Professional Documents

Culture Documents

Ice Cream 285

Uploaded by

Subhash KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ice Cream 285

Uploaded by

Subhash KumarCopyright:

Available Formats

Ice-Cream

Booklet No. 285 Dairy Management And Milk Products: DMMPS-15

Contents Preface I. Introduction ll. Types III. Ingredients and composition A. Dairy products B. Sweetening agents C. Fruits and nuts D. Additives E. Equipments F. Average composition IV. Role of the Constituents V. Manufacturing Methods Preface Ice-cream is a very popular frozen confectionary dairy product consumed in India and other countries as well. Ice- cream is a mixture of cream, sugar and flavouring converted into a semi solid porous frozen mass by mixing in a freezer. The quality of ice cream is determined by its raw materials, composition, body and texture, flavouring and colouring, processing and storage. This booklet deals with all these aspects of ice-cream in detail. Dr. K.T. Chandy, Agricultural & Environmental Education I. Introduction There is a growing world-wide market for frozen dairy products and frozen confectionary. A good profit can be realized by breaking into the ice-cream novelty market. Today the icecream may be considered a luxury food item although its popularity is increasing rapidly. Ice-cream is a popular milk-product. This is prepared by mixing cream and milk in different proportions. About 0.3 percent of the total milk produced in India is utilized for icecream making. The demand for ice-cream has recently increased a great deal in towns and cities. The quality of ice-cream is determined by its raw materials, composition, body and texture, flavouring and colouring, processing, and storage. The body and texture of ice-cream made from buffalo milk may be slightly better than that of cow milk. Ice-cream may be defined as a frozen dairy product made by suitable blending and processing of cream and other milk products, together with sugar and flavour, with or without stabilizer or colour, and with the incorporation of air during the freezing process. It may contain permitted stabilizers and emulsifiers not exceeding 0.5 % by weight. The product should contain not less than 10% milk fat, 3.5 % protein and 36.0 % total solids. Starch may be added to a maximum extent of 5 percent.

No standard classification of ice-cream has yet been adopted by the industry, even in developed countries. However, some of the important frozen desserts can be classified as follows. II. Types There are various types of ice-cream available in the market. The different types of icecreams are based on colour, flavour, taste and the base composition. The different types of icecreams consumed are briefly stated here. 1. Plain It is an ice cream in which the colour and flavour ingredients together amount to less than 5 percent of the volume of the unfrozen ice cream. 2. Chocolate It is an ice cream flavoured with cocoa or chocolate. 3. Fruits It is an ice cream containing fruits with or without additional fruit flavouring or colour. Fruits such as strawberry, apricot, pineapple, mango, banana, frozen, packed, canned or preserved are added. 4. Nut Ice cream containing nut, such as almonds, pistachio walnuts, cashewnuts etc. with or without additional flavouring or colour. 5. Milk ices or milk lollies These cream are frozen product obtained from milk, skim milk or milk products with or without the addition of cane sugar, eggs, fruits, fruit juices, nuts chocolates, edible flavours and permitted food colours. The product should contain not more than 2.0% milk fat, not less than 3.5 percent proteins and not less than 20% total solids. 6. Ice Ice are made of fruits juice, sugar and stabilizer with or without additional fruit acid, colour, flavouring or water, and frozen to the consistency of ice cream. Usually contain 28 to 29 percent sugar, 20 to 25 percent over run and no dairy products. 7. Sherbet Sherbet is made of fruit juices, sugar stabilizer, and milk products. 8. Fancy moulded In this, the ice-cream is moulded in fancy shapes and composed either of one colour and flavour of ice cream or a combination of colours and flavours, or one decorated. Examples are: brick ice cream, cakes, cakes roll, moulds representing fruits etc. 9. Novelties A novelty ice-cream or frozen confectionary is an specially shaped and usually a lowpieced package containing and individual serving whose main appeal consists in its shape, size, colour or convenience for eating. 10. Soft ice cream (softy)

