Professional Documents

Culture Documents

Rupak Knocking

Uploaded by

Rupak BisenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rupak Knocking

Uploaded by

Rupak BisenCopyright:

Available Formats

Knocking

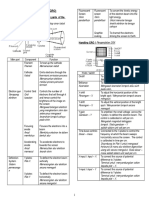

Knocking (also called pinking or pinging)technically detonation in internal combustion engines occurs when fuel in the cylinder is ignited by the firing of the spark plug and smooth burning proceeds but some of the unburned mixture in the combustion chamber explodes before the flame front can reach it, combusting suddenly before the optimum moment of the four-stroke cycle. The resulting shockwave collides with the rising piston, creating a characteristic metallic "pinging" sound.

Detonation

The fuel/air mixture is normally ignited slightly before the point of maximum compression to allow a small time for the flame-front of the burning fuel to expand throughout the mixture, so that maximum pressure occurs at the optimum point. The flame-front moves at about 1100 feet/second during normal combustion. It is only when the remaining unburned mixture is heated and pressurized by the advancing flame front for a certain length of time that the knocking effect occurs. It is caused by an instantaneous ignition of the remaining fuel/air mixture in the form of an explosion. The cylinder pressure rises dramatically beyond design limits. If allowed to persist detonation will cause vibration and damage to engine parts. Detonation can typically be prevented by:

The use of higher octane petrol The addition of octane-increasing "lead", isooctane, or other fuel additives Reduction of cylinder pressure by increasing the engine revolutions or reducing the load on the engine, or both Reduction of in-cylinder temperatures (such as through cooling or compression ratio reduction), or Retardation of spark plug ignition. Adding water in the form of humidity to the air. Proper combustion chamber design which concentrates mixture near the spark plug and generates high turbulence to promote fast even burning.

Correct ignition timing is essential for optimum engine performance and fuel efficiency. Modern automotive and small-boat engines havesensors that can detect knock and delay the spark plug firing to prevent it, allowing engines to safely use petrol of lower octane ratings, with the consequence of reduced power and efficiency. These knock sensors work by using a small piezoelectric microphone connected to the ecu. Spectral analysis is used to detect the trademark frequency produced by detonation at various RPMs. When detonation is detected, ignition timing is retarded, reducing the knocking and protecting the engine.

Pre-ignition

Detonation is a different phenomenon from pre-ignition, which occurs when the air/fuel mixture in the cylinder (or even just entering the cylinder) ignites before the spark plug fires. Pre-ignition is caused by an ignition source other than the spark. Heat can buildup in engine intake or cylinder components due to improper design or maintenance, or overheating of the air/fuel mixture during compression. This heat buildup can only be prevented by eliminating the overheating (through redesign) or the compression effects (by reducing the load). As such, if pre-ignition is allowed to continue for any length of time, power output reduces drastically and engine damage can result. Pre-ignition may lead to detonation and detonation may lead to pre-ignition or either may exist seperately.

Knocking order falls with branching, unsaturation, aromatization etc. The knocking order is: Straight chain paraffins > branched chain paraffins > olefins > naphthenes > Arenes. The knocking may be prevented by adding compounds like TEL or tetra ethyl lead. The gasoline from petrol pump which we get contain anti knock compounds (TEL). Octane no. of gasoline is the no. for rating anti knock qualities of gasoline. The higher the octane no.,lesser the tendency for knocking and better being the fuel. Octane no. is derived by assuming 100 arbitrary value for isooctane and zero for n-heptane. Thus no. is the % of isooctane in a mixture of isooctane and n-heptane whose knocking resembles with the knocking of fuel used. The octane no. of fuel is increased by two to three units by adding 2 to 4 ml of TEL in one Gallon petrol. Tetra ethyl lead is supposed to dissociate as (C2H5)4Pb 4C2H5 + Pb

Ethyl free radical The ethyl free radical converts some of the straight chain hydrocarbons into branched chain hydrocarbons and thus increases the octane number. In addition to TEL, a little ethylene dibromide is also added which converts Pb to PbBr2, which comes out through exhaust and prevents its deposition in engine due to decomposition of TEL. Pb + CH2BrCH2Br PbBr2 + CH2=CH2 Volatile A gasoline fuel with octane no. 30 or above is good fuel. The efficiency of fuel increases as the octane no increases. Addition of TEL in petro, no doubt improves the octane number of fuel but it also causes lead pollution in atmosphere. The attempts are therefore been made to improve octane number of fuel by some other means. Unleaded or lead free gasoline marketed today is the gasoline obtained by isomerisation and alkylation blended with BTX (Benzene, toluene, xylene) or methyl-t. butyl ether. Its octane number is 90. Thus following processes are used for getting lead free gasoline with better octane number. (i) Isomerisation (Reforming) : By passing gasoline vapours over aluminium chloride (AICI3) at 200oC

(ii) Alkylation : Isobutylene formed during cracking on alkylation with isobutene forms iso-octane in presence of concentrated H2SO4.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- BCN 3224 - Exam 3 ReviewDocument34 pagesBCN 3224 - Exam 3 Reviewmgwin17No ratings yet

- RC2 Series Screw Compressor Maintenance ManualDocument161 pagesRC2 Series Screw Compressor Maintenance ManualMichele CassiniNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Project Title: TBA: Client: ContractorDocument4 pagesProject Title: TBA: Client: ContractorIzza Halim100% (2)

- Centrifugal Aftermarket Solutions BrochureDocument8 pagesCentrifugal Aftermarket Solutions BrochureJose Renato MendesNo ratings yet

- IGCSE Topical Past Papers PhysicsDocument64 pagesIGCSE Topical Past Papers PhysicsHubert DMelloNo ratings yet

- Design DocumentDocument10 pagesDesign DocumentLiza WoodsNo ratings yet

- 4E Roadmap for Energy Efficient Electric Motors and Motor SystemsDocument30 pages4E Roadmap for Energy Efficient Electric Motors and Motor SystemsCarlos LopezNo ratings yet

- 7216Document8 pages7216siicmorelosNo ratings yet

- 7088-Unit 1 A Guide To The IALA MBS 1 An Introduction To The IALA MBSDocument5 pages7088-Unit 1 A Guide To The IALA MBS 1 An Introduction To The IALA MBSZuri MpowerNo ratings yet

- Turbo Machines and Propulsion Exam Questions on Pumps, Turbines, Pipe FlowDocument3 pagesTurbo Machines and Propulsion Exam Questions on Pumps, Turbines, Pipe FlowAdams100% (1)

- Damping FactorDocument2 pagesDamping FactorAngel Morales MartínezNo ratings yet

- Polyken 1600 High TempDocument2 pagesPolyken 1600 High TempKyaw Kyaw AungNo ratings yet

- SeminarDocument4 pagesSeminarmukulNo ratings yet

- Unit 2 - EDDocument42 pagesUnit 2 - EDMohit L.E. 008No ratings yet

- N-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDDocument9 pagesN-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDAnonymous p1ig0zX6p0No ratings yet

- Cathode Ray Oscilloscope (Cro)Document2 pagesCathode Ray Oscilloscope (Cro)jesunathan44@yahoo.comNo ratings yet

- Mastertop TC 458 PDFDocument3 pagesMastertop TC 458 PDFFrancois-No ratings yet

- Commercial LightingDocument6 pagesCommercial LightingRehan RameezNo ratings yet

- The Forbidden Gate: Dave MorrisDocument79 pagesThe Forbidden Gate: Dave MorrisLopinNo ratings yet

- FibrotexDocument2 pagesFibrotexMan ChupingNo ratings yet

- List of FEM Documents 2012Document5 pagesList of FEM Documents 2012Gustavo AquinoNo ratings yet

- Ccsviiid1 2029-3Document2 pagesCcsviiid1 2029-3DieguitoOmarMoralesNo ratings yet

- Diamond Pin Locator and V Blocks 1Document8 pagesDiamond Pin Locator and V Blocks 1pratik thakareNo ratings yet

- Strength Calculation and Dimensioning of Joints: Prepared By: Samson Yohannes Assistant ProfessorDocument45 pagesStrength Calculation and Dimensioning of Joints: Prepared By: Samson Yohannes Assistant ProfessorBK MKNo ratings yet

- Thermochemistry: Purpose of The ExperimentDocument20 pagesThermochemistry: Purpose of The ExperimentAngel LacsonNo ratings yet

- Foundation DesignDocument7 pagesFoundation DesignPrasad GNNo ratings yet

- Introduction To Soil MechanicsDocument20 pagesIntroduction To Soil MechanicsMaeen AhmedNo ratings yet

- Defense Acquisition GuidebookDocument927 pagesDefense Acquisition GuidebookJudkerrNo ratings yet

- Banyule Standard DrawingsDocument103 pagesBanyule Standard DrawingsTarek AbulailNo ratings yet

- AHU-Guideline 01 General Requirements Fo PDFDocument24 pagesAHU-Guideline 01 General Requirements Fo PDFkayden chinNo ratings yet