Professional Documents

Culture Documents

Use and Limitations of in Vitro Dissolution Testing: Topic Introduction and Overview

Uploaded by

Muthu VenkateshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Use and Limitations of in Vitro Dissolution Testing: Topic Introduction and Overview

Uploaded by

Muthu VenkateshCopyright:

Available Formats

Use and Limitations of In Vitro

Dissolution Testing:

Topic Introduction and Overview

Lawrence X. Yu, Ph. D.

Deputy Director for Science and Chemistry

Office of Generic Drugs

Food and Drug Administration

Advisory Committee for Pharmaceutical Science

and Clinical Pharmacology

August 8, 2012

In Vitro Dissolution Testing: Objectives

Assure batch to batch quality

Guide development of new formulations

Provide process control and quality

assurance

Ascertain the need for bioequivalence studies

Different strengths

Post-approval changes

Multi-source products

2

Dissolution Testing: Issues

Dissolution testing can be non-discriminating.

Dissolution testing can be over discriminating.

Products that dissolve about 70% in 45 minutes often

have no medically relevant bioequivalence problems.

Dissolution testing (especially only a single point

criterion) is often not sufficient to assure product

quality/ bioavailability.

Demonstration of in vitro-in vivo correlation (IVIVC) is

necessary.

IVIVCs are Product Specific.

3

Desired Future State of

In Vitro Dissolution Testing

Sensitive enough to detect relevant product

changes so as to ensure the quality and

consistent performance of products

Predictive of in vivo performance of drug

products and thus reduce unnecessary human

studies, accelerate drug development, and

hasten evaluation of post-approval changes

4

Uses and Limitations of

In Vitro Dissolution Testing

Use and Limitations of In Vitro Dissolution Lawrence Yu

Testing: Topic Introduction and Overview

Dissolution Testing: Evolving Dissolution Cindy Buhse

Apparatus

Dissolution Testing: Evolving Dissolution Arzu Selen

Media for Predicting In Vivo Performance

Oral Bioperformance & 21st Century Gregory Amidon

Dissolution Testing

Dissolution Testing and Quality-by-Design Lawrence Yu

Followed by:

Topic Wrap-up and Future Directions

Questions to the Committee/Committee Discussion

5

Dissolution Testing:

Evolving Dissolution Apparatus

Advisory Committee for Pharmaceutical Science and

Clinical Pharmacology

August 8, 2012

Cindy Buhse, Ph.D., Director

Zongming Gao, Ph.D., Chemist

Division of Pharmaceutical Analysis

Center for Drug Evaluation and Research

US Food and Drug Administration

Dissolution Testing Evolves from Disintegration Test

Stoll-Gershberg disintegration apparatus

ERSHBERG S, STOLL FD, 1946, Apparatus, for tablet disintegration, and for shaking-

out extractions, Journal of the American Pharmaceutical Association, 35(9), 284-7.

Convenient and sensitive chemical

analyses weren't available in 1950s.

Official disintegration tests were

adopted in 1945 by the British

Pharmacopoeia and in 1950 by the

USP.

However, disintegration was

recognized as an incomplete test as

evidenced by the 1950 USP-NF

statement that "disintegration does

not imply complete solution of the

tablet or even of its active

ingredient".

G

2

A Proliferation of Designs for Dissolution Apparatuses

between 1960 and 1970 Basket Method

Searl and Pernarowski, 1967

Belachew Desta, An evaluation of the USP dissolution apparatus, 1972, Thesis of the University of British Columbia.

3

A Proliferation of Designs for Dissolution Apparatuses

between 1960 and 1970 Paddle Method

Levy-Hayes, 1960

Belachew Desta, An evaluation of the USP dissolution apparatus, 1972, Thesis of the University of British Columbia.

4

A Proliferation of Designs for Dissolution Apparatuses

between 1960 and 1970 -- Reciprocating Cylinder Method

Vliet, 1959

Belachew Desta, An evaluation of the USP dissolution apparatus, 1972, Thesis of the University of British Columbia.

5

A Proliferation of Designs for Dissolution Apparatuses

between 1960 and 1970 Flow-through Method

Lapidus and Lordi, 1966

Belachew Desta, An evaluation of the USP dissolution apparatus, 1972, Thesis of the University of British Columbia.

6

The First USP Dissolution Apparatus 1, Basket

USP Apparatus 1

A Basket

B 1000ml resin flask

C Cover

D High-torque stirring

motor

1970 - Dissolution test, apparatus 1

(basket), USP 18

1976 - Dissolution test, apparatus 2

(paddle), USP 19

Belachew Desta, An evaluation of the USP dissolution apparatus, 1972, Thesis of the University of British Columbia.

7

Early Dissolution Testing in a FDA Lab in 1970s

USP rotating-basket apparatus

and a centering tool

USP paddle apparatus

Pharmaceutical Technology, April, 1978, Vol 2, 16-53 8

FDAs Definition and Views on

Dissolution Testing in 1970s

In vitro dissolution testing as applied to solid-dosage drug forms

measures the amount of drug dissolved in a known volume of

liquid medium at a predetermined time, using a specified

apparatus designed to carefully control the parameters of

dissolution testing.

In vitro dissolution testing can help pinpoint formulations that

may present potential bioequivalence problem.

Once a formulation has been shown to be bioavailable,

dissolution testing is of great value in assuring lot-to-lot

bioequivalence.

Don C. Cox, Carol C. Douglas, William B. Furman, Ross D. Kirchhoefer, James W. Myrick and Clyde E.

Wells, 1978, Guidelines for dissolution testing, Pharmaceutical Technology, Vol 2, No.4, 41-53 9

FDAs Concerns and Standpoint

on Dissolution Testing in 1970s

Dissolution tests are critical and difficult to carry out properly. Care and

attention must be given to those aspects that have been identified as crucial.

It is our hope that other scientists will share their findings and techniques so

that dissolution testing may be advanced to a reproducible and reliable

scientific procedure.

If labs can not be expected to agree on the results of a dissolution test, then

an IVIVC obtained by one lab can not be generalized as being valid in all

labs.

Differences between dissolution results obtained in industrial labs and those

obtained in agency labs raise problems in the making of regulatory

decisions.

Don C. Cox, Carol C. Douglas, William B. Furman, Ross D. Kirchhoefer, James W. Myrick and Clyde

E. Wells, 1978, Guidelines for dissolution testing, Pharmaceutical Technology, Vol 2, No.4, 41-53 10

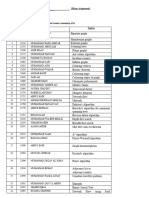

USP Monographs for Dissolution Testing

Table 1.

Number of monogrnplls tn Ule US Pharmacopeia and l tite ational Formulary

which r-equire dissohJUon o.r :rel.ease tests

USP Monographs for Dissolution Testing

Table 1.

Number of monogrnplls tn Ule US Pharmacopeia and l tite ational Formulary

which r-equire dissohJUon o.r :rel.ease tests

EdiUoDiyear Monographs for

immediate-release

dosage forms

Monographs for

modlii ed-re1case

dosage forms

EKtended Delayed

USP l8-NF 1.31.19'70 6

USP l 9-NF 141.1915 12

USP 20-NF 1.511980 60

USP 2[ -NF 1.611985 400

USP 22-NFI7H990 462 18 5

U SP 23-NFl8/l 995

USP 24-NFI9/2000

USP 29-NF2412006

50.1

552

619

6

2.6

38

25

[4

l4

www.fda.gov

Aristides Dokoumetzidis, Panos Macheras, 2006, Historical Perspectives: A century of dissolution research: From

Noyes and Whitney to the Biopharmaceutics Classification System, International Journal of Pharmaceutics, 321, 111

11

FDAs Guidances for Dissolution Testing

1978 FDA/DPA published a guideline for dissolution testing

1984 FDA/DPA published the Guidelines for dissolution testing: an addendum

1995 Guidance for Industry, SUPAC-IR: Immediate-Release Solid Oral Dosage Forms:

Scale-Up and Post-Approval Changes: Chemistry, Manufacturing and Controls, In

Vitro Dissolution Testing, and In Vivo Bioequivalence

1997 Guidance for Industry, SUPAC-MR: Modified Release Solid Oral Dosage Forms

Scale-Up and Postapproval Changes: Chemistry, Manufacturing, and Controls; In

Vitro Dissolution Testing and In Vivo Bioequivalence

1997 Guidance for Industry, Dissolution Testing of Immediate Release Solid Oral Dosage

Forms

1997 Guidance for Industry, Extended Release Oral Dosage Forms: Development,

Evaluation, and Application of In Vitro/In Vivo Correlations

2010 Guidance for Industry, The Use of Mechanical Calibration of Dissolution Apparatus 1

and 2 Current Good Manufacturing Practice (CGMP)

2011 Guidance for Industry, Q4B Evaluation and Recommendation of Pharmacopoeial

Texts for Use in the ICH Regions, Annex 7(R2) Dissolution Test General Chapter

12

Current Official USP Dissolution Apparatuses

13

USP 6 (cylinder)

USP 1 (basket) USP 5 (paddle over disk)

Te perature, rotation

speed, dissolution medium

Primary use is for semi-solid

topical dosage forms but has

also been used for drug

release and skin/membrane

permeation for transdermal

patches.

Apparatus 5

(Paddle over

disk)

Temperature, rotation

speed, dissolution medium

Transdermal system. Apparatus 6

(Cylinder)

Temperature, rotation

speed, dissolution medium

Immediate-release, extended-

release, and delayed-release

dosage forms.

Apparatus 2

(Paddle)

Temperature, rotation

speed, dissolution medium

Test Parameters

Immediate-release, extended-

release, and delayed-release

dosage forms.

Apparatus 1

(Basket)

Samples Apparatus

m Temperature, rotation

speed, dissolution medium

Primary use is for semi-solid

topical dosage forms but has

also been used for drug

release and skin/membrane

permeation for transdermal

patches.

Apparatus 5

(Paddle over

disk)

Temperature, rotation

speed, dissolution medium

Transdermal system. Apparatus 6

(Cylinder)

Temperature, rotation

speed, dissolution medium

Immediate-release, extended-

release, and delayed-release

dosage forms.

Apparatus 2

(Paddle)

Temperature, rotation

speed, dissolution medium

Test Parameters

Immediate-release, extended-

release, and delayed-release

dosage forms.

Apparatus 1

(Basket)

Samples Apparatus

Pictures copied from website, http://www.protechcro.com/images/01Dissolution.pdf, accessed July 2, 2012

USP 2 (paddle)

Current Official USP Dissolution Apparatuses

Reciprocating Apparatus is typically used for

imitating the pH changes that occur in the body and is

suited for extended and sustained release dosage

forms.

Te perature, dip rate,

dissolution medium

Transdermal system,

extended-release dosage

forms (coated tablet)

Apparatus 7

Temperature, dip rate,

dissolution medium.

Test Parameters

Immediate-release, extended-

release, and delayed-release

dosage forms.

Apparatus 3

Samples Apparatus

m Temperature, dip rate,

dissolution medium

Transdermal system,

extended-release dosage

forms (coated tablet)

Apparatus 7

Temperature, dip rate,

dissolution medium.

Test Parameters

Immediate-release, extended-

release, and delayed-release

dosage forms.

Apparatus 3

Samples Apparatus

USP 3 - reciprocating cylinder

Angled

disk

Disk cylinder

Pointed

rod

spring

holder

USP 7 - reciprocating holder

Pictures copied from website, http://www.protechcro.com/images/01Dissolution.pdf, accessed July 2, 2012

14

Current Official USP Dissolution Apparatuses

USP 4 flow through

Tablet cell

12 mm

Cell for

implants

Tablet cell

22.6 mm

Cell for

suppositories

and soft

gelatin capsules

Cell for

powders

and granulates

Temperature-

Measuring Head

T st Parameters Samples

Temperature, flow rate,

pulses per minute,

dissolution medium

Immediate-release, extended-release, and

delayed-release dosage forms.

tablets, capsules, suppositories, powders, drug

eluting stents, creams, gels, suspensions etc.

e Test Parameters Samples

Temperature, flow rate,

pulses per minute,

dissolution medium

Immediate-release, extended-release, and

delayed-release dosage forms.

tablets, capsules, suppositories, powders, drug

eluting stents, creams, gels, suspensions etc.

Pictures copied from website, http://www.sotax.com/USP-4-Semi-automated-systems.127.0.html, accessed July 2, 2012

15

16

Does Current Dissolution Method Have Any

Biological Relevance?

Disintegration

Solids transfer

Dissolution

Changing pH

X

Food and drink

Absorption

X

Clearance

X

Picture copied from website,

http://www.google.com/images?q=digest+system&hl=en&gb

ju0gHx8oCYAg&start=20&sa=N, accessed July 30, 2012

v=2&tbm=isch&ei=uZQZUIT4O-

Picture copied from website,

http://www.protechcro.com/images/01Dissol

ution.pdf, accessed July 2, 2012

www.fda.gov

New Designs for Dissolution Testing

1 8

1. ads (IJ 8 mrnl

21 Chama, er (f 35 mm size O.s mm.

wire 0. rnm]

3. Dosagoform

4. lnflatab:te

6

.5. Sol ettoi d valve$

r6,

Ste ppir; g motot

1. strrr-er (paUdle 1535 mm2j

.a. :sampling

t . Standard ves&eJ

f ig. l . Schemati c representati on of the dissoluti on stress t est devi oe.

Garbacz, G. et al. Irregular absorption profiles observed from diclofenac extendedrelease tablets can be predicted using a

dissolution test apparatusthat mimics in vivo physical stresses. Eur. J. Pharm. Biopharm. 2008, 70 (2), 421428. 17

New Designs for Dissolution Testing

Drug Sampling

n

I Apical side I

j Basal side j

~

~

5

I

Stirring

I

Stirri ng

Caco-2 monolayer

Fig. 1. Schematic ill ustration of the dissolution/ permeation system

(DfP system). Caco-2 monolayer was mounted between the apical

and basal chambers. Both sides of the monolayer were filled wit h

transport mediwn (apical side; pH = 6.5, volume = 8 ml, basal side;

pH = 7.4, volume = 5.5 ml) and stirred by magnet ic stirrers con-

stantly. Drugs were applied to the apical side as solid. suspension, or

solution.

sampling sampling

perfusion chamber installed

with a M llliceii-PCF filter

t t

r-------1 .... , --,..------11 1--- ----,

Donor side n Acceptor side

1

drug-<fissolvl1g

solution {pHl .D) .pH 1.0 6.0

Caco-2

t

acceptor solution (pH7.4)

pH adju slmerrt

solution (pH 12.0)

.... =:::::::::::::::;:=r ......

J <" .1- ltf ~ T

scarnng bar ..-cm \ {

Drug-dissolving pH Adjustment

Vessel \ / Vessel

3ml

Makoto KATAOKA et al. 2011, In Vitro

Dissolution/Permeation System to Predict the Oral

Absorption of Poorly Water-Soluble Drugs: Effect of Food

and Dose Strength on It, Biol. Pharm. Bull. 34(3) 401407

M. Kobayashi et al. International Journal of Pharmaceutics 221 (2001) 8794

18

New Designs for Dissolution Testing

Hanks Balanced Salts Solution (HBSS) at pH 6.8

was used as the dissolution medium, in order to

accommodate the Caco-2 monolayer.

SGF and deionized water do not support Caco-2 cell

viability.

The dissolution testing time is limited by Caco-2 cells

for less than 2 hours.

Mark J. Ginski, Rajneesh Taneja, and James E. Polli, 1999, Prediction

of Dissolution-Absorption Relationships from a Continuous

Dissolution/Caco-2 System, AAPS Pharmsci, 1 (3) article 3

L. Hughes et al. Dow Apparatus (FloVitro)

19

New Designs for Dissolution Testing

A

B

c

D

E

F

G

H

I

J

K

L

M

N

0

p

Q

TNOTIM-1

System Schematic

Stomach Comparunem.

Perisultl c Valve

Duodenum Compartment

Jejunum Compartment

Ileum Compartment

Pressure Sensor

Stomach Secretion

Duodenum Secretion

Jelunum Secretion

Ileum Sccretlon

Pre.filtu

Semi-Permeable Membrane

Filtrate Pump

pH Bectrode

LeYel Sensor

Tempel'1ltl.lre Sensor

Dosing Port

Q

l .t mi./Min@ M

Paul A. Dickinson, et al. An Investigation into the Utility of a Multi-compartmental, Dynamic, System of the Upper Gastrointestinal Tract

to Support Formulation Development and Establish Bioequivalence of Poorly Soluble Drugs. The AAPS Journal, Vol. 14, 196-205, 2012.

20

New Designs for Dissolution Testing

UV/vis UV/vis

Dissolution

Medium

Waste

Cell 1 Cell 2

Z Gao, AAPS PharmSciTech, 10(4), 2009, 1401-1405.

21

New Designs for Dissolution Testing

USP4 as dissolution apparatus @ 4mL/min

150 mL SGF for 1 hour

Then, 500 SIF for 23 hours

BCS I, propranolol HCl

BCS II, phenazopyridine HCl

Z Gao, AAPS PharmSciTech, submitted, 2012.

22

Advantage and Disadvantage of Newly Developed

Dissolution Method

Current

USP

Dissolution

Methods

X

X

X

Disintegration

Solids transfer

Dissolution

Changing pH

Food and drink

Absorption

Clearance

Standardized Method

X

Newly

Developed

Dissolution

Methods

23

Dissolution Testing: Evolving Dissolution

Media for Predicting In Vivo Performance

Arzu Selen, Ph.D.

Biopharmaceutics Research Lead

Office of New Drug Quality Assessment/OPS/CDER/FDA

Advisory Committee for Pharmaceutical Science

and Clinical Pharmacology

August 8, 2012

Outline

Background

Dissolution test to relevance of dissolution medium

Recommendations from the guidance

Types and function

Some examples: product characterization, food

effect, screen for alcohol dosedumping

Next phase? Integration of QualitybyDesign

(QbD) and Biopharmaceutics and mechanistic

value

Summary

2

Dissolution Rate Linked with Clinical Outcome

IN A RECENT study of factors affecting the

absorption rate and gastrointestinal irritant effect of

aspirin (1) it was concluded that (a) absorption rates

and incidence and severity of local irritation are

interrelated, (b) both of these characteristics are a

function of the dissolution rate of aspirin in its

particular dosage form, and (c) there are significant

differences in in vitro dissolution rates among

different nationally distributed brands of aspirin

tablets.

Gerhard Levy, Comparison of Dissolution and Absorption Rates of Different

Commercial Aspirin Tablets, J. Pharm. Sci. Vol. 5, 388392, 1961

3

From the Beginning

2009

2006

199

198

1950s and 1960s

0s

7

Ref.1: Workshop cosponsored by ASCPT/DIA/APS/FDA, 1987

Ref.2: From Commentary on AAPS Workshop, May 2006, Arlington, VA

C.Tong, S.S. DSouza, and T. Mirza, Pharm. Res. 24 (9), 16031607, 2007

A dissolution method (and

the acceptance criteria)

should be defined to deliver

desired performance of a

product in the intended in vivo

environment. (Ref. 2)

IVIVC is a future objective

for ER formulations

Dissolution testing for

process control, stability,

minor formulation changes

and manufacturing site

changes. (Ref. 1)

4

Our Increasing Expectations in Drug

Dissolution/Release Testing

Provide basic criteria for drug release from the

product

For batch to batch consistency/quality (product

specification)

As potential surrogate for in vivo BE studies

For linking the product and its in vivo

performance (correlations or relationships: IVIVC

or IVIVR)

5

Recommendations from

Guidance for Industry Dissolution Testing of

Immediate Release Solid Oral Dosage Forms (August 1997)

An aqueous medium pH range 1.2 to 6.8 (ionic strength of

buffers the same as in USP)

To simulate gastric fluid (SGF), a dissolution medium of pH

1.2 (without enzymes)

The need for enzymes in SGF and SIF should be evaluated

on a casebycase basis and should be justified.

To simulate intestinal fluid (SIF), a dissolution medium of pH

6.8 should be employed (also, recommended for testing of

ER products).

A higher pH should be justified on a casebycase basis and,

in general, should not exceed pH 8.0.

6

Recommendations for Dissolution Medium

(Continued)

With gelatin capsule products medium containing enzymes

(pepsin with SGF and pancreatin with SIF) may be used to

dissolve pellicles.

Use of water alone as a dissolution medium is discouraged

(water source may affect test conditions such as pH and

surface tension, and may change during the dissolution test

due to the influence of the active and inactive ingredients)

For water insoluble or sparingly water soluble drug products,

use of a surfactant such as sodium lauryl sulfate is

recommended (Shah 1989, 1995). The need for and the

amount of the surfactant should be justified.

7

A Short List of Dissolution Media

Standard Compendial (in USP):

Simulated Gastric Fluid (with and without pepsin)

Simulated Intestinal Fluid (with and without pancreatin)

Water

Their modifications (media with surfactants)

Additional Media (including patented Biorelevant media)

FastedState Simulated Gastric Fluid (FaSSGF)

FedState Simulated Gastric Fluid (FeSSGF)

Fasted State Simulated Intestinal Fluid (FaSSIF)

Fed State Simulated Intestinal Fluid (FeSSIF)

Blank Fasted and Fed (GF) and (IF)

And others (such as Ensure Plus for forecasting foodeffect)

8

CompositionofFaSSGF andFeSSGF

Reference: Jantratid et al., Europ. J of Pharm. and Biopharm. 69, 776785, 2008

9

Last 20 30 years:

Dissolution/release Testing

Links drug product to

its in vivo performance

Quality control tool

And recently:

Can/should QbD merge the two paths?

Does it help if single and/or multiple media are

used?

10

Desired State for

Drug Release/Dissolution Method

Reliable,

reproducible, well

characterized

method

Influenced by

Critical Quality

Attributes

Has in vivo

relevance

Supports

linking

process,

product and

patient

11

Desired State for

Drug Release/Dissolution Media

Standardized, well

characterized, easy to

prepare and stable

during testing

Facilitates Assessment

of Critical Quality

Attributes has

product relevance

Has in vivo

relevance

Supports

linking

process,

product and

patient

12

Considerations for Selection of

Dissolution Medium

Consistent with route of drug administration and in

vivo environment (Relevance)

Physiological and conditional similarity (such as

fed/fasted)

Function (mechanistic understanding, exploratory

vs. predictive)

Possible alternates (such as simplified media)

Ease of preparation (reliable method)

Standardized (reproducible and stable during

testing)

13

In Vitro Tests for Product Characterization

(using compendial and/or noncompendial methods)

USP Apparatus and compendial media (and/or modifications)

Assessing solubility, dispersion and conditions leading to

precipitation

Bile salt solubility

Exploring in vivo solubilizing capacity of gut lumen

Formulation dispersion, dissolution and drug precipitation

Formulation development

Testing changes in formulation and product and

environment interactions (foodeffect, alcohol dose

dumping)

In vitro digestion/lipolysis tests as possible predictors for food

effect (effect of the digestion products)

14

Effect of Likely Components in the Gut Lumen

on Rate and Extent of Dissolution

Mean Dissolution Profiles of Romazin Tablets (Troglitazone) in Various Media

References: Nicolaides, Galia, Efthymiopoulos, Dressman, and Reppas. Pharm. Res.

16: 18771883, 1999 and C.W. Pouton, Europ. J. of Pharm. Sci. 29, 278287, 2006

15

Furosemide Solubility in Simulated Gastric Media

1:1 milk:

Blank FeSSGF

FaSSGF (FastedState Simulated Gastric Fluid, pH 1.6) and FeSSGF

(Fed State Simulated Gastric Fluid, pH 5), and corresponding blank

buffers (without surfactant)

Reference: From the 2011 AAPS poster presentation of Sarah Gordon, Anette Muellertz and others

16

Exploring Food Effect and Possible Use of

Simplified Biorelevant Media

Ketoconazole Release from Nizoral Tablets in

Biorelevant Media and Respective Blank Buffers

Time (min)

%

R

e

l

e

a

s

e

Reference: T. Zoeller and S. Klein, Dissol. Technol. 813, November 2007

17

Ketoconazole Release from Nizoral Tablets in

Simplified Biorelevant Dissolution Media (Continued)

Time (min.)

%

R

e

l

e

a

s

e

18

Single Medium vs. pH Gradient Method

Diclofenac release from diclofenac sodium modified release pellets

(E. Jantratid, V. De Maio. E. Ronda et al. Eur. J. Pharm. Sci. 37, 434441, 2009)

19

Single Medium

900 mL pH 6.8

Phosphate buffer

Biorelevant pH Gradient Method

In vitro results

from the

biorelevant pH

gradient method

predict food effect

Plasma diclofenac concentrations after a single oral dose of

modifiedrelease diclofenac sodium pellets (n=16 healthy

volunteers, fasted and fed states).

20

In Vitro Release of Opioids from Oral Prolongedrelease Preparations

in Simulated Gastric Fluid and Simulated Gastric Fluid with Ethanol

H

y

d

r

o

m

o

r

p

h

o

n

e

R

e

l

e

a

s

e

d

(

%

)

40% ethanol

20%

15%

10%

5%

control

10 20 30 40

50 60

10

20

30

40

90

80

70

60

50

100

0

0

Time (min)

Reference: Walden et al, Drug Dev. And Indust. Pharm. 33:11011111, 2007

21

Screening for Alcohol Effect on DrugProduct Integrity

Correlation Between Hydromorphone Cmax and In Vitro

Release at 30 min. and 60 min.

Palladone XL was

given with 240 mL

water and also

with 4%, 20% and

40% alcoholic

beverage

22

Reference: Lennernas,Molec. Pharma. 6(5), 14291440, 2009

Integration of QbD and Biopharmaceutics

23

June 2009 workshop of QbD and

Biopharmaceutics Rockville, MD

Ref.: AAPSJ, 12(3), 465472, September 2010

Patient

Benefit

QTPP driven

specification

Biopharmaceutics

Risk Assessment

Road Map

Mechanistic

Understanding

(in vivo and

in vitro)

Summary: Towards Developing an In Vitro Test

Mimicking In Vivo Conditions

(Mechanistic/Predictive Methods)

Dissolution/release test method should be well

characterized (sources of variability and the impact of

changes should be known).

Dissolution test media should be physiologically

meaningful.

Dissolution/release test conditions (e.g. agitation),

duration and sample collection times should be

consistent with its intended release pattern/environment,

and use (as in Quality Target Product Profile).

24

Oral Bioperformance

&

21

st

Century Dissolution Testing

Gregory E. Amidon

Research Professor of Pharmaceutical Sciences

College of Pharmacy

University of Michigan

1

What is it that we cant do today, but if we

could, it would revolutionize our business?

Joel Barker

Futurist

Comprehensive computational tools and

meaningful in vitro test methods that accurately

reflect and predict oral bioperformance would

revolutionize oral formulation development.

2

Topics

Where are we now?

What opportunities are there? There are many!

GI physiology

Fluid volume

Hydrodynamics

Buffer (bicarbonate)

Advanced dissolution methods

Two phase systems (simulating dissolution and absorption)

Two compartment systems (simulating stomach and intestine)

Computational Tools

Fluid Dynamics

Dissolution

Absorption Modeling

3

USP Compendial Tests for Oral Bioperformance

1950: Disintegration Test

1970: Dissolution Apparatus 1 (rotating basket)

1980: Dissolution Apparatus 2 (paddle)

.

.

USP Disintegration Test

USP Dissolution Test (basket)

USP Dissolution Test (paddle)

4

Dissolution Testing is what links the dosage form

to the proven efficacy (eg: typically the clinical

lot used in the Phase 3 pivotal efficacy study)!

..

Dissolution testing is what links every lot of the

dosage form from every manufacturer to the

labeling (proven efficacy and safety)! This can

be 100s or 1000s of lots separated by years or

decades as well as continents from the pivotal

efficacy lot.

5

Some areas of success (1970-2012)

Dissolution Testing as an analytical measure of:

Product consistency

Product quality

Manufacturing process control

IVIVC, IVIVR, IVIVE

BCS

Intestinal media simulation

FaSSIF

FeSSIF

Physiologically relevant solubility

Improved understanding of GI environment

Application of computational tools

6

Some weaknesses (1970-2012)

IVIVC, IVIVR, IVIVE

Application of oral physiology understanding to drug and

drug product testing

Dissolution Testing as in vivo simulation

Application of advanced computational tools

Application of comprehensive physicochemical

principles to oral absorption

7

The price of less than ideal in vitro methods is:

Over-discriminatory in vitro test methods

Result is wasted resources and delays in the development of new

products to meet unmet medical needs

Chasing down unimportant problems

Spending unnecessary development and analytical resources

Slowing development of innovative dosage forms for difficult

to deliver drugs

Conducting unnecessary clinical or animal testing

Under-discriminatory in vitro test methods

Result in a lack of meaningful product quality control

Difficulty comparing innovator and generic products

Product failure (eg: efficacy and/or safety) in patients!

8

A better dissolution test!

Rube Goldberg

More Accurate Oral Bioperformance Prediction would help:

Formulation finding/screening (early development)

Define meaningful in vitro performance requirements such as

disintegration, dissolution, supersaturation extent and time,

functional excipient impact (solubilizer, precipitation inhibitor) etc.

Optimize dosage form delivery rate

Enhance material and process understanding ( Quality by Design)

Facilitate meaningful in vitro testing of varying in vivo conditions

9

Topics

Where are we now?

What opportunities are there (there are many)?

GI physiology

Fluid volume

Hydrodynamics

Buffer (bicarbonate)

Advanced dissolution methods

Two phase systems (simulating dissolution and absorption)

Two compartment systems (simulating stomach and intestine)

BCS Advances

Computational Tools

Fluid Dynamics

Dissolution

Absorption Modeling

10

What have we learned about human physiology that

might related to dissolution testing?

Key considerations include:

Fluid volume

Intestinal surface area

Buffer (bicarbonate)

pH (average, range)

Ionic strength

Surfactants (bile acids)

Carbonic anhydrase

Hydrodynamics

Residence time

Stomach emptying rate

.

Intestinal Contents

Bicarbonate (mEq L

-1

)

Bile salts (mM)

Lipids (mg/mL)

Phospholipids (mM)

Pepsin (mg/mL)

Lipase

Potassium (mM)

Sodium (mM)

Chloride (mM)

Calcium (mM)

Buffer capacity (mmol L

-1

pH

-1

)

Osmolality (mOsm kg

-1

)

Surface tension (mN m

-1

)

Viscosity

Volume

Shear

pH

11

Physiology: What volume of liquid is the dosage form exposed to?

Average aqueous volume in the fasted small intestine is ~100 ml (Refs: multiple)

Total volume in the small intestine

Fasted Mean

Range

Fed Mean

Range

86, 81, 11227, 109 36, 16522, 10572

~ 100 mL

34-46, 37-130, 45-319

47, 381, 59073, 5441

18-78, 343-491, 20-156

Evidence of liquid pockets Schiller et al. Aliment Pharmacol .Ther. 22:971-979 (2005).

Fasted Fed

Number of liquid

pockets

Mean 4 6

Individual

(approx.)

2, 3, 4, 5, 8 2, 5, 6, 7, 11

Volume of liquid

pocket (mL)

Median 12 4

Ref: D.M. Mudie, G.L. Amidon, and G.E. Amidon. Physiological Parameters for Oral

Delivery and In Vitro Testing. Mol Pharmaceutics. 7:1388-1405 (2010).

12

Physiology is complex

Jejunum

Ileum

So - compendia! dissolution testing in 900

ml with a paddle (or rotating basket)

doesn't really capture it.

13

Some physiological dissolution systems

Artificial Dynamic GI System, TIM-1 (TNO)

Stress test apparatus

Dissolution/Permeation system (uses Caco-2 cells)

Two-compartment apparatus:

Artificial Stomach and Duodenum (ASD)

FloVitro Technology (Rohm and Haas)

Two-phase dissolution apparatus

Simultaneous dissolution and partitioning in single

compartment containing two phases (water:organic)

1-octanol

water

14

In-vivo Intestinal Fluid Flow Rates

Time (s)

Gutzeit A, Patak MA, Weymarn Cv, Graf N, Doert A, Willemse E, Binkert CA, Froehlich JM 2010. Feasibility of Small

Bowel Flow Rate Measurement With MRI. Journal of Magnetic Resonance Imaging 32:345-351.

15

Hydrodynamics of dissolution apparatus: USP

Apparatus 2 - Velocity & Shear Profiles

meters/s

Highest velocities occur at the tip of

the paddle (~20 cm/sec)

The lowest velocities are directly

beneath the centerline of the

impeller and around the shaft of the

impeller.

The Reynolds numbers (Re) vary depending on

the rotational speed and location(Re ~ 10

4

).

The shear rates throughout the vessel are

heterogeneous.

Maximum shear rates: 92s

-1

at 50 RPM

Average shear rates: ~ 20s

-1

at 50 RPM

Ref: Bai G, Wang Y, Armenante PM 2011. Velocity Profiles and Shear Strain Rate Variability in the

USP Dissolution Testing Apparatus 2 at Different Impeller Agitation Speeds. International Journal of

Pharmaceutics 403:1-14.

16

Flow Through Cell

May allow for testing at more physiologically relevant Reynolds

number (5 300) and flow rates (0.1 0.6 cm/sec).

Velocity Profiles in a 12mm Cell

Ref: Schematic of a flow through cell: Kakhi (2009). Mathematical Modeling of the Fluid Dynamics in the Flow

Through Cell. International Journal of Pharmaceutics. Vol 376, pg 25.

17

Impact of Fluid Shear on Particle Dissolution (h

app

):

High Performance Computational Analysis

IJO.O

t bpp, IOOrp11

IM

..... ""' lrtnlllnt, lhpm

-dl', l

I

"'

I

!

I

llfi = 1'05'r

;'

.;

Rl

10.0

J

10.0

lr;;

!

lU8!8

0.0

0.0 10.0 lM JO.O

Sar&ce !Uiios

120

61.0

....

-----.. --1-""- ......

.-.

....

- S=Os-1

- s = 0.1 51

- s= 1 s-1

- S= 10s-1

s = 100 51

- s = soo s-1

20 40 60 80 100

Radius (t.tm)

..........

Hintz, Johnson (1989)

Predicted based on

Ref: (1) JJSheng, etal. JPharmSci. 97:4815-4829 (2008).

human intestinal shear

(2) Wang, Brasseur, Penn State University (unpublished) rates

18

Importance of physical chemistry and

physiologic buffer (bicarbonate)

Drug Properties:

Solubility

pKa

Diffusion coefficient

Particle size

Physiological Properties:

pH

Buffer species and concentration

Fluid hydrodynamics

Intestinal motility

Bulk concentration

Volume and temperature etc.

19

Bicarbonate Buffer Physiological

Relevance

Bicarbonate is secreted by the pancreas and

epithelial cells throughout the GI lumen.

GI Lumen

Blood

Ref: Sly WS, Hu PY 1995.

Human Carbonic Anhydrases

and Carbonic Anhydrase

Deficiencies. Annu Rev

Biochem 64:375 - 401

20

Dissolution (37

o

C) of Ibuprofen in bicarbonate

buffer compared to phosphate buffer (rotating disk)

Bicarbonate buffer, pH=6.5

Phosphate buffer pH=6.5

Dissolution in 50 mM phosphate

buffer @ pH=7.2 (USP test)

is 0.7 mg/cm2/min

21

Topics

Where are we now?

What opportunities are there (there are many)?

GI physiology

Fluid volume

Hydrodynamics

Buffer (bicarbonate)

Advanced dissolution methods

Two phase systems (simulating dissolution and absorption)

Two compartment systems (simulating stomach and intestine)

BCS Advances

Computational Tools

Fluid Dynamics

Dissolution

Absorption Modeling

22

Combining dissolution and

absorption (two phase model)

1-octanol

water

Ten + systems described in literature

Being used in industry

Overcome difficulties in maintaining

sink conditions for poorly-soluble

drugs (BCS 2, 4), super-saturable

systems, and controlled-release

Circumvent analytical difficulties

associated with lipid-based capsule

formulations

Simultaneously study impact of

formulation changes (e.g.

surfactants) on dissolution and

absorption processes!

Can potentially be scaled to more

accurately reflect in vivo conditions!

23

Two-phase IVIVR: Nifedipine GITS tablets

BCS IIc

Log P = 2 - 4

Sol. FaSSIF = 0.024mg/ml

Two-phase

Single-phase

24

Two phase physiologic dissolution model

P

m

= 5 x 10

-4

cm/sec, particle radius = 50 m

100

BCS Class II

90

Sol=100g/mL Dose

= 25 mg

80

(Dose number = 1)

70

A/V = 2.3

60

Vw = 100 mL

50

%

% in buffer - two phase

40

% in 1-octanol

% dissolved - two phase

30

% in buffer (% dissolved) - single phase

% saturation in buffer - two phase

20

% saturation in buffer - single phase

10

0

0 50 100 150 200 250 300 350

time, min

25

Two phase physiologic dissolution model

P

m

= 2 x 10

-4

cm/sec, particle radius = 50 m

%

100

90

80

70

60

50

40

30

20

10

0

0 50 100 150 200 250 300 350

time, min

BCS Class II

Sol=100g/mL Dose

= 25 mg

(Dose number = 1)

A/V = 2.3

Vw = 100 mL

% in buffer - two phase

% in 1-octanol

% dissolved - two phase

% in buffer (% dissolved) - single phase

% saturation in buffer - two phase

% saturation in buffer - single phase

26

Two phase physiologic dissolution model

P

m

= 1 x 10

-4

cm/sec, particle radius = 50 m

27

%

100

90

80

70

60

50

40

30

20

10

0

0 50 100 150 200 250 300 350

time, min

BCS Class II

Sol=100g/mL Dose

= 25 mg

(Dose number = 1)

A/V = 2.3

Vw = 100 mL

% in buffer - two phase

% in 1-octanol

% dissolved - two phase

% in buffer (% dissolved) - single phase

% saturation in buffer - two phase

% saturation in buffer - single phase

Two phase physiologic dissolution model

P

m

=1x10

-4

cm/sec, particle radius = 5 m

%

100

90

80

70

60

50

40

30

20

10

0

0 20 40 60 80 100 120 140 160

time, min

BCS Class II

Sol=100g/mL Dose

= 25 mg

(Dose number = 1)

A/V = 2.3

Vw = 100 mL

% in buffer - two phase

% in 1-octanol

% dissolved - two phase

% in buffer (% dissolved) - single phase

% saturation in buffer - two phase

% saturation in buffer - single phase

28

Stomach and intestine: Two-compartment

dissolution apparatus

Several publications in

literature describing

Artificial Stomach-

Duodenum (ASD)

Used in pharmaceutical

industry

Used to compare ASD

performance with in vivo

bioavailability values

Relative bioavailability estimation

of carbamazepine crystal forms

C

max

AUC

SRCarino, DCSperry, MHawley. JPharmSci 95:116-125 (2006).

29

Impact of stomach pH on Oral Absorption of

Anticancer Agents

Table3 Effect of acid-reducing agents on the oral absorption of targeted anticancer agents

Mean change

Drug(dose) Acid-reducing agent AUC

em ax

Subjects Comments

Dasatinib (50 mg) Famotidine (40 mg) 10 hours prior to dasatinib

Famotidine (40 mg) 2 hours after dasatinib

..1.61%

H

..1.63%

H

Healthy subjects

AUC0-12

Dasatinib (50 mg) Maalox30ml2 hours priorto dasatinib

Maalox30ml coadministered with dasatinib

H

..1.55%

t26%

..1.58%

Healthy subjects

AUC0-12

Dasatinib (100 mg) Omeprazole (40mg) dailyfor5 days and on day 5with

dasatinib

..1.43% ..1.42% Healthy subjects

AUCint

Erlotinib (150 mg) Omeprazole (40mg) dailyfor7 days ..1.46%

..1.58%

8

..1.61%

..1.69%"

Healthy subjects Primary

metabolite

Erlotinib (150 mg) Ran it idine 300 mg daily for 5 days and erlot inib 150 mg

single dose 2 hours after ranitidine dose on third day

..1.33% ..1.54% Healthy subjects

Erlotinib (150 mg) Ranitidine 150mg b.i.d. for5 daysanderlotinib 150mg

single dose 2 hours before and 10 hours after ranitidine

on third day

J, 15% J, 17% Healthy subjects

Gefitinib (250mg) Two oral doses of 450mg ranitidine (13 hours and 1

hour before 250 mg of gefitinib) follcmed by sodium

bicarbonate to maintain gastric pH above5 for 8 hours

..1.44% J, 70% Healthy subjects

lmatinib (400 mg) Omeprazole (40mg) dailyfor5 days and on day 5with

imatinib

Healthy subjects

lmatinib (400 mg) Maalox Max (20 ml) 15 minutes before imatinib H H Healthy subjects

Lapatin ib ( 1,250 mg) Esomeprazole (40 mg) daily for 7 days at bedtime ..1.26% NA Cancer patients

Nilotinib (400mg) Esomeprazole (40 mg) daily for6 day sand on day6 with

nilotinib

..1.34% ..1.27% Healthy subjects

Axitinib (5 mg) Rabeprazole (20mg) q.d. J, 15% ..1.40% Cancer patients

AUC, area under the curve, Crnax, peak plasma concentration; NA, not applicable.

"Primary metabolite data.

Ref: N.R. Budha, A. Frymoyer, G.S. Smelick, J.Y. Jin, M.R. Yago, M.J. Dresser, S.N. Holden, L.Z. Benet, and J.A.

Ware. Clinical Pharmacology & Therapeutics (2012).

30

Advantages & disadvantages of two-

compartment systems

Advantages

Sequentially exposes drug to gastric followed by intestinal

media

Differing media properties in stomach and intestine (e.g. pH,

lipid & bile salt concentrations) can affect dissolution

Captures in vivo gastric-emptying rates and flow rates

Can vary to simulate effect on dissolution

Potential to integrate peristaltic motion

Disadvantages

Does not contain separate phase/chamber for absorption

Assumes dissolved drug proportional to drug in plasma

31

Topics

Where are we now?

What opportunities are there (there are many)?

GI physiology

Fluid volume

Hydrodynamics

Buffer (bicarbonate)

Advanced dissolution methods

Two phase systems (simulating dissolution and absorption)

Two compartment systems (simulating stomach and intestine)

Computational Tools

Fluid Dynamics

Dissolution

Absorption Modeling

a

particle path

32

Exciting research is going on.

Motility and Absorption in the Small Intestine

Quantification of Small Bowel Water/Physiology

Coupling Biorelevant Dissolution Testing with PBPK Modeling

Modeling Hydrodynamics in the Intestine

Bicarbonate Buffer and Surface pH

In Vitro Dynamic Lipolysis Model

Precipitation Kinetics of Poorly Soluble Drugs under Supersaturated State and Precipitation

Inhibitors

Rotating Disk as a Dissolution Tool

Artificial Stomach Duodenum (2 compartment dissolution)

Miniscale Dissolution-membrane Partitioning System

Two Phase Dissolution System

Two Compartment Caco2 model /Mini-scale Dissolution

In vivo and computational biopharmaceutical aspects of precipitation and intestinal permeability

Dynamic Dissolution (TIM-1)

Methods for Estimation of Biorelevant Drug Solubility

Combining Experimental and Computational Approaches for Predicting Oral Bioperformance

33

Future Direction and Research Needs

Enhanced Understanding In Vivo environment (human, animal)

Hydrodynamics

Volume

Gastric Emptying

Fluid content, buffer

Development of Relevant In Vitro Methodologies

Likely not one-size-fits-all

Address/simulate dissolution and absorption kinetics

Precipitation assessment / inhibition

Modified / Delayed Release optimization

Development of Advanced Computational Tools (In Vitro & In

Vivo)

Hydrodynamics

Dissolution

Absorption

Metabolism

Application of physicochemical principles to dissolution

34

Questions/discussion

35

Dissolution Testing and

Quality-by-Design

Lawrence X. Yu, Ph. D.

Deputy Director for Science and Chemistry

Office of Generic Drugs

Food and Drug Administration

Advisory Committee for Pharmaceutical Science

and Clinical Pharmacology

August 8, 2012

1

Quality-by-Design

ICH Q8(R2)

Pharmaceutical Quality-by-Design (QbD) is a

systematic approach to development that begins with

predefined objectives and emphasizes product and

process understanding and process control, based on

sound science and quality risk management

Quality-by-Design Tools

Prior knowledge

Risk assessment

Design of experiments and data analysis

Process analytical technology (PAT) tools

2

QbD: Linking Process/Product /Patient

Patient

Product

Quality Target

Product Profile

Critical Quality

Attributes

Process

Material Attributes &

Process Parameters

3

Quality Target Product Profile (QTPP)

QTPP

A prospective summary of the quality

characteristics of a drug product that ideally

will be achieved to ensure the desired quality

(performance)

Guide to establish product design strategy

and keep product development effort

focused and efficient

4

What Does QTPP Include?

Intended use in clinical setting

Route of administration, dosage form (delivery

systems), and container closure system

Quality attributes of drug product

Appearance, Identity, Strength, Assay, Uniformity,

Purity/Impurity, Stability, and others

Active pharmaceutical ingredient release or

delivery and attributes affecting pharmacokinetic

characteristics (safety and efficacy)

Dissolution, aerodynamic performance, etc.

5

Dissolution and QbD

Dissolution can be used to help relate the

Product to the Patient in the QbD paradigm

Relate in vivo performance of a drug to in vitro

measurements

Enable development of clinically relevant

specifications

Understand the impact of formulation and

manufacturing process variations

Clinically meaningful dissolution specifications

that assure consistent therapeutic benefit can

aid manufacturing control strategy development

6

Roles of Dissolution Testing

A quality control tool

Batch-to-batch consistency

Provide quality assurance

An in vitro surrogate for product

performance

Formulation development

Bioequivalence studies

7

Dissolution for Quality Control

A product specific quality control test

The hydrodynamics and medium for this test

are chosen for reproducibility and detection of

product changes

The design of this test is not constrained by a

desire to mimic in vivo conditions

Acceptance criteria for consistency of batches

8

Dissolution for In Vivo Performance

A biorelevant dissolution test

Correlates with in vivo dissolution

The hydrodynamics and medium for this test

are chosen to reflect in vivo

Biorelevant dissolution test is a one-time test

to provide a baseline for product performance

9

Predictive Dissolution Enables

Efficient Product Development

It is unrealistic to conduct in vivo bioequivalence

studies for every formulation and manufacturing

change during pharmaceutical development or

for every post-approval change

Predictive dissolution can streamline product

development and lead to time and cost savings

during product development while enhancing

the significance of in vitro testing

10

FDA IVIVC Guidance

IVIVC = in vitro-in vivo

correlation

Contents

Data/formulation

requirements

Predictability evaluation

Application in waivers of in

vivo bioequivalence studies

and dissolution specifications

(pre- and post-approval)

11

Oral Drug Absorption Process

Transit

Permeation

Dissolution

Metabolism

Gastric

Emptying

Disintegration

Dissolution

12

Limits to Oral Drug Absorption

Gastric emptying

Dissolution

DS dissolution rate = D *S/h (C

s

- C

l

)

D - diffusion coefficient

S - dissolution surface area : Drug substance

h - Aqueous boundary thickness

Cs - Solubility: Drug substance

Cl - Concentration in dissolution media

Permeability: Drug substance

13

In Vitro and In Vivo Relationship

Limits to oral drug absorption

Dissolution-limited

dM D

=

S

( C

S

-

C )

l

dt h

Solubility-limited

Permeability-limited

Dissolution

Permeation

Concentration Solubility

14

The CAT Model

Small Inte

K

t

tinal Tract s

15

Plasma

Ka

Ka Ka

M

0 M

exit

Liver

Dissolution

Predicting Oral Absorption

0.2

0.4

0.6

0.8

1.0

Predicted

Experimental

0.0

Human Permeability (cm/hr)

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

F

r

a

c

t

i

o

n

o

f

D

o

s

e

A

b

s

o

r

b

e

d

1.0

0 20 40 60 80 100

0.0

Particle Diameter (m)

F

r

a

c

t

i

o

n

o

f

D

o

s

e

A

b

s

o

r

b

e

d

0.8

0.6

0.4

0.2

1.0

Dose = 250 mg

Dose = 500 mg

Dose = 1000 mg

0 10 20 30 40 50 60

0.8

0.6

0.4

0.2

0.0

Diameter of Particle (m)

F

r

a

c

t

i

o

n

o

f

D

o

s

e

A

b

s

o

r

b

e

d

Permeability-limited

Dissolution-limited

Solubility-limited

16

Biopharmaceutics Classification System

Amidon, et al., Pharm. Res., 1995

The Biopharmaceutics Classification System (BCS) is a

scientific framework for classifying drugs based on their

aqueous solubility and intestinal permeability.

Biopharm. Class Solubility Permeability

I High High

II Low High

III High Low

IV Low Low

The understanding of drugs based on BCS can aid in

formulation and manufacturing development in a QbD

paradigm.

17

BCS Class I and III Drugs

Rapid dissolution for BCS Class I drugs

and very rapid dissolution for BCS Class

III drugs ensure that in vivo dissolution is

not the rate limiting step. Bioequivalence

is assured provided no effect of excipient

on absorption and similar dissolution

profiles

18

Transit

Permeation

Metabolism

Gastric

Emptying

Disintegration

Dissolution

Dissolution

BCS Class II and IV Drugs

IVIVR possible for BCS Class II drugs

and difficult for BCS Class IV drugs. In

reality, it is often not attempted to

develop in vitro dissolution that is

predictive of in vivo

19

Transit

Permeation

Metabolism

Gastric

Emptying

Disintegration

Dissolution

Dissolution

BCS Class I

BCS Class I drugs formulated in an

immediate release dosage forms

No bioequivalence studies may be needed for

developing predictive dissolution

Rapid dissolution may be used for formulation

development and establishment of design space

Rapid dissolution for BCS Class I drugs in

immediate release dosage forms may be used to

justify formulation and manufacturing changes

20

BCS Class II

BCS Class III drugs formulated in an

immediate release dosage forms

No bioequivalence studies may be needed

Very rapid dissolution may be used for

formulation development and establishment of

design space

Very rapid dissolution for BCS Class III drugs

in immediate release dosage forms may be

used to justify manufacturing changes

Excipient effect needs to be further

investigated

21

BCS Class II and IV

BCS Class II and IV drugs formulated in

an immediate release dosage forms

Bioequivalence studies are most likely

needed to develop predictive dissolution

Predictability of biorelevant dissolution should

be further explored and investigated

22

Extended-release Dosage Forms

Extended-release Dosage Forms

Bioequivalence studies are likely needed to

establish IVIVC/IVIVR and develop predictive

dissolution

Predictive dissolution can then be used to

support establishment of a design space

IVIVC/IVIVR can be used to support

manufacturing changes

23

Dissolution for a BCS Class I Drugs

%

D

R

U

G

R

E

L

E

A

S

E

D

110

100

90

ANDA1

ANDA2

80

ANDA3

ANDA4

70

ANDA5

ANDA6

60

ANDA7

ANDA8

50

ANDA9

74-217

40

UMAB-SLOW

UMAB-MEDIUM

30

UMAB-FAST

20

10

0

0 5 10 15 20 25 30 35

TIME IN MINUTES

24

I I

I I

In Vitro vs. In Vivo Dissolution

A

10

B

10

"0

"0 8

<IJ

8

~

;;;.

;;;.

-

- 6

c

6

0

,.,.,

~

,.,.,

~

- in vivo.fasted

- - 4

~

4

- in vivo. fasted

Q

- in vivo. fed

~

- in vivo. fed

':!(

2

:[in vitro (l (Yo SLS) ~

2

~

I in vitro (water) 0 in vitro (0.1% SLS

0.2 0.4 0.6 0.8 l 1.2 1 2 3 4 5 6

Time (hr) Time (hr)

I I

I I

c 10

D 1

8

"0

"'0

<IJ

~

;;;.

;;;.

-

- 6

0

0

~ - in vivo.fed

':1)

~

':1)

- in vivo.fasted

-

X Wei bull input.fasted

- 4 Q

Q

- in vivo.fed Q weibull input.fed

~

~

~

2

X Wei bull input

~

::1: in vitro (0.1 %SLS, 50rpm

J:in vitro (water) :I in vitro (0.1 %SLS, 75rpm

5 10 15 20 25 30 10 20 30 40 50

Time (hr) Time (hr)

IR suspension IR tablet

XR tablet

XR capsule

25

)

)

)

Future Directions

Application of the QbD approach has the

potential to bridge the gaps between in vitro

measurements and in vivo performance

A science based approach incorporating studies both

in the laboratory and clinic

Utilization of advanced dissolution methodologies for

predictive dissolution

Other approaches other than IVIVC/IVIVR are

possible that provide increased product and

process understanding

26

Conclusions

There are many tools related to dissolution

that can aid in implementation of QbD

Biorelevant dissolution methods, which may

utilized advanced apparatus and/or media

Predictive dissolution modeling

IVIVC or IVIVR studies

All of these tools can aid product quality

Enhanced product and process understanding

Clinically relevant specifications

27

You might also like

- Pharm MCQDocument17 pagesPharm MCQArun Kumar100% (2)

- Oral Mucosal Drug Delivery and TherapyDocument289 pagesOral Mucosal Drug Delivery and TherapyАлександр ВолошанNo ratings yet

- QBD Approach To Dissolution Through Understanding of The Release Mechanisms and Critical in Vivo ParametersDocument61 pagesQBD Approach To Dissolution Through Understanding of The Release Mechanisms and Critical in Vivo Parametersvg_vvgNo ratings yet

- The Advanced Formula For Total Success - Google Search PDFDocument2 pagesThe Advanced Formula For Total Success - Google Search PDFsesabcdNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- BMath3 ProjectDocument6 pagesBMath3 ProjectRainbow VillanuevaNo ratings yet

- An Introduction To Forced Degradation Studies For Drug Substance Drug ProductDocument5 pagesAn Introduction To Forced Degradation Studies For Drug Substance Drug ProductElizabethValverdeNo ratings yet

- Content Uniformity (CU) Testing For The 21st Century CDER PerspectiveDocument36 pagesContent Uniformity (CU) Testing For The 21st Century CDER PerspectiveRezaul Razib100% (1)

- Usp Review AlbuterolDocument82 pagesUsp Review Albuterolsrayu2603No ratings yet

- Reprocessing Biotech ProductsDocument14 pagesReprocessing Biotech ProductsawadsonNo ratings yet

- Guideline Quality Transdermal Patches enDocument27 pagesGuideline Quality Transdermal Patches endinaNo ratings yet

- Ophthalmic Drug Delivery Systems, 2ed. 2003Document727 pagesOphthalmic Drug Delivery Systems, 2ed. 2003VuqarNo ratings yet

- Quality Process and QC in Production CellDocument22 pagesQuality Process and QC in Production CellCaths AprilliaNo ratings yet

- Analytical Methods Transfer: Considerations For Biological Products Alfred V. Del Grosso, Ph.D. Fda - CberDocument26 pagesAnalytical Methods Transfer: Considerations For Biological Products Alfred V. Del Grosso, Ph.D. Fda - CberamolNo ratings yet

- Tobradex Suspension BE GuidanceDocument5 pagesTobradex Suspension BE Guidancejaiminrshah1990No ratings yet

- USP 1086 Impurities in Drug Substances and Drug ProductsDocument3 pagesUSP 1086 Impurities in Drug Substances and Drug ProductsMuhammad JamilNo ratings yet

- MaPP CMC QBB November 2014 PDFDocument12 pagesMaPP CMC QBB November 2014 PDFP S R PrasadNo ratings yet

- DEC Study in Formulation DevelopmentDocument9 pagesDEC Study in Formulation Developmentfad12345No ratings yet

- Disintegration TestingDocument9 pagesDisintegration TestingganeshaexactNo ratings yet

- Workshop - Specifications in Early Development (Regulatory Perspective-Stephen Miller, FDA)Document30 pagesWorkshop - Specifications in Early Development (Regulatory Perspective-Stephen Miller, FDA)lhthang1990No ratings yet

- Oral Controlled Release Formulation Design and Drug Delivery: Theory to PracticeFrom EverandOral Controlled Release Formulation Design and Drug Delivery: Theory to PracticeHong WenNo ratings yet

- Nonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsFrom EverandNonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsWilliam J. BrockNo ratings yet

- Forensic Dental TechniquesDocument3 pagesForensic Dental Techniqueschrisr310No ratings yet

- Yaskawa Product CatalogDocument417 pagesYaskawa Product CatalogSeby Andrei100% (1)

- Practice For The CISSP Exam: Steve Santy, MBA, CISSP IT Security Project Manager IT Networks and SecurityDocument13 pagesPractice For The CISSP Exam: Steve Santy, MBA, CISSP IT Security Project Manager IT Networks and SecurityIndrian WahyudiNo ratings yet

- FDA - ICH M7 (R1) - Control of Mutagenic Impurities in Pharmaceuticals 03.2018Document131 pagesFDA - ICH M7 (R1) - Control of Mutagenic Impurities in Pharmaceuticals 03.2018Catrinescu OanaNo ratings yet

- The Quality Control of Medicines: Proceedings of the 35th International Congress of Pharmaceutical Sciences, Dublin, 1975From EverandThe Quality Control of Medicines: Proceedings of the 35th International Congress of Pharmaceutical Sciences, Dublin, 1975P.B. DeasyNo ratings yet

- European Journal of Biomedical AND Pharmaceutical SciencesDocument14 pagesEuropean Journal of Biomedical AND Pharmaceutical SciencesSACHIN BHASKAR NARKHEDENo ratings yet

- Quality by Design For ANDAs - MR TabletsDocument161 pagesQuality by Design For ANDAs - MR TabletsShilpa Kotian100% (1)

- Selection of DissolutionDocument5 pagesSelection of DissolutionGirishNo ratings yet

- Metronidazol 500 MGDocument12 pagesMetronidazol 500 MGAbou Tebba SamNo ratings yet

- Industrial Training PRESENTATION (Benazir)Document6 pagesIndustrial Training PRESENTATION (Benazir)Benazir ShuguftaNo ratings yet

- Development of Forced Degradation and Stability Indicating Studies of Drugs-A Review PDFDocument7 pagesDevelopment of Forced Degradation and Stability Indicating Studies of Drugs-A Review PDFtristanprNo ratings yet

- ISPE Organics Impurities Analysis 2019 - 2Document51 pagesISPE Organics Impurities Analysis 2019 - 2Siti Hajar Nur SafitaNo ratings yet

- Wurstertechnology ProcessvariablesinvolvedandScaleupscienceDocument11 pagesWurstertechnology ProcessvariablesinvolvedandScaleupsciencemadhuNo ratings yet

- Re NDA #!13!217S-036 SKELAXIN Me Tax Alone) Tablets 400 MGDocument74 pagesRe NDA #!13!217S-036 SKELAXIN Me Tax Alone) Tablets 400 MGTigran KalenchyanNo ratings yet

- Preformulation NotesDocument19 pagesPreformulation NotesAnkit Arora67% (3)

- Chapter Nine - Isolation, Culture and Propagation of Natural Killer CellsDocument11 pagesChapter Nine - Isolation, Culture and Propagation of Natural Killer CellsManoj Kumar pandreNo ratings yet

- Disperse Systems Vol-3 PDFDocument1,088 pagesDisperse Systems Vol-3 PDFvijayns_250355172No ratings yet

- Formulation and Evaluation of Anti Emetic Patch Comprising On Dan Set Ron Hydro ChlorideDocument107 pagesFormulation and Evaluation of Anti Emetic Patch Comprising On Dan Set Ron Hydro ChlorideuduriskNo ratings yet

- Hatch-Waxman Act & Paragraph IV LitigationDocument23 pagesHatch-Waxman Act & Paragraph IV LitigationParag MehtaNo ratings yet

- Guide For The Quality Module 3 - Part S Drug SubstanceDocument7 pagesGuide For The Quality Module 3 - Part S Drug SubstanceShiraz KhanNo ratings yet

- Assay and Dissolution EtoricoxibDocument8 pagesAssay and Dissolution Etoricoxibsesilia dyah novitrianiNo ratings yet

- Pharmaceutical Suspension: Nahla S. Barakat, PH.DDocument43 pagesPharmaceutical Suspension: Nahla S. Barakat, PH.DRaisa Alvina100% (1)

- SC I E. Dissolution Testing of Solid Oral Dosage FormsDocument4 pagesSC I E. Dissolution Testing of Solid Oral Dosage FormsCioroiu BogdanNo ratings yet

- Sustained Release Drug FormulationDocument14 pagesSustained Release Drug Formulationapi-3750955100% (5)

- Tips and Tricks HPLC Troubleshooting PDFDocument30 pagesTips and Tricks HPLC Troubleshooting PDFjuakfuenmayorNo ratings yet

- An Overview On Tablet CoatingDocument4 pagesAn Overview On Tablet Coatingronahaniifah11No ratings yet

- The FDA Process For Approving Generic DrugsDocument16 pagesThe FDA Process For Approving Generic DrugsTawfeeq BA AbbadNo ratings yet

- Dissolution Calibration NetDocument7 pagesDissolution Calibration Net0921pyNo ratings yet

- Osmotic Drug Delivery SystemDocument10 pagesOsmotic Drug Delivery SystemkishoreNo ratings yet

- Stability of Pharmaceuticals-1Document96 pagesStability of Pharmaceuticals-1Hely PatelNo ratings yet

- Dissolution Profile ComparisonDocument17 pagesDissolution Profile Comparisondipti_srivNo ratings yet

- Photo StabilityDocument11 pagesPhoto StabilityHaroon RasheedNo ratings yet

- Analysis of The Tablet Coating ProcessDocument17 pagesAnalysis of The Tablet Coating Processشروق سعد الدينNo ratings yet

- Solid Dosage Forms - CapsulesDocument14 pagesSolid Dosage Forms - CapsulesHellcroZNo ratings yet

- 1228 5 PDFDocument5 pages1228 5 PDFdeepanmb007No ratings yet

- Dissolution Case StudiesDocument70 pagesDissolution Case Studieslhthang1990100% (1)

- Bioavailability, Bioequivalence and BCS System: by Dr. Ashwani Kumar VermaDocument35 pagesBioavailability, Bioequivalