Professional Documents

Culture Documents

HSE-04 - Hot Work Permit

Uploaded by

Maheshwor Man JoshiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE-04 - Hot Work Permit

Uploaded by

Maheshwor Man JoshiCopyright:

Available Formats

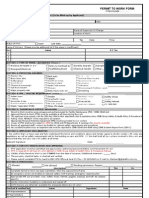

Integrated Management System

DOCUMENT TITLE:

Doc Ref. No QAB-IMS-HSE-04 Issue Date Page No 10 Nov 2012 Page 1 of 3

HOT WORK PERMIT

Welding

Permit No. SECTION 1: DETAILS OF THE RECEIVER

Name of Welder ID Number Contact No. Under the employ of Engineer Responsible Safety officer In-charge

Gas Cutting

Brazing

Grinding

Procedure Ref#

Others

SECTION 2: PERMIT VALIDITY

Date of Issue Time of Issue Area of Work Date(s) of Validity Valid till what time Equipment to Work No. of Shift of Validity Expiring After

SECTION 3: PREREQUISITE

No work involving cutting/welding, open flame or spark producing materials should be done without observing the under-mentioned procedures. Work may be stopped if any of the following is not complied with.

Hazards and Precaution Checklist Yes No N/A Controlled

Flammable materials have been removed from the location and inspection carried out by authorized person Appropriate fire extinguisher readily provided in the area of work Operator or Welder is trained in the use of fire extinguishers. Adequate and appropriate PPE is in use. Welding Gen set and terminal insulations in place with adequate earthling. Fire Watch Personnel is present. Cutting, Welding or spark producing equipment is in order All sources of flammable vapors or combustible dusts have been eliminated. Area of work now clean and dry The area of work is properly barricaded against unauthorized entrants. Adequate safety warnings and signs are now in place. The flash back arrestor gas cylinder is in place and cylinders are kept in trolley and secured Equipment and containers been cleaned and purged of all combustibles flammable liquids respectively. Fire watch size corresponds with the size of available extinguisher and personnel aware of fire alarm location.

SECTION 4: DECLARATION BY THE PERMIT RECEIVER I, representing hereby declare that I have checked the location and have briefed the welder/operator of all the prerequisites and emergency procedures and he is now informed. Name _________________________________________ Name and Address of employer (if other than QAB) Company Name: .. Nature of job: P.O. Box No. ..Tel No .. Page 1 of 3

Signed__________________________ Date______________

Contact Number (Site Rep.)

SECTION 5: PERMIT APPROVAL The Receiver, being a competent and responsible person, and having satisfactorily met the requirements as in section 3 of this permit, is hereby given permission to carry out the work as indicated above and on the equipment as demanded. PERMIT AUTHORISED BY: SIGNATURE: PRINT NAME: ___________________________ ____________________________ Being an authorized person: POSITION: ______________________________ Date:_______________ Time ______________

SECTION 6: CLEARANCE

At the end or completion of work, the recipient must declare his freedom clearance from the site and equipment. I confirm after thoroughly checking physically in the afore mentioned Hot Work area that proper housekeeping is done, leaving behind the area safe, hence closing Hot Work Permit. Closed by (Receiver): _________________________ Designation _______________________________

Signature: ___________________________________

Date:_______________ Time: _____________

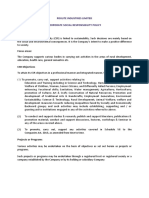

-----------------------------------------------------------------------------------------------------------------------------------------------HOT WORK PERMIT DIRECTION NOTE

PERMIT SCOPE: This permit is designed to serve the purpose of authorizing all employees, contractors and sub-contractors who have need to cut, weld, braze, grind or solder metal in and for Qatar ALPHA Beton Ready Mix Co W.L.L. This however, does not include welding or cutting activities being performed in the designated welding area(s) of the company. It is intended also to keep the HSE office informed and alerted as to when and where a hot work is to be performed in or by the company. It also aims at reassuring the competence of the Hot Work performers, as well as check excesses. DESCRIPTION: The Hot Work Permit is to be included with all bids submitted by the QAB Works and Maintenance Manager to employees, contractors or sub-contractors while assigning them any duty involving cutting, welding or any spark producing work. The Works& Maintenance Manager, with appropriate precautionary inspection of the work area, obtains the permit from Health Safety & Environment (HSE) office and issues to the receiver. The prerequisite that must be complied with is hereby stated in section 3 and it forms the condition for the release of the form by the HSE. NOTIFICATION: Prior to the commencement of the work, the receiver communicates the HSE officer with the start time and date(s) as provided in the validity in section 2. If a contractor or sub-contractor is involved, an approved copy of this permit must be submitted to the Security Officer in-charge for security purposes.

EMERGENCY NUMBER: In case of fire outbreak or any other life threatening emergency, please call Qatar Alpha Beton Safety Officer on company emergency number:77343524 and in extreme situations call 999.

Page 2 of 3

PERMIT REMAINS SECURED AT THE WORKSITE UNTIL THE WORK IS COMPLETED, AND THEREAFTER, FORWARDED TO THE HSE DEPARTMENT.

Page 3 of 3

You might also like

- Hot Work Permit: SI Tracking #Document6 pagesHot Work Permit: SI Tracking #gurvinder singhNo ratings yet

- Permit To Work ProcedureDocument25 pagesPermit To Work ProcedureGordon Watson100% (1)

- 26 - Hot Work Procedure V2Document18 pages26 - Hot Work Procedure V2Hussain AhmedNo ratings yet

- Hot Work Permit FormDocument2 pagesHot Work Permit FormN.JNo ratings yet

- Ofs Permit To Work FormDocument2 pagesOfs Permit To Work FormZ Babar KhanNo ratings yet

- Safety ManualDocument74 pagesSafety ManualKentDemeterio100% (1)

- Hot Work PermitDocument2 pagesHot Work PermitAndiWSutomoNo ratings yet

- Permit To Work Form UpdatedDocument3 pagesPermit To Work Form UpdatedJoseph Tran86% (7)

- Pressure Test Work PermitDocument2 pagesPressure Test Work PermitMd Abdul Raja83% (6)

- Electrical Permit (Isolation) FormDocument2 pagesElectrical Permit (Isolation) FormNassim Akrouche100% (1)

- Toolbox Talk Fire SafetyDocument1 pageToolbox Talk Fire SafetyAdel Suker0% (1)

- Work Permit For Working at HeightDocument2 pagesWork Permit For Working at HeightVipul BansalNo ratings yet

- Confined Space ProcedureDocument14 pagesConfined Space Procedurewanazuadi100% (1)

- Electrially Energized Area Entry PermitDocument1 pageElectrially Energized Area Entry PermitShahrukh Faizan AhmedNo ratings yet

- PTWDocument2 pagesPTWMazhairil Paet100% (1)

- Request For Permit To Work (PTW) - Contactor Application: PLTG 75 MW Paya Pasir MedanDocument2 pagesRequest For Permit To Work (PTW) - Contactor Application: PLTG 75 MW Paya Pasir MedanDimas Dwi SwarnaNo ratings yet

- 7 Hand Held Power ToolsDocument4 pages7 Hand Held Power ToolsGilmar MonteiroNo ratings yet

- Incident Investigation Procedure.Document5 pagesIncident Investigation Procedure.Naga Rajan0% (1)

- Safe Driving & Nutrition MonthDocument12 pagesSafe Driving & Nutrition Monthkashifbutty2kNo ratings yet

- Chemical Spill Response GuideDocument7 pagesChemical Spill Response GuideDaniel BobbittNo ratings yet

- Legislation Register - ExampleDocument10 pagesLegislation Register - ExampleKingsley AhanonuNo ratings yet

- Title: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Document5 pagesTitle: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Adeyinka MichealNo ratings yet

- Loto FormDocument9 pagesLoto FormJoey GNo ratings yet

- HSE Training Plan-2013Document1 pageHSE Training Plan-2013Abd Zouhier100% (1)

- QHSE-P221 Qalhat Safety Regulation For Work Under Permit (Permit To Work) Oman LNGDocument147 pagesQHSE-P221 Qalhat Safety Regulation For Work Under Permit (Permit To Work) Oman LNGMauro MLRNo ratings yet

- R-16 Safety Management Review MeetingDocument2 pagesR-16 Safety Management Review MeetingSandeep Kumar100% (1)