Softy is sold as drawn from the freezer without hardening. III. Ingredients and Composition Commercial preparation of ice cream involves certain ingretients and constituents. These may be briefly mentioned and explained as follows: A. Dairy products Dairy products include sweet cream, frozen cream, plastic cream, unsalted butter & butter oil. These also serve as a source of fat for the preparation of ice cream. Source of milk -not fat: -Skim milk -Skim milk powder -Condensed skim milk (plain I sweetened -Sweet cream butter milk. B. Sweetening agents The sweetening agents used as additives for the r preparation of ice-cream commercially are as following. -Corn sweetener: Refined com sugar (dextrose) or -Corn syrup (liquid) -Contain dextrose and maltose. -Dried corn syrup solids: Contain dextrose and maltose together with dextrin. -Invert sugar: Mixture of different parts of glucose and fructose and generally obtained in one from of syrup. Sweeter than sucrose. -Saccharin: This is most commonly used as an artificial sweetener. -Sucrose: This is commonly known as granulated cane or beet-sugar. This is the most widely accepted source of sugar thought the world. C. Fruits and nuts The various types of fruits and nuts used in ice-cream preparations are apple, banana, mango, pineapple, grape almonds, pistachio, walnut, groundnut are generally used. They help to improve the acceptability and palatability of ice- cream. D. Additives Additives are the substances added in a food product in small amounts for a special purpose. They are mainly chemical in nature. Additives are added in addition to other ingredients but for a special purpose. 1. Colours There are various forms of colouring agents used in the preparation of ice-cream. Mainly the colours used are in, the powdered form or liquid form. The commonly used colours are yellow, green, pink, etc. depending on the type of ice- cream 2. Eggs solids Yolk solids improve whipping ability of the ice-cream mixture. 3. Stabilizers The various stabilizing agents used in the preparation of ice-cream are -Gelatin of animal source -Sodium alginate -this is of vegetable origin and widely used, -Guargum -this is of Indian origin

4. Emulsifiers The emulsifiers used in the preparation of ice-cream are the mono- or di-glycerides of fat -forming fatty acids. 5. Flavours The flavouring agents used in the preparation of ice-cream are vanilla, chocolate, strawberry, pineapple, lemon, banana, mango and orange etc. E. Equipments The following materials/equipments are required for the preparation of ice-cream: -Mixing tank -Pasteurizing plant -Homogenizer -Ice-cream freezer -Filling unit -Hardening cabinet -Ice-cream cups with lids -Weighment facilities F. Average composition The average composition of a plain ice-cream can be briefly enumrated here. Total solids (percent by weight) -36.0 (minimum) Milk fat % -10.0 min Acidity % -0.25 (max) Sucrose % -15.00 (max) Weight in grams, per lit/min -525 IV. Role of the constituents The various ingredients and constituents used in the preparation of ice-cream have been discussed. Now, here we discuss about the role, function and importance of these constituents in the ice-cream. 1. Milk fat Milk fat helps to enrich and give a full, creamy flavour. If the milk fat is slightly offflavoured, the defect will be noticeable. The fat also contributes to the body and melting resistance of ice-cream while producing a smoothness of texture. 2. Milk -solids -not fat (MSNF) They consist of milk proteins, milk sugar and mineral matter, They are high in food value and also inexpensive. The milk proteins help to make ice- cream more compact and smooth, 3. Sugar The main function of sugar is to increase the acceptability of ice-cream. The desired sweetening effect is only produced by sucrose, Sugar are usually the cheapest source of the total solids in the mix. 4. Stabilizers Stabilizers are used to prevent the formation of objectionably large ice crystals in icecream, especially during storage since they are added in very small quantities, they have a negligible influence on food value and flavour.

