Professional Documents

Culture Documents

En 24

Uploaded by

V. A. TripathiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En 24

Uploaded by

V. A. TripathiCopyright:

Available Formats

EN 24 Material

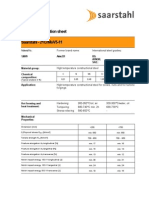

EN24 is a popular grade of through-hardening alloy steel due to its excellent machinability in the "T" condition. EN24T is used in components such as gears, shafts, studs and bolts. EN24T can be further surface-hardened to create components with enhanced wear resistance by induction or nitriding processing. International Steel Specification Comparison (EN24T) BS 970:1955 BS 970:1991 German / DIN French AFNOR American AISI / SAE German Werkstoff No. European Standard Typical chemical composition of En24 C SI MN S 0.36/0.44 0.10/0.35 0.45/0.70 0.040 max

EN24T 817M40T 34CrNiMo6 35NCD6 4340 1.6582 EN10277-5 P 0.035 max Cr 1.00/1.40 Mo 0.20/0.35 Ni 1.30/1.70

Used in construction of aircrafts and heavy vehicle for crankshaft, gearshaft, camshaft, propellershaft etc Carbon(C) Directly influences the hardness and strength of the steel, decreases toughness. Chromiun(Cr) Improves Hardenability, high temperature strength, wear resisitance and even corrosion resistance(Cr>14%). Cobalt(Co) Improves retention of hardness at high temperatures. Molybdenum(Mo) Increases yield point and strength. Improves Hardenability and wear resistance. Manganese Lowers effects of Iron sulphides, increases hardenability, wear resistance. Nickel(Ni) Increases toughness at lower temperatures, slows the corrosion process. Improves toughness, grainstructure, high temperature strength, wear resistance, etc. Vanadium(V) Increases wear resistance, high temperature strength, retention of hardness etc. Silicon(Si) It is a deoxidizing agent. Increases strength and wear resistance. It is of importance that certain elements are as low as possible. Elements like Hydrogen, Oxygen, Nitrogen, Phosphorous, Sulphur create defects inside & also reduce the mechanical properties of steels. Hardening: Heat uniformly to 823/850C until heated through. Quench in oil. Tempering: Heat uniformly and thoroughly at the selected tempering temperature, up to 660C and hold at heat for two hours per inch oftotal thickness. Tempering between 250-375C in not recommended as this can seriously reduce the steels impact value. Stress Relieving: Heat slowly to 650-670C, soak well before cooling the EN24 tool in a furnace or in air. Mechanical Properties Heat Treatment T T U V W X Z Tensile Yield a% on Impact Impact Strength Stress 5.665So Izod J KCV J Rm N/mm Re N/mm 850/1000 654 13 40 35 850/1000 680 13 54 50 925/1075 755 12 47 54 1000/1150 850 12 47 42 1075/1225 940 11 40 35 1150/1300 1020 10 34 28 1550 1235 5 10 9 Proof Stress rp0.2 635 665 740 835 925 1005 1125 Hardness HB 248/302 248/302 269/331 293/352 311/375 345/401 444 Size mm >150250 >63250 >29100 >1363 >629 >629 >629

Vindhyavesh Tripathi vatripathi@rediffmail.com www.facebook.com/dimpu.tripathi

You might also like

- Offshore Insulation Specification for Piping & EquipmentDocument43 pagesOffshore Insulation Specification for Piping & EquipmentRajkumar ANo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Cor-Ten - Weather & Corrosion Resistant SteelDocument5 pagesCor-Ten - Weather & Corrosion Resistant SteelAnjan DeyNo ratings yet

- Alloy Steels 8620: Chemistry DataDocument6 pagesAlloy Steels 8620: Chemistry DataVijay PalNo ratings yet

- Material PropertiesDocument16 pagesMaterial PropertiesMadan Kulkarni100% (1)

- AVESTA How To Weld Duplex SteelDocument20 pagesAVESTA How To Weld Duplex SteelGMacella100% (1)

- Esab Welding Filler Metal Databook - Usa 2016Document426 pagesEsab Welding Filler Metal Databook - Usa 2016Mahiro MacNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Pheonwj X DSH 0001 0Document227 pagesPheonwj X DSH 0001 0Iksan Adityo Mulyo100% (1)

- Durehete 950Document5 pagesDurehete 950ellisforheroes100% (1)

- Ship Building MaterialsDocument21 pagesShip Building Materialsimran5705074No ratings yet

- Duplex Stainless Steel Guide - Strengths, Uses & LimitationsDocument7 pagesDuplex Stainless Steel Guide - Strengths, Uses & LimitationsRizalzi BachtiarNo ratings yet

- Pernos Huck C50LDocument4 pagesPernos Huck C50LAngelina Santiago JimenezNo ratings yet

- R0.4 - Piping Material Specification - 04.03.21Document26 pagesR0.4 - Piping Material Specification - 04.03.21Fabio TemporiniNo ratings yet

- Esab DublexDocument8 pagesEsab DublexSuphi YükselNo ratings yet

- Internship Report of Poeples Steel MillsDocument88 pagesInternship Report of Poeples Steel MillsShahid Ali LeghariNo ratings yet

- ST 12 - Echivalenta DC01Document12 pagesST 12 - Echivalenta DC01mariussinhoNo ratings yet

- EN8 SteelDocument1 pageEN8 SteelDeep Narayan JaiswalNo ratings yet

- Alloy SteelDocument7 pagesAlloy SteelRavinJohnNo ratings yet

- AISI 1024 Steel, 1024 Stainless Steel, 1024 Alloy Structural SteelDocument2 pagesAISI 1024 Steel, 1024 Stainless Steel, 1024 Alloy Structural SteelDhileepan Kumarasamy67% (3)

- 25CR20NIDocument2 pages25CR20NIShariq KhanNo ratings yet

- AN ISO 9001: 2000: ProductsDocument2 pagesAN ISO 9001: 2000: ProductsKamlesh DalavadiNo ratings yet

- En24 Alloy SteelDocument1 pageEn24 Alloy SteelpraghavannairNo ratings yet

- 21 CR Mo V511Document1 page21 CR Mo V511uksrajNo ratings yet

- EN24T Alloy Steel: High Strength, Shock & Wear ResistantDocument4 pagesEN24T Alloy Steel: High Strength, Shock & Wear ResistantDalibor CetojevicNo ratings yet

- EN24Document1 pageEN24skyheighst1594184No ratings yet

- EldaDocument28 pagesEldaEldayadi Nefty Rizky ArismawanNo ratings yet

- XAR 450 (WB 710) EnglischDocument3 pagesXAR 450 (WB 710) EnglischMario MoranNo ratings yet

- En 24Document1 pageEn 24Puneet BNo ratings yet

- OCR12VMDocument4 pagesOCR12VMcvgfgNo ratings yet

- Heat Treat 2Document5 pagesHeat Treat 2gawaNo ratings yet

- 708M40 Alloy Steel: Form of SupplyDocument3 pages708M40 Alloy Steel: Form of SupplyLUCIA MAÑAYNo ratings yet

- PK2SPDocument3 pagesPK2SPEmanuelValenciaHenaoNo ratings yet

- EN24 Steel PropertiesDocument1 pageEN24 Steel Propertieskanha15102003100% (1)

- Wear-Resistant Steel SpecificationDocument3 pagesWear-Resistant Steel Specificationmarcos crisostoNo ratings yet

- EN24 and EN24T SteelDocument3 pagesEN24 and EN24T Steelpatrik710No ratings yet

- UTOPEX2Document4 pagesUTOPEX2emregnesNo ratings yet

- SINOXX 4116 Steel: Designation by StandardsDocument2 pagesSINOXX 4116 Steel: Designation by StandardsSamirNo ratings yet

- Aerospace Materials GuideDocument6 pagesAerospace Materials Guidesnuffit11No ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- FinDocument3 pagesFinTVP_contechNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKiranNo ratings yet

