manual reset will need to be reset everytime high set point is reached. 6. Adjust Low setpoint (direct acting) to desired set point or shut off pressure. This can be determined by closing upstream block valve and observing upstream pressure when valve is closed. The manual reset will need to be reset everytime the low set point is reached. 7. Once both Hi and Low set points have been achieved, tighten lock nut on pilot adjustment knob to lock pilot. 8. Open upstream and downstream block valves to begin flow. 9. Check for any leaks around pilot or valve area at this time and correct if necessary.

HIGH PRESSURE REGULATORS

Models HPMV

GAP CONTROL REGULATOR:

In a Gap Control Regulator the sense line is connected to either upstream or downstream of the valve depending on desired control. The Gap Control Regulator typically uses a pressure open ( fail closed ) valve configuration. The Gap Control Regulator is fully self-contained with both supply and sense lines being connected to the valve. An instrument gas regulator is installed to cut the upstream pressure to the recommended pressure for the actuator (30 - 35 psig). The drip pot is added to collect any liquid that might be in the upstream gas. The function of the Gap Control Regulator is to allow medium to flow through the valve within pilots control range. The Gap Control Regulator will control upstream or downstream range. Upstream Gap Controller will monitor upstream pressure and open the valve when pressure reaches Hi set point, the valve will remain open until low set point is achieved and will then close. The regulator will remain closed until high set point is sensed by pilot and valve will open again. 1. Make sure all block and vent valves are closed. 2. Back out the pilot adjusting screw. 3. Carefully open the following valves in this order: a. Pilot supply and control line valves, if applicable. b. Upstream block valve. c. Downstream block valve. 4. If a supply gas regulator is being used set to 35 psig at this time. 5. Adjust HI set point pilot to desired set point or open pressure by turning adjustment screw in to increase pressure. High set point can be reached by shutting downstream block valve and and adjusting Hi pilots adjustment screw in until valve opens. It may be required to repeat this several times until set point is achieved. 6. Adjust Low set point pilot to desired set point or closed pressure by turning adjustment screw in to increase low set point. Low set point can be reached by shutting upstream block valve and monitoring pressure when valve closes. It may be required to repeat this several times until set point is achieved. 7. Once both Hi and Low set points have been achieved, tighten lock nut on pilot adjustment knob to lock pilot. 8. Open upstream and downstream block valves to begin flow. 9. Check for any leaks around pilot or valve area at this time and correct if necessary.

Downstream Gap Controller will monitor downstream pressure and close the valve when downstream pressure reaches Hi set point, the valve will remain closed until downstream reaches low pilot set point. At low set point the regulator will open and remain open until downstream pressure reaches Hi level set point and will close again. 1. Make sure all block and vent valves are closed. 2. Back out the pilot adjusting screw. 3. Carefully open the following valves in this order: a. Pilot supply and control line valves, if applicable. b. Upstream block valve. c. Downstream block valve. 4. If a supply gas regulator is being used set to 35 psig at this time. 5. Adjust HI set point pilot to desired set point or closed pressure by turning adjustment screw in to increase pressure. High set point can be reached by shutting downstream block valve and and adjusting Hi pilots adjustment screw in until valve closes. It may be required to repeat this several times until set point is achieved. 6. Adjust Low set point pilot to desired set point or open pressure by turning adjustment screw in to increase low set point. Low set point can be reached by shutting downstream block valve and monitor pressure when valve open. It may be required to repeat this several times until set point is achieved. 7. Once both Hi and Low set points have been achieved, tighten lock nut on pilot adjustment knob to lock pilot. 8. Open upstream and downstream block valves to begin flow. 9. Check for any leaks around pilot or valve area at this time and correct if necessary.

HIGH PRESSURE REGULATORS

Models HPMV

REDUNDANT REGULATOR:

In a Redundant Regulator the sense line is connected downstream, and the valves are typically operated in a pressure open (fail closed) mode. The Redundant Regulator is fully self-contained with both supply and sense lines being connected to the valve. An instrument gas regulator is installed to cut the upstream pressure to the recommended pressure for the actuator (30 -35 psig). The drip pot is added to collect any liquid that might be in the upstream gas. Redundant Regulators are two pressure reducing regulators that share the same sense point, while operating independently from one another. In case of a pilot failure set point will always remain constant. 1. Make sure all block and vent valves are closed. 2. Back out the pilot adjusting screw. 3. Block sense line on regulators sense line, a ball valve works well for this. 4. Carefully open the following valves in this order: a. Pilot supply and control line valves, if applicable. b. Upstream block valve. C. Downstream block valve. 5. If a supply gas regulator is being used set to 35 psig at this time. 6. Open sense line ball valve of first regulator. 6. Adjust pilot of first regulator until desired control pressure is achieved. Tighten adjustment bolt to increase downstream set point and loosen adjustment bolt to decrease downstream set point. 7. Once desired set point is achieved tighten lock nut on pilot adjust ment knob to lock pilot. 8. Open ball valve to sense line of second regulator and close ball valve on sense line of first regulator. 9. Adjust pilot of second regulator until desired control pressure is achieved. Tighten adjustment bolt to increase downstream set point and loosen adjustment bolt to decrease downstream set point. 10. Once desired set point is achieved tighten lock nut on pilot adjust ment knob to lock pilot. 11. Open ball valve on first regulator. 12. Check for any leaks around pilot or valve area at this time and cor rect if necessary.

WORKER MONITOR REGULATOR:

In a Worker Monitor Regulator the sense line is connected downstream, and the valves are typically operated in a pressure open (fail closed) mode. The Redundant Regulator is fully self-contained with both supply and sense lines being connected to the valve. An instrument gas regulator is installed to cut the upstream pressure to the recommended pressure for the actuator (30 -35 psig). The drip pot is added to collect any liquid that might be in the upstream gas. Worker Monitor Regulators are designed to control a downstream pressure. The first regulator in line is designed to monitor the second regulator and in case of a failure the first regulator will take over and control will never be lost. Both regulators can be set at the same pressure, because a pressure sensing pilot is connected to sense the line pressure between regulators. It is set at a slightly higher pressure to avoid interaction with the primary regulator. 1. Make sure all block and vent valves are closed. 2. Back out the pilot adjusting screw. 3. Block sense line on regulators sense line, a ball valve works well for this. 4. Carefully open the following valves in this order: a. Pilot supply and control line valves, if applicable. b. Upstream block valve. C. Downstream block valve. 5. If a supply gas regulator is being used set to 35 psig at this time. 6. Turn the adjusting screw on the Monitor Pilot clockwise all the way down. 7. Turn the adjusting screw on the Standby Regulator Pilot clockwise two turns after you feel it engage the spring. The Standby Regula tor valve should open. The gauge on the Standby Regulator Pilot should read 0, and the gauge on the Monitor Pilot should read downstream pressure. 8. Begin turning the the adjusting screw on the Primary Regulator Pilot clockwise. The Primary Regulator should begin to open. Continue turning the adjusting screw until the desired downstream pressure setting is reached. The Primary Regulator is now set. Set the lock nut on the adjusting screw. 9. Turn the adjusting screw on the Monitor Pilot counterclockwise. At some point the gauge on the Standby Regulator Pilot will begin to show pressure. Turn the adjusting screw at least one more full turn counter clockwise. This will keep the Monitor Pilot from interfering with further setup. 10. Close the small block valve on the sense line of the Primary Regulator Pilot, and open the bleed valve. The Primary Regulator should fully open, the gauge on the Primary Regulator Pilot should read 0.

HIGH PRESSURE REGULATORS

Models HPMV

TROUBLESHOOTING:

11. The Standby Regulator should now be controlling downstream pressure. Position the adjusting screw on the Standby Regulator Pilot until the desired downstream pressure setting is reached. The Standby Regulator is now set. Set the lock nut on adjusting screw. 12. Slowly turn the adjusting screw on the Monitor Pilot clockwise. At some point the gauge on the Standby Regulator Pilot will begin to indicate loss in pressure. At this point turn the adjusting screw on the Monitor Pilot 1/2 turn counter clockwise. The Monitor Pilot is set. Shut the bleed valve on the Primary Regulator Pilot, open the block valve. 13. To restore control to the Primary Regulator turn the adjusting screw on the Monitor Pilot 1/2 turn clockwise. Pressure indicated on the gauge of the Standby Regulator Pilot should drop to 0. The Standby Regulator should fully open, and the Primary Regulator should move into control. After control by the Primary Regulator is verified, turn the adjusting screw on the Monitor Pilot 1/2 turn counter clockwise to restore its setting. Set the lock nut on the adjusting screw. The entire unit is now set. * When the Primary Regulator is in control (normal conditions) the gauge on the Standby Regulator will read 0. Regulator is not stable Oversized trim. Improper piping, regulators require a minimum of 10 times pipe O.D. Upstream and Downstream of valve. Move sense line, turbulance through body causing false reading. Regulator will not open Check for clogged control line.

Make sure control line and supply line are properly connected.

Make sure supply gas is turned on. Check actuator diaphragm for damage Regulator will not close Check pilot control line, clogged or broken. Check pilot vent plug for restriction. Check actuator diaphragm for damage No adjustment in Regulator Check pilot sense area for damaged diaphragm or bellow assembly Check for broken spring in pilot bonnet Check actuator diaphragm for damage Make sure regulator is operating in control range of pilot. Check supply gas pressure, requires 30-35 psig

You might also like

- Manual Regulators Man Slamshut 2-4inchDocument20 pagesManual Regulators Man Slamshut 2-4inchDelfin Rosanieto TapiaNo ratings yet

- SG Actuator Gas Over OilDocument4 pagesSG Actuator Gas Over Oiltoader56No ratings yet

- Solenoid Operated Valves: Nuclear Power GenerationDocument12 pagesSolenoid Operated Valves: Nuclear Power GenerationVeerabhadra BujurkeNo ratings yet

- EZR Installation ManualDocument40 pagesEZR Installation ManualRoberto Aldayuz HerediaNo ratings yet

- 67Document10 pages67johnnylim456No ratings yet

- GS02 33 35Document2 pagesGS02 33 35Adal VeraNo ratings yet

- GgsDocument21 pagesGgsKrishna KumarNo ratings yet

- Vortex Pilot Gas Heater Over Temperature ProtectionDocument17 pagesVortex Pilot Gas Heater Over Temperature ProtectionDon BettonNo ratings yet

- Flow ComputerDocument29 pagesFlow ComputerCahyo PrasetyoNo ratings yet

- Type Ezr EstancoDocument40 pagesType Ezr EstancoJuan JuanNo ratings yet

- Sample Exam2cDocument10 pagesSample Exam2cnaefmubarakNo ratings yet

- 8255 - SeminarDocument28 pages8255 - SeminarJKNo ratings yet

- FloBoss IO ModulesDocument5 pagesFloBoss IO ModulesAdeel HassanNo ratings yet

- PLC CurriculumDocument4 pagesPLC CurriculummanisegarNo ratings yet

- Iscan2 ScannerDocument2 pagesIscan2 ScannerjqithriNo ratings yet

- Thermodynamics QuestionsDocument4 pagesThermodynamics QuestionsPiyush BaidNo ratings yet

- Chemical Composition of Carrot Seeds Daucus Carota PDFDocument8 pagesChemical Composition of Carrot Seeds Daucus Carota PDFMaurizio ArdizziNo ratings yet

- Gorter r200Document6 pagesGorter r200Manish SaraswatNo ratings yet

- FloBoss™ S600+ Flow Computer Instruction Manual PDFDocument152 pagesFloBoss™ S600+ Flow Computer Instruction Manual PDFSibabrata ChoudhuryNo ratings yet

- About Gas Expoison 1. English Lampung, Indonesia. A Lampung Man Suffered Severe Burns After ADocument13 pagesAbout Gas Expoison 1. English Lampung, Indonesia. A Lampung Man Suffered Severe Burns After AnfinisaNo ratings yet

- Intro Process Xmitters (Suresh)Document33 pagesIntro Process Xmitters (Suresh)sreeyukthaNo ratings yet

- IC 8155 InformationDocument13 pagesIC 8155 InformationKajol PhadtareNo ratings yet

- LP Gas Regulators Equipment Application Guide Technical Section en 126594 PDFDocument152 pagesLP Gas Regulators Equipment Application Guide Technical Section en 126594 PDFIsaac FloresNo ratings yet

- Natural Gas AssignmentDocument9 pagesNatural Gas AssignmentJagathisswary SatthiNo ratings yet

- Natural Gas Chromatograph (NGC) 8206: Data Sheet 2101164-AGDocument5 pagesNatural Gas Chromatograph (NGC) 8206: Data Sheet 2101164-AGishibhoomiNo ratings yet

- (Job Title #1) / (Job Title #2) : (NAME)Document3 pages(Job Title #1) / (Job Title #2) : (NAME)Rashid Mahmood JaatNo ratings yet

- 399ADocument24 pages399ADana Mera100% (2)

- Directional Valves WebinarDocument18 pagesDirectional Valves WebinarhaggNo ratings yet

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1No ratings yet

- 21314Document5 pages21314HirkanipatilNo ratings yet

- Btu CalculationsDocument1 pageBtu CalculationsVíctor RojasNo ratings yet

- Omni Flow Computer ManualDocument57 pagesOmni Flow Computer ManualRifki AsfariNo ratings yet

- Chapter-8 (Part-I) : (Programmable Peripheral Interface)Document12 pagesChapter-8 (Part-I) : (Programmable Peripheral Interface)belihuNo ratings yet

- Pneumatic NotesDocument5 pagesPneumatic NoteskanscseNo ratings yet

- Pressure Operated Valves 2 - 2 Air Operated 290 CAT 00047GBDocument8 pagesPressure Operated Valves 2 - 2 Air Operated 290 CAT 00047GBNelson AlvarezNo ratings yet

- Fluid CircuitsDocument189 pagesFluid CircuitsM.Saravana Kumar..M.E100% (1)

- FCDocument46 pagesFCJcRodriguezNo ratings yet

- Slam Shut Off FlowgridDocument16 pagesSlam Shut Off FlowgridmateuNo ratings yet

- PIPEMILL - Piping Engineering, Design and AnalysisDocument1 pagePIPEMILL - Piping Engineering, Design and Analysisfahid masoodNo ratings yet

- Natural Gas Dynamics - Mod 2Document44 pagesNatural Gas Dynamics - Mod 2sujaysarkar85No ratings yet

- Variable-Area FlowmeterDocument15 pagesVariable-Area FlowmeterhotnatkapoorNo ratings yet

- Frame 5001 Operation DetailsDocument1 pageFrame 5001 Operation DetailsJJNo ratings yet

- Frequently Asked Questions On Natural Gas - Hindustan Petroleum Corporation Limited, IndiaDocument5 pagesFrequently Asked Questions On Natural Gas - Hindustan Petroleum Corporation Limited, IndiaDAYARNAB BAIDYANo ratings yet

- GC Principle of OperationDocument30 pagesGC Principle of OperationWilmer EgeaNo ratings yet

- 12186Document2 pages12186Harsh BhatiaNo ratings yet

- 2017 Cold Storage Solutions-Antech Group PDFDocument26 pages2017 Cold Storage Solutions-Antech Group PDFGhanshyam PatilNo ratings yet

- PGT005 Control Valves TrainingDocument12 pagesPGT005 Control Valves TrainingJom BonhayagNo ratings yet

- Model 2000 Flow ComputerDocument8 pagesModel 2000 Flow ComputerAdnan SalihbegovicNo ratings yet

- PLC CourseDocument3 pagesPLC CourseNisar AhmedNo ratings yet

- Seminar: 8255A PPIDocument15 pagesSeminar: 8255A PPIyuvraj singhNo ratings yet

- Cartridge Filters: Technical Manual MT 080Document30 pagesCartridge Filters: Technical Manual MT 080abessiNo ratings yet

- Solenoid OperationDocument3 pagesSolenoid Operationchamara kumarasingheNo ratings yet

- Chapter 6b Digital Filter IIRDocument21 pagesChapter 6b Digital Filter IIRfarina ilyanaNo ratings yet

- Redundant Solenoid ValveDocument2 pagesRedundant Solenoid ValveAmanda PorterNo ratings yet

- Operating Manual Manual de Instrucciones Manuel D'utilisationDocument16 pagesOperating Manual Manual de Instrucciones Manuel D'utilisationCarlos EscalonaNo ratings yet

- Convertidor Neumatico Y695ADocument8 pagesConvertidor Neumatico Y695AALBERTONo ratings yet

- E 55L 60Document2 pagesE 55L 60Gustavo Acosta MorenoNo ratings yet

- BPRVDocument18 pagesBPRVPatel UsamaNo ratings yet

- Hypro D50 Service ManualDocument32 pagesHypro D50 Service Manualjimi9488No ratings yet

- Type 1805P Pilot-Operated Relief ValveDocument8 pagesType 1805P Pilot-Operated Relief ValveJOMAGUESNo ratings yet

- Eep D2 1842 1843 24856 24857 002 PDFDocument1 pageEep D2 1842 1843 24856 24857 002 PDFDanny SánchezNo ratings yet

- Cabling Standard - ANSI-TIA-EIA 568 B - Commercial Building Telecommunications Cabling StandardDocument62 pagesCabling Standard - ANSI-TIA-EIA 568 B - Commercial Building Telecommunications Cabling StandardJosé Luis Arévalo100% (1)

- Eep D2 1842 1843 24856 24857 006Document1 pageEep D2 1842 1843 24856 24857 006Danny SánchezNo ratings yet

- Fe 101aDocument1 pageFe 101aDanny SánchezNo ratings yet

- Product Bulletin Fisher 3582 3582i Positioners 582i Electro Pneumatic Converter en 124122Document12 pagesProduct Bulletin Fisher 3582 3582i Positioners 582i Electro Pneumatic Converter en 124122Sakthi Sekar CbiNo ratings yet

- 4200004589-DE-HD-01-001-R0-Fuente Respaldo UPSDocument9 pages4200004589-DE-HD-01-001-R0-Fuente Respaldo UPSDanny SánchezNo ratings yet

- Arranque y Sincronización EasyGenDocument31 pagesArranque y Sincronización EasyGenDanny SánchezNo ratings yet

- Easygen-3100 and 3200 - P1-P2 - Software Version 1.2102 or Higher - 37532E - WOODWARD® PDFDocument754 pagesEasygen-3100 and 3200 - P1-P2 - Software Version 1.2102 or Higher - 37532E - WOODWARD® PDFpevare100% (3)

- Control Generador Easy GenDocument69 pagesControl Generador Easy GenDanny SánchezNo ratings yet

- Wiring EasyGenDocument67 pagesWiring EasyGenDanny SánchezNo ratings yet

- Modbus Easy GenDocument102 pagesModbus Easy GenDanny SánchezNo ratings yet

- Ingersoll RandDocument56 pagesIngersoll RandDavid Yucra0% (1)

- Eep D1 1842 1843 24856 24857 001Document1 pageEep D1 1842 1843 24856 24857 001Danny SánchezNo ratings yet

- Eep D1 1842 1843 24856 24857 001 PDFDocument1 pageEep D1 1842 1843 24856 24857 001 PDFDanny SánchezNo ratings yet

- Fig. 691 & 691B Full Port Brass Ball: Morrison Bros. Co. Specification SheetDocument1 pageFig. 691 & 691B Full Port Brass Ball: Morrison Bros. Co. Specification SheetDanny SánchezNo ratings yet

- Mvi56 Hart User ManualDocument171 pagesMvi56 Hart User ManualDanny SánchezNo ratings yet

- Ingersoll RandDocument56 pagesIngersoll RandDavid Yucra0% (1)

- UPS - Especificaciones TécnicasDocument4 pagesUPS - Especificaciones TécnicasDanny SánchezNo ratings yet

- 246c HidraulicoDocument29 pages246c HidraulicoJose CarmonaNo ratings yet

- SPP-Bomba PRINCIPAL, Mod. TE10D-750@180-CurvaDocument2 pagesSPP-Bomba PRINCIPAL, Mod. TE10D-750@180-CurvaSergio Garcia Alfaro100% (1)

- Design and Modeling of Fluid Power Systems: ME 597/ABE 591 Lecture 12Document22 pagesDesign and Modeling of Fluid Power Systems: ME 597/ABE 591 Lecture 12Elias80No ratings yet

- Katalog Produk General ARITADocument72 pagesKatalog Produk General ARITAanon_969520527No ratings yet

- Tartarini B-249-ApDocument12 pagesTartarini B-249-Apjuan manuel chavezNo ratings yet

- Hydraulic Components: Hydraulic Pumps Hydraulic Motors Cartridge Kits Directional Control Accessories and MORE ValvesDocument6 pagesHydraulic Components: Hydraulic Pumps Hydraulic Motors Cartridge Kits Directional Control Accessories and MORE ValvesAbraham AstudilloNo ratings yet

- Booster Pump CalculationDocument3 pagesBooster Pump CalculationYe Myat Thu93% (14)

- SFVL & DSVL Data Sheet RD7FE102 PDFDocument8 pagesSFVL & DSVL Data Sheet RD7FE102 PDFLuciano CaireNo ratings yet

- Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaDocument17 pagesFakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakasyukzzNo ratings yet

- Pipe Sizes and DimensionsDocument10 pagesPipe Sizes and DimensionsAbuAhmedQuaziNo ratings yet

- Piping CalculationsDocument19 pagesPiping CalculationskakoullisgNo ratings yet

- General Piping System Part4Document8 pagesGeneral Piping System Part4ReadersmoNo ratings yet

- Bomba Active ChecklistDocument6 pagesBomba Active ChecklistPerwira Khusairi RahmanNo ratings yet

- Manpower Deployment Plan Ot2499Document1 pageManpower Deployment Plan Ot2499becemNo ratings yet

- PSDV-11803 Installation Procedure - Rev.b (Per Cms Comment)Document3 pagesPSDV-11803 Installation Procedure - Rev.b (Per Cms Comment)IsaalexNo ratings yet

- Hydraulics - Assignment 1Document3 pagesHydraulics - Assignment 1Jhett100% (1)

- HovalDocument46 pagesHovalCristina OisteNo ratings yet

- VVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVDocument2 pagesVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVFernandoNo ratings yet

- LP GasDocument158 pagesLP GasRaulNo ratings yet

- Fdocuments - in 35-22-02 Rev 2pdfDocument50 pagesFdocuments - in 35-22-02 Rev 2pdfqwertyxyz123789100% (1)

- Manual T10A3 BDocument37 pagesManual T10A3 BRonald EsquivelNo ratings yet

- ShinJin Hydrotec-Tonners Is Specialized in Manufacturing Various Hydraulic Tools and Equipment in Korea and Is Now Trying To Enter The Global MarketDocument2 pagesShinJin Hydrotec-Tonners Is Specialized in Manufacturing Various Hydraulic Tools and Equipment in Korea and Is Now Trying To Enter The Global MarketPR.comNo ratings yet

- API - Valve STDDocument3 pagesAPI - Valve STDRL SanNo ratings yet

- M320 Excavator Hydraulic System - Attachment: Item Component NoDocument2 pagesM320 Excavator Hydraulic System - Attachment: Item Component NoLhsan Rajawi100% (1)

- Hydraulic Separation CaleffiDocument20 pagesHydraulic Separation CaleffibaxxieNo ratings yet

- Caleffi 3-Way Mixing Valves 521 Installation ManualDocument8 pagesCaleffi 3-Way Mixing Valves 521 Installation Manuale-ComfortUSANo ratings yet

- MP 0023Document4 pagesMP 0023Loren ViejayNo ratings yet

- Datasheet PSV PDPDEDocument8 pagesDatasheet PSV PDPDERicardo NapitupuluNo ratings yet

- Libro 2Document1 pageLibro 2Pablo EduardoNo ratings yet

- Centrifugal Pump - Working Principle, Main PartsDocument13 pagesCentrifugal Pump - Working Principle, Main Partsrishabh tomarNo ratings yet