Professional Documents

Culture Documents

Relay Block PDF

Uploaded by

Japheth K. KiptooOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Relay Block PDF

Uploaded by

Japheth K. KiptooCopyright:

Available Formats

This Datasheet for the

IC660BBR101

Block Relay Output Normally Open 16 Circuits http://www.qualitrol.com/shop/p-14438-ic660bbr101.aspx Provides the wiring diagrams and installation guidelines for this GE Series 90-30 module.

For further information, please contact Qualitrol Technical Support at 1-800-784-9385 support@qualitrol.com

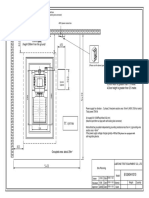

16-Circuit Relay Output Block

June 2002 GFK-0038E

Description ____________________________________

Relay Output blocks provide 16 output circuits in four independent groups of four relay-type outputs each. The block power may be either 115V or 230V AC. There are two types of Relay Output blocks: Normally-Closed Relay Output Block (IC66*BBR100), Normally-closed contacts Normally-Open Relay Output Block (IC66*BBR101), Normally-open contacts Relay blocks are compatible with a wide range of low-power control and indicating devices such as relays, contactors, and lamps. Output devices may operate in the range of 5V to 250V AC or 5V to 220V DC, and switch up to 60 Watts or 125 VA.

Specifications _________________________________

Catalog Number

Output Block, NormallyClosed Relays Electronics Assembly Terminal Assembly Output Block, NormallyOpen Relays Electronics Assembly Terminal Assembly IC66*BBR100 IC66*EBR100 IC66*TBR100 IC66*BBR101 IC66*EBR101 IC66*TBR101 8.83 (22.44cm) x 3.34 (8.48cm) x 3.91 (9.93cm) 4 lbs. (1.8 kg) Unit OK, I/O Enabled Individual relay coil state 0 C to +60 C (+32 to +140 F) -40 to +100 C (-40 to +212 F) 5% to 95% (non-condensing) 5-10 Hz 0.2 (5.08mm) displacement, 10-200 Hz at 1G 47-63 Hz (115VAC) 93 to 132VAC; (230VAC) 185 to 265VAC 87mA at 115 VAC 1 cycle 1500 VAC 1500 VAC 1700 VDC 1500 VAC 1700 VDC 1500 VAC 10.1 watts max. with 16 outputs on 2 Amps per circuit 60 Watts or 125 VA 2 Amps per circuit 0.1 mA 20 cycles/minute (inductive loads) 5ms 5V to 250V AC or 5V to 220V DC 10mA

Block Specifications

Size (height x width x depth) Weight LEDs (I/O Block) LEDs (each circuit) Operating temperature Storage temperature Humidity Vibration

Environmental Specifications

Relay Output Normally Open ( 115/230 ) 50/60 Hz

Block Power Specifications

Frequency Operating voltage Power requirement Power supply dropout time

Isolation

All outputs to chassis ground Between output groups Power terminals to chassis ground Power terminals to outputs Comms terminals to power terminals Comms terminals to outputs Heat Dissipation

Output Specifications

Maximum Output current Maximum switching power Maximum inrush current Output OFF leakage current Maximum switching frequency Output turn-on delay (maximum) Output voltage range Minimum recommended load

Features

Each group of four outputs on a Relay Block can be powered by a separate AC or DC source. Group to group isolation is 1500 volts. Block features include: Output powerup defaults Output Hold Last State or default CPU Redundancy type Bus Switching Module control

Relay Specifications

Relay Type Fixed coil moving armature Initial Contact Resistance 100 milliohms, maximum Typical Life: Operating Maximum Current for Load* Type Typical Life Voltage (operations) Resistive Lamp Solenoid 250VAC 0.5A --200,000 250VAC -0.1A 0.1A 100,000 125VAC 1.0A 0.2A 0.3A 100,000 220 VDC 0.3A --100,000 110 VDC 0.6A --100,000 30VDC 2.0A --500,000 30VDC -0.2A 0.3A 100,000 12VDC -0.3A 0.5A 100,000 Effect of Load on Operating Life Operating Current in Load Type Typical Life Voltage (operations) Resistive Lamp Solenoid 250VAC 0.1A --1,500,000 125VAC 0.3A --1,000,000 30VDC 1.0A --2,000,000 12VDC 2.0A --1,000,000 * Lamp loads are defined as a X10 inrush with a power factor (PF) of 1.00; when turned OFF, they represent a PF of 1.00. Solenoids are defined as a X10 inrush with a PF of 0.65; when turned OFF, they represent a PF of 0.35.

