Professional Documents

Culture Documents

Industrial Training Report

Uploaded by

Nuwan BandaraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Training Report

Uploaded by

Nuwan BandaraCopyright:

Available Formats

UNIVERSITY OF MORATUWA Faculty of Engineering Non-GPA Module 399: Industrial Training

INDUSTRIAL TRAINING REPORT

Kularathna M.P.D.S.C. Registration No: 080246F Department of Electrical Engineering

Lanka Electricity Company (Pvt) Ltd Ceylon Electricity Board Amithi Power Consultants (Pvt) Ltd From 02nd of March 2011 to 03th of September 2011 Date of submission - 17th of September 2011

Training Report_______________________________________________________________________________________________________________

PREFACE This report was prepared as a requirement at the end of our Industrial Training period. This training was a great opportunity to expose ourselves to industrial environment, let us to apply the knowledge we gathered at the university and to gain some experience about the industry.

I have included my experiences, skills and practices I gained for 24 weeks duration starting from 28th February 2011 to 12th August 2011 about electrical engineering field as an electrical engineering undergraduate trainee of the University of Moratuwa at Ceylon Electricity Board, Lanka Electricity Company (Pvt) Ltd and Amithi Power Consultants (Pvt) Ltd.

The report consists of 3 major chapters. First chapter mainly includes Information about Training Establishment. This Chapter begins with a brief introduction of each training places .Then First chapter describes main functions, Organizational Structure and hierarchical levels, Present Performance, Strengths, Weaknesses, profitability, Usefulness to Sri Lankan Society of each training Establishments.

The second chapter describes daily entries in detail, it contains about the technical experience and knowledge which I have gathered during my training period, in different places in CEB and LECO. Also in there I have included many electrical designs involved in APCL and gathered knowledge and experiences while involved in those designs.

The third or final chapter includes the conclusion of the report. This conclusion include an assessment on the current Industrial Program which coordinated by University Of Moratuwa. There have summarized training experienced which I gained for 24 weeks within Ceylon Electricity Board, Lanka Electricity Company (Pvt) Ltd and Amithi Power Consultants (Pvt) Ltd. I added my comments that describe how Industrial Training should change to provide a maximum merit to implant trainees. Also I appended comments and suggestions that describe how industrial training program should improve. Kularathna, M.P.D.S.C. Department of Electrical Engineering University of Moratuwa ii

Training Report_______________________________________________________________________________________________________________

ACKNOWLEDGEMENT Here my sincerely thanks go to the Industrial Training Division of University of Moratuwa and National Apprentice & Industrial Training Authority (NAITA) for taking all the necessary arrangements for making this training program a success and giving me this opportunity to gain the in plant traineeships in Ceylon Electricity Board, Lanka Electricity Company (Pvt) Ltd and Amithi Power Consultants (Pvt) Ltd.

I would like to express my gratitude towards all the Engineers, technicians, workers and other staff of Ceylon Electricity Board in Samanalawewa Power Station, Sapugaskanda Thermal Plant, Kelanithissa Power Plant, Kelanithissa Combined Cycle Power Plant, Generation & transmission Planning division, Transmission Operation and Maintenance (Colombo region), System Control Centre, Rathmalana GSS and Pannipitiya GSS for spending their valuable time and sharing their knowledge to success my in plant traineeship.

Next I should convey my gratitude for who helped me in Lanka Electricity Company (Pvt) Ltd, all the Engineers, technicians, workers and other staff of Maharagama Customer Service Centre, Branch Office, Operation Division, Engineering Division and Ekala-Training Centre for enhancing my knowledge about electrical engineering field and receiving necessary experiences and skills.

Next my special gratitude go to Mr. D.G Rienzi Fernando, Chairman and Managing Director of Amithi Power Consultant (Pvt) Ltd for his decision to recruit engineering students as trainees and support he gave in various ways to develop our practical knowledge and I would like to thank the entire staff of the Amithi Power Consultant (Pvt) Ltd. Its very important to memorize and give my special gratitude my parents, my friends, and especially my dear Mrs Suwanthri Katuwapitiya, be with me and help me in various ways to complete my training report successfully.

iii

Training Report_______________________________________________________________________________________________________________

Table of Contents

1. Introduction to the Training Establishment ......................................................................................... 1 1.1 Lanka Electricity Company (Pvt) Ltd ...................................................................................... 1

1.1.1 Introduction to LECO .............................................................................................................. 1 1.1.2 History of the LECO................................................................................................................ 1 1.1.3 Vision and Mission of LECO .................................................................................................. 2 1.1.4 Organization Structure of the LECO ....................................................................................... 2 1.1.5 Present Performances and Strength of the LECO ................................................................... 2 1.1.6 Profitability of the LECO ........................................................................................................ 2 1.1.6 Usefulness of LECO to Sri Lankan Society ............................................................................ 3 1.2 Ceylon Electricity Board ................................................................................................................ 3 1.2.1 Introduction to CEB................................................................................................................. 3 1.1.2 Organization Structure of the CEB .......................................................................................... 4 1.2.3 Present Performances and Strength of the CEB ...................................................................... 4 1.2.4 Usefulness of CEB to Sri Lankan Society ............................................................................... 4 1.2.4 Suggestions for improvements ................................................................................................ 4 1.3 Amithi Power Consultants (Pvt) Ltd .............................................................................................. 5 1.3.1 Introduction to APCL .............................................................................................................. 5 1.3.2 History of the APCL ................................................................................................................ 5 1.3.3 Organization Structure of the APCL ....................................................................................... 5 1.3.4 Present Performances and Strength of the APCL .................................................................... 6 1.3.5 Profitability of the APCL ........................................................................................................ 6 1.3.6 Suggestions for improvements ................................................................................................ 6 1.3.7 Usefulness of APCL to Sri Lankan Society ............................................................................ 6 2. TRAINING EXPERIENCES............................................................................................................... 7 iv

Training Report_______________________________________________________________________________________________________________

2.1

Training Experience in Lanka Electricity Company (Pvt) Ltd ................................................ 7

2.1.1 Maharagama LECO Depot ...................................................................................................... 7 2.1.1.1 HT maintenance ............................................................................................................... 7 2.1.1.2 Consumer Breakdown maintains ..................................................................................... 8 2.1.1.3 Field billing ...................................................................................................................... 8 2.1.1.4 Disconnecting process ..................................................................................................... 8 2.1.1.5 Breakdown registry .......................................................................................................... 8 2.1.1.6 Equipments and Materials use in LECO Depots ............................................................. 9 2.1.2 Nugegoda LECO Branch Office ....................................................................................... 10 2.1.2.1 LECO Construction work .............................................................................................. 10 2.1.2.2 Planning & construction ................................................................................................ 11 2.1.2.3 Job Costing..................................................................................................................... 11 2.1.2.4 LV Planning ................................................................................................................... 12 2.1.3 LECO Head Office ................................................................................................................ 12 2.1.3.1 Engineering Division ..................................................................................................... 12 2.1.3.2 Load forecast .................................................................................................................. 12 2.1.3.3 Planning ......................................................................................................................... 12 2.1.3.4 Load flow analysis ......................................................................................................... 11 2.1.4Operation Division ............................................................................................................. 11 2.1.4.1Distribution Control Centre ............................................................................................ 11 2.1.4.1.1 Task of system control centre ................................................................................. 11 2.1.4.1.2 Preparing reports ..................................................................................................... 12 2.1.4.2 Ekala LECO Training Centre......................................................................................... 12 2.1.4.2.1 Meter testing laboratory .......................................................................................... 12 2.1.4.2.2 Tests apply on Energy meter................................................................................... 16 v

Training Report_______________________________________________________________________________________________________________

2.1.4.3.1 Transformer Testing................................................................................................ 17 2.2 Training Experience in Ceylon Electricity Board ........................................................................ 19 2.2.1 Samanalawewa Hydropower Plant ........................................................................................ 19 2.2.1.2 Surge Chamber............................................................................................................... 19 2.2.1.3 Power house ................................................................................................................... 20 2.2.1.5 Active power control...................................................................................................... 20 2.2.1.6 Reactive power control .................................................................................................. 20 2.2.1.7 Power Transformers ....................................................................................................... 21 2.2.1.8 Switchyard ..................................................................................................................... 21 2.2.1.9 Auxiliary supply............................................................................................................. 22 2.2.1.10 Governor ...................................................................................................................... 22 2.2.1.10 Battery bank ................................................................................................................. 22 2.2.2 Kelanithissa Thermal Power Plant ........................................................................................ 22 2.2.2.1 Small Gas turbines (GTs)............................................................................................... 22 2.2.2.2 Synchronous Condenser Mode ...................................................................................... 23 2.2.2.3 Starting of Small Gas turbines (GTs)............................................................................. 23 2.2.2.4 115MW Large Gas turbine (GT) ................................................................................... 23 2.2.2.5 GIS ................................................................................................................................. 23 2.2.3 Kelanithissa Combined Cycle Power Plant ........................................................................... 24 2.2.3.1 Starting the GTs ............................................................................................................. 24 2.2.4 Spugaskanda Power Plant ...................................................................................................... 25 2.2.4.1 Overview of the Plant .................................................................................................... 25 2.2.4.2 Fuel oil System .............................................................................................................. 26 2.2.4.3 Engine modules .............................................................................................................. 26 2.2.4.4 Turbo Charger ................................................................................................................ 27 vi

Training Report_______________________________________________________________________________________________________________

2.2.4.4 Generator........................................................................................................................ 27 2.2.4.5 Switch yard of the Power plant ...................................................................................... 28 2.2.4.6 Maintains........................................................................................................................ 28 2.2.5 System Control Centre........................................................................................................... 29 2.2.5.1 System Stability Limits .................................................................................................. 29 2.2.5.2 System Operation ........................................................................................................... 29 2.2.5.3 Operation Planning ........................................................................................................ 30 2.2.5.4 Under Frequency Load Shedding .................................................................................. 30 2.2.6 CEB Head office Generation and Transmission Planning division ...................................... 31 2.2.6.1 Planning and Demand forecasting ................................................................................. 31 2.2.6.2 Generation Planning....................................................................................................... 32 2.2.6.3 Transmission Planning ................................................................................................... 33 2.2.6.4 The load flow analysis ................................................................................................... 33 2.2.7 Rathmalana and Pannipitiya Grid Sub Station ...................................................................... 34 2.2.7.1 Rathmalana Grid Sub Station......................................................................................... 34 2.2.7.3 Components in substations ............................................................................................ 35 2.2.7.4 Power Transformer ........................................................................................................ 35 2.2.7.5 Protection method of Power Transformer...................................................................... 36 2.2.7.5.1 Hot spot temperature ............................................................................................... 36 2.2.7.5.2 Bucholz relay .............................................................................................................. 36 2.2.7.6 On load tap changer ....................................................................................................... 36 2.2.7.7 Dehydrate filter breather ................................................................................................ 36 2.2.7.8 Pressure relief Valve ...................................................................................................... 37 2.2.7.9 Switching in a switch yard ............................................................................................. 37 2.2.7.12 Circuit Breakers ........................................................................................................... 37 vii

Training Report_______________________________________________________________________________________________________________

2.2.7.13 Current Transformers ................................................................................................... 38 2.2.7.14 Potential Transformers ................................................................................................. 39 2.3 Training Experience in Amithi Power Consultants (Pvt) Ltd ...................................................... 40 2.3.1Testing and Measurement ....................................................................................................... 40 2.3.1.1 Insulation Testing........................................................................................................... 40 2.3.1.2 Cable Insulation Testing ................................................................................................ 41 2.3.2.3Relay testing.................................................................................................................... 42 2.3.2.3.1 Secondary injection and Primary injection test on relays ....................................... 43 2.3.3 Capacitor Bank Designing ..................................................................................................... 44 Applicable Standard ................................................................................................................... 44 2.3.3.1 Energy survey Results.................................................................................................... 44 2.3.3.2 Recommendations .......................................................................................................... 45 2.3.3.3 Calculation and the Size of the Capacitor bank ............................................................. 45 2.3.3.4 Phase balancing .............................................................................................................. 47 2.3.4 Lightning Protection System Designing ................................................................................ 48 2.3.4.1 Direct lightning .............................................................................................................. 48 2.3.4.2 Indirect lightning ............................................................................................................ 48 2.3.4.3 Protection of structures against lightning ...................................................................... 48 2.3.4.4 Risk Level assessment for the building ......................................................................... 49 2.3.4.5 Methods of Air Termination System as per IEC ........................................................... 51 2.3.4.6 Main Components of lightning protection system ......................................................... 53 2.3.5 Thermal Imaging ................................................................................................................... 55 2.3.5.1 Concept of Thermal Imaging ......................................................................................... 55 2.3.5.2 Importance of thermal imaging ...................................................................................... 55 2.3.5.3 Suitable for Thermal imaging in .................................................................................... 56 viii

Training Report_______________________________________________________________________________________________________________

2.3.5.4 Thermal imaging in LV switch board and Cables ......................................................... 57 2.3.5.4 Consider the following analysis of thermal images ....................................................... 57 2.3.6 Electrical installation design .................................................................................................. 60 2.3.6.1 Lighting design And Switch placing................................................................................. i 2.3.6.1.1 Factors and procedure to consider while lighting design ........................................... i 2.3.6.1.2 Utilization factor ........................................................................................................ i 2.3.6.1.3 Maintenance factor.................................................................................................... ii 2.3.6.1.4 Suitable lighting and fittings ..................................................................................... ii 3. Conclusion .......................................................................................................................................... iv ANNEX 01 ......................................................................................... Error! Bookmark not defined.

ix

Training Report_______________________________________________________________________________________________________________

List of Figures Figure 1.1 Product (Electricity) flow of electricity Figure 2.1 Isolation and Earthing of lines Figure 2.2 Insulated T-Off Connectors Figure 2.3 Pre Insulated Joints Figure 2.4 Pre Insulated Bimetal Lug Figure 2.5 Uninsulated Joint Figure 2. 6 H Type Compression Connector Figure 2.7 Hydraulic Crimper Figure 2.8 Ratchet Lever Hoist Figure 2.9 Surge Arrestor Figure 2.10 Structure of Branch Figure 2.11 Construction work done by the LECO Figure 2.12 Procedure of construction Figure 2.13 Disk of energy meter Figure 2.14 Megger test on transformer Figure 2.15 Power plant Figure 2.16 Dame Section Figure 2.17 Surge Chamber Figure 2.18 AVR Figure 2.19 Samanalawewa Switch yard Figure 2.20 Small GT in Kelanithissa Figure 2.21 HRSG Figure 2.22 Sapugaskanda Power Station Engine Arrangement Figure 2.23 Fuel oil System Figure 2.24 Turbo charger system Figure 2.25 Self Exciter Figure 2.26 - Transmission planning process Figure 2.27 WASP-iV Software Figure 2.28 Model in PSS Figure 2.29 SF6 breaker Figure 2.30 Current Transformer (CT) Figure 2.31 Potential Transformer (CVT) Figure 2.32 internal arrangement of Megger tester Figure 2.33 testing insulation levels of cables Figure 2.34 Digital Insulation Tester Figure 2.35_Secondary Injection test on relay Figure 2.34_ Measured Active power and Reactive Power Apparent power against Time 03 07 09 09 09 09 09 09 09 09 10 10 11 15 18 19 19 19 21 21 22 24 23 26 27 28 32 33 34 38 38 39 40 41 42 43 44 x

Training Report_______________________________________________________________________________________________________________

Figure 2.37_ Measured each phase currents against Time Figure 2.38 Phaser diagram before and after install the capacitor bank Figure 2.39 Measured each phase currents against Time Figure 2.40 Capacitor Figure 2.41 Selection of lightning protection system Figure 2.42 Calculation of collection area Figure 2.43 Protective angle method Figure 2.44 Rolling sphere method Figure 2.45 Distribution T/F in firing Figure 2.46 Power T/F firing Figure 2.47 Thermal Images of Electrical Systems Figure 2.48 Thermal image of cable Figure 2.49 Digital image of cable Figure 2.50 Thermal image of LV breaker Figure 2.51 Digital image of LV breaker Figure 2.52 Lighting design List of Tables Table 1.1- Training Establishments Table 2.1 percentage error tests on Energy meter Table 2.2 System stability limits Table 2.3 Under frequency load shading schedule Table 2.4 Cable insulation levels Table 2.5 specific voltage level for insulation testing Table 2.6 Energy survey result summery Table 2.7 System variable before and after capacitor bank installation Table 2.8 Standards for lightning protection design Table 2.9 Max allowable Temperatures for LV panels. Table 2.10 Cable temperature Analysis in FLIR software Table 2.11 LV panel temperature Analysis in FLIR software.

45 45 47 47 49 50 51 52 54 54 55 57 57 58 59 60

01 17 29 31 41 43 44 46 48 56 57 58

xi

Training Report_______________________________________________________________________________________________________________

1. Introduction to the Training Establishment

This industrial training programme module had specially been allocated in to two main sessions for Electrical Engineering students, Total period for the industrial training program was 24 weeks and it was divided in to two main sessions with a period of twelve weeks for each according to the schedule given by the Industrial Training Division of Faculty of Engineering, University of Moratuwa. Following table shows exactly time periods of the training Programme. Table 1.1- Training Establishments

Session 1 Training Establishment Lanka Electricity Company (Pvt) Ltd Ceylon Electricity Board 2 Amithi Power Consultant (Pvt) Ltd Allocated Period 4 weeks 8 weeks 13 weeks

1.1 Lanka Electricity Company (Pvt) Ltd 1.1.1 Introduction to LECO LECO is the only one privet organization of Sri Lankan power sector having a license to carry out power distribution function within the country. By purchasing power (11kV from primary substations) from Ceylon Electricity Board and distribute to the customers in (400V) coastal belt from Negombo to Galle excluding Colombo city, Dehiwala and Mount Lavinia. Now a day LECO area is in operation in their seven branches, and got the authority to provide electricity supply to Kotte, Nugegoda, Kelaniya, Moratuwa, Galle, Kaluthara and Negombo areas. Provides its service with 7 Branch Offices, 24 Customer service Centers, 2 Main Stores, Meter Test Lab, Technical Training Center and Transformer Repair Workshop.

1.1.2 History of the LECO In 1984 LECO started their distribution functions in some cities of western and Southern coastal belt between Negombo and Galle.By recognizing the weaknesses of Local distribution functions carried by CEB such as unreliability of supplies, high electrical losses, unsatisfactory revenue collection procedures and the required investments for system improvements, by avoiding these inconvenients

Training Report_______________________________________________________________________________________________________________

and unsatisfactories as a result of that the Lanka Electricity Company (Pvt) Limited was established in September 1983 under the Companies Act. 1.1.3 Vision and Mission of LECO Vision Enjoy being the light for the lives of people through innovative eco-friendly business Mission To provide the best energy solutions to the society through continuous innovations

1.1.4 Organization Structure of the LECO Organization structure of the LECO is given in ANNEX 01 (Organization Structure of LECO)

1.1.5 Present Performances and Strength of the LECO LECO won the National Quality Award in 2001 and Ceylon Petroleum Corporation Award best energy conservation project. Maintaining supply voltage at customer premises within 216-244 volt (230 V6%) Voltage drop is reduced by using more distribution transformers in low capacities instead of using high capacity transformers and long distribution cables. LECO has reduced its system losses to 5.5%, which remained at over 20% when electricity distribution was carried out by local authorities. LECO introduced for the first time in Sri Lanka the use of Arial Bundled conductors (insulated conductors) for low voltage (11KV and 400V) distribution. There by reducing customer outages significantly. This will help to reduce losses due to way leaves and unauthorized tapping. This is also an achievement because to give this type of supply at consumer ends planning and maintains should be done properly. As a business organization while profit making, satisfaction of consumer also were been taken in to consideration.

1.1.6 Profitability of the LECO Company should have profits to run the company even at the beginning LECO runs as unprofitable institution now it is a profitable company. This is due to their best business strategy by reducing unwanted losses in their whole network of distribution and net work in the organization.

Training Report_______________________________________________________________________________________________________________

1.1.6 Usefulness of LECO to Sri Lankan Society As a power supplying company their role in the country is appreciable for taking every possible effort to supply much more reliable Electricity to consumer premises. Customers are treated well and presently they are planning to improve the efficiency and quickness of their service. LECO is using new technologies to enhance the quality and reliability of the power supply.

1.2 Ceylon Electricity Board 1.2.1 Introduction to CEB Ceylon Electricity Board controls one of a major consumer requirement which is Electricity. As an island wide large organization they bare the license and responsibilities of fulfilling the electricity demand of whole country. This is operated under the Ministry of Power and Energy. A large portion of the power generation, totally whole transmission functions and a large portion of distribution are done by CEB. So the CEB acts main role in Power sector inside the country any aspect of developments and civilization is always combined with Electricity therefore their functions are impact for the development of the country. To supply as possibly maximum service and for ease of management CEB has divided in to three divisions according to their functionalities known as Generation, Transmission & Distribution Divisions and distribution division has four distribution regions known as Colombo, Kandy, Galle and Anuradhapura. The product flow of electricity is as follows. Cash flowing is also in same but reverse direction its happening. Also in consumer points are also produce electricity after introduce the two way metering using solar photovoltaic and other means. It is negligible compared to total power flow.

CEB Generation Independent power producers Small power purchase

Transmission network CEB Distribution 4 Regions LECO distribution

Consumer

Figure 1.1 Product (Electricity) flow of electricity 3

Training Report_______________________________________________________________________________________________________________

1.1.2 Organization Structure of the CEB The organizational structure and hierarchical levels are shown in ANNEX 01 (Organization Structure of CEB).

1.2.3 Present Performances and Strength of the CEB The electricity transmission part is totally owned to CEB, large portion of the electricity generation is also done by CEB. The large hydro complex such as Mahawelli and Laxapana has the most profit making hydro power plants. Existing thermal capacity is 517 MW and hydro capacity is 1205 MW. 900 MW of Coal Power Plant is committing in Puttalam and 150 MW of committed hydro capacity in Upper Kotmale. CEB is governed under Ministry of Power and Energy to supply reliable and quality electrical power for the development of the country and improve the living quality of lives with all about 14000 employees in different levels and skilled. Ceylon Electricity board got large number of valuable assets spread all over the country and this is one of a largest organization in Sri Lanka.

1.2.4 Usefulness of CEB to Sri Lankan Society CEB is so important to the Sri Lankan society since it is the governing authority of Sri Lankan electricity Generation, Transmission and Distribution. All the communication systems, most of functions in various kind of industrial, domestic and public are depending on the electricity supply. So the reliable and efficient electricity supply is essential factor to the Society. This organization serves the people in Sri Lanka by delivering an efficient and reliable supply to the community. Activities and decision taken by this organization will directly affects to the economical development of the county. This company always try to serve and satisfy the customers first and then they get the benefit of it. And this company has created number of job opportunities and it helps to develop the life stand of people. Therefore this company is very important to the Sri Lankan society and people can get a lot of benefits through this company.

1.2.4 Suggestions for improvements Should avoid political recruitments and make the opportunity for only skillful workers. As I heard there are many other unsuitable political involvements inside this organization and so many external effects from many ways. This all involvements are as in past the organization will put in to trouble. At present organization has well organized management structure as suitable for this type of organization

Training Report_______________________________________________________________________________________________________________

this. will make proffits Introduce new software systems to do the transmission network analyzing tasks, forecasting tasks and other requirements. Introduce an evaluation procedure for the workers and engineers to enhance their efficiency. There should be a group to study and introduce new technologies by looking at the world. There should be a quick and reliable good and tools supply procedure in a situation such as breakdown in grid substation etc

1.3 Amithi Power Consultants (Pvt) Ltd 1.3.1 Introduction to APCL Amithi Power Consultants is one of a leading electrical design firm in Sri Lanka. Many types of high voltage and low voltage design consultants are handled by APCL. So many local and also foreign projects have design and consulted by APCL. As the owner and the managing director of this company Mr. Rienzie Fernando does a great service in the company to leading and giving instructions.

1.3.2 History of the APCL Mr. D.G. Rienzie Fernando, owner and the managing director of this company has established this company in 1996 after retiring from the post DGM of CEB. Since that APCL has successfully completed large number of projects and services in electrical field. Vision Strengthen the capabilities of Sri Lankan Engineering professionals to the International Standards by improving the status of Sri Lankan Electrical Engineering sector through continuous efforts Mission Cater the vacuum of consulting service in and out of the island, in the relevant electrical fields To spread our wings over a foreign market to work to fill the increasing gap of engineering services

1.3.3 Organization Structure of the APCL The organizational structure is shown in ANNEX 01 (Organization Structure of Amithi power consultants).

Training Report_______________________________________________________________________________________________________________

1.3.4 Present Performances and Strength of the APCL This firm supplies their services in the electrical sector locally and internationally some of very giant project which APCL has handled are Brandix Apparel City in India, Niyagala Open University Project, Design and project supervision of Embilipitiya Substation and the transmission line. Lighting Sri Lanka- Hambantota Project, Senok Wind Power Station, Ambewela wind Power Station. Under the guidance of Mr.Rienzie Fernando and director board APCL team of expertise is always in alert about new technologies and latest updates of standards about electrical engineering. These days they are doing a power plant design project in Iraq. Apart from that Safety audits, electrical testing are also performed

1.3.5 Profitability of the APCL Since the beginning of this organization was a profitable organization due to the dedication and determination of the all staff members.

1.3.6 Suggestions for improvements There is some points in my view to improve the profitability and that it does not going to compete with other organizations. It performs its job which they got and do not run for projects. And they do not carefully about spreading their name over the country. That is over time hours are not given to the employees and this would effect to motivation of employees worse.

1.3.7 Usefulness of APCL to Sri Lankan Society APCL supply high quality and reliable services of electrical engineering field. They contribute to earn foreign currency in to our country because they are involved in foreign projects also. Most important thing is that this place makes skilled professionals in Electrical Engineering field by providing working opportunities to make their carrier path while earning their salary.

Training Report_______________________________________________________________________________________________________________

2. TRAINING EXPERIENCES

2.1 Training Experience in Lanka Electricity Company (Pvt) Ltd 2.1.1 Maharagama LECO Depot 2.1.1.1 HT maintenance In any kind of maintains in their HT lines that the depot should ask for a work permit. Control centre plan interruptions and allows them to do maintains the HT lines as minimum no of consumer are affected for the power cut and CSC are received docket by mentioning every details. There is a sketch of positions to be switched to isolate required portion of net work by load break switches. After completed the maintain network is re arranged according to control center information they always in connection with control centre through radio communication links. At maintain procedure first they isolate through LBSs, the required line part and earth each end of line through bare conductor connectors. At an end of line all three phase lines are connected conductors and clamped to single conductor and grounded.

Single Line Drawing of

1

the

Network

Near

1

Maintain

3

3 Phases Earthing Points

Required Portions to Isolate

2 1 3 3 3 2 2

for Maintain

Load Break Switches on poles

3

Figure 2.1 Isolation and Earthing of lines There are reasons to consider for additional protection using earth the conductors even isolated lines.

Training Report_______________________________________________________________________________________________________________

If voltage is generated in low voltage side of consumers it will stepped up into 11 kV lines. If another 11kV line above, induced voltages may be in the lower line. Normally HT lines are induced due to inductive behavior and may charge due to capacitor behavior at some points. The load break cutoff may reconnect (rare) due to unusual occurrences.