- EHS PPE ProcedureDocument19 pagesEHS PPE ProcedureRene Gonzalez100% (1)

- Contractor - Permit To Work in Occupied Areas: (Select All That Apply)Document2 pagesContractor - Permit To Work in Occupied Areas: (Select All That Apply)AAT SupplyNo ratings yet

- Electrical Isolation PermitDocument2 pagesElectrical Isolation Permitsindarth raveendrakrishnan100% (9)

- Combined Group Co. For Trading & Contracting: Hse Objectives 2015Document1 pageCombined Group Co. For Trading & Contracting: Hse Objectives 2015loveson709100% (1)

- 010 - Permit To Work Procedure Feb 2013Document61 pages010 - Permit To Work Procedure Feb 2013vdeviv100% (1)

- 06-F03 Ohs Introduction & Induction: Safety Induction Training Check-ListDocument2 pages06-F03 Ohs Introduction & Induction: Safety Induction Training Check-ListSn AhsanNo ratings yet

- 2.2 Lock Out, Tag Out and Try OutDocument11 pages2.2 Lock Out, Tag Out and Try OutSuad BushiNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitMenGuitarNo ratings yet

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 pagesJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- PTW Training PackageDocument39 pagesPTW Training PackageMoucha JustdoitNo ratings yet

- HSEkpisDocument14 pagesHSEkpissam lissenNo ratings yet

- PR08 Permit To WorkDocument10 pagesPR08 Permit To WorkMuhammad WaleedNo ratings yet

- Ppe ProcedureDocument32 pagesPpe ProcedureIbrahim Umer100% (2)

- Lock Out Tag OutDocument2 pagesLock Out Tag OutPablo Arreola RomeroNo ratings yet

- Confined Space Entry: Approval and Authority To CommenceDocument2 pagesConfined Space Entry: Approval and Authority To CommenceAndiWSutomo100% (1)

- First Aid Risk Assessment TemplateDocument3 pagesFirst Aid Risk Assessment TemplateRameeSahibaNo ratings yet

- Permit To Work Presentation - OriginalDocument25 pagesPermit To Work Presentation - OriginalAntonne E. PhillipNo ratings yet

- Safe Work Permit FormDocument1 pageSafe Work Permit FormAbdulah Asagi33% (3)

- General Work Permit R1Document1 pageGeneral Work Permit R1Muthu AyyanarNo ratings yet

- EWAC Safety InductionDocument14 pagesEWAC Safety InductionPritesh Ramesh BareNo ratings yet

- Bhate & Raje Construction Co. Pvt. LTD: Electrical Work PermitDocument1 pageBhate & Raje Construction Co. Pvt. LTD: Electrical Work Permitvinayak salve100% (1)

- Ppe Policy PDFDocument22 pagesPpe Policy PDFash100% (1)

- 7.4 Lockout TagoutDocument18 pages7.4 Lockout TagoutJose de la PazNo ratings yet

- Consequence Management Sytem EsepplDocument1 pageConsequence Management Sytem Eseppluttam mishra100% (2)

- Hot Work PermitDocument1 pageHot Work PermitAndy SaycoNo ratings yet

- HSE Policy SampleDocument1 pageHSE Policy SampleRajkumar NandaNo ratings yet

- Permit To Work No.: - 1-General Information - 4 - Additional PrecautionsDocument3 pagesPermit To Work No.: - 1-General Information - 4 - Additional PrecautionsHenry WoartNo ratings yet

- General Work PermitDocument1 pageGeneral Work Permitgurvinder singhNo ratings yet

- DEE EHU-03!5!1 Health and Safety Committee Meeting MinutesDocument2 pagesDEE EHU-03!5!1 Health and Safety Committee Meeting MinutesFred AlmaNo ratings yet

- Form-58 Confined Space Entry LogDocument1 pageForm-58 Confined Space Entry LogRajesh Kumar SinghNo ratings yet

- Official (Cultural) Holidays For Srawan 2074 - Chaitra 2074: S.N Month Day English MTH Day Days HolidaysDocument2 pagesOfficial (Cultural) Holidays For Srawan 2074 - Chaitra 2074: S.N Month Day English MTH Day Days HolidaysMaheshwor Man JoshiNo ratings yet