Using this Datasheet ____________________________

This datasheet summarizes information about block installation, configuration, and diagnostics. Your primary reference should be the Discrete and Analog Blocks Users Manual. It includes detailed instructions for block installation and configuration. For additional information about systems and communications, including bus specifications, refer to the I/O System and Communications Manual.

Refer to GFK-0867 for product standards and general specifications.

16-Circuit Relay Output Block

June 2002 GFK-0038E

Compatibility ___________________________________

These blocks are compatible with a Hand-held Monitor identified by catalog number IC66*HHM501 only. For an IC697 series PLC, the CPU and programming software must be version 2.0 or later. The Bus Controller must be IC697BEM731C or later. For an IC600 series PLC, the CPU must be rev. 105 or later. For an IC600 Plus series PLC, rev. 110 or later is required. The programming software must be rel. 4.02 or later. For an IC550 series PLC, the CPU must be rev. 3.0 or later. The programming software must be rel. 2.01 or later.

If the block is at either end of the bus, connect a terminating resistor of the appropriate type (see the System and Communications Users Manual for details) across its Serial 1 and Serial 2 terminals.

Start of Bus Terminating Resistor Serial 1 Serial 2 Shield In Shield Out End of Bus Terminating Resistor Serial 1 Serial 2 Shield In Shield Out

Installation Instructions __________________________

Carefully inspect all shipping containers for damage. If any equipment is damaged, notify the delivery service immediately. Save the damaged shipping container for inspection by the delivery service. After unpacking the equipment, record all serial numbers. Save the shipping containers and packing material in case it is necessary to transport or ship any part of the system.

Using a Relay Block as a BSM Controller

A Relay block can be used to control a Bus Switching Module. There are two different BSM versions available. It is important to match the BSM to the type of voltage that will power the blocks outputs. If the voltage will be 24/48 VDC, BSM version IC66*BSM021 is required. If the voltage will be 115 VAC or 125 VDC, IC66*BSM120 is needed instead. Install the BSM at the blocks serial bus terminals, as described in the Bus Switching Module datasheet. Connect the bus cable to the BSM. Connect the BSM wires to the block as explained below.

Block Mounting

Genius I/O blocks are considered "open equipment" and therefore must be installed within a protective enclosure. They should be located in an area that is clean and free of airborne contaminants. There should be adequate cooling airflow. The block can be mounted right side up, or upside down. Leave at least 2 inches of space between blocks. Mount the block by drilling two screw or bolt holes for 8-32 hardware. Position the block so that the notches in the upper and lower flanges line up with the mounting holes. Mount the block using 8-32 screws. Use star washers to provide ground integrity.

Field Wiring

Terminals 5 to 32 are for field devices. They take a single wire up to AWG #14 (avg 2.1mm2 in cross-section). Minimum recommended size is AWG #20 (avg .54mm2 in cross-section). Power for AC loads may come from the block AC power supply or other AC source(s). Power for DC loads may come from one or more DC sources. Each group may use a separate AC or DC source.

NOTE: Make no connections to NC terminals * Voltage per Isolated Group AC: 5 to 250 VAC or DC 5 to 220 VDC 115 VAC set up when shipped from factory

H H J1 J2 N 115 VAC H OR N H J1 J2 N 230 VAC

Grounding

The blocks mounting screws must not be used as the only means of grounding the block. Connect the green ground screw on the block to a reliable ground system using a short wire lead, minimum size AWG #12 (avg 3.3mm2 in cross-section). Warning If mounting screws do not make good ground connection and the ground screw is not connected to a reliable ground, the block is not grounded. Electrical shock hazard exists. Death or personal injury may result.