2.1.1.2 Consumer Breakdown maintains Always depot Technical staff is in alert about consumer calls about their supply problems. They are ready to response for these interruptions as possible as quickly normally these consumer breakdowns, maintains and complains are regards as follows, Burning of MCB due to high current flowing Energy meter related requests 400V Lines, Poles and consumer supply line related requests

2.1.1.3 Field billing According to the supply connection or on the other word according to the tariff, customers are categorized as domestic, general purpose, industries, temporary and religious.. Domestic bills are counted by the revenue officer and bulk consumer bills are prepared by customer service superintendent. 2.1.1.4 Disconnecting process Branch office informs the list of disconnections to the Customer Service Centre with the ACC No, substation (transformer), address, name, and bill amount. The bill is checked in the computer at the CSC also before going to disconnection to see whether he paid the bill at a just a moment before. After disconnecting the bill is handed over to the consumer. When that bill has paid, the branch will inform the Customer Service Center to reconnect it here LECO charge additional fine for the inconvenience. 2.1.1.5 Breakdown registry Consumer complains of breakdowns may be a tree fallen down to the line, MCB has burnt, meter is not working, or No supply etc That complains are recorded with persons went to resolve the problem, vehicle, day & time, place, equipments used etc 8

Training Report_______________________________________________________________________________________________________________

2.1.1.6 Equipments and Materials use in LECO Depots There was large number of equipments and materials in the depot store room, few of them are as shown in below Insulated T-Off Connectors These are suitable for line tapping from aerial bundle conductors. It is safe even live conductors are also possible to tapped. Normally use to tape to connect consumer supply lines. Pre Insulated Joints These are suitable for joining two L.V. bundle conductor lines in mid span. After stripping of conductors as length marked on the body of the joint, inserted two conductors in both end and use hydraulic crimper to tighten. Pre Insulated Bimetal Lug Figure 2.3 Pre Insulated Joints Figure 2.2 Insulated T-Off Connectors

These are used for connecting bundle conductor to a copper pad or to transformer studs. After stripping of conductor as length marked on the body of the joint, inserted the cable end and use hydraulic crimper die to tighten. Figure 2.4 Pre Insulated Bimetal Lug Uninsulated Joint These are suitable only for uninsulated neutral conductor joining. Same crimping die used on the neutral and phase joints. Figure 2.5 Uninsulated Joint

H Type Compression Connector for Overhead Lines These are used to tap off uninsulated ABC conductors Figure 2.6 H Type Compression Connector Hydraulic Crimper Used in above mention jointing Ratchet Lever Hoist Surge Arrestor

Figure 2.7 Hydraulic Crimper

Figure 2.8 Ratchet Lever Hoist

Figure 2.9 Surge Arrestor

Training Report_______________________________________________________________________________________________________________

2.1.2 Nugegoda LECO Branch Office A branch office is doing all stuff of works under the supervision of the Branch Engineer. Normally at upper levels of organization structure Engineers are having large experiences they have here in industry for a long time. Basically branch office carry out LV Planning, handling construction works, job costing, Estimation preparation, route survey, customer services, service from accounting division, and administrative functions inside the office etc. There are several depots under any Branch office all super vision of depots are also under the branch office.

Branch Manager

Branch Engineer

Administrative officer (head) Chief Accountant

Electrical Engineer

Administrative staff ACC/assistant General

Chief technical officer, draftsman and that staff

ACC/assistant revenue collection

Computer Supervisor

Staff

Figure 2.9 Structure of Branch 2.1.2.1 LECO Construction work LECO Construction works

LECO Required System Development System Maintains Consumer Requested New connection Shifting poles Meter changing Change connection etc.

Figure 2.10 Construction work done by the LECO Branch office involves in planning, development, maintain of LV System and to provide the consumer requested services

10

Training Report_______________________________________________________________________________________________________________

2.1.2.2 Planning & construction Branch office considers the planning of the LV distribution system (400V network). According to the level of work, who involves in the planning surveying and construction is dependent. Their Surveying, job costing of new constructions are doing under Electrical Engineer and hand over to the branch engineer for the approval. Contribution from the branch office for the procedure of construction is as follows.

Consumer request Route Survey Estimation by TO Recommendation and approval Select a contractor

Construction

Figure 2.12 Procedure of construction

File is sent to CSC

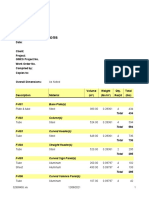

According to the consumer request, a survey is done in order to identify how the job to be done according to the location if only necessary. Once the survey completed legal permissions should be taken from required authority to place poles and to erection of lines, this takes much time and while job costing is done and estimation prepared. Then with the approval a contractor is selected and through the CSC constructions are done. 2.1.2.3 Job Costing Standard cost manual is referred in cost estimations to get the standards cost given by the PUCSL. In the standard cost manual there are prices of each and every one of items used in distribution construction. Cost can be basically categorized in to four types, Material cost, Labor cost, and Construction cost and Over head cost. For each specified jobs these costs are represented using above 4 types of costs and they are denoted by Index called KIT (KIT numbers). According to the job there is the cost value in the cost manual. MKIT - KIT Index to denote the Material LKIT - KIT Index to denote the Labor CKIT - KIT Index to denote the Construction cost VKIT - KIT Index to denote the Variable cost (Over head cost)

By entering theses KIT indexes according to the job we can calculate the cost for any construction using computer software called PRONTO or possible to calculate the cost manually also. PRONTO make it easy the jobs costing. 11

Training Report_______________________________________________________________________________________________________________

2.1.2.4 LV Planning Planning the LV distribution systems after secondary substations in the other word 400V network planning, this is done to supply recommended voltage level at the consumers end by considering the length of conductors and consumer loads. Hence the voltage drops of conductors are calculated. If not satisfied the voltage levels new secondary substation or tie line is proposed to supply quality electricity to consumers.

2.1.3 LECO Head Office 2.1.3.1 Engineering Division Basically this division does the system development, procurements handling for the following. For the system development process they forecast the future energy demand and the other thing is planning the network as suitably for distribute that energy. Then do the load flow analysis to identify the system under worst cases and identify the required upgrades in the network. If the present primary substations are not enough then have to go for new primary substations. For the above upgrading financial analysis do using the above reports. 2.1.3.2 Load forecast There are four possible method/ models for Load forecasting Judgmental method Time trend Model Regression Model Econometric Model

LECO uses time trend and regression models, in this process present and past 10 years data uses and assuming liner system forecasted the future demand. 2.1.3.3 Planning Under the planning network of 11 kV system is modeled and then do the load flow analysis to plan the network system as suitably. Network spread over LECO area have mapped in the mapping process GPS is used to find the exact coordinates of the locations. For that they have equipment which can

12

Training Report_______________________________________________________________________________________________________________

communicate with satellites. At the construction of each poles, transformers, LBS etc they are included in to map with their details. 2.1.3.4 Load flow analysis Load flow analysis is done for the overall peak because peaking time for each transformer is different. So the maximum demand of each transformer is multiplied by a factor called contribution to the peak (65% for industrial, 80% for domestic). Then get the addition of loading of all the transformers at the peak and compare with the actual feeder loading near the primary substation. Then we can use the voltage near the primary substation, active and reactive power of each transformer as inputs to the software PSS (Power System Simulator). And run the software to find the required details such as feeder loadings, voltage drops, and losses. If there are problems with results, simulate the network with available proposals to avoid those issues. In this way the load flow analysis is done for five years future while increasing the loads of transformer according to the forecasting and proposed solutions to the problems and unwanted system behavior. 2.1.4Operation Division Operation division does the maintaining of the present system to supply consumer required Electrical energy in efficient manner. 2.1.4.1Distribution Control Centre 2.1.4.1.1 Task of system control centre Whole 11kV LECO distribution network system is controlled according to the command given by this centre current status of the whole distribution system can be seen from the control centre. Each and every one of breakdowns and interruptions and repairs are informed to here according this information always they update the single line diagram (MIMIC panel). Scheduled interruptions are requested by branch officers to the control centre. Then they study the situation and select the optimum way to shift loads and isolate power lines as possible as minimum the number of consumers affected from the interruption and the day which they allow. For giving permission for interruption they prepare a switching instruction and send them to the depot through branch office.