- Raman Construction Pvt. Ltd. Sifal-7, Kathmandu: Asset Transfer FormDocument2 pagesRaman Construction Pvt. Ltd. Sifal-7, Kathmandu: Asset Transfer FormMaheshwor Man JoshiNo ratings yet

- For Umesh: Cleaning Schedule For Staff RoomsDocument4 pagesFor Umesh: Cleaning Schedule For Staff RoomsMaheshwor Man JoshiNo ratings yet

- Functional ObjectiveDocument1 pageFunctional ObjectiveMaheshwor Man JoshiNo ratings yet

- Raman Construction Pvt. Ltd. Sifal-7, Kathmandu: Asset Transfer FormDocument2 pagesRaman Construction Pvt. Ltd. Sifal-7, Kathmandu: Asset Transfer FormMaheshwor Man JoshiNo ratings yet

- M-105 - Equipment History CardDocument2 pagesM-105 - Equipment History CardMaheshwor Man JoshiNo ratings yet

- Registration FormDocument2 pagesRegistration FormMaheshwor Man JoshiNo ratings yet

- Daily Inspection Checklist For ExcavatorDocument1 pageDaily Inspection Checklist For ExcavatorMaheshwor Man JoshiNo ratings yet

- Job Analysis QuestionnaireDocument5 pagesJob Analysis QuestionnaireMaheshwor Man JoshiNo ratings yet

- RQMS HRD 01 - Employee Record Rev0Document2 pagesRQMS HRD 01 - Employee Record Rev0Maheshwor Man JoshiNo ratings yet

- Vehicle Repair Order - Work OrderDocument1 pageVehicle Repair Order - Work OrderMaheshwor Man JoshiNo ratings yet

- M-105 - Equipment History CardDocument2 pagesM-105 - Equipment History CardMaheshwor Man JoshiNo ratings yet

- Log Sheet FormDocument1 pageLog Sheet FormMaheshwor Man JoshiNo ratings yet

- Employee Clearance FormDocument1 pageEmployee Clearance FormMaheshwor Man JoshiNo ratings yet

- 03 Interview PlanDocument1 page03 Interview PlanMaheshwor Man JoshiNo ratings yet

- 04-General Interview QuestionnaireDocument1 page04-General Interview QuestionnaireMaheshwor Man JoshiNo ratings yet

- Interview Assessment Form: Position Name of Candidate Date of Interview Start Time DurationDocument1 pageInterview Assessment Form: Position Name of Candidate Date of Interview Start Time DurationMaheshwor Man JoshiNo ratings yet

- Business Management IntroductionDocument6 pagesBusiness Management IntroductionMaheshwor Man JoshiNo ratings yet

- 04-General Interview QuestionnaireDocument1 page04-General Interview QuestionnaireMaheshwor Man JoshiNo ratings yet

- Interview Screening ChecklistDocument1 pageInterview Screening ChecklistMaheshwor Man JoshiNo ratings yet

- H-100 - Employee Information SheetDocument1 pageH-100 - Employee Information SheetMaheshwor Man JoshiNo ratings yet

- Interview Assessment Form: Position Name of Candidate Date of Interview Start Time DurationDocument1 pageInterview Assessment Form: Position Name of Candidate Date of Interview Start Time DurationMaheshwor Man JoshiNo ratings yet

- RQMS PF 100 - Daily Site DiaryDocument2 pagesRQMS PF 100 - Daily Site DiaryMaheshwor Man JoshiNo ratings yet

- H-100 - Employee Information SheetDocument1 pageH-100 - Employee Information SheetMaheshwor Man JoshiNo ratings yet

- New Employee Joining ReportDocument1 pageNew Employee Joining ReportMaheshwor Man JoshiNo ratings yet

- QF-150 - CAPA (Corrective and Preventive Action)Document2 pagesQF-150 - CAPA (Corrective and Preventive Action)Maheshwor Man Joshi100% (1)

- Raman Employee HandbookDocument9 pagesRaman Employee HandbookMaheshwor Man JoshiNo ratings yet

- Job Analysis QuestionairreDocument5 pagesJob Analysis QuestionairreMaheshwor Man JoshiNo ratings yet