1 2 3 4

SERIAL 1 SERIAL 2 SHIELD IN SHIELD OUT

Block Wiring ____________________________________

Do not overtorque the terminal screws. Recommended torque for all terminals is 6 in/lb (.678 N/M).

H J1 J2 N NC

COM

~

N

Serial Bus Wiring

Using one of the cable types recommended in the System and Communications User's Manual connect the serial bus to terminals 1-4 as shown. (If the block will be used as a BSM controller, do not attach the serial bus to terminals 1-4. See "Using a Relay Block as a BSM Controller" instead). Terminals 1 to 4 are for the serial bus. These terminals accept one AWG #12 wire (avg 3.3mm2 cross-section) or two AWG #14 wires (each avg 2.1mm2 in cross-section). The minimum recommended wire size is AWG #22 (avg .36mm2 in cross-section). Terminals 1 4 can also accommodate spade or ring terminals up to 0.27 inch (6.85mm) wide with a minimum opening for a #6 screw, and up to 0.20 inch (5.1mm) depth from the screw center to the back barrier. Be sure unshielded wire ends are not longer than 2 inches (5 cm).

1 2 3 4 NC

COM

Block Power Options

COM H *115 VAC N

5 6 7 8 NC

COM

LOAD LOAD

1 4

9 10 11 12 NC

COM

Example 115 VAC Output Connections

COM *24 VDC LOAD LOAD 1 4

13 14 15 16

Example 24 VDC Output Connection

16-Circuit Relay Output Block

June 2002 GFK-0038E

Block Power

Relay Output blocks require a 115 VAC or 230 VAC power source. Voltage selection is made by jumpers on the Terminal Assembly. When shipped from the factory, the power selection jumpers are set for 115 VAC operation. For 230 volt AC power, change the jumpers as shown. Correct jumper placement is important; incorrect jumper placement may result in damage to the block. Connect the power source to the H and N terminals (5 and 8). For applications where Class 1 Division 2 conditions must be met for Factory Mutual, install an external 250 volt 1/8 amp slow-blow fuse in series with the Hot AC power connector as shown below.

250V, 1/8 Amp slow-blow fuse

H H N

Block Powered by 23VAC, Points Powered by 115VAC or 125VDC

If the block is powered by 230 VAC and the points are powered by either a 115 VAC source or a 125 VDC source, use BSM version BSM120. Connect one wire of the BSM to point 1. For a 125 VDC source, connect the other BSM wire to DC-. For a 115 VAC source, connect the other BSM wire to the neutral side of the power supply.

BSM

H N

230 VAC

DCfor 125VDC source or neutral for 115VAC source

N

H J1 J2 N NC COM 1

AC Power Source

DC+ for 125VDC source or H for 115VAC source

External Fuses and Snubbers

Relay blocks have no internal fuses. Following normal practices, external fuses of 2 Amps or less can be installed in series to protect loads. External snubbers are not necessary for correct operation of the block. However, the use of snubbers is recommended. Snubbers will reduce switching transient pulses and lengthen the contact life of the relays. Use a diode connected in parallel with a DC inductive load or an R-C network across the contacts.

With the external fuse indicated, this block meets FM Class 1 Divi

sion 2 requirements. Block and Points Powered by 115VAC

If the block and points are powered by 115 VAC, connect one wire of BSM version IC66*BSM120 to point 1 and connect the other BSM wire to N. Jumpering terminal J1 to COM as shown above right allows the points to operate on the same 115 VAC source that powers the block.

Removing an Electronics Assembly ______________

Jumper

BSM

H N

N (-)

~ 115 VAC

H (+)

H J1 J2 N NC COM 1

The blocks Electronics Assembly can be replaced with a compatible model without removing field wiring or reconfiguring the block.

Electronics Assembly Retaining Screws (Qty. 2)

Block Powered by 230VAC, Points Powered by 24-48VDC

If the block is powered by 230VAC and the points are powered by a 24-48 VDC source, connect one wire of BSM version IC66*BSM021 to point 1 and the other to DC- (24-48VDC).