11

Training Report_______________________________________________________________________________________________________________

2.1.4.1.2 Preparing reports Service call report and Electricity supply outage reports are prepared here Service cal report Service cal report contains all the service calls and they are sorted in few categories as flows. Branch wise Customer Service Centre wise Type of fault wise Time of the day wise

They check number of calls per 100 consumers and average restoration time. It includes detailed report and group of each branch. Outage report Outage report contains all outage details both due to interruptions and breakdowns. Using those details, they calculate following reliability performance measurement indices. SAIDI - System Average Interruption Duration Index SAIFI - System Average Interruption Frequency Index CAIDI - Consumer Average Interruption Duration Index MAIFI - Momentary Average Interruption Frequency Index

Each index is calculated for each and every branch. Also get final average value for company. This report can be used to get the whole idea about the performances of the LECO distribution system.

2.1.4.2 Ekala LECO Training Centre 2.1.4.2.1 Meter testing laboratory At the meter testing place where they repair the faulted energy meters by replacing the damaged parts with relevant parts of other broken meters. Finally testing and small adjustments has done in order to send for the use. In the meter testing lab there are testing benches, that benches for testing more meter at simultaneously, only analog meters are tested in this type of test bench. In this laboratory bulk meters are programmed also.

12

Training Report_______________________________________________________________________________________________________________

Jail Bearing

Disk

Magnetic Bearing Damper Magnet Spring Suspension

Figure 2.13 Disk of energy meter Disk is divided into 100 parts and the disk is on a magnetic repulsion force. Other bearing type is jail bearing which has a small point at the end of the shaft and directly contacted with the base by means of these friction on rotation is reduced as maximum possible. The meters are mounted on the meter testing bench. And small adjustments are done. Permanent magnet is pushed towards the disk to slow down the speed, pulled to speed up. Voltage coil is adjusted with low load and no adjustments for current coil.

2.1.4.2.2 Tests apply on Energy meter Single phase and three phase mechanical and digital meters are tested here to confirm a single phase meter 3 tastings are conducted. Percentage error test Creep error test Dial test

2.1.4.2.2.1 Percentage error test This test should be done by applying rated voltage with different currents and power factors as shown in below. If the required error percentage is not meet, then adjust the Voltage and current coil positions by rotating the screw given in the energy meter and again do testing until reach the required error percentage or below that level.

16

Training Report_______________________________________________________________________________________________________________

Table 2.1 percentage error tests on Energy meter

Applying current 5% base current 100% Base current Maximum current 100% Base current power factor (pf) Unity Unity Unity 0.5 lagging Condition for confirmation ok if error is between in 2.5% ok if error is between in 2% ok if error is between in 2% ok if error is between in 2%

2.1.4.2.2.2 Creep error test Apply 80% to 110% of rated voltage with no current input to the current coil about 20 minutes. If the disk cannot complete at least single revolution meter is considered as acceptable for creep test (no creep error). If the disk completed one or more rotation adjust the damping magnet and test again until meet the required error less condition.

2.1.4.2.2.3 Dial test Apply current and rated voltage and all testing meters are connected to flowing 1kWh and counting the revolutions of the disk to ensure weather the applied energy is indicated correctly and the indicated in registry correctly.

2.1.4.3 Transformer repair centre 2.1.4.3.1 Transformer Testing 2.1.4.3.1.1 Megger test Transformer were testing to find winding insulation failure using megger tester resistance was measured between each winding by applying high voltage Check the Megger reader before test. Then Keeping voltage at 2500 V Test HV wingding to earth insulation level. Test HV wingding to LV wingding insulation level Keeping voltage at 1000 V Test LV to Earth insulation level 500 or above insulation level is ok

17

Training Report_______________________________________________________________________________________________________________

Neutral Terminal

Megger tester Phase Terminals Transformer Cover

Primary Winding

Secondary Figure 2.14 Megger test on transformer 2.1.4.3.1.2 Ratio test 400 V is applied to the HV side and Check the voltage of phase to neutral for each phase. Phase to phase for each tap position of the tap changer. For each phase to neutral voltage should same For each phase to phase voltages should be same Winding

18

Training Report_______________________________________________________________________________________________________________

2.2 Training Experience in Ceylon Electricity Board 2.2.1 Samanalawewa Hydropower Plant Samanalawewa hydro power plant is possible to contribute of 120MW normal power output to the national power system. Power generation is done by using 60MW salient pole two synchronous generators. 10.5 kV output from generators are setup into 132kV using two power transformers. Through the switch yard this is connected to Balangoda and Embilipitiya Double circuit lines. Power plant Following shows a brief sketch of power plant

Resavoiur

Intake

Surge chamber Portal Valve house Power tunnel Penstoke Power house

Tail race

Figure 2.15 Power plant Dame

Rock fill

Clay Core

Figure 2.16 Dame Section Rock fill clay core type dam has maximum height of 100m and length of 480m

power tunnel Penstoke

Surge Chamber

2.2.1.2 Surge Chamber Figure 2.17 Surge Chamber The surge chamber is to bear the sudden pressure impact when the main inlet valve (MIV) is closed at the power house. Otherwise the penstock may be damaged. There are different types of surge chambers, this surge chamber is orifice type one.

19

Training Report_______________________________________________________________________________________________________________

2.2.1.3 Power house Water coming through the pen stoke is blocked by main inlet valve (MIV). The flow of water is controlled due to power variations by the wicket gates. There are three turbines to produce electricity. The type of turbine is Francis. Name plate data of turbine and generator are as follows. GENERATOR Output: 70.6MVA/60.1MW Output voltage: 10.5kV Power factor: 0.85 Rated Speed: 500 rpm Excitation: 120 V and 1400 A 12 poles salient pole type synchronous generator TURBINE Type: Francis Speed: 500 rpm Output: 70.2MW Vertical shaft turbine

2.2.1.5 Active power control According to variation of load connected to transmission net work is varying time to time therefore system frequency is trying to change simultaneously. It is possible increase or lower the power output by varying mechanical input given to the generator. For this Water flow is controlled by turbine governor. Wicket gates are opened when more active power is required. This is a closed loop system coupled with the speed of the turbine. Samanalawewa power station is possible to use for frequency controlling when water level is sufficient in the reservoir. 2.2.1.6 Reactive power control AVR is used to regulate the terminal voltage in a set value. Excitation is increased when the terminal voltage is decreased. Excitation is given by using a battery bank at the starting of generator and then it is switch in to excitation transformer of the generator output. The excitation for the rotor field is obtained from a 10.5-kV/270-V 600-kVA transformer rectified by thyristors and controlled by voltage regulator. The star point of the stator windings is earthed through a 8.5-kV/250-V transformer rated at 24 kVA.

20

Training Report_______________________________________________________________________________________________________________

Power Transformer 132kV 10.5kV AVR +Firing circuit Excitation transformer Generator Generator Excitation

FCB

Battery Bank

Thyristor bank

Figure 2.18 AVR 2.2.1.7 Power Transformers There are two main power transformers which are use to step up the generated voltage 10.5 kV up to 132 kV one for each generator. They are71 MVA transformers vector group is YND11 and cooling system is ONAN/ONAF. 2.2.1.8 Switchyard The 132kV double circuit transmission lines are connecting from Embilipitiya and Balangoda through switchyard. Simple single line sketch of switch yard is as follows. (Even here is not consist all equipments)

Balangoda Balangoda line-1 line-2

Bus Bar1

Bus Bar2

Figure 2.19 Samanalawewa Switch yard

Embilipitiya Embilipitiya line-2 line-1

21

Training Report_______________________________________________________________________________________________________________

Switchyard consists of two basbars ,SF6 circuit breakers, isolators, surge arrestors etc. The breakers in the switchyard can be connected to either busbar. Local control is also available for emergency and maintenance purposes. A mechanical interlock system is provided through out the electrical system. 2.2.1.9 Auxiliary supply Auxiliary supply means power required for the plant premises for lighting, maintain for office etc. For the more reliability there are three systems available auxiliary transformers for the station gives output of 400 V. in addition there is a stand by auxiliary transformer. In emergency case or blackout there is a diesel generator to give station supply. 2.2.1.10 Governor Governor mainly consists of regulator, actuator and a SSG. The regulator is of the PID type. It consists of speed sensing circuit and PID circuits and a power amplifier circuit. When the unit speed changes the actuator immediately responds to the electrical signal from the regulator which converts the speed change of the unit to the electrical signal and operates the converter to control the guide vane servomotor. The guide vane opening is changed to change the generator output so as to keep the unit speed at the rated speed. Speed sensing is provided by a SSG which is installed at the top of the generator housing. The main governor characteristics: Range of speed droop: 0-10% Governor dead time: less than 0.25 sec SSG frequency: 1000 Hz

2.2.1.10 Battery bank Batter bank is essential for a power station. Battery voltage is120 V. those are NiCad (Nickel cadmium) batteries. Excitation at the start Turbine auxiliaries Transformer auxiliaries Governor auxiliaries 22

Training Report_______________________________________________________________________________________________________________

2.2.2 Kelanithissa Thermal Power Plant Colombo is the main load centre of the Sri Lanka therefore it is very better the power station near the load centre. Kelanithissa power station is in the Colombo. In Kelanithissa power station there are six 20MW small gas turbines and 115MW one large gas turbine generator (GT). One of small turbine is damage heavily and out off working. Total available capacity is 215 MW even though they are not possible to work in their full load capacity. Only two of GTs was running in synchon (synchronous condenser) mood to supply KVar to the system. 2.2.2.1 Small Gas turbines (GTs) Compressor compressed inlet air and insert in to combustion chamber atomized diesel fuel particles are mixed with compressed air. This mixer diesel is ignited in combustion chamber. From the combustion process makes a high pressure and high temperature output this is directed to turbine and rotate the turbine. Then it couples to a synchronous generator so the electrical power is generated. This is the normal energy conversion process in any kind of gas turbine. Apart from that, this20 MW small GTs having disengaging gear box therefore they are possible to run in synchon mode. Baring motor Starting diesel engine Disengaging gear box box Generator compressor exhaust air turbine Disengaging gear

Inlet air Fuel inlet Figure 2.20 Small GT in Kelanithissa Due to heavy weight of the rotor if it allows to cool gas turbine that the rotor may sag and again starting may dangers and may cause damages to the machine. This is avoiding by a process called Combustion chamber

22

Training Report_______________________________________________________________________________________________________________

baring. Baring is even if the gas turbine shut down its rotor is regularly rotate at very low speed to avoid this sagging. 2.2.2.2 Synchronous Condenser Mode Sometimes the generators run in this mode. In this mode generator provide reactive power requirement to the national grid. While in this mode generator absorbs active power from the grid and generate reactive power to maintain the magnitude of the voltage. At this stage turbine shaft is departed from the generator shaft. Then the generator shaft rotates alone by taking active power from the grid. 2.2.2.3 Starting of Small Gas turbines (GTs) At the starting of these GTs up to 100rpm speed they are running using a diesel engine. At this speed fuel atomized gas injects to the combustion chamber and start the firing. Until come to 3000rpm diesel engine does not disengage the gas turbine and then the diesel engine is removed. Then turbine is speed up until a speed of 5100 rpm is acquired then synchronize machine to grid. 2.2.2.4 115MW Large Gas turbine (GT) This 115MW generator is also having same operation principle, differences are it consists of 1MW high torque motor to start the GT and due no disengaging gear box to disengage generator and turbine. Baring and other all process are required in here also. Starting process of this GT is as same as the GT start in combined cycle power plant GT. 2.2.2.5 GIS In plant premises there are 220kV and 132kV two GIS. GIS means gas insulated switch, all the switching functions are possible as in normal outdoor switch yard. This type of GIS is most suitable for urban area where less space taken for the system. Insulation gas medium is SF6. Breakers, isolators and bas bars all components are inside the pressurized SF6 medium.

23

Training Report_______________________________________________________________________________________________________________

2.2.3 Kelanithissa Combined Cycle Power Plant In Kelanithissa Combined Cycle Power plant synchronous generator coupled to the gas turbine generates with max power output of 115MW. Exhaust of that can run a steam turbine generator and which has max power of 50MW. Main GT is same as the large GT in Kelanithissa power plant. In combined cycle power plant the special unit is the HRSG (Heat Recovery Steam Generation) and steam turbine. Exhaust flue gas from the gas turbine contain large heat energy. That heat energy is extracted in HRSG to run steam turbine without wasting that heat energy

Steam power generation

To HRSG feed water tank Compressur

Exhast without steam producing

Exhaust from GT

Generator

Cooling Water

Generator High Pressure Turbine HRSG Combustion Camber Air inlet Fuel inlet Gas Turbine

Low Pressure Turbine

Figure 2.21 HRSG 2.2.3.1 Starting the GTs First GT is running using 1MW (cranking) motor into a 27% of its full speed (The rated speed of the turbine is 5100 rpm) and then slows down in to a 14% of its full speed .The diesel mixed gas is injected and an electric spark is given to start the burning process. Then cranking motor is speed up into 60% of GTs full speed, then control the fuel to bring up the turbine speed into 5100rpm so the speed of the turbine is reduced through gear box to connect to generator. After the magnitude of the voltage is varied by changing the excitation the frequency and the phase shift is matched through the Synchroscope. When all these three conditions fulfilled the breaker is closed.

24

Training Report_______________________________________________________________________________________________________________

2.2.4 Spugaskanda Power Plant 2.2.4.1 Overview of the Plant Sapugaskanda Power Station produces electricity which unit cost is the lowest thermal generation cost compared to plants belong CEB. All are reciprocating cargo engine, these types of engines normally produce large acoustic pollution and vibration this is due to reciprocating mechanism. Even though maintains are heavily required, this plant does the lowest cost thermal electricity power generation.

Sapugaskanda Power Station

SECTION A 4x20MW (installed capacity) SEMT PielstickFrance V-type engine each having 18 cylinders Commissioned in1984 4x16 (currently running capacity)

SECTION B

Section B1 4x10 MW (installed capacity) MAN & B&W Germany Inline-type engine each having 8 cylinders Commissioned in1998 4x9 (currently running capacity)

Section B1 4x10 MW (installed capacity) MAN & B&W Germany Inline-type engine each having 8 cylinders Commissioned in1999 4x9 (currently running capacity)

Figure 2.22 Sapugaskanda Power Station Engine Arrangement Total installed capacity is 160 MW. But currently these engines are not possible to run on that amount of full load due to reducing their capabilities this is called derating of system of generation. Thermal problems (reducing the efficiency of the cooling system) Reduce the efficiency of engine Generator winding efficiency reduce

This type of reasons cause to decrease the capacities of generation units For the Electricity generation process, there are large no of other systems are also contribute in many ways. Specially Fuel oil system, Lube oil system, cooling water system, fire protection system, steam or hot water system, engine modules, generators, control panel systems, Transformers, switch yard etc.. These are called auxiliary system.