- Raman - Awarness Training PresentationDocument134 pagesRaman - Awarness Training PresentationMaheshwor Man JoshiNo ratings yet

- Smu Lms SynopsisDocument13 pagesSmu Lms SynopsisMaheshwor Man JoshiNo ratings yet

- Belbin's Team ModelDocument2 pagesBelbin's Team Modelsonu_saisNo ratings yet

- Procedure Issuing EtaDocument5 pagesProcedure Issuing EtaCarlos FrançaNo ratings yet

- Important Questions - BlockchainDocument1 pageImportant Questions - BlockchainHarsh Varshney100% (1)

- Elephant Catalog V13 PDFDocument96 pagesElephant Catalog V13 PDFsamuelNo ratings yet

- ResearchDocument12 pagesResearchIsla, AltheaNo ratings yet

- Pertemuan 1 - Verb, Noun, Adjective and AdverbDocument6 pagesPertemuan 1 - Verb, Noun, Adjective and AdverbHaris PambudiNo ratings yet

- UA5000 V100R019C06 Hardware Description 05 PDFDocument563 pagesUA5000 V100R019C06 Hardware Description 05 PDFdabouzia slahNo ratings yet

- Rack Interface Module 3500 20SDocument71 pagesRack Interface Module 3500 20SmaheshNo ratings yet

- Stulz C7000R 01 PDFDocument198 pagesStulz C7000R 01 PDFNarciso Torres0% (1)

- 67 - Es - Ut Republic Csalamade BooDocument47 pages67 - Es - Ut Republic Csalamade BooTyler LeeNo ratings yet

- TEMPLATE - MODULE 5 - 8 Step Change Management WorksheetDocument9 pagesTEMPLATE - MODULE 5 - 8 Step Change Management Worksheetapril75No ratings yet

- STIGA - Vue Eclatée Moteur BRIGGS & STRATTONDocument32 pagesSTIGA - Vue Eclatée Moteur BRIGGS & STRATTONregis.petitjeanNo ratings yet

- Program Documentation Lesson 10Document32 pagesProgram Documentation Lesson 10Armechelyn DerechoNo ratings yet

- AIMS Manual - 2021Document82 pagesAIMS Manual - 2021Randyll TarlyNo ratings yet

- CSR of Pidilite PDFDocument2 pagesCSR of Pidilite PDFtarang keraiNo ratings yet

- Future Christchurch: Solutions. Housing: Biran HeDocument108 pagesFuture Christchurch: Solutions. Housing: Biran HecamiayoungNo ratings yet

- Anti FoundationalismDocument4 pagesAnti FoundationalismKostasBaliotisNo ratings yet

- Swot Analysis of Revlon IncDocument5 pagesSwot Analysis of Revlon IncSubhana AsimNo ratings yet

- HTTPHeader LiveDocument199 pagesHTTPHeader LiveDenys BautistaNo ratings yet

- Appendix-Design CalculationsDocument3 pagesAppendix-Design CalculationsVanessa M. MartinezNo ratings yet

- Multimedia Critique Paper 1Document4 pagesMultimedia Critique Paper 1api-345838334No ratings yet

- 01-Toy Product DesignDocument54 pages01-Toy Product DesignJuanNo ratings yet

- Senarai Harta Modal Makmal KomputerDocument20 pagesSenarai Harta Modal Makmal Komputerapi-19878848100% (1)

- All Excell FunctionsDocument3 pagesAll Excell Functionsrajesh_jeyachandranNo ratings yet

- Equinoxes and Solstices: UttarayanamDocument2 pagesEquinoxes and Solstices: UttarayanamRahul SharmaNo ratings yet

- Khairro SanfordDocument2 pagesKhairro SanfordJezreel SabadoNo ratings yet

- Eng1-LAS MELC-3 FINALDocument10 pagesEng1-LAS MELC-3 FINALFarrah Joy AguilarNo ratings yet

- Laws of ThermoDocument13 pagesLaws of ThermofabyunaaaNo ratings yet

- 16 Advantages & 10 Disadvantages of Solar Panels in 2022Document29 pages16 Advantages & 10 Disadvantages of Solar Panels in 2022xaxinev359100% (1)