Professional Documents

Culture Documents

Retaining Wall Design For Us Wing Wall

Uploaded by

Balaji Rao ChOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Retaining Wall Design For Us Wing Wall

Uploaded by

Balaji Rao ChCopyright:

Available Formats

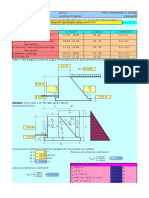

DESIGN OF RCC ABUTMENT UNDER SLRB

2.300

1.400 0.000

0.900 + 338.715

W

1

0.275 + 338.440

0.300 W

2

A + 338.140

W

3

20.929 W

6

0.000 W

4

2.000 E B 3.200

D C + 317.786

0.600 W

5

+ 316.986

2.300

2.000 7.500

Using M-20 grade concrete, the design parameters to be adopted are the following

o

st

= 200

N/mm

2

o

cbc

= 6.67

N/mm

2

m = 13.993

k = 0.318

j = 0.894

Q = 0.948

DIMENSIONS OF THE BASE:-

Length of the toe = 2.000 m

Length of the heel = 2.000 m

Thickness at the top = 1.4 m

Thickness of the bed block = 0.9 m

Thickness at the bottom = 2.3 m

Height of the stem = 20.929 m

Thickness of the base slab = 2 m

Height of the wall H = 15.329 m

Unit weight of soil considered = 21 KN/m

3

Unit weight of concrete considered = 25 KN/m

3

Angle of internal friction = 32

B

force F

force

R

reaction

Value of K

a

= 0.307

Value of Kp = 3.257

Reaction coming on to the abutment = 35.069 KN

Breaking force = 0 KN

Frictional force = 0 KN

Safe bearing capacity of the

soil considered = 600 KN/m

2

Coefficint of friction between

soil and concrete = 0.6

Clear cover provided = 0.075 m

804 Main reinfortcement provided(Toe) = 32 mm

804 Main reinfortcement provided(Heel) = 32 mm

201 Distribution steel provided(Heel) = 16 mm

201 Distribution steel provided (stem) = 16 mm

804 Main reinfortcement provided (stem) = 32 mm

0 Consider a live load surcharge of = 0 m

DESIGN

Minimum depth of foundation

Ka =

Ka = 0.307

d = 600 / 21 x 0.307

= 2.693 m

However provide d = 2.25 m below ground level

The ratio of the length of the toe slab to the base width b is given by

o =

Where

H = Height of the wall including thickness of the base

o = 1 - 600 / ( 2.2 x 21 x 22.929)

= 0.153

Width of the base

b =

= 0.95x15.329x(0.307/(1-0.153)x(1+3x 0.153))^0.5

2

0

sin 1

sin 1

|

|

.

|

\

|

+

=

|

|

q

d

|

|

.

|

\

|

+

|

|

sin 1

sin 1

H

q

2 . 2

1

0

( ) ( )

2

3 1 1

95 . 0

o o +

a

K

H

= 7.258 m

The base width with respect to sliding

b =

= 0.7 x 15.329 x 0.307

( 1 - 0.153) x 0.6

= 6.482 m

Provide b = 0.6H

b = 9.197 m

Provide 7.500 m

Width of toe slab = o x b

= 1.148 m

Provide 2.000 m

Thickness of the base slab

= H / 12

= 1.277 m

Provide 2 m

Thickness of the stem

Height H

1

= 15.329 m

Considering 1m length of the retaining wall

Max bending moment at B

= K

a

H

1

3

/6 + K

a

wH

1

2

/2

= 3870.329 Kn-m

Effective depth required = 2020.551 mm

Effective depth provided = 2209 mm

HENCE SAFE

( ) o

1

7 . 0

a

K H

Stability of wall

S.NO Designation MagnitudeLever arm

Moment

about toe

1 W

1

9.625 3.6

34.65

2 W

2

6.75 2.45

16.538

3 W

3

1170.36 3.15 3686.62

4 W

4

0 2 0

5 W

5

375 3.75 1406.25

6 W

6

1406.43 5.9 8297.93

7 W

7

0 5.9 0

8 R

REACTION

35.069 2.45 85.919

9 B

Force

0 21.454 0

10 F

Force

0 21.454 0

Total 3003.23 KN 13527.9 KN - m

Total resisting moment

M

r

= 13527.906 KN - m

Earth pressure

P = 757.452 KN

Check for over turning

Over turning moment = 3870.327 KN - m

Factor of safety against over turining moment = 3.495 > 2

SAFE

Check for sliding

Factor of safety against sliding = 2.379 > 1.5

SAFE

As the section fails against sliding provide a shear key

0

0

3.2 x 0 x 21

35.069

3.2 x 20.929 x 21

1 x 2.3 x 20.354 x 25

0.5 x 0 x 20.354 x 25

Force

1.4 x 0.275 x 25

0.9 x 0.3 x 25

2 x 7.5 x 25

Pressure distribution

Net moment

EM = 9657.579 KN - m

Lever arm from toe = 3.216 m

Eccentricity e = 0.534 m

e

max

= 1.250 m

Pressure P

1

at toe P

1

= 571.49

KN/m

2

Pressure P

2

at heel P

2

= 229.37

KN/m

2

Pressure P at the junction of the stem with toe slab

= 480.26 KN/m

2

Pressure P' at the junction of the stem with heel slab

= 425.52 KN/m

2

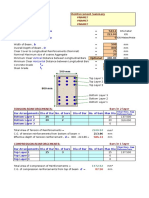

Design of toe slab 1.4

0.9

A

2.300

2.000 B 3.200

D C

0.400

7.500

2.000

229.37

571.49

480.26 425.52

The weight of the soil above toe slab is neglected

The forces acting on it are

(i) Up ward soil pressure

(ii) Down ward weight of slab

Down ward weight of slab per unit area = 50 KN / m

2

Net pressure intensity under D = 521.49 KN / m

2

Net pressure intensity under E = 430.26 KN / m

2

Total force = shear force at E = 951.754 KN

x from E = 1.032 m

Bending moment at E = 982.21 KN - m

Effective depth required d = 1017.883 mm

Effective depth provided = 1909 mm

HENCE SAFE

Area of steel A

st

= 2877.603

mm

2

This reinforcement is provided at the bottom face with a spacing of.

= 275 mm c/c

= 2923.055 mm

2

HENCE SAFE

32mm dia bars at a spacing of 275mm C/C

Distribution steel = 0.15% of area

= 2250 mm

2

Provide 16mm dia bars at a spacing of = 85 mm c/c

Design of heel slab

The forces that are acting on it are

(i) Down ward weight of soil

(ii) Down ward weight of heel slab

(iii) Up ward soil pressure

(i) Down ward weight of soil = 1406.429 KN

Acting at = 1.6 m from B

(ii) Down ward weight of heel slab = 160 KN

Acting at = 1.6 m from B

(iii) Up ward soil pressure = 1047.819 KN

Acting at = 1.44 m from B

Total force = Shear force at B = 518.61 KN

Bending moment at B = 997.427 KN - m

Effective depth required d = 1025.738 mm

Effective depth provided = 1909 mm

HENCE SAFE

Area of steel A

st

= 2922.185

mm

2

Required 32mm dia bars at a spacing of = 275 mm C/C

Provided 32mm dia bars at a spacing of = 95 mm C/C

Area of steel provided = 8461.474 mm

2

HENCE SAFE

Distribution steel = 0.15% of area

= 2250 mm

2

provide 16mm dia bars at a spacing of = 85 mm c/c

Area of steel provided = 2364.235 mm

2

Nominal Shear stress = 0.259 N/mm

2

Percentage of steel provided = 0.423 %

Permissible Shear stress = 0.2754 N/mm

2

SAFE

Design of stem

Max bending moment = K

a

H

1

3

/6

= 3870.329 KN - m

Effective depth required d = 2020.551 mm

Effective depth provided = 2209 mm

Area of steel A

st

= 9799.065

mm

2

Required 32mm dia bars at a spacing of = 80 mm C/C

Provided 32mm dia bars at a spacing of = 50 mm C/C

Area of steel provided = 16076.8 mm

2

HENCE SAFE

Curtailment of reinforcement in the stem

(I)

Considering a section at depth h below the top of the stem,

The effective depth at top of stem = 2209 mm

The effective depth d' at that section = 2209 + ( ( 2209 - 2209 ) / 15.329 ) x h

= 2209 + 0 x h

Hence h / H

1

=

A

st

1

= Reinforcement at depth h

d

1

= Efective depth at depth h

A

st

= Reinforcement at depth H

1

d = Effective depth at depth H

1

If A

st

1

= 1/2 A

st

A

st

1

1

A

st

2

Therefore h

H

1

d

H

A

st

3

o

( )3

1

d A H

st

=

3

1

1 1

|

|

.

|

\

|

d A

d A

st

st

=

3

1

1

2

1

|

|

.

|

\

|

=

d

d

Substituting the values of d, d

1

and H

1

h = 15.329 x[ ( 2209 + 0 x h) / ( 2 x 2209)] ^(1/3)

12.2 h = 12.167

50% of the reinforcement is to be curtailed at a height of

= 15.329 - 12.167 + 12 x 0.032

= 3.462 m from the base of the stem

(II)

A

st

1

1

A

st

4

Therefore h

H

1

Substituting the values of d, d

1

and H

1

h = 15.329 x[(2209 + 0 x h)/(4x2209)]^(1/3)

9.66 h = 9.657

50% of the remaining reinforcement is futher curtailed at a height of

= 15.329 - 9.657 + 12 x 0.032

6.056 m from the base of the stem

The remaining reinforcement is to be continued to the top

Check for shear

Shear force p = K

a

H

2

/2

= 757.452 KN

Nominal shear stress = 0.343 N/mm

2

Percentage of steel provided = 0.728 %

Permissible shear stress = 0.3456 N/mm

2

HENCE SAFE

Distribution and temperature reinforcement

Average thickness of the stem = 2.3 m

Distribution reinforcement = 0.15 % of area

= 3450 mm

2

Provide 16 mm at a spacing of = 55 mm C/C

=

3

1

1

4

1

|

|

.

|

\

|

=

d

d

2.300

32mm at 200mm C/C

32mm at 100mm C/C

32mm at 50mm C/C

16mm at 85mm C/C

15.329 16mm at 55mm C/C

20.929

6.056

16mm at 85mm C/C

3.462

32 mm AT 95mm C/C 32 mm AT 95mm C/C

2.000 16mm at 85mm C/C

32mm at 50mm C/C

REINFORCEMENT AT THE INNER FACE OF THE STEM

0.600 0.600

2.000 16mm at 85mm C/C

32mm dia bars at a spacing of 275mm C/C 3.200

7.500

SECTION OF WALL WITH RCC DETAILS

c

V

Design of shear key

The wall is unsafe in sliding, and hence shear key will have to be provided

below the stem

Let the depth of the key = a

Intensity of pressure Pp developed in front of the key depends up on the soil

Pressure p in the front of the key.

p

p

= K

p

x p

= 1564.207 KN/m2

P

p

= p

p

x a

= 1564.207 x a

Sliding force at level D

1

C

1

= 0.307 x 21 / 2 x ( 15.329 + a )^2

Weight of soil between bottom of base and D

1

C

1

= 2 x a x 21

42 x a

EW = 3003.228 + 42 x a

For equilibrium of wall, permitting factor of safety as 1.5 against sliding.

1.5 =

4.835 a

2

-1441.168 a + -665.758 = 0

a = 298.531 mm

Provide = 100 mm

Width of the key = 1000 mm

a

1

= a x tan

= a x tan(45+/2)

= aKp

= 0.18 m

Actual available length of the slab

= 2 m

Hence safe

0.6 x ( 3003.228 + 42 x a ) + 1564.207 x a

0.307 x 21 / 2 x ( 15.329 + a )^2

H

p

P

P W

+

=

u

5 . 1

Size of the key = 100 x 1000 mm

P

H

= 0.307 x 21 / 2 x ( 15.329 + a )^2

= 767.367 KN

P

p

= 1564.207 x a

= 156.421 KN

EW = 3003.228 + 42 x a

= 3007.428 KN

Actual force to be resisted by the key at a factor of safety of 1.5 is

= 1.5 x PH - m x SW

= -653.4063

You might also like

- Retaining Wall Design - 1Document23 pagesRetaining Wall Design - 1abhijithaval100% (3)

- Retaining Wall Based On ACI 318-02Document6 pagesRetaining Wall Based On ACI 318-02ابو عمر الأسمريNo ratings yet

- Reatining Wall With Sloping BackfillDocument16 pagesReatining Wall With Sloping BackfillSana UllahNo ratings yet

- AbutmentDocument31 pagesAbutmenthrpinfra100% (1)

- Counter Fort Reatining WAll With HORZONTAL Bach FillDocument52 pagesCounter Fort Reatining WAll With HORZONTAL Bach FillRajib Chowdhury100% (1)

- Counter Fort Reatining WAll With HORZONTAL Bach FillDocument35 pagesCounter Fort Reatining WAll With HORZONTAL Bach FillUlasi IfeanyiNo ratings yet

- Design Water TankDocument83 pagesDesign Water TankHemant Sonawadekar100% (2)

- DESIGN OF CANTILEVER RETAINING WALLDocument39 pagesDESIGN OF CANTILEVER RETAINING WALLmegget100% (5)

- Retaining Wall CalculationDocument9 pagesRetaining Wall CalculationAlexPakNo ratings yet

- Retaining Wall Excel SheetDocument7 pagesRetaining Wall Excel Sheetfordesign92% (12)

- RCC retaining wall design for cantilever type up to 6m heightDocument180 pagesRCC retaining wall design for cantilever type up to 6m heightVictor Rudio71% (7)

- Design of Retaining WallDocument33 pagesDesign of Retaining WallAbhay Mishra50% (2)

- Design of Gravity Retaining WallDocument36 pagesDesign of Gravity Retaining WallCarmel Buniel Sabado100% (10)

- Design of Retaining WallDocument5 pagesDesign of Retaining Walljoshua humirangNo ratings yet

- Design of Square Footing F2Document18 pagesDesign of Square Footing F2Mohammed Sumer100% (1)

- Design of Rectangular Footing Col at Edge - 3Document27 pagesDesign of Rectangular Footing Col at Edge - 3Glenn SarneNo ratings yet

- Retaining Wall DesignDocument6 pagesRetaining Wall DesignK Divakara Rao0% (1)

- RC Retaining WallDocument10 pagesRC Retaining WallGertjan DuniceriNo ratings yet

- ACI 318 08 Design of Retaining Wall With Counterfort Rev1Document4 pagesACI 318 08 Design of Retaining Wall With Counterfort Rev1KING ENG100% (2)

- Analysis For Retaining Wall 1. Design Data.: KN/M KN/M KN/MDocument4 pagesAnalysis For Retaining Wall 1. Design Data.: KN/M KN/M KN/Mbhaskardharani50% (2)

- Continue One Way SlabDocument31 pagesContinue One Way Slabanon_601117903No ratings yet

- Counter Fort Retaining Walls Penul TPT CounterfortDocument23 pagesCounter Fort Retaining Walls Penul TPT Counterfortcoreteam100% (3)

- BOX CULVERT Spread SheetDocument20 pagesBOX CULVERT Spread Sheetdsananda0% (1)

- Abutment and Wingwall Design Example - US Units - Design Step 7Document96 pagesAbutment and Wingwall Design Example - US Units - Design Step 7rajsedasari100% (1)

- Counterfort Retaining WallDocument1 pageCounterfort Retaining WallAjay ThouraniNo ratings yet

- Retaining Wall (Counterfort)Document11 pagesRetaining Wall (Counterfort)Er R Raman0% (1)

- Stair Case Design Single FlightDocument3 pagesStair Case Design Single Flightrahul100% (1)

- 3.3.1 Retaining WallDocument31 pages3.3.1 Retaining WallNeil SonNo ratings yet

- DESIGN OF GRAVITY RETAINING WALLDocument10 pagesDESIGN OF GRAVITY RETAINING WALLD.V.Srinivasa RaoNo ratings yet

- Corbel Excel Sheet WorksDocument5 pagesCorbel Excel Sheet WorksIbrahim A.LNo ratings yet

- Design of RCC Retaining Wall at RelangiDocument18 pagesDesign of RCC Retaining Wall at RelangiD.V.Srinivasa RaoNo ratings yet

- Retaining WallDocument35 pagesRetaining WallSumaiyakhanam100% (1)

- Combined FootingDocument5 pagesCombined FootingKain Pasang Ruby IINo ratings yet

- StaircaseDocument2 pagesStaircaseMAGED MOHMMED AHMED QASEMNo ratings yet

- Slab DesignDocument4 pagesSlab DesignRubina HannureNo ratings yet

- Pier & Footing For Canal TroughDocument18 pagesPier & Footing For Canal TroughjaffnaNo ratings yet

- Canal Trough DesignDocument27 pagesCanal Trough DesignVenkatarathnam PulipatiNo ratings yet

- Design of GLSRDocument263 pagesDesign of GLSRBattula Sridhar100% (2)

- L Shaped Reatining WAll With HORZONTAL Bach FillDocument29 pagesL Shaped Reatining WAll With HORZONTAL Bach Fillsarveshfdk48100% (2)

- Design and Detailing of Counterfort Retaining WallDocument48 pagesDesign and Detailing of Counterfort Retaining WallSWADES RANJAN PAIRANo ratings yet

- 4.2.6 Design of Lift WallDocument9 pages4.2.6 Design of Lift WallSudip ShresthaNo ratings yet

- Design of Counterfort Retaining WallDocument14 pagesDesign of Counterfort Retaining WallMonjit Gogoi100% (5)

- Design of Compound WallDocument4 pagesDesign of Compound WallMaku Rajkumar100% (2)

- Structural Report On 400 KLD STPDocument16 pagesStructural Report On 400 KLD STPVipin SinghalNo ratings yet

- RCC Retaining Wall DesignDocument12 pagesRCC Retaining Wall DesignifylasyNo ratings yet

- Stepped Footing - 1 PDFDocument11 pagesStepped Footing - 1 PDFSushil Dhungana93% (15)

- Aci BeamDocument6 pagesAci BeamkumsbamaNo ratings yet

- CWR 3700KL R5Document10 pagesCWR 3700KL R5NitinShepurNo ratings yet

- 150 KLD Structural Design 21.05 Calculations PDFDocument16 pages150 KLD Structural Design 21.05 Calculations PDFParvez Khan100% (1)

- Stepped FootingDocument12 pagesStepped FootingV.m. RajanNo ratings yet

- Planning Analysis and Design of Shopping MallDocument46 pagesPlanning Analysis and Design of Shopping MallSanjeev Kumar60% (15)

- Wing Wall DesignDocument19 pagesWing Wall DesignMAGED MOHMMED AHMED QASEMNo ratings yet

- Retainingwall bs8110Document11 pagesRetainingwall bs8110unionewNo ratings yet

- Design of RCC retaining wall in ExcelDocument30 pagesDesign of RCC retaining wall in ExcelRenuga DeviNo ratings yet

- STRAP FOOTING DESIGN FOR MULTI-STOREY BUILDINGDocument5 pagesSTRAP FOOTING DESIGN FOR MULTI-STOREY BUILDINGNabin Acharya100% (1)

- RCC Retaining WallSDocument25 pagesRCC Retaining WallSAnde BhanuNo ratings yet

- Water TankDocument22 pagesWater TankSamik SenNo ratings yet

- Sump Design Chas 5.10.09Document22 pagesSump Design Chas 5.10.09battulas1953No ratings yet

- Inze TankDocument9 pagesInze TankHabib Ur RahmanNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Perry Mason MysteriesDocument183 pagesPerry Mason MysteriesBalaji Rao Ch67% (3)

- Basudhar Et Al., NCFRS, 2007Document5 pagesBasudhar Et Al., NCFRS, 2007Balaji Rao ChNo ratings yet

- (Factored Loads) : Vertical Load Moment @X-X MX Moment @y-Y MyDocument10 pages(Factored Loads) : Vertical Load Moment @X-X MX Moment @y-Y MyBalaji Rao ChNo ratings yet

- Circular Pier With Circular Footing.Document25 pagesCircular Pier With Circular Footing.Balaji Rao Ch100% (5)

- Est of Chute Fall On Kuwa Branch CanalDocument28 pagesEst of Chute Fall On Kuwa Branch CanalBalaji Rao ChNo ratings yet

- RANKINE Wing WallDocument2 pagesRANKINE Wing WallnirajlamichhaneNo ratings yet

- Abstract For Vrb'sDocument33 pagesAbstract For Vrb'sBalaji Rao ChNo ratings yet

- Sheet Piling DesignDocument30 pagesSheet Piling Designchaichan100% (4)

- SLRB Raft Design ImportantDocument10 pagesSLRB Raft Design ImportantBalaji Rao ChNo ratings yet

- Design of large thrust blocks for rising mainDocument20 pagesDesign of large thrust blocks for rising mainBalaji Rao Ch100% (1)

- SLRB Raft Design ImportantDocument10 pagesSLRB Raft Design ImportantBalaji Rao ChNo ratings yet

- RCC Dam Design Example Problem AnalysisDocument3 pagesRCC Dam Design Example Problem Analysisnywd806033No ratings yet

- Basudhar Et Al., NCFRS, 2007Document5 pagesBasudhar Et Al., NCFRS, 2007Balaji Rao ChNo ratings yet

- 9 Design of Bed Block Under ABUTMENTDocument2 pages9 Design of Bed Block Under ABUTMENTBalaji Rao Ch100% (1)

- Concrete Pipe Design ManualDocument555 pagesConcrete Pipe Design Manualv100% (5)

- Support For Very Weal RockDocument20 pagesSupport For Very Weal RockBalaji Rao ChNo ratings yet

- Design of Thrust BlockDocument35 pagesDesign of Thrust BlockBalaji Rao Ch100% (1)

- USACE Manual on Gravity Dam DesignDocument88 pagesUSACE Manual on Gravity Dam DesignOmar Castro ZeballosNo ratings yet

- Basudhar Et Al., NCFRS, 2007Document5 pagesBasudhar Et Al., NCFRS, 2007Balaji Rao ChNo ratings yet

- Tutorial 24 Tunnel Lining DesignDocument32 pagesTutorial 24 Tunnel Lining DesignBalaji Rao ChNo ratings yet

- Design of Tikhri Tunnel of IspDocument11 pagesDesign of Tikhri Tunnel of IspBalaji Rao Ch100% (1)

- Mechanics of Deformable Bodies Solved ProblemsDocument10 pagesMechanics of Deformable Bodies Solved ProblemsYan NieNo ratings yet

- Thermal Effect and Cost Estimation of Expanded Polystyrene Insulated Cavity Wall in Buildings of Composite ZoneDocument4 pagesThermal Effect and Cost Estimation of Expanded Polystyrene Insulated Cavity Wall in Buildings of Composite ZoneijsretNo ratings yet

- Design to BS 5950 Part 1: Limit State Design of Tubular StructuresDocument55 pagesDesign to BS 5950 Part 1: Limit State Design of Tubular StructuresTingluhelen90% (10)

- P01-E12 Rev 1 Sep 2015 Dynamic Effects On Piping SystemsDocument11 pagesP01-E12 Rev 1 Sep 2015 Dynamic Effects On Piping Systems234ahmedNo ratings yet

- Strength of Materials Objective and Conventional by S K MondalDocument434 pagesStrength of Materials Objective and Conventional by S K MondalSiva Kumar Siva100% (1)

- FHC - Sprinkler Hydraulic Calculation Software For The Fire Sprinkler IndustryDocument4 pagesFHC - Sprinkler Hydraulic Calculation Software For The Fire Sprinkler IndustryAisha Riaz100% (1)

- Zhu Et Al. - 2022 - Heat Transfer Enhancement For Microchannel Heat SiDocument14 pagesZhu Et Al. - 2022 - Heat Transfer Enhancement For Microchannel Heat Simosab.backkupNo ratings yet

- GC2 3 ThermochemistryDocument34 pagesGC2 3 ThermochemistryBea MoradaNo ratings yet

- Determination of Ultimate Pile Bearing Capacity From A Seismic Method of Shear Wave Velocity in Comparison With Conventional MethodsDocument5 pagesDetermination of Ultimate Pile Bearing Capacity From A Seismic Method of Shear Wave Velocity in Comparison With Conventional MethodsAndrea DeleonNo ratings yet

- Free Point Calculation v03Document2 pagesFree Point Calculation v03prasarnboonNo ratings yet

- Stark, T. D., & Olson, S. M. (1995) - Liquefaction Resistance Using CPT and Field Case Histories. Journal of Geotechnical Engineering PDFDocument14 pagesStark, T. D., & Olson, S. M. (1995) - Liquefaction Resistance Using CPT and Field Case Histories. Journal of Geotechnical Engineering PDFDiana DamianNo ratings yet

- The Measurement of Local Axial Strains in Triaxial Tests Using LVDTsDocument5 pagesThe Measurement of Local Axial Strains in Triaxial Tests Using LVDTsPinak RayNo ratings yet

- Strain-Rate Effects on Austenitic Stainless SteelDocument11 pagesStrain-Rate Effects on Austenitic Stainless SteelHugo IgrejaNo ratings yet

- Sheet Pile Wall, With Tieback Anchors, Design Based On AASHTO (HB-17), 2018 IBC & ACI 318-19Document3 pagesSheet Pile Wall, With Tieback Anchors, Design Based On AASHTO (HB-17), 2018 IBC & ACI 318-19afvilavilanoriegaNo ratings yet

- Misiulia-Angulo de Helice de EntradaDocument34 pagesMisiulia-Angulo de Helice de EntradaMiguel AnNo ratings yet

- Experiment Instructions: WL 352 Free and Forced Convection UnitDocument98 pagesExperiment Instructions: WL 352 Free and Forced Convection Unitmohamadreza1368No ratings yet

- Ahmad Alavian NTNU PHD Thesis PDFDocument275 pagesAhmad Alavian NTNU PHD Thesis PDFHamahid pourNo ratings yet

- Training Text Gas TurbineDocument87 pagesTraining Text Gas Turbinebmw316100% (1)

- WFC-SC30 & -SH30 Water Chiller SpecsDocument2 pagesWFC-SC30 & -SH30 Water Chiller SpecsKristina BožićNo ratings yet

- Finite element analysis of prestressed structural membranesDocument15 pagesFinite element analysis of prestressed structural membranesCenelia Alvarez EcheverriNo ratings yet

- Thermal Comfort Factors in Building DesignDocument4 pagesThermal Comfort Factors in Building DesignSovit GurungNo ratings yet

- Influence Lines & CablesDocument26 pagesInfluence Lines & CablesArah Louise ApostolNo ratings yet

- Course ContentsDocument5 pagesCourse ContentsMatthew ColeNo ratings yet

- Plate and Frame Heat ExchangerDocument53 pagesPlate and Frame Heat ExchangerShivanand YadavNo ratings yet

- Why Earthquake HappenDocument21 pagesWhy Earthquake HappenAsyer OcthavNo ratings yet

- Steady vs Transient Heat Transfer AnalysisDocument19 pagesSteady vs Transient Heat Transfer AnalysisSangana NevilonNo ratings yet

- Steam Distillation Separation of A Mixture of P-DichlorobenzeneDocument19 pagesSteam Distillation Separation of A Mixture of P-Dichlorobenzeneشهد إيادNo ratings yet

- CalorimeterDocument2 pagesCalorimeterUrvi MaruNo ratings yet

- 6c. ELASTICITY and OSCILLATIONDocument19 pages6c. ELASTICITY and OSCILLATIONAllan Gabriel LariosaNo ratings yet

- Thermowell Design Accelerator: Emerson Confidential 1Document6 pagesThermowell Design Accelerator: Emerson Confidential 1Jaqueline MartínezNo ratings yet