25

Training Report_______________________________________________________________________________________________________________

2.2.4.2 Fuel oil System Storag Refinery e Fuel Oil Centrif uge Fuel treatment house Treated oil

Fuel module Engine cylinder

(Injectors) Figure 2.23 Fuel oil System The engines started by diesel and continuous running with Lanka Heavy Furnace Oil (HFO). To avoid freezing the HFO the fuel lines are coupled with Heat tracking line (hot water line). Both lines are covered with glass wool insulation. Air to fuel ratio is 14.1: 1 and free air is compressed by turbo charger. Then charged air is cold to raise the density of air in order to insert more air mass into the cylinder. Then charged air temperature is about 550C and after the compression stroke of the engine the temperature of the compressed air is about 5000C. 2.2.4.3 Engine modules There are two types of engines are in section A and section B as shown in Figure of Engine arrangement these are cargo type heavy engines therefore at the starting of engines compressed air should be injected in to the cylinder according to a sequence and drive the engine before combustion process until come to speed which suitable for combustion (before diesel inject). Four strokes this engines should be maintain, not only engine modules all the subsystems are maintain and test according to a plan after taking outages. Turbo charging is concept available in engine to increase the efficiency of the combustion process and then overall efficiency.

26

Training Report_______________________________________________________________________________________________________________

2.2.4.4 Turbo Charger Exhaust out of the engine emit large amount of heat energy, using this energy a turbine is driven and the axis of that turbine is coupled to a compressor to pressurize inlet air supply to combustion process this will increase the efficiency of the engine.

Air lesser heat and pressure Atmospheric air inlet

Compressor

Shaft

Turbine

Engine outlet hot air

Engine Inlet compressed air Engine head cooling after

Figure 2.24 Turbo charger system 2.2.4.4 Generator In section A all generation module consists generators are salient pole 14 poles machine, their excitation current is supplied with the pole mounted PMG (Permanent Magnet DC Generator) excitation level is controlled by AVR to stabilized required voltage output. In section B all generation module consists generators are also salient pole14 poles machine, their excitation current is supplied self exciter. Its operation is as follows, inside the generator having 5phase auxiliary winding, due to residual current in windings a current induces in that auxiliary winding. That current is rectified through rectifier system and control through AVR and energizer the exciter winding in exciter stator winding. Exciter rotor produces 3-phase current and this current is rectified through rotating rectifier system and finally that DC current energized the generator excitation level and now it is possible to control the excitation level from AVR.

27

Training Report_______________________________________________________________________________________________________________

5-phase auxiliary winding

5-phase

5-phase diode rectifier system AVR

feed back from terminal voltage

Stator Winding Stator of Generator Rotor of Generator

Exciter stator

Exciter rotor Rotating rectifier in the rotar

Figure 2.25 Self Exciter 2.2.4.5 Switch yard of the Power plant Generation voltage is 11 kV and stepped up to 132kV by 5 50MVA transformers. Generated power is transferred to Biyagama grid substation by using a double circuit lines. 2.2.4.6 Maintains As mention in early this type of engine required heavy maintains in very efficient manner to manage the plant for next future years, minimize the efficiency reducing and reduce the unplanned outage of machines. Not only for this plant normally any plant should have the following maintain procedures to achieve the above mentioned goals. Conditional Maintains Preventive Maintains Routine Maintains Breakdown Maintains

Preventive and Routine maintains are scheduled maintains monthly, daily or according to running time. Conditional maintain is using measurements and check up determined required maintain before breakdown. Even the machines are maintained carefully there may be some break downs at that kind of breakdown maintains are called breakdown maintains.

28

Training Report_______________________________________________________________________________________________________________

2.2.5 System Control Centre System control centre is the place where is controlling the whole Sri Lankan Electricity Transmission line including Power plants and Grid substations. According to the electricity demand System control centre command power plants to connect the system or dispatch the plant from the system. Always monitor the system frequency, system voltage, amount of Active power and reactive power, and condition of main breakers. This center communicates with all plants and Grid Substations especially with frequency controlling machine to keep the system stability. 2.2.5.1 System Stability Limits System frequency should be 50 Hz 1% and main system voltages should be as follows Table 2.2 System stability limits

System Voltages 220 kV 132kV 33kV Required Voltage Limitations Between +5% to -5% error range Between +10% to -10% error range Between +2% to -2% error range

System control centre control only 220kV and 132kV net work only. If the demand active power is greater than the generation power, frequency decreases and vice versa. There system control operators orders power station to increase their active power feed to the system when the voltage drops they adds reactive power to the system. Kothmale, Laxapana and Samanalawewa operate as frequency control centre of Sri Lankan power system. Hydro plants are taken as frequency control due to the less responding time and more controllability. Frequency control plant normally operates at half lord of its capacity. Droops setting at the power plant is changed to frequency control mood 2.2.5.2 System Operation System operation means the controlling process of whole power system by communicating with all plants and Grid Substations. This is the task should done by the operation Engineer of the system control centre. Plant connection and dispatching is not a random task. It is done according to a planning process. 29

Training Report_______________________________________________________________________________________________________________

2.2.5.3 Operation Planning According to the load curve, to satisfy the demand generation should be planned by considering losses also. For maintain of plant, grid substation or Transmission line outage planning should decide in the systematical way to minimize to disturbances to the system. Choosing of thermal power plants is depends on start/stop cost and unit cost of the thermal plants. But decisions relevant hydro power plants are more complex. The main hydro power complexes are Mahawelli and Laxapana hydro power complexes. So the raining pattern of the year must be considered in order to select the more suitable complex. The Laxapana complex is totally owned to CEB and can be use the water in the complex at any time. But Mahawelli complex is not only for power generation. Priority of the usage in Mahawelli complex is as follows. Drinking water Environmental Irrigation Power generation

So the operation of the power plants of Mahawelli complex should follow the plans got by water management meeting. The water levels of the reservoirs and ponds and cascading arrangement of the ponds are also considered by the system control engineer in order to select the running power plant. There is a parameter called water value depends on water level which is affecting to the power plant selection. Normally system control Engineers works with historical data and with their past experience. According to the predicted demand curve they inform power station to connect, remove, increase and decrease their power. For that they make daily dispatch schedule and send them to the relevant power stations individually. 2.2.5.4 Under Frequency Load Shedding Under Frequency Load shading concept is important if suddenly large load connected to system or if a plant trip off due to fault. Then that system becomes unstable at such moment frequency controlling machine also may not possible to bear the impact. Frequency is decreasing rapidly this may cause cascade tripping of generators and may cause total black out, system can regain the stability by

30

Training Report_______________________________________________________________________________________________________________

reducing loads from the system. Feeders should cut off automatically to reduce the load. According to following table feeders are cutoff by breakers. Table 2.3 Under frequency load shading schedule