Professional Documents

Culture Documents

The Seven Keys To World-Class Manufacturing

Uploaded by

Sherif El-SherifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Seven Keys To World-Class Manufacturing

Uploaded by

Sherif El-SherifCopyright:

Available Formats

WHITE PAPER

The Seven Keys to World-Class Manufacturing

Manufacturers are facing more challenges than ever: global competition, regulatory policies, and rising customer expectations, just to name a few. Some see these challenges as obstacles. But world-class manufacturers see them as opportunities to differentiate and distance themselves from their competition. What does it mean to be a world-class manufacturer? World-class manufacturers consistently deliver results that place them in the top 25th percentile of their industries, and they achieve this by continuously examining business processes; aggressively applying solutions to improve in key areas; measuring themselves on financial and operational metrics; and focusing on success. They are successful in their chosen market against any competition regardless of size, country of origin, or resources. They are able to match or exceed any competitor on quality, lead-time, flexibility, cost/price, customer service, and innovation. They know how to pick their battles, competing where and when they choose and on terms that they dictate. They are in control and their competitors struggle to emulate their success. How can your company become and remain world class? There are seven keys to becoming a world-class manufacturer that distill the broad concepts above into

specific actions that can be addressed and accomplished in your company. When manufacturers excel in these areas, they strengthen their core competencies - and outmatch the competition. Each of the seven keys is presented with a brief discussion and examples of its impact on a manufacturing organization and its competitiveness. A more detailed whitepaper discussion each individual key is also available from MAPICS, Inc. The keys to success, in no particular order, are: Reduce Lead Times Cut Operations Costs Improve Business Performance Visibility Speed Time-to-Market Exceed Customer Expectations Streamline Outsourcing Processes Manage Global Operations Each of these objectives is important in and of itself; however, taken together, they describe the focus of the activities and attitudes that define world class.

www.mapics.com

Reduce Lead Times

Metronic Sofamor Danek cut lead times for internally manufactured products down 42 percent.

Shorter lead times are always a good thing. In many markets, the ability to deliver sooner will win business away from competitors with similar product features, quality and price. In other markets, quick delivery can justify a premium price and will certainly enhance customer satisfaction. In all cases, shorter lead times increase flexibility, reduce the need for inventory buffers, and lower obsolescence risk. Lead times are cumulative and bi-directional that is, order handling, planning, procurement, inspection, manufacturing, handling, picking, packing and delivery all contribute to lead times; and the time it takes to get signals down the supply chain to initiate each activity adds to the overall time it takes to get the job done. Business rules and policies can drive undesired effects. Purchasing rules too focused on unit cost lead to large quantity buys that result in high inventory and long lead times. Ironically, this type of buying can also lead to shortages, since longer lead times mean you will be making and buying to a more inaccurate forecast. The best combination of price and lead time often comes from a stable buyer-supplier relationship based on long term contracts with deliveries according to a forecast that is shared with the supplier and updated frequently. The same is true on the customer side. Instead of focusing on securing large, one-time, single orders that clog up the supply chain, companies must focus on creating long term contracts and sharing forecast information with customers to reduce lead times. The same issues concerning large lot sizes also apply to internally produced parts and products. Large lots, driven by a focus on lowest unit cost, raise inventory and lengthen lead times while reducing flexibility and responsiveness, increasing eventual cost through premium expediting instead of using large fixed lots. Companies must dynamically adjust the lot size based

on market demand, product mix and capacity. Ongoing continuous improvement efforts focused on reducing setup times can help companies reduce lot sizes, which provides flexibility in responding to market demand. Appropriate measurements contribute to high performance on the plant floor. On-time shipment and inventory turns are good examples of high-level measures that tie to company objectives. Focusing on isolated measurements like equipment utilization on nonconstraining resources encourages "busy work" that creates excess inventory and longer lead-times. Shop floor measurements must encourage overall performance shipping orders on time at minimal total cost and minimal total cycle times. Performing manual transactions often slows down the supply chain and adds to lead times. Reporting transactions at each operation or creating a paper purchase order before suppliers work on a component are just two examples. In addition, manual transaction reporting often introduces errors and impacts work productivity. Companies must eliminate non-value add transactions and automate transactions to speed up the supply chain. For example, back flushing can be used on the shop floor, and supplier purchase orders can be electronically sent or completely eliminated using VMI programs.

Cut Operations Costs

Olson International reduced the time it takes to produce their plant work schedule from 3 days to a few hours.

Although recent developments in planning and customer relationship management have focused more on top-line benefits (increased revenue), the bottom line is still greatly dependent on controlling costs. Companies with a lower operational cost structure enjoy an obvious advantage in profitability and the ability to adjust pricing to meet competitive pressures if necessary to maintain or gain market share.

2 The Seven Keys to Wold-Class Manufacturing

www.mapics.com

Costs are really just part of the scoreboard. When a company implements world-class operational processes, it improves multiple measurements simultaneously, including cost, lead times, inventory, and customer service. This approach contrasts with a pure cost reduction focus without associated business process change, which can negatively impact other operational measurements. Localized cost reduction efforts can often increase costs in other areas. Moving production overseas to an area with lower labor rates, for example, will increase costs for procurement, transportation, inventory and reduced flexibility, among others. The relative cost of source/make/deliver and therefore the opportunities for cost reduction will vary with the industry that the manufacturer is in and the kind of products the manufacturer makes. Most manufactured products today have relatively little direct labor content, generally less than 20% and often less than 10%, whereas the material content of most products is more than half of cost-of-goods sold (COGS). The rest is "overhead." Since most direct labor costs tend to be fixed, effective deployment of these resources can reduce unplanned manufacturing overtime, premium expediting, and outsourcing in addition to dramatically reducing cycle times. Since material cost is the dominant cost, significant opportunities exist in reducing this cost by analyzing current spending and

Additionally, fulfillment costs do not receive as much attention as they deserve; inventory costs, transportation, and storage account for a significant part of the cost of doing business. Fortunately, improving customer service can also generate cost benefits at the same time.

Improve Business Performance Visibility

Club Car provides their worldwide network with real-time access to critical business transactions & relevant information.

Today's fast-moving, ever-changing manufacturing environment demands faster responsiveness to changes in the market, product innovation, and tight supply chain management. In this environment, ignorance is one of the greatest threats to a manufacturing company's health and success. Executives and senior managers must understand how the enterprise is meeting strategic objectives. Middle-level managers need visibility into how they are performing against tactical objectives. Responsible individuals must be notified immediately when supply chain issues threaten the completion of objectives, so actions can be taken to ensure customer delivery and quality requirements continue to be met. A well-implemented and effective enterprise information system delivers overall visibility into the health of the company and its operations and provides detailed information for performance measurement, process management, and problem identification and remediation. Such a system can help improve revenue through competitive advantage, can help you understand your business and manage it better, reduce operational costs, improve performance, and improve results for all stakeholders owners, executives, managers and employees. An enterprise information system will capture literally thousands of pieces of information each day, as activities are reported throughout the enterprise. All of this detailed data is of little use without placing it in context and seeing each activity in relationship with all the other activities and the overall plan. Turning data into meaningful information is an up-and-down process.

Typical manufacturers profit margins average under 1%. Profit margins for their world-class counterparts average over 4.5%. For a US $500M manufacturer this translates into over $20M in shareholder value annually.

devising effective sourcing strategies for material. Overhead reduction is always a fertile area for cost reduction, using automation to streamline the procurement, manufacturing, and customer management processes.

3 The Seven Keys to World-Class Manufacturing

www.mapics.com

Bits of data, taken together and summarized, form higher level contextual information that shows status, accomplishments, and importance. From high-level summaries, the observer must be able to dive back down to details to understand exactly what is happening and how to drive those activities toward the goals and objectives. Management information and analysis is only as good as the data it is based on. Therefore, it is important to make sure that data is collected as quickly as possible and with the least amount of human intervention, which tends to introduce delays and errors. It is equally important to use automation as much as possible for collecting data from supply chain partners. Electronic Data Interchange (EDI) is the most commonly used method today, but EDI is rapidly being replaced by XML-based e-commerce communications and Web-based portal technologies. All systems should be integrated so information can pass freely between them without manual re-entry. Over the years, many manufacturers have been left with "islands of automation" after implementation of specialized information systems in isolated portions of the business. While each island contains valuable information, absence of integration prevents the effective use of that information for overall management and coordination of effort toward company objectives.

improvements, corrections, and variations throughout the product lifecycle. Market research, customer requests, technological advances, regulatory concerns, and competitive pressures often subject products to frequent engineering changes.

Typical manufacturers generate US $134,000 in revenue per employee. Worldclass manufacturers average US $189,000, or 41% more revenue per employee.

Changes and improvements are easiest to make and least costly and disruptive earlier in the process. It is good business practice to collaborate with all operational areas of the business when the product and process is still being designed. Cooperation should be focused on making sure the new product meets market needs (marketing and sales), is priced to sell and generate a profit (marketing and accounting), can be manufactured efficiently (production, production engineering, quality, purchasing and key suppliers), and can be maintained and serviced (service). Because customer expectations are increasing, and competition is coming from new players around the world, bringing better and cheaper products to market quickly is more crucial than ever. Research and development is a key success factor in a manufacturer's survival and growth. Efficiency and responsiveness of

Speed Time-to-Market

Day-Brite Capri Omega increased inventory turns from 9 to 20.

Developing and introducing new products and services is vital to most manufacturing companies. Good ideas are not enough; well-managed processes for bringing new products to market can lead to significant competitive advantages. Those activities, however, represent a significant risk that can lead either to missed opportunities or to huge financial losses. In addition to new product development, the same processes and resources are applied to product

R&D processes will impact the top line as well as the bottom line. Customers are now quick to compare and switch vendors. The Internet empowers buyers by providing fingertip access to many more suppliers around the globe; they can even customize products over the Internet without having to ask an engineer to quote their specific requirements. These capabilities change behaviors and expectations, and success in today's markets can only be achieved through innovation, agility and aggressive marketing.

4 The Seven Keys to World-Class Manufacturing

www.mapics.com

Arguably, the most important aspect of customer service

Exceed Customer Expectations

Hartzell Propeller experienced 34 months of 100 percent ontime delivery of vehicles.

The ultimate key to success in any business enterprise is to please your customers. The most successful companies don't just meet customer expectations they exceed them and beat the competition by setting the bar at a level that makes it difficult if not impossible for others to surpass. Successful manufacturers manage the entire customer relationship from prospect to postsales service and support involving the entire organization in a customer focus. Whether or not they have direct contact with the customer, contributors must keep the customers' needs in mind as they plan and carry out day-to-day operations. It's important to truly understand the customer's goals and objectives. Your products and services must strive to support the customer's vision. Communication is very important, because neglect is the number one reason that customers terminate a relationship. The key is to give customers access to all appropriate information about your relationship and make it readily available whenever and wherever they might need; the Web is your ally in achieving this objective. As most companies have painfully learned in recent years, customers often change their mind. To be fair, market conditions are such that product cycles and demand patterns are constantly changing. Agility is extremely important. A solid, collaborative partnership with customers will provide you with the most reliable, advanced information and, therefore, the earliest warning of upcoming changes. In short, the best strategy is to make the customer want to do business with you. Strive to be the preferred supplier through competitive products, high quality, the right price and superior customer service.

is on-time performance. There are two sides to on-time delivery: promising a realistic date; then delivering on that promise. It is imperative that you take that promise seriously, meaning that it is not given lightly all considerations and constraints are factored in before committing to a delivery date. Performance measurements are a must; if you don't know how you are performing, you cannot improve upon it. It is not unusual for companies to consistently have 98% - 99% success in meeting agreed-to shipment dates. Quality must be considered a given. Work with your customers and engineering as early as possible in the product development cycle to determine the required measurements. Measuring and improving all processes through the order and fulfillment cycles, with an eye toward continuous improvement, will allow you to achieve or even surpass expectations.

Streamline Outsourcing Processes

Tactical Vehicle Systems reduced cycle times from 80-90 days to 10-12 days.

Outsourcing of manufacturing operations is a common practice today because it offers flexibility the ability to change products or processes rapidly and can often save money by exploiting economies of scale or other favorable cost factors the contractor has to offer. There are two approaches to outsourcing: a single process step or group of steps may be performed by an outside resource heat treating, for example, or electroplating or the entire manufacturing process might be contracted out to a third party. In either case, the manufacturer relieves demand on its own plants and has an opportunity to concentrate on its core competencies (which might not include volume manufacturing), while its partner(s) provide the resources for producing products.

5 The Seven Keys to World-Class Manufacturing

www.mapics.com

Depending upon your current resources and circumstances, outsourcing a part of the manufacturing process could save you from having to expand your manufacturing space (perhaps even adding a new plant), searching for and hiring experienced resources, training the new hires, and incurring various costs involved in ramping up a new production line or process. Capital assets can become a liability in a fast-changing marketplace. As customer demands and technologies change the nature and makeup of products, it can be an advantage to not be tied to a relatively inflexible physical plant. For companies large and small, the goal is to become a world-class organization and to be able to compete in today's global markets. For manufacturers, the fastest and easiest way to achieve this goal is through partnerships with companies that have attained superior capabilities in particular phases of the process like production. By partnering with world-class contract manufacturers you can reap the benefits almost immediately well-managed processes, high quality, on time deliveries and increase your performance and delivery to meet your customers' expectations. At the same time, you can focus your own resources on the things that you do best product innovation, design, marketing, distribution, sales or manufacturing.

opportunity. If you tend toward the half-empty-glass point-of-view, you are likely to see significant threats in virtually unlimited competition from literally any place on earth.

Typical manufacturers turnover their inventories just over six times per year. World-class manufacturers turnover their inventories ten times per year.

Like it or not, every executive must recognize this new reality and factor global business into plans, processes and strategies. Design products to appeal to international markets. Search for suppliers in other geographies. Understand local regulations and expectations, import/export processes, and requirements. Consider language challenges in labeling, documentation, and marketing. Establish new sales channels or coordinate manufacturing operations across geographies and time zones. The Internet is a key tool for joining the global business community and conducting business around the globe. Globalization and e-commerce have changed traditional business behaviors and practices. If manufacturers don't expand into new geographic markets, their market share is likely to shrink as new competitors will be entering their own territory and targeting their historical customers. Companies must

Manage Global Operations

Tactical Vehicle Systems reduced cycle times from 80-90 days to 10-12 days.

There's no question the world is shrinking, and virtually every business is now involved in some form of international trade whether marketing and selling to customers in other countries or simply using parts or materials that are produced elsewhere. We can thank the Internet (or blame the Internet if you prefer) for opening markets to products and services almost without regard to time and distance. The "glass-is-half-full" crowd will view these developments as the onset of unlimited

adapt their products and services to those new potential customers. They must leverage the Internet to quickly establish a virtual presence. They must use collaborative technology in order to respond to customer's requirements better and faster. Manufacturers often grow and enter new markets by acquiring or merging with other companies. This usually means, however, that different facilities within the newly merged enterprise are using different systems on different hardware platforms. They might have different part numbers for the same items, and operating procedures are undoubtedly different. The challenge is

6 The Seven Keys to World-Class Manufacturing

www.mapics.com

MAPICS, Inc.

1.888.3MAPICS

1.770.886.4058 (Outside the U.S.)

to bring as much uniformity to the varied facilities as practical without destroying the uniqueness and competitive edge that the individual units displayed before the merger. The new divisions have to communicate, exchange many kinds of data (product information, customers, suppliers, employees, etc.), coordinate and synchronize logistics operations, provide visibility on materials and components requirements, optimize fixed assets utilization across multiple facilities, consolidate financials, and much more. A natural consequence of having operations scattered through multiple locations whether around the world or in a specific region is the need to gain visibility across all sites. Visibility can lead to more negotiating power for purchased parts, more efficient centralized credit and collections and accounts payable, and opportunities for improved customer service by having (information) access to world-wide inventories and production capabilities.

additional products and uses that may arise in the future. This practice is even more important with an information system because the handling and use of information is changing faster than any other technology on the planet. And, remember that information management is a fundamental support for each and every one of the keys to world-class performance. When looking at enterprise systems or supply chain systems (whichever term you prefer), some people tend to get distracted by details of the technology and miss the bigger picture. Keep in mind the reasons you are looking for a system in the first place to provide tools to manage the information that is essential to effective business management. And that's the application software, not the hardware or operating system. On the technology side, you only have to ensure, as much as you can, that the equipment is capable of supporting your business needs today and in the foreseeable future, and that the supplier(s) will be around when you need them. Of course, no one knows the future, but you can certainly improve your odds with careful selection. Connectivity and interoperability (for data communications, supply chain collaboration and workflow messaging) are important issues that are reliant on underlying technology; however, any and all mainstream technologies today are fully capable of participating in these kinds of connections. In addition, many industry groups are working hard to develop and publish neutral standards, guidelines and protocols that will link disparate systems and further enable the connectivity that is so vital to supply chain collaboration and interaction. Information-enabled collaboration and coordination are what makes a supply chain work. The keys to world-class manufacturing leverage information to generate cost savings, efficient operations and responsiveness, superior customer service, and well-managed resources no matter where they are located or how complex your facilities and relationships might be.

Unlocking the Potential

The keys to becoming a world-class manufacturer are not a secret they are not even especially profound. They are simply a distillation of the experiences of leading companies and how they have managed to excel in their chosen markets. Any company can take advantage of the wisdom and the practices developed in more than a hundred years of manufacturing since the Industrial Revolution, but many simply do not have the insight or the will to recognize what must be done and to accomplish it. It is a poor workman who blames his tools for shoddy work, but it is also true that professionals understand the value of good tools and insist on having and using the best whenever possible. When selecting a production machine a machining center, insertion machine, automated assembly line or robot you would certainly look for one that can handle the tasks you have in mind, but also one that is flexible enough to adapt to

7 The Seven Keys to World-Class Manufacturing

www.mapics.com

Being world class is all about being as good as any competitor in the world, and just a little bit better, quicker, smarter, or more responsive than the rest. Worldclass manufacturers can choose their battles and compete on their own terms. They are in control of their own destiny and are seldom, if ever, blindsided by something they haven't anticipated or cannot handle. World-class manufacturers use information as a strategic tool for becoming and remaining the best they can be.

MAPICS is a visionary, global software company focused exclusively on delivering collaborative business applications and expert consulting services that help manufacturers become world class. Copyright 2004 MAPICS, Inc. MAPICS is a registered trademark of MAPICS, Inc. All other brand and product names may be trademarks of their respective owners. MPWPCUST

8 White Paper Title

www.mapics.com

MAPICS, Inc.

1.888.3MAPICS

1.770.886.4058 (Outside the U.S.)

You might also like

- How Does Operations Strategies Help A Business Sustain Its Competitive Advantage andDocument5 pagesHow Does Operations Strategies Help A Business Sustain Its Competitive Advantage andKrishna Kannan100% (1)

- The Technology Procurement HandbookDocument329 pagesThe Technology Procurement HandbookAlexander Jose Chacin NavarroNo ratings yet

- Cost Reduction StrategiesDocument10 pagesCost Reduction StrategiesmeetsarkarNo ratings yet

- Full Download Solution Manual For Operations Management 13th Edition PDF Full ChapterDocument6 pagesFull Download Solution Manual For Operations Management 13th Edition PDF Full Chapterdewdrop.threat.7ia4yn100% (17)

- Justification of ERP Part1Document5 pagesJustification of ERP Part1faizal rizkiNo ratings yet

- The Essential Guide To Inbound Freight Management EbookDocument42 pagesThe Essential Guide To Inbound Freight Management EbookTonatiuh de la TorreNo ratings yet

- Cooper, Slagmulder - 1998 - The Scope of Strategic Cost ManagementDocument2 pagesCooper, Slagmulder - 1998 - The Scope of Strategic Cost ManagementEric FerreiraNo ratings yet

- Skirmishes Graham Harman PDFDocument383 pagesSkirmishes Graham Harman PDFparaiaNo ratings yet

- OPENING & CLOSING PROGRAM NARRATIVE REPORT (Grade 7)Document4 pagesOPENING & CLOSING PROGRAM NARRATIVE REPORT (Grade 7)Leo Jun G. Alcala100% (1)

- The Seven Keys For World Class ManufacturingDocument6 pagesThe Seven Keys For World Class ManufacturingJackrobin Vc JNo ratings yet

- Creating QRM EnterprisesDocument6 pagesCreating QRM EnterprisesMohamed YassinNo ratings yet

- BWP SRM GlanceDocument20 pagesBWP SRM GlancemikejudNo ratings yet

- Act WCMDocument15 pagesAct WCMManoj MathurNo ratings yet

- Institutional Strategy For Operations, Logistics and Supply Chain of RID Projects Within The University.Document9 pagesInstitutional Strategy For Operations, Logistics and Supply Chain of RID Projects Within The University.Laimi MutikishaNo ratings yet

- Manage Inventory To Meet Profit Goals: Getting Smart About InventoryDocument5 pagesManage Inventory To Meet Profit Goals: Getting Smart About Inventorykuko12No ratings yet

- Role of Suppliers in Supply Chain Management: Identifying Performance OpportunitiesDocument5 pagesRole of Suppliers in Supply Chain Management: Identifying Performance OpportunitiesRaja NatarajanNo ratings yet

- Case 7Document4 pagesCase 7Viễn Nguyễn KýNo ratings yet

- Vendor Managed Inventory (Vmi)Document10 pagesVendor Managed Inventory (Vmi)France ParodiNo ratings yet

- Decision EngineeringDocument7 pagesDecision EngineeringutorrentNo ratings yet

- Strategic Development in Hospitality: Lesson 1Document26 pagesStrategic Development in Hospitality: Lesson 1Yeunna LaurenNo ratings yet

- Le. Eg. Class Notes, Research Papers, Presentations...Document4 pagesLe. Eg. Class Notes, Research Papers, Presentations...isuru anjanaNo ratings yet

- Sales Forecasting: Just in TimeDocument5 pagesSales Forecasting: Just in TimeRitika AgrawalNo ratings yet

- 2A VMI Kellogg ReportDocument12 pages2A VMI Kellogg ReportPrafull MalviyaNo ratings yet

- Supply Chain Management Term Paper TopicsDocument5 pagesSupply Chain Management Term Paper Topicsafmzynegjunqfk100% (1)

- Module 1 (Introduction To Strategic Operations Management)Document5 pagesModule 1 (Introduction To Strategic Operations Management)Jayzell MonroyNo ratings yet

- Peration ManenemtDocument8 pagesPeration ManenemtCool BuddyNo ratings yet

- Ibm Unit - 4Document15 pagesIbm Unit - 4Aishwarya SairamNo ratings yet

- 19mbaj0190 Sri Sai Aditya Sec D Activity 1Document5 pages19mbaj0190 Sri Sai Aditya Sec D Activity 1YASEEN AKBARNo ratings yet

- The Order To Delivery Cycle: Quick Response Is Essential: Cause and EffectDocument4 pagesThe Order To Delivery Cycle: Quick Response Is Essential: Cause and EffectjustingordanNo ratings yet

- 5 Ways For Lead Time ReductionDocument5 pages5 Ways For Lead Time ReductionYamini ShamiNo ratings yet

- Lecture 10 Collaborative Product DevelopmentDocument12 pagesLecture 10 Collaborative Product DevelopmentkanjanaNo ratings yet

- Memo 709 v2013Document11 pagesMemo 709 v2013WesleyNo ratings yet

- Supply Chain Performance: The Supplier's Role: Executive Brief Industry Directions Inc. March 2005Document6 pagesSupply Chain Performance: The Supplier's Role: Executive Brief Industry Directions Inc. March 2005Himura SanzouNo ratings yet

- Solution Manual For Operations Management 13th EditionDocument36 pagesSolution Manual For Operations Management 13th Editiongowdie.mornward.b50a100% (48)

- Lean Accounting VGDocument11 pagesLean Accounting VGpeter358No ratings yet

- Demand Management:: Customize Products Through The Use of Product Completion CentersDocument13 pagesDemand Management:: Customize Products Through The Use of Product Completion CentersGabriela CándanoNo ratings yet

- Supply Chain Management and The Catalytic Role of The Management AccountantDocument7 pagesSupply Chain Management and The Catalytic Role of The Management Accountantvb_krishnaNo ratings yet

- Unit I Lesson 9 - Strategic Analysis: Management Information SystemsDocument13 pagesUnit I Lesson 9 - Strategic Analysis: Management Information Systemsriya_8No ratings yet

- Hitachi Key IssuesDocument12 pagesHitachi Key IssuesKirti SrivastavaNo ratings yet

- AdmmDocument5 pagesAdmmHarshi AggarwalNo ratings yet

- Five Differences Between Service and Manufacturing OrganizationsDocument6 pagesFive Differences Between Service and Manufacturing Organizationsullaschaudhari100% (3)

- SC MGT - Supply Chain Management in Hospitality Industry (PRELIM NOTES)Document13 pagesSC MGT - Supply Chain Management in Hospitality Industry (PRELIM NOTES)chloekent loreNo ratings yet

- Bottlenecks in Procurement ProcessDocument8 pagesBottlenecks in Procurement ProcessSarath MNo ratings yet

- A Simpler Way To Modernize Your Supply ChainDocument7 pagesA Simpler Way To Modernize Your Supply Chainquad111No ratings yet

- A Discussion of Order Winning CriteriaDocument7 pagesA Discussion of Order Winning CriteriaVivek ShuklaNo ratings yet

- Operation ManagementDocument4 pagesOperation ManagementHananiya GizawNo ratings yet

- Orgl 3321 - Artifact - Business Research Reduce Cost and Improve Profit v2Document8 pagesOrgl 3321 - Artifact - Business Research Reduce Cost and Improve Profit v2api-632483826No ratings yet

- A Simpler Way To Modernize Your Supply ChainDocument23 pagesA Simpler Way To Modernize Your Supply ChainragerahulNo ratings yet

- WP-Inventory Rationalization Right Sizing StrategiesDocument6 pagesWP-Inventory Rationalization Right Sizing StrategiesManoj SharmaNo ratings yet

- BCG Time Paradigm Jan1988Document3 pagesBCG Time Paradigm Jan1988anahata2014No ratings yet

- Assignment Report ON: " " (451) Unit - IiiDocument13 pagesAssignment Report ON: " " (451) Unit - IiiRobin GanjooNo ratings yet

- Working Capital InventoryDocument3 pagesWorking Capital InventoryKrishna SinghNo ratings yet

- Cost Analysis Through Life Cycle Analysis and Target CostingDocument35 pagesCost Analysis Through Life Cycle Analysis and Target CostingSunny KhsNo ratings yet

- Configurator White PaperDocument16 pagesConfigurator White Papermehul3685No ratings yet

- Bussiness Process Management Chapter 1 ResumeDocument8 pagesBussiness Process Management Chapter 1 ResumexcavoxNo ratings yet

- Vendor Managed InventoryDocument3 pagesVendor Managed InventoryHarshal BadheNo ratings yet

- Master of Business Administration - MBA Semester 2 MB 0044 - Production and Operation Management (4 Credits) (Book ID:B1627) AssignmentDocument8 pagesMaster of Business Administration - MBA Semester 2 MB 0044 - Production and Operation Management (4 Credits) (Book ID:B1627) AssignmentVikas WaliaNo ratings yet

- Assignment: 1 Submitted By: Sagar Arora A00118051 Submitted To: Prof. Chetan PagareDocument6 pagesAssignment: 1 Submitted By: Sagar Arora A00118051 Submitted To: Prof. Chetan PagareSharry AroraNo ratings yet

- Production Management Set1 and Set2Document40 pagesProduction Management Set1 and Set2Shiva PrakashNo ratings yet

- VMI in Apparel Manufacturing: Concept Note: 1Document6 pagesVMI in Apparel Manufacturing: Concept Note: 1Priyanka JanaNo ratings yet

- Operations Management Gyan CapsuleDocument6 pagesOperations Management Gyan CapsuleAnandbabu RadhakrishnanNo ratings yet

- Vendor Managed Inventory Research PaperDocument4 pagesVendor Managed Inventory Research Papersoezsevkg100% (1)

- Lean-based Production Management: Practical Lean ManufacturingFrom EverandLean-based Production Management: Practical Lean ManufacturingNo ratings yet

- Conflict Management A Practical Guide To Developing Negotiation Strategies Barbara A Budjac Corvette Full ChapterDocument67 pagesConflict Management A Practical Guide To Developing Negotiation Strategies Barbara A Budjac Corvette Full Chapternatalie.schoonmaker930100% (5)

- 2011 Burris CatalogDocument56 pages2011 Burris CatalogMario Lopez100% (1)

- (14062020 0548) HF Uniform Logo GuidelinesDocument4 pages(14062020 0548) HF Uniform Logo GuidelinesBhargaviNo ratings yet

- EEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinDocument6 pagesEEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinAaa AaaNo ratings yet

- 5 Grade: Daily MathDocument130 pages5 Grade: Daily MathOLIVEEN WILKS-SCOTT100% (3)

- Biography Worksheet: Name: Gerardo Angeles MartinezDocument1 pageBiography Worksheet: Name: Gerardo Angeles MartinezAlejandro AngelesNo ratings yet

- All Worksheets MYSQLDocument33 pagesAll Worksheets MYSQLSample1No ratings yet

- Combinational Logic-Part-2 PDFDocument25 pagesCombinational Logic-Part-2 PDFSAKSHI PALIWALNo ratings yet

- Practice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDDocument8 pagesPractice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDMarc Stanley YaoNo ratings yet

- Void Engineers (Convention: Mage The Ascension)Document6 pagesVoid Engineers (Convention: Mage The Ascension)Beth0% (1)

- Mathematics4 q4 Week4 v4Document11 pagesMathematics4 q4 Week4 v4Morales JinxNo ratings yet

- MGNM801 Ca2Document19 pagesMGNM801 Ca2Atul KumarNo ratings yet

- 00.diesel Engine Power Plant Design PDFDocument4 pages00.diesel Engine Power Plant Design PDFmardirad100% (1)

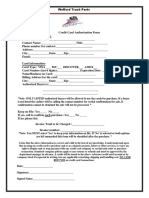

- Credit Card Authorization Form WoffordDocument1 pageCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaNo ratings yet

- Libherr CraneDocument157 pagesLibherr Craneali67% (3)

- The 5 Pivotal Paragraphs in A PaperDocument1 pageThe 5 Pivotal Paragraphs in A PaperFer Rivas NietoNo ratings yet

- Solutions of Inverse Geodetic Problem in Navigational Applications PDFDocument5 pagesSolutions of Inverse Geodetic Problem in Navigational Applications PDFLacci123No ratings yet

- Effect of Minor and Trace Elements in Cast IronDocument2 pagesEffect of Minor and Trace Elements in Cast IronsachinguptachdNo ratings yet

- Bombas KMPDocument42 pagesBombas KMPReagrinca Ventas80% (5)

- DAY 3 STRESS Ielts NguyenhuyenDocument1 pageDAY 3 STRESS Ielts NguyenhuyenTĩnh HạNo ratings yet

- Swenson 1 Dan Swenson Printing Press: Part One (Timeline)Document6 pagesSwenson 1 Dan Swenson Printing Press: Part One (Timeline)Dan SwensonNo ratings yet

- 1.2 The Basic Features of Employee's Welfare Measures Are As FollowsDocument51 pages1.2 The Basic Features of Employee's Welfare Measures Are As FollowsUddipta Bharali100% (1)

- KSP Solutibilty Practice ProblemsDocument22 pagesKSP Solutibilty Practice ProblemsRohan BhatiaNo ratings yet

- Dissertation MA History PeterRyanDocument52 pagesDissertation MA History PeterRyaneNo ratings yet

- 2011 Frequency AllocationsDocument1 page2011 Frequency Allocationsculeros1No ratings yet

- 74 Series Logic ICsDocument6 pages74 Series Logic ICsanon-466841No ratings yet

- Swot Matrix Strengths WeaknessesDocument6 pagesSwot Matrix Strengths Weaknessestaehyung trash100% (1)