5. Emulsifiers Emulsifiers are used mainly to improve and provide a uniform whipping quality to the mixture, and to produce a drier ice-cream with smoother body and texture. 6. Flavour and colour Flavour increases the acceptability of ice-cream, and colour improves its aesthetic appeal. V. Manufacturing Methods A simple process for the manufacture of ice- cream is given below. 1. Procurement of raw material Milk and cream or any other raw milk products should be fresh and free from any kind of off-flavour. Other material such as sugar, stabilizer and colour should also be pure and of high quality. 2. Cleaning and sterilization of appliances Assemble the freezer part and the utensils to be used. Thoroughly clean them using about 25% soda solution. Sterilize with hot water above 180F. This should be done in order to ensure freedom from off -flavours to reduce bacterial count, and to avoid contamination of pathogenic organisms. 3.1ce-cream mix preparation First of all, weigh separately all the ingredients to be used. Then mix the ingredients thoroughly with sugar while heating and this mixture slowly to the liquid ingredients. The order in which ingredients are added as follows. All liquid ingredients are placed in the jacketed vat provided with a power stirrer. The dry ingredients including skim milk powder, sugar and stabilizer, are added while the liquid material is agitated and before the temperature reaches 49c (120F). Proper suspension to avoid lumpiness of the dry ingredients may be obtained by either mixing the dry material thoroghly with part of the sugar before slowly adding it to the liquid or by slowly adding these substance to the liquid. If gelatin is the stabilizer used, it is best added after it is thoroughly mixed with an equal volume of sugar, and before the liquid material reaches 49C (120F) alternative, it can be sprinkled on the surface of the cold liquid and allowed to soak before the mixture is heated, or soaked in water and then the mixture is heated to completely dissolve the gelatin, which is usually added to a warm (38- 49/100- 120 F) mix. If sodium alginate is used, it should not be added until the temperature of the liquid material has reached at least 66 (150F). The dry sodium alginate is not allowed to soak but is stirred up with cold water and immediately dumped into the hot mix. When butter, plastic cream, frozen cream or other frozen products are used, they should be cut into fairly small pieces and added after time has been given to allow for complete melting before the pasteurizing temperature is reached. 4. Pasteurizing

Proper pasturization of all ice -cream mixes is compulsory because this process destroys all pathogenic or disease producing bacteria, thereby safe guarding the health of the consumer. The advantages of pasturization are a. It renders the mix completely free of pathogenic bacteria b. Dissolves and help to the blend the ingridient of the mix c. It improves flavour d. It improves keeping quality e. It produces a mole uniform product. Proper pasteurization consist in rapidly heating the mix to a definite temperature (68.5 oC or 155 F) holding it at that temperature for a definite minimum period of time (30 minutes) and then rapidly cooling it below 5C (40 F). 5. Homogenization Homogenization of the ice-cream mix is essential. The main purpose of homogenization is to make a permanent and uniform suspension of fat by reducing the size of the fat globule to a very small diameter. It provides a more uniform and smoother texture to the ice-cream. The mix is usually homogenized at temperature from 63 to 77 C (145 to 170F). For the house hold preparation the mixie can be used for the homogenization process. 6. Cooling and ageing Cooling the mix immediately after homogenization to 0- 5C (32-40F) is essential after which it should be held in ageing tanks until used. Ageing refers to holding the mix at a low temperature for a definite time before freezing. The ageing temperature should not exceed 5C (40F). The ageing time under average commercial condition may be 3 to 4 hours. Ageing improves the body and texture of ice-cream and increase melting resistance. 7. Freezing the mix When the mix has been properly aged. it is ready for the freezing process, which follows immediately. Freezing is one of the most important operation in the making of ice-cream on which depends the quality, palatability and yield of the finished product. When the ice-cream is partially frozen to a certain consistency, it is drawn from the freezer into packages and quickly transferred to cold storage rooms, where the freezing and hardening process is completed. Normally the freezing will take place in about 10 minutes. Freezing may be stopped when the ice-cream has progressed to a sufficient stiffness. 8. Hardening and storage When ice-cream is drawn from the freezer and put into the container to be placed in the hardening room, it has a semi -fluid consistency not stiff enough to hold it in shape. The freeing process is, therefore continued without agitation during hardening until the temperature of the ice-cream reaches -18 C (OF) below. Most operators allows a hardening time for 12 hours. As in the freezer, quickly hardening is better, since slow hardening gives rise to large ice crystals and coarseness. The different hardening systems are given in the following table 1.

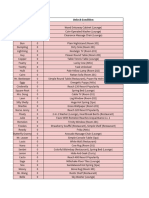

Table 1: Ice-cream hardening systems Sl.No 1 2 3 Hardening systems Hardening rooms Hardening tunnels Hardening cabinets Temp. maintained C F (-) 12 to (-) 45 10 to (-) 50 (-) 34 to (-) 45 (-) 30 to (-) 50 (-) 23 to (-) 26 (-) 10 to (-) 15

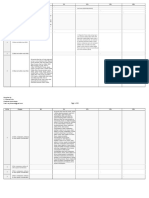

After the ice -cream is hardened, it may be immediately marketed, or it may be stored for a week or two at the most. The operation of storage rooms is the same as for the hardening room with two exceptions: The temperature should be maintained uni-formily at a point between -23 o C to -18 C (-10oF to 0oF) and the packages should be piled very close to each other. Some precaution to be observed in the operation of hardening or storage rooms are: a. Provide facilities for calling for aid, if the operator accidentally is trapped inside. b. Keep both an axe and a sledge hammer in a definite place just inside the door. c. Avoid fluctuation in the temperature. 9. Overrun Overrun is usually defined as the volume of ice-cream obtained in excess of the volume of mix. It is usually expressed as a percentage. This increased volume is composed mainly of the air incorporated during the freezing process. The amount of air which is incorporated depends upon the composition of the mix and the way it is processed and is regulated so as to give that percentage of overrun or yield which will give the proper body, texture and palatability necessary to a good quality products. Too much air will produce a snowy, fluffy, unpalatable icecream while too little, a soggy and heavy product. The desirable percentage overrun in different ice- creams is given in the following table 2. Table 2: Percentage overnln in ice-creams Sl.No Products % overrun 1 Ice-cream packaged 70 to 80 2 Ice-cream bulk 90 to 100 3 Soft ice-cream (softy) 30 to 50 10. Distribution When ice-cream is marketed, the manufacturer usually transports it to the retailer under refrigeration at the same temperature as is maintained in the retailer cabinet. The various methods of refrigerating the distribution vehicle are: a. Dry ice refrigeration The dry ice is solid carbon dioxide with a freezing point of 78o C ( -109o F). It is used extensively for packages delivers. I It is cut into pieces of an appropriate size, which are wrapped in paper to delay the rapid evaporation, and then placed around the package of the ice-cream inside an insulated packet or in a single service type packet. The later is usually a cardboard box and is used especially for the carry package. This system is popular for the carry out package. This system is popular for retailing ice-cream in push cart in big cities of India.

Advantages The advantages of dry ice refrigeration system can be briefly mentioned here. -It is neither moist nor messy. -The package is neat in appearance. -It is very light. ii. Disadvantages The disadvantages of the dry ice refrigeration system can be briefly enumerated here. -At present, it is expensive and availability is limited. -Loss during handling and storage is up to 10 -15% -There greater opportunity for heat shock, which may injure texture of the ice-cream. b. Refrigerated truck This is the most commonly used means of the transportation for ice-cream in developed countries. The truck is refrigerated overnight, and loaded with hardened ice cream the following morning. c. Frozen containers (Freezers) Jacketed metal containers, known as Eutectic pads, which contain calcium chloride. Solution of specific gravity of amount 1.1, are refrigerated in a similar brine tank whose specific gravity is about 1.26, at a temperature of -32 C (-25F) The container attain a temperature of -21C (-5F) and are then placed around the packaged ice-cream. This arrangement is used by a few ice-cream factories for air-lifting ice-cream in this country . A. Soft Ice-cream (softy) There is a tremendous demand for the form of ice -cream which has generally come to be known as "softy". The term has been applied largely because this product is marketed in a soft condition and is ready for consumption shortly after it is drawn from the freezer. It is solid under different trade names such as Dairy Queen, Zesto, Sweeden freeze. But in our country it is mostly known as "SOFfY". The composition of the softy ice-cream has been given in the following table 3. Table 3: Composition of soft Ice-cream Sl.No 1 2 3 4 Constituent Fat Milk-solid (not fat) Sugar Stabilizer & emulsifier Percentage -3 to 6 -11 to 14 -12 to 15 -0.4 to 0.6

1. Selection of ingredients for preparation of softy The following essential and optional ingredients are required for the preparation of softy commercially. a. Dairy products Essential Ingredients Optional Ingredients

1. Fresh sweet milk 2. Fresh sweet cream 3. Dried skim milk

1. Plain condensed milk 2. Plain condensed skim milk 3. Sweetened condensed milk 4. Sweetened condensed skim milk 5. Evaporated milk 6. Sweet butter milk poV(der 7. Cream 8. Sweet, unsalted butter 9. Butter oil Optional 1. Dextrose, gulcose or com sugar 2. Com syrup, liquid or dried Optional 1. Indian gum 2. Agar-agar 3. Pactin 4. Sodium-coboxy-methyl alluloso (CMC) Artificial 1. Vanilla compounds 2. Artificial fruit flavours 3. Imitation not flavour etc.

b. Sweetening Agents Essential 1. Cane sugar c. Stabilizers and Ernulsifers Essential 1. Sodium alginate (Stabilizer) 2. Glycerol mono-stearate (G.M.S.) (Emulsifier) d. Flavouring Natural 1. Vanilla 2. OJcoa 3. Chocolate etc. 4. Strawberry 5. Pineapple 6. Lemon 7. Banana 8. Mango 9. Orange

e. Colours It is very essential that the colour of soft serve ice-cream must match with the corresponding flavour used. 2. Mixing the ingredients To avoid difficulties in mixing precalculated quantities of milk powder, sugar and stabilizer emulsifier should be mixed in the lot. Similarly the liquid ingredients, namely cream and milk should be mixed separately in a container. The solids should be mixed with the liquid ingredient gradually with constant stirring and heating to the temperature of 150F (65.5C). 3. Homogenization In order to avoid fat separation and fat churning in soft ice-crearn, the mix should be homogenized resulting in breaking of fat globules. All the mixes should be heated to 1.50F (65.5C) and homogenized in 2 stages, first at a pressure of 2500 psi. and then at 500 psi. For the household preparation mixie can be used for homogenization.

4. Pasteurization To safeguard the health of consumers by way of destroying all pathogenic and disease producing organisms present in soft ice-cream mix it must always be pasteurized. For small quantities of mix, pasteurization can be carried out in cans dipped in hot water heated by steam. All the mixes must be pasteurized at 160F (71.7C) for 30 minutes. 5. Cooling The mixes could be initially be cooled by dipping the cans in tap water. The mixes can further be cooled to about 20C (68F) by immersing the cans in chilled water. 6. Freezing A softy ice cream freezer, apart from freezing a portion of water of ice-cream mix, also incorporates the air in the mix to obtain a swell in volume or overrun. To get efficient freezing and good overrun in the ice-cream it is very essential that the optimum quantity of the mix should be taken in the freezer for freezing. This quantity of mix varies from freezer to freezer. So the freezer manufacturers advice should be followed strictly when taking the quantity of mix for freezing. Once the ice cream has dry appearance, good in consistency, contains 50- 60 percent overrun and has a temperature of -9.6C (22.5F), it should be drawn and served to the consumers. %%%%%%%%%%%

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 80% Cake Cream Margarine Trans FA RecipeDocument2 pages80% Cake Cream Margarine Trans FA RecipefernandoferozNo ratings yet

- 300+ Foods From Trader Joe's, Along With Nutritional InformationDocument53 pages300+ Foods From Trader Joe's, Along With Nutritional InformationdandvdNo ratings yet

- Chocolate Delice: December 9th, 2009Document17 pagesChocolate Delice: December 9th, 2009Daniel AgostinelliNo ratings yet

- Responsive Recipe MockupDocument3 pagesResponsive Recipe MockupAmanda AlexanderNo ratings yet

- Milkfat and Related Ingredients Serving Today's MarketplaceDocument16 pagesMilkfat and Related Ingredients Serving Today's MarketplacekanikaNo ratings yet

- Butter Manufacture PDFDocument8 pagesButter Manufacture PDFArpita S WodeyarNo ratings yet

- Case Study FormatDocument5 pagesCase Study Formatmatthew lomongoNo ratings yet

- Livret 5 GB PDFDocument20 pagesLivret 5 GB PDFJenniDelgado83% (6)

- Project On Operations ManagementDocument5 pagesProject On Operations Managementprasanthg_mba6239No ratings yet

- KP1 - Energy Balance of Mixing Process PDFDocument13 pagesKP1 - Energy Balance of Mixing Process PDFwindie annisaNo ratings yet

- Being Creative: Philippe Contic IniDocument10 pagesBeing Creative: Philippe Contic IniTalles Ribeiro33% (3)

- Easiest Homemade Ice Cream RecipeDocument12 pagesEasiest Homemade Ice Cream RecipeBryan Paul BautistaNo ratings yet

- Desserts in Jars Cookbook - Quic - Louise DavidsonDocument105 pagesDesserts in Jars Cookbook - Quic - Louise DavidsonEdgardo CamasNo ratings yet

- Milk Composition and Health BenefitsDocument35 pagesMilk Composition and Health BenefitsBorja Bueno GarciaNo ratings yet

- Resortopia - Guests GuideDocument4 pagesResortopia - Guests Guideintan3951No ratings yet

- Lista Arancelaria EUADocument547 pagesLista Arancelaria EUAvilisbeth18No ratings yet

- Homemade Ice Cream - pdf'-1Document10 pagesHomemade Ice Cream - pdf'-1Alberto KayNo ratings yet

- Catalogue Update Format (MZ)Document60 pagesCatalogue Update Format (MZ)Aung Phyoe ThetNo ratings yet

- Exercise For Final TestDocument16 pagesExercise For Final TestI Gusti Agung Yulia Kurmala DewiNo ratings yet

- 【清真认证2020】MORAs Decree No. 464 - 2020Document60 pages【清真认证2020】MORAs Decree No. 464 - 2020周永樂No ratings yet

- Indian import duty rates for live animals, meat, fish and aquatic productsDocument98 pagesIndian import duty rates for live animals, meat, fish and aquatic productsGopal UNo ratings yet

- Increasing The Protein Content of Ice Cream: J. Dairy Sci. 89:1400-1406Document7 pagesIncreasing The Protein Content of Ice Cream: J. Dairy Sci. 89:1400-1406Andres Tellez RochaNo ratings yet

- Standards and Procedures in Storing Pastry ProductsDocument8 pagesStandards and Procedures in Storing Pastry ProductsRovie Valdez100% (3)

- CustomsDocument472 pagesCustomssthapitNo ratings yet

- SITHPAT006 Produce Desserts PDFDocument20 pagesSITHPAT006 Produce Desserts PDFTikaram Ghimire100% (1)

- Backwoods Home Magazine - #64 - UnknownDocument98 pagesBackwoods Home Magazine - #64 - Unknownjlmeadowsjr100% (5)

- Coffee Drinks With and Without Liquor PDFDocument2 pagesCoffee Drinks With and Without Liquor PDFPapp AttilaNo ratings yet

- National Dysphagia Level 1 Pureed Nutrition TherapyDocument3 pagesNational Dysphagia Level 1 Pureed Nutrition TherapyNada Irva NabillaNo ratings yet

- Avocado Yummy - 50 Delicious Healthy Recipes (PDFDrive)Document110 pagesAvocado Yummy - 50 Delicious Healthy Recipes (PDFDrive)Vitor GuilhermeNo ratings yet

- Group 6Document20 pagesGroup 6Linh ChiNo ratings yet