Terminal Assembly Connector Pins

BSM

H N

~ 230 VAC

DC-

H J1 J2 N NC COM 1

1. 2.

Unscrew the retaining screws at the top and bottom of the block. Using a Block Puller (IC660BLM507), engage the tabs in the first vent slots. Move the tool to the center of the block and squeeze the handle. Pull the Electronics Assembly upward. Warning If power is applied to the field terminals, power is also exposed on the connector pins at the base of the Terminal Assembly, and electrical shock hazard exists. Do not touch the connector pins! Death or injury may result.

To Power Supply

DC+ To Power Supply

3.

16-Circuit Relay Output Block

June 2002 GFK-0038E

Inserting an Electronics Assembly

1. Align the Electronics Assembly in the guides and push down firmly. Caution Do not exert excessive force; it may damage the block. 2. If unusual resistance is met, remove the Electronics Assembly. If power is applied to the block, DO NOT TOUCH THE CONNECTOR PINS! Inspect the Terminal Assembly, connector receptacle, and connector edge board (on the Electronics Assembly). Be sure the keying matches. Remove any obstacles and reinsert the Electronics Assembly. Pay close attention to the alignment of the guide pins. Secure the Electronics Assembly with the screws on the top and bottom of the Terminal Assembly.

LEDs _______________________________________

The block's Unit OK and I/O Enabled LEDs show its operating status: Unit OK ON ON ON Blinking Blinking I/O Enabled ON OFF Blinking ON OFF Block functioning No CPU communications for 3 bus scans Block functioning, Circuit forced Circuit fault, CPU communicating Circuit fault No CPU communications for 3 bus scans Alternate Blinking Synchronous Blinking OFF Dont Care Circuit fault, Circuit forced No CPU communications - block number conflict No block power, or block faulty Meaning Block functioning, CPU communicating

3.

Block Operation ________________________________

All 16 relay-type outputs are either normally-open or normallyclosed, depending on the block version. Outputs are grouped into four groups of four relays. Each group of four shares a common input terminal. Each circuit has its own LED that shows the commanded state of the coil. A logical 1 received from the CPU causes the block to energize the corresponding relay coil, and 0 causes the coil to be deenergized. This has opposite effects on these two blocks. When the coil of a normally-open relay is energized, the relay is energized and the relay contact closes. When the coil of a normally-closed relay is energized, the relay contact opens. The Relay Output blocks provide an EEPROM Failure diagnostic only. There are no diagnostics associated with the individual circuits. Circuit LEDS show the commanded state of each coil.

Individual circuit LEDS show the commanded state of each coil.

Configuration ________________________________

First, the block must be configured with a Hand-held Monitor to: Enter its Device Number (serial bus address). Enter its Reference Number (required only for IC600 and IC550 series PLCs only). Note: If a block is configured offline, it must be properly grounded and have a 75 Ohm resistor installed across its Serial 1 and Serial 2 terminals. See the Discrete and Analog I/O Blocks Users Manual for instructions. The rest of the features can be configured either using a Hand-held Monitor, or by sending a Write Configuration datagram to the block from the host. Feature Device Number Reference Address Baud Rate Hold Last State Output Def. State Circuit or Block Block Block Block Circuit Circuit Block Block Blockl Block Block Block Factory Setting null none 153.6 std no coil off no no 3 bus scans none off disabled Selections 0 to 31 (a number must be selected) Depends on host CPU type 153.6 std, 153.6 ext, 76.8, 38.4 Kbd yes, no coil on, off yes, no yes, no 2.5, 10 seconds none, duplex, hot standby on, off enabled, disabled

Common

Relay

Coil

Coil Voltage

R

VDD

Coil Control from VDD Micro processor

LED

LED

VDD

3 MOV 4 Field Connections Terminal Assembly

LED

VDD

BSM Present BSM Controller Outputs Default Time Redundancy Mode Duplex Default Configuration Protection

LED

Electronics Assembly

Note: Relay Normally-Open version shown. Normally-closed is the same, except for relay type.

You might also like

- Inversor Abb 2 5kwDocument2 pagesInversor Abb 2 5kwapi-290643326No ratings yet

- IC200MDD840 and 843 VersaMax Ten 24VDC Inputs Six Relay Outputs gfk2540 PDFDocument2 pagesIC200MDD840 and 843 VersaMax Ten 24VDC Inputs Six Relay Outputs gfk2540 PDFJosé Alexis Valero VillanuevaNo ratings yet

- DVP Slim Digital I/O Extension Instruction SheetDocument2 pagesDVP Slim Digital I/O Extension Instruction SheetBustamante PerroneNo ratings yet

- DVP SS2 ManualDocument19 pagesDVP SS2 ManualMUIFTIKHARNo ratings yet

- Delta Dvp-Se I Mul 20130208Document20 pagesDelta Dvp-Se I Mul 20130208daocongdablNo ratings yet

- Notifier FCM 1 Supervised Control ModuleDocument2 pagesNotifier FCM 1 Supervised Control ModuleAbduBuserNo ratings yet

- Instruction Manual: Model 7SL High/Low LimitrolDocument48 pagesInstruction Manual: Model 7SL High/Low LimitrolkmpoulosNo ratings yet

- MEX016UDocument15 pagesMEX016USergeyNo ratings yet

- Online UPS User ManualDocument30 pagesOnline UPS User ManualaxsalazarNo ratings yet

- Rcbo Panels PDFDocument4 pagesRcbo Panels PDFVipul GuptaNo ratings yet

- Controllogix Voltage/Current Input Module: Installation InstructionsDocument20 pagesControllogix Voltage/Current Input Module: Installation InstructionsMarco RojasNo ratings yet

- DVP-Slim Digitai IO Module Instruction SheetDocument2 pagesDVP-Slim Digitai IO Module Instruction SheetAgnimuthuNo ratings yet

- 004 Pwm-OcxiDocument7 pages004 Pwm-OcxiNeodymeNo ratings yet

- Installation And Maintenance Manual JOSLYN P/N 1455-85-M JOSLYN P/N 1455-85-MN Ac Power Arresters 208/120 VAC, 3φ, 4 WIRE, GROUNDED WYEDocument8 pagesInstallation And Maintenance Manual JOSLYN P/N 1455-85-M JOSLYN P/N 1455-85-MN Ac Power Arresters 208/120 VAC, 3φ, 4 WIRE, GROUNDED WYEsrogan2323No ratings yet

- ATS22C59Q soft starter data sheetDocument9 pagesATS22C59Q soft starter data sheetthavaselvanNo ratings yet

- Dvpes2 ManualDocument10 pagesDvpes2 Manualmarie1320No ratings yet

- UDx2916 DatasheetDocument10 pagesUDx2916 DatasheetBruno NascimentoNo ratings yet

- Altistart 22 ATS22C14QDocument9 pagesAltistart 22 ATS22C14QJavier SaireNo ratings yet

- Man-1092 Synhro RepeterDocument12 pagesMan-1092 Synhro RepetersvirkomartinkoNo ratings yet

- PID Temperature Controller: Installation and Basic OperationDocument6 pagesPID Temperature Controller: Installation and Basic OperationTito RamosNo ratings yet

- Moxa Imc 101 Series Qig v9.3Document13 pagesMoxa Imc 101 Series Qig v9.3Stéphane SintesNo ratings yet

- DVP-10SX PLC DeltaDocument2 pagesDVP-10SX PLC Deltawilfredomolina100% (1)

- ATS22C11Q soft starter data sheetDocument9 pagesATS22C11Q soft starter data sheetMuneeb ImtiazNo ratings yet

- ALSTOM Instntneous Voltage Relay VAGM HighResDocument4 pagesALSTOM Instntneous Voltage Relay VAGM HighResMorgan Brooks0% (1)

- Service Manual: History Information For The Following ManualDocument56 pagesService Manual: History Information For The Following ManualMalanie Sriya De SilvaNo ratings yet

- JVC AV-21CS24 AV-21CX14 Service ManualDocument86 pagesJVC AV-21CS24 AV-21CX14 Service ManualLara Atos100% (4)

- Midas Venice ManualDocument29 pagesMidas Venice Manualcb4pdfsNo ratings yet

- ACX 57xx Series Controller Installation InstructionsDocument12 pagesACX 57xx Series Controller Installation Instructionsanas.iajNo ratings yet

- Installation Instructions: Netcontroller IiDocument10 pagesInstallation Instructions: Netcontroller IinandodefariaNo ratings yet

- Inversor Abb 5kwDocument2 pagesInversor Abb 5kwapi-290643326No ratings yet

- Akai Pdp42z5ta (SM)Document141 pagesAkai Pdp42z5ta (SM)ricardo0% (1)

- Speaker Protection CircuitDocument3 pagesSpeaker Protection Circuitsontuyet820% (2)

- DVP PLC I/O Module SpecificationsDocument2 pagesDVP PLC I/O Module SpecificationsMauro KowalczukNo ratings yet

- 250T Frequency TransmitterDocument13 pages250T Frequency Transmitterreality88No ratings yet

- ATS22D88QDocument10 pagesATS22D88QSurendra PatamsettyNo ratings yet

- Ajustable Precision Zenner Shunt Regulador LM 431Document13 pagesAjustable Precision Zenner Shunt Regulador LM 431Freddy InimaNo ratings yet

- Panasonic PT 52lcx66Document83 pagesPanasonic PT 52lcx66ferdialvascribdNo ratings yet

- AXIOMATIC DSDA-SMB-SC-MT-1A Solenoid DriverDocument10 pagesAXIOMATIC DSDA-SMB-SC-MT-1A Solenoid Driverdylan_dearing@hotmail.comNo ratings yet

- LVC 2500 ManualDocument28 pagesLVC 2500 ManualMmusi KehetileNo ratings yet

- Imc-101g Hig 4eDocument15 pagesImc-101g Hig 4emrs.arporn22No ratings yet

- 80W 3-channel audio amplifier ICDocument13 pages80W 3-channel audio amplifier ICAnonymous r68sPjNo ratings yet

- A5800 and A5801: Discontinued ProductDocument13 pagesA5800 and A5801: Discontinued Productitamar_123No ratings yet

- Pilot Wire ProtectionDocument5 pagesPilot Wire Protectionprabhakaran_hdec100% (1)

- Connections and SchemaDocument7 pagesConnections and SchemaKukuh WidodoNo ratings yet

- ZXDU68 G020 (V5.0) DC Power System Quick User GuideDocument8 pagesZXDU68 G020 (V5.0) DC Power System Quick User GuideJose Luis Gonzalez100% (1)

- Chapter - 5 Fatek FbsDocument6 pagesChapter - 5 Fatek Fbstahir204No ratings yet

- Pioneer PDP 434cmx PDP 43mxe1 S (ET)Document153 pagesPioneer PDP 434cmx PDP 43mxe1 S (ET)VFinNo ratings yet

- Philips L7.3a Aa Chassis TV SMDocument49 pagesPhilips L7.3a Aa Chassis TV SMRoger_74No ratings yet

- 2SC0106T ManualDocument19 pages2SC0106T ManualNazmus SakibNo ratings yet

- Description Power Range: Analog Servo DriveDocument7 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Instructions For Cutler-Hammer LDB, LD, HLD, HLDB, LDC, LW, HLW, LWC, CLD, CHLD, CLDC Circuit Breakers and L-Frame Series C SwitchesDocument12 pagesInstructions For Cutler-Hammer LDB, LD, HLD, HLDB, LDC, LW, HLW, LWC, CLD, CHLD, CLDC Circuit Breakers and L-Frame Series C Switchespayolin77No ratings yet

- JVC Sb3 Chassis Av65wp74 Projection TV DDocument126 pagesJVC Sb3 Chassis Av65wp74 Projection TV DtelevizionistulNo ratings yet

- Foxboro FM242Document16 pagesFoxboro FM242jose luisNo ratings yet

- Chromalox 3910 ControllerDocument34 pagesChromalox 3910 ControllerkmpoulosNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- EVM3C48 Manr5Document2 pagesEVM3C48 Manr5luis2006041380No ratings yet

- Richard Nakka's Experimental Rocketry SiteDocument8 pagesRichard Nakka's Experimental Rocketry Siteazrim02No ratings yet

- Somayya Polytechnic, Wadgaon, Chandrapur Department of Mining and Mine Surveying 2 Year - Subject Notes Subject: Mine Ventilation Unit: 01 - Mine AirDocument136 pagesSomayya Polytechnic, Wadgaon, Chandrapur Department of Mining and Mine Surveying 2 Year - Subject Notes Subject: Mine Ventilation Unit: 01 - Mine AirMayur BawaneNo ratings yet

- BetonDocument2 pagesBetonEmily StaffordNo ratings yet

- Irfpc50, Sihfpc50: Vishay SiliconixDocument9 pagesIrfpc50, Sihfpc50: Vishay Siliconixxor_45No ratings yet

- IGCSE Term 2 Assessment - Date sheetDocument7 pagesIGCSE Term 2 Assessment - Date sheetKausthubhi KillamsettiNo ratings yet

- Rate Processes: MSE 202 IIT KanpurDocument24 pagesRate Processes: MSE 202 IIT KanpurSanchit AgarwalNo ratings yet

- Seccionalizador ENTECDocument4 pagesSeccionalizador ENTECedwin_rollyNo ratings yet

- SOLAR BOOST™ 3024i: Installation and Operation ManualDocument19 pagesSOLAR BOOST™ 3024i: Installation and Operation ManualArgenis BriceñoNo ratings yet

- RAC Assignment 3Document2 pagesRAC Assignment 3Pawan Kumar100% (1)

- Astor: Test TransformerDocument1 pageAstor: Test TransformermominzadahNo ratings yet

- PedgkDocument32 pagesPedgkGokulakrishnanNo ratings yet

- Final Diesel DesignDocument111 pagesFinal Diesel DesignJerome JeremiasNo ratings yet

- Kac 728 628 528Document12 pagesKac 728 628 528solungeNo ratings yet

- Nec 10 11 12Document9 pagesNec 10 11 12Marie Grace DollentasNo ratings yet

- Introduction To Current Electricity and A.C Theory FinalDocument76 pagesIntroduction To Current Electricity and A.C Theory FinaldeoNo ratings yet

- A Polyhydron Group Company: DescriptionDocument3 pagesA Polyhydron Group Company: DescriptionHorea CordunianuNo ratings yet

- Description Features: Ait Semiconductor IncDocument10 pagesDescription Features: Ait Semiconductor IncMaktum KamatNo ratings yet

- B Voc Renewable EnergyDocument4 pagesB Voc Renewable EnergyBlessy JoyNo ratings yet

- Steam BlowingDocument11 pagesSteam BlowingSamNo ratings yet

- PTK MateriDocument101 pagesPTK MateriAnnisah MardiyyahNo ratings yet

- Multi-Band Spectrum Sensing and Resource Allocation For Iot in Cognitive 5G NetworksDocument15 pagesMulti-Band Spectrum Sensing and Resource Allocation For Iot in Cognitive 5G NetworksYounes BalboulNo ratings yet

- Engg Chemistry R13 Model Question PapersDocument4 pagesEngg Chemistry R13 Model Question PapersBell P PedNo ratings yet

- Chapter Fluid MachineryDocument50 pagesChapter Fluid MachineryWan AimanNo ratings yet

- Energy Transfer Forms and MeasurementDocument4 pagesEnergy Transfer Forms and MeasurementAlberto CasiniNo ratings yet

- Optimal Design of Cooling Water Systems: August 2011Document23 pagesOptimal Design of Cooling Water Systems: August 2011Hansraj RahulNo ratings yet

- CRT5000 Manual PDFDocument8 pagesCRT5000 Manual PDFYadwinder SinghNo ratings yet

- Waste Collection Report: An Analysis of Traditional and Automated SystemsDocument135 pagesWaste Collection Report: An Analysis of Traditional and Automated SystemsCamila Correa MendozaNo ratings yet

- GHGT-15: ConferenceDocument36 pagesGHGT-15: ConferencechomiNo ratings yet