- X210CR12 GradeDocument3 pagesX210CR12 GradekartsoftNo ratings yet

- En40b PDFDocument3 pagesEn40b PDFjeyakumarNo ratings yet

- 1.4922 SteelDocument2 pages1.4922 Steeldnageshm4n244No ratings yet

- ThyssenKrupp - XAR PLUSDocument3 pagesThyssenKrupp - XAR PLUSParametric EngineeringNo ratings yet

- Catalog ElectrDocument140 pagesCatalog ElectrMocanu Stefan ArtemonNo ratings yet

- High Strength Alloy 6082 Data SheetDocument1 pageHigh Strength Alloy 6082 Data SheetPrashant MalveNo ratings yet

- Technical Data: ApplicationsDocument3 pagesTechnical Data: ApplicationssushmaxNo ratings yet

- Cutting Materials, Tools and CoolantsDocument63 pagesCutting Materials, Tools and CoolantsLeonardo BarabasNo ratings yet

- Tool Steel Alloy Cr12MoVDocument5 pagesTool Steel Alloy Cr12MoVMujjo Sahb100% (1)

- High strength micro alloyed steel for fracture split connecting rodsDocument13 pagesHigh strength micro alloyed steel for fracture split connecting rodsemregnesNo ratings yet

- Thermanit_2535R. Aporte Manaurita XMDocument1 pageThermanit_2535R. Aporte Manaurita XMarnoldbatista55No ratings yet

- TDS 351do enDocument1 pageTDS 351do enMumkoNo ratings yet

- Lastek 90 Ceweld - Croni 29-9 S - 2013-06-27Document1 pageLastek 90 Ceweld - Croni 29-9 S - 2013-06-27Niksa ZekicNo ratings yet

- 308H Tig Welding Wire for Stainless SteelsDocument1 page308H Tig Welding Wire for Stainless SteelsFilipe CordeiroNo ratings yet

- En 19 TDocument3 pagesEn 19 TchaitanyaNo ratings yet

- 4340Document1 page4340ralishNo ratings yet

- En 19Document1 pageEn 19CharminNo ratings yet

- High Temp Resistant SteelDocument14 pagesHigh Temp Resistant SteelrajivashishNo ratings yet

- Material Specification Sheet Saarstahl - 36crnimo4Document1 pageMaterial Specification Sheet Saarstahl - 36crnimo4Anonymous rYZyQQot55No ratings yet

- Cast Materials: Sulzer PumpsDocument6 pagesCast Materials: Sulzer PumpsElmey Bin JulkeplyNo ratings yet

- Case Hardening Alloy Steel Bar 6587Document3 pagesCase Hardening Alloy Steel Bar 6587CelsoNo ratings yet

- Hollow Bar Ovako 280Document3 pagesHollow Bar Ovako 280fernandojNo ratings yet

- Aar603 StructureDocument9 pagesAar603 StructureMUHAMMAD AQIL BIN RAMLINo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Principal of Minimum Potential EnergyDocument3 pagesPrincipal of Minimum Potential EnergyV. A. TripathiNo ratings yet

- Agriculture Needs Engineering CultureDocument4 pagesAgriculture Needs Engineering CultureV. A. TripathiNo ratings yet

- Surface Texture Details When Used With Machining SymbolsDocument1 pageSurface Texture Details When Used With Machining SymbolsV. A. TripathiNo ratings yet

- Defination of Dead Mild SteelDocument1 pageDefination of Dead Mild SteelV. A. TripathiNo ratings yet

- Snackindia Com PDFDocument1 pageSnackindia Com PDFV. A. TripathiNo ratings yet

- I Bipt - Shri Vindhya Mechanical-VindhyaveshDocument12 pagesI Bipt - Shri Vindhya Mechanical-VindhyaveshV. A. TripathiNo ratings yet

- Department of Management of Studies, IIT Delhi: PresentsDocument29 pagesDepartment of Management of Studies, IIT Delhi: PresentsV. A. TripathiNo ratings yet

- Abstract For Manually Operated Harvesting Machine - Vindhyavesh Tripathi (Dimpu)Document1 pageAbstract For Manually Operated Harvesting Machine - Vindhyavesh Tripathi (Dimpu)V. A. TripathiNo ratings yet

