Professional Documents

Culture Documents

Dynamelt PUR Series Adhesive Bag Melter

Uploaded by

ITWDynatecCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dynamelt PUR Series Adhesive Bag Melter

Uploaded by

ITWDynatecCopyright:

Available Formats

The Next Level of Technology

Dynamelt PUR Series - Adhesive Supply Unit

The Dynamelt PUR Series bag melter is designed to meet the unique needs for the melting and delivery of PUR hot melt adhesives. Models are available to provide gentle melting of PURs packaged in either 2Kg or 20Kg metalized Mylar bags. Escape of harmful gases into the atmosphere and intrusion of moisture into the adhesive is prevented using a patented, air-tight sealing ring at the bottom of the feed tube. This patented sealing design allows units using a typical PUR to be de-energized and left unattended for several days with no need to purge, provided the exposed application orifices are properly sealed.

DYNAMELT PUR Series:

The PUR hotmelt does not require unpacking, it is simply melted out of its foiled packaging. Designed to allow gentle melting directly from a bag without need for a protective inert gas blanket or moisture extraction methods. Precision gear pumps can accommodate a wide variety of adhesives and viscosities. Clean operation with virtually no adhesive residue waste. Circulating design reduces adhesive degradation.

Simplicity

DynaControl touchscreen panel is user-friendly and easy to operate.

Flexibility

Configurations include single or dual drive motor with one or two stream metered outputs.

Reliability

Integrated adhesive reservoir eliminates the need to shut down the system when changing bags.

ITW Dynatec - DynameltTM PUR-20 Series

The Dynatec Difference...

Recirculating Adhesive System

The Dynamelt PURs circulating design keeps adhesive in a constant state of motion from the melt tank, through the heated hoses and applicator module, back to the melting unit. This constant circulation of adhesive reduces cross-linking due to thermal set .

Dynamelt PUR Series - Adhesive Supply Unit

System

Hopper Capacity Max Operating Temperature Melt Rate (per hour) Gear Pumps Standard Adhesive Bag Size Outside Diameter (mm) Maximum Working Hydraulic Pressure Electrical Service Standard Options Working Viscosity

*Dependent upon adhesive type.

PUR-2

.5 kg (1 lb) 200C (392F) 6 kg/hr (13 lb/hr)* 2 Single Pumps or 1 dual pump 124 - 126 85 bar (1233 PSI) 240 VAC 3Phase 50/60 Hz 380 VAC 3Phase Y 50/60 Hz 500 to 50,000 cps

PUR-20

10 kg (22 lbs) 200C (392F) 35 kg/hr (77 lb/hr)* 2 Single Pumps or 1 dual pump 283 - 287 (US) 277 - 281 (Europe) 85 bar (1233 PSI) 240 VAC 3Phase 50/60 Hz 380 VAC 3Phase Y 50/60 Hz 500 to 50,000 cps

PUR-20D

10 kg (22 lbs) 200C (392F) 35 kg/hr (77 lb/hr)*

2 dual pumps

283 - 287 (US) 277 - 281 (Europe) 85 bar (1233 PSI) 240 VAC 3Phase 50/60 Hz 380 VAC 3Phase Y 50/60 Hz 500 to 50,000 cps Full and spent adhesive bags

Dimensions

Height (H) Depth (D) Width (W) Service (S)* Weight (empty)

*Maintenance area.

PUR-2

152 cm (60 in) 97.5 cm (38.4 in) 50.5 cm (19.9 in) 102 cm (40.2 in) 190 kg (419lbs)

PUR-20

152 cm (60 in) 105 cm (41.3 in) 64cm (25.2 in) 143.5 cm (56.5 in) 240 kg (529lbs)

PUR-20D

152 cm (60 in) 105 cm (41.3 in) 64cm (25.2 in) 143.5 cm (56.5 in) 240 kg (529lbs) Platen assembly above feed tube

Inserting a new bag or slug of adhesive into the melt unit

ASIA

12/2012 ITW Dynatec ITW Dynatec reserves the right to discontinue or change specifications, designs, materials and equipment without notice or obligation.

ITW Dynatec Suzhou Unit2, B1 Building No.9 Weixin Road SIP, Suzhou, China 215122 Telephone +86.512.6289.0620 Fax +86.512.6289.0621 dynatecsuzhou@itwdynatec.cn

ITW Dynatec 31 Volunteer Drive Hendersonville, TN 37075 Telephone 6158243634 +1.800.860.6150 Fax +1.615.264.5248 dynatec@itwdynatec.com

AMERICAS

JAPAN

ITW Dynatec K.K. Tsukimura Building 5th Floor 26-11, Nishikamata 7-chome Ota-ku, Tokyo 144-0051, Japan Telephone +81.3.5703.5501 Fax +81.3.5703.5505 info@itwdynatec.co.jp

EUROPE, AFRICA and MIDDLE EAST

ITW Dynatec GmbH Industriestrasse 28 D-40822 Mettmann, Germany Telephone +49.210.4915.0 Fax +49.210.491.5111 e.mail@itwdynatec.de

Visit us at www.itwdynatec.com

You might also like

- Compsim PDFDocument40 pagesCompsim PDFciucalata88No ratings yet

- Sea WaterDocument39 pagesSea WaterArun GuptaNo ratings yet

- Dynamelt S Series - MasterDocument2 pagesDynamelt S Series - MasterITWDynatecNo ratings yet

- 100ah - 12V - 6FM100 VISIONDocument2 pages100ah - 12V - 6FM100 VISIONBashar SalahNo ratings yet

- Netflix ESG Report 2020Document23 pagesNetflix ESG Report 2020utpalnath100% (1)

- Dynamini Series Adhesive Supply UnitDocument2 pagesDynamini Series Adhesive Supply UnitITWDynatecNo ratings yet

- Wrapid Sleeve PDSDocument2 pagesWrapid Sleeve PDSjayhuacat7743No ratings yet

- HL-ADS compressed air dryer packagesDocument17 pagesHL-ADS compressed air dryer packagesMarcoAlbaNo ratings yet

- Thom-Katt Brochure USDocument8 pagesThom-Katt Brochure USjeremias floresNo ratings yet

- DM55 Bulk Adhesive Drum UnloaderDocument2 pagesDM55 Bulk Adhesive Drum UnloaderITWDynatecNo ratings yet

- Dynamelt S Series APS Adhesive Supply UnitDocument2 pagesDynamelt S Series APS Adhesive Supply UnitITWDynatecNo ratings yet

- Affordable Reservoir and Port Dredging with the IMS DM-60Document2 pagesAffordable Reservoir and Port Dredging with the IMS DM-60Mohamed ZaghloulNo ratings yet

- Davis Standard, LLC - Extrusion Systems - Products - Wire & Cable - OverviewDocument3 pagesDavis Standard, LLC - Extrusion Systems - Products - Wire & Cable - Overviewanindya198794790% (1)

- VersaDrum Bulk Melters With Gear PumpDocument2 pagesVersaDrum Bulk Melters With Gear PumpNordson Adhesive Dispensing SystemsNo ratings yet

- Technical Proposal for Olympic Pool Filtration SystemDocument10 pagesTechnical Proposal for Olympic Pool Filtration SystemAlma DerajNo ratings yet

- A1200 Red Thread II PipingDocument0 pagesA1200 Red Thread II PipingjimmycabreraNo ratings yet

- Miller Spectrum 875 XtremeDocument4 pagesMiller Spectrum 875 XtremeomaralihasNo ratings yet

- Liberty Pro-380WebDocument4 pagesLiberty Pro-380WebMerNo ratings yet

- Upvc Pressure Pipes and FittingsDocument8 pagesUpvc Pressure Pipes and FittingsjafarkhansfNo ratings yet

- Canusa Wrap Benzi Termocontractibile Izolatii Conducte OtelDocument2 pagesCanusa Wrap Benzi Termocontractibile Izolatii Conducte Oteleugen_alexutzNo ratings yet

- Ficha Tecnica Hepa 24x48x5 Tm2Document4 pagesFicha Tecnica Hepa 24x48x5 Tm2EDWLYCANNo ratings yet

- Covalence WPC100M Shrink Sleeves PDFDocument2 pagesCovalence WPC100M Shrink Sleeves PDFJMROMANTNo ratings yet

- UFD Equity Fiberized Spray Adhesive ApplicatorDocument2 pagesUFD Equity Fiberized Spray Adhesive ApplicatorITWDynatecNo ratings yet

- 2009 PI Piezo Actuators Components Nano Positioning CatalogDocument48 pages2009 PI Piezo Actuators Components Nano Positioning CatalogburakbalciNo ratings yet

- Cutmaster 81Document4 pagesCutmaster 81Silverio JaimeNo ratings yet

- TDW Hot Tapping and Plugging SolutionsDocument20 pagesTDW Hot Tapping and Plugging SolutionsBoban Stanojlović100% (4)

- Hydraulic Seals Data From ParkerDocument7 pagesHydraulic Seals Data From Parkerjuan_set8822No ratings yet

- The 26 - 200 Kva RangeDocument16 pagesThe 26 - 200 Kva Rangerodyf100% (1)

- Polyken 4000 PrimerlessDocument2 pagesPolyken 4000 PrimerlessKyaw Kyaw AungNo ratings yet

- PX Pumps FolletoDocument4 pagesPX Pumps FolletoBenicio Joaquín Ferrero BrebesNo ratings yet

- 462 CatDocument2 pages462 Catanoop9079No ratings yet

- XHXDocument12 pagesXHXMatias MancillaNo ratings yet

- COPPUS Portable VentilatorsDocument24 pagesCOPPUS Portable Ventilatorsebrahimbatul2No ratings yet

- COPPUS-Catalog-2020-(Digital)Document24 pagesCOPPUS-Catalog-2020-(Digital)elliotmoralesNo ratings yet

- Hunter Catalog emDocument172 pagesHunter Catalog emGrigore DanaNo ratings yet

- DC Motores - KinematicDocument24 pagesDC Motores - KinematicWilfredo Rojo CastañoNo ratings yet

- Jet-X High-Expansion Foam Generators: Data/SpecificationsDocument6 pagesJet-X High-Expansion Foam Generators: Data/SpecificationsmukeshsinghtomarNo ratings yet

- Turcon Stepseal K 2KDocument17 pagesTurcon Stepseal K 2Kแบด พิษNo ratings yet

- ProfilDocument18 pagesProfilAnonymous 6EW2MsFbkNo ratings yet

- Catalogo Cutmaster VictorDocument2 pagesCatalogo Cutmaster Victorchavez.cesarNo ratings yet

- Catalogue Ipsi EpDocument70 pagesCatalogue Ipsi EprachedscribNo ratings yet

- Glass Lined BrochureDocument8 pagesGlass Lined BrochureKarna2504No ratings yet

- Process CryostarDocument8 pagesProcess CryostarNarayan MarndiNo ratings yet

- Manual de Celda UXDocument2 pagesManual de Celda UXvhcamiloNo ratings yet

- SPEC Pulsatron E PLUS SeriesDocument2 pagesSPEC Pulsatron E PLUS SeriesAlfonso Javier Medina PernethNo ratings yet

- VersaDrum Bulk Melters With Piston PumpDocument2 pagesVersaDrum Bulk Melters With Piston PumpNordson Adhesive Dispensing SystemsNo ratings yet

- Hidronicos 2Document17 pagesHidronicos 2Gerardo Zumbado MNo ratings yet

- WPCT Heat Shrink SleevesDocument4 pagesWPCT Heat Shrink SleevesHamzaHashimNo ratings yet

- Product Data: 40RUA / 40RUSDocument56 pagesProduct Data: 40RUA / 40RUSSergio SaldiviaNo ratings yet

- Tkis-Polytrack-Factsheet-210 X 297-WebpdfDocument2 pagesTkis-Polytrack-Factsheet-210 X 297-WebpdfHa Kim BJNo ratings yet

- Hi Ride Mud HopperDocument4 pagesHi Ride Mud HopperAnonymous VNu3ODGav100% (1)

- AEC Drying Brochure AEC2-115.1Document12 pagesAEC Drying Brochure AEC2-115.1serdigital0No ratings yet

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- Wire and Cable Extrusion SystemsDocument8 pagesWire and Cable Extrusion Systemsanindya19879479No ratings yet

- Increase Production Efficiencies - Minimize Rework - Extend Shelf Life - Improve Package QualityDocument2 pagesIncrease Production Efficiencies - Minimize Rework - Extend Shelf Life - Improve Package QualityBarba LuisNo ratings yet

- Polyken 1600 High TempDocument2 pagesPolyken 1600 High TempKyaw Kyaw AungNo ratings yet

- Barclay SilencersDocument12 pagesBarclay SilencerspostboxsgNo ratings yet

- Biofuge Contifuge Stratos 120 200 208 240V DualDocument103 pagesBiofuge Contifuge Stratos 120 200 208 240V DualAndrew Holmes50% (2)

- Piping FG Smith FiberglassDocument12 pagesPiping FG Smith Fiberglassnader0123100% (1)

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Helix Rotary SprayDocument2 pagesHelix Rotary SprayITWDynatecNo ratings yet

- DynaPack Adhesive Supply UnitDocument2 pagesDynaPack Adhesive Supply UnitITWDynatecNo ratings yet

- DY2002 Pattern ControllerDocument2 pagesDY2002 Pattern ControllerITWDynatecNo ratings yet

- Next Generation Dynamelt S SeriesDocument2 pagesNext Generation Dynamelt S SeriesITWDynatecNo ratings yet

- BF MicroBeadDocument2 pagesBF MicroBeadITWDynatecNo ratings yet

- ITW Dynatec Overview BrochureDocument2 pagesITW Dynatec Overview BrochureITWDynatecNo ratings yet

- DY2002 Pattern ControllerDocument2 pagesDY2002 Pattern ControllerITWDynatecNo ratings yet

- Cross CoatDocument2 pagesCross CoatITWDynatecNo ratings yet

- TPC-2 Pattern ControllerDocument2 pagesTPC-2 Pattern ControllerITWDynatecNo ratings yet

- DPC-2 Pattern ControllerDocument2 pagesDPC-2 Pattern ControllerITWDynatecNo ratings yet

- Packaging TriFoldDocument2 pagesPackaging TriFoldITWDynatecNo ratings yet

- DY2008 Pattern ControllerDocument2 pagesDY2008 Pattern ControllerITWDynatecNo ratings yet

- Technical Service & Support BrochureDocument2 pagesTechnical Service & Support BrochureITWDynatecNo ratings yet

- ITW Dynatec Overview BrochureDocument2 pagesITW Dynatec Overview BrochureITWDynatecNo ratings yet

- APEX Adhesive Slot Die ApplicatorDocument2 pagesAPEX Adhesive Slot Die ApplicatorITWDynatecNo ratings yet

- EDI Precision Coating and Laminating SystemDocument2 pagesEDI Precision Coating and Laminating SystemITWDynatecNo ratings yet

- BF Micro Adhesive ApplicatorDocument2 pagesBF Micro Adhesive ApplicatorITWDynatecNo ratings yet

- Gemini Automatic Adhesive HosesDocument2 pagesGemini Automatic Adhesive HosesITWDynatecNo ratings yet

- Dynamelt GC Series - MasterDocument2 pagesDynamelt GC Series - MasterITWDynatecNo ratings yet

- Dynamelt LC Series - MasterDocument2 pagesDynamelt LC Series - MasterITWDynatecNo ratings yet

- Vector Technology White PaperDocument3 pagesVector Technology White PaperITWDynatecNo ratings yet

- Dynamelt M Series Adhesive Supply UnitDocument2 pagesDynamelt M Series Adhesive Supply UnitITWDynatecNo ratings yet

- Consistent Quality in Hot Melt Slot Die CoatingDocument2 pagesConsistent Quality in Hot Melt Slot Die CoatingITWDynatecNo ratings yet

- Benefits of Automatic Bulk Adhesive Feed SystemsDocument2 pagesBenefits of Automatic Bulk Adhesive Feed SystemsITWDynatecNo ratings yet

- Vector Adhesive Spray ApplicatorDocument2 pagesVector Adhesive Spray ApplicatorITWDynatecNo ratings yet

- Hot Melt Efficiencies - Cut Costs & Minimize WasteDocument3 pagesHot Melt Efficiencies - Cut Costs & Minimize WasteITWDynatecNo ratings yet

- EVC-1 Electronic Volume ControllerDocument2 pagesEVC-1 Electronic Volume ControllerITWDynatecNo ratings yet

- Actual Tour Guiding ScriptDocument3 pagesActual Tour Guiding Scriptaqmendoza0444valNo ratings yet

- Marine Resources in Pakistan: A Tentative InventoryDocument10 pagesMarine Resources in Pakistan: A Tentative InventorymishwiNo ratings yet

- Hydropower Enhances Lives in IndonesiaDocument2 pagesHydropower Enhances Lives in IndonesiaAlbin Mokhammed SofianNo ratings yet

- Petroleum GeologyDocument13 pagesPetroleum GeologyRaihan FuadNo ratings yet

- Saturn - Late BloomerDocument14 pagesSaturn - Late BloomerNina Elezovic Simunovic100% (1)

- Research and Development: Applied Research IN Renewable Energy SystemsDocument22 pagesResearch and Development: Applied Research IN Renewable Energy SystemsBilaljafraniNo ratings yet

- Total Automation Solution in Super Critical Thermal Power Plant PDFDocument28 pagesTotal Automation Solution in Super Critical Thermal Power Plant PDFpredic1No ratings yet

- CSEB (Chhattisgarh State Electricity Board) Korba East Vocational Training Presentation I IDocument44 pagesCSEB (Chhattisgarh State Electricity Board) Korba East Vocational Training Presentation I Ihaxxo24No ratings yet

- Handbook of Photovoltaic Science and Engineering: Instituto de Energ Ia Solar, Universidad Polit Ecnica de Madrid, SpainDocument8 pagesHandbook of Photovoltaic Science and Engineering: Instituto de Energ Ia Solar, Universidad Polit Ecnica de Madrid, SpainBijuNo ratings yet

- Compressor Packager Guide WEB NewDocument4 pagesCompressor Packager Guide WEB NewJaroslav KurucNo ratings yet

- An Environmentally Friendly Investment: Lifecycle Assessment of A V80-2.0 MW Onshore Wind TurbineDocument14 pagesAn Environmentally Friendly Investment: Lifecycle Assessment of A V80-2.0 MW Onshore Wind TurbineHung NGUYENNo ratings yet

- HCI 534F/544F - Technical Data SheetDocument8 pagesHCI 534F/544F - Technical Data SheetAshadi Angka NolNo ratings yet

- MS G484 Jan11Document9 pagesMS G484 Jan11samy9387No ratings yet

- Manual Instalacion y Mantenimiento Generador EolicoDocument71 pagesManual Instalacion y Mantenimiento Generador EolicoAnto VerduNo ratings yet

- RET Important QuestionsDocument6 pagesRET Important QuestionsSharanya EmmadisettyNo ratings yet

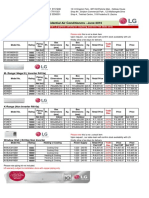

- LG Trade Price List June 2016Document2 pagesLG Trade Price List June 2016musturNo ratings yet

- Merlin XX EngineDocument6 pagesMerlin XX EngineIvan Kopić100% (2)

- Praveen Gupta Deputy Director Central Electricity Authority New DelhiDocument73 pagesPraveen Gupta Deputy Director Central Electricity Authority New DelhiAnkur PathakNo ratings yet

- Orginal ProjectDocument18 pagesOrginal ProjectSaravana KumarNo ratings yet

- Akai Apiflo File - 461c9a72a4fa6APIFLO M Series BrochureDocument6 pagesAkai Apiflo File - 461c9a72a4fa6APIFLO M Series Brochure2009tamerNo ratings yet

- Geothermal and Solar Energy in Cerro PrietoDocument7 pagesGeothermal and Solar Energy in Cerro Prietorheina alfi yunitaNo ratings yet

- Wind Turbine FoundationDocument4 pagesWind Turbine FoundationnenmilNo ratings yet

- Case Study of Bujagai Hydro Power ProjectDocument24 pagesCase Study of Bujagai Hydro Power ProjectManuel LemosNo ratings yet

- Renewable resources at VIT UniversityDocument8 pagesRenewable resources at VIT UniversitySingaraju SarathNo ratings yet

- BUS6100 Mo1Document5 pagesBUS6100 Mo1Thelma AkpataNo ratings yet

- Understanding Blower Door Test ResultsDocument6 pagesUnderstanding Blower Door Test Resultskulov1592No ratings yet

- SCORE Provides Energy for Sarawak DevelopmentDocument162 pagesSCORE Provides Energy for Sarawak DevelopmentMani JackNo ratings yet

- Pulse Boost White LEDDocument9 pagesPulse Boost White LEDsinghadkNo ratings yet