- TranSoul A Business Idea : - Vindhyavesh Tripathi (Dimpu)Document10 pagesTranSoul A Business Idea : - Vindhyavesh Tripathi (Dimpu)V. A. TripathiNo ratings yet

- SEMINAR REPORT RCC RoadDocument25 pagesSEMINAR REPORT RCC RoadAkshay GhorpadeNo ratings yet

- Corrosion Repair Works in ICF Coaches and LHB Coach Maintenance at C&W PeramburDocument28 pagesCorrosion Repair Works in ICF Coaches and LHB Coach Maintenance at C&W PeramburVishnu GopiNo ratings yet

- Water Distribution Piping Materials & InstallationDocument1 pageWater Distribution Piping Materials & InstallationEslam ElsayedNo ratings yet

- EPOXY COATING HIGH CHEMICAL RESISTANCEDocument3 pagesEPOXY COATING HIGH CHEMICAL RESISTANCEu nizamiNo ratings yet

- GrasaDocument2 pagesGrasaeduardoNo ratings yet

- Plant Visits and Seminars For Ce Assignment 5.1Document7 pagesPlant Visits and Seminars For Ce Assignment 5.1CYREL VINCE CASUGBONo ratings yet

- Cege0009 - PP2 10-12-2020Document3 pagesCege0009 - PP2 10-12-2020eyu HungryfishNo ratings yet

- Stramit TH120 Top Hat Sections Product Technical SupplementDocument12 pagesStramit TH120 Top Hat Sections Product Technical SupplementThaiNguyenNo ratings yet

- PDF ST Hochofenrinne e 7 2014.en.19Document6 pagesPDF ST Hochofenrinne e 7 2014.en.19Henry SunarkoNo ratings yet

- RC Wall Construction - TutorialDocument32 pagesRC Wall Construction - TutorialBitch CarrieNo ratings yet

- Standard Specifications Roll and Cut Groove For Steel Pipe Technical Data General DescriptionDocument4 pagesStandard Specifications Roll and Cut Groove For Steel Pipe Technical Data General DescriptionMohammad SaleemNo ratings yet

- Antenna FundamentalsDocument16 pagesAntenna FundamentalsMarco Aurelio PereiraNo ratings yet

- Company Name Address City State Zip Contact Email Phone Commodity Codes Average Gross Receipts Status Effective ExpirationDocument5 pagesCompany Name Address City State Zip Contact Email Phone Commodity Codes Average Gross Receipts Status Effective ExpirationSam ShaneNo ratings yet

- A02 41 (Highlighted)Document1 pageA02 41 (Highlighted)HasmukhNo ratings yet

- RB02CR PP Random Copolymer Technical DataDocument1 pageRB02CR PP Random Copolymer Technical DataPiyush A JoshiNo ratings yet

- SP-P-003 - Rev 1 - Specification For Steam JacketingDocument19 pagesSP-P-003 - Rev 1 - Specification For Steam Jacketingvishal bhamreNo ratings yet

- Detail 2006 7+8 PDFDocument29 pagesDetail 2006 7+8 PDFGabriela MantoiuNo ratings yet

- Structural Steel Fabrication Process ControlDocument1 pageStructural Steel Fabrication Process ControlMrk KhanNo ratings yet

- Detail of Common Toilet: Section Elevation C - C' Section Elevation D - D'Document1 pageDetail of Common Toilet: Section Elevation C - C' Section Elevation D - D'RichaNo ratings yet

- Special Program For Technical Vocational EducationDocument20 pagesSpecial Program For Technical Vocational EducationDee SireNo ratings yet

- Libro 1Document136 pagesLibro 1Maela C O'SheaNo ratings yet

- 1 Metallography Lab SheetDocument5 pages1 Metallography Lab SheetAlexNo ratings yet

- Pioneer Araya PDFDocument32 pagesPioneer Araya PDFAmit GolaNo ratings yet

- ISO 8434-2-2007 Standard UnlockedDocument60 pagesISO 8434-2-2007 Standard UnlockedalanNo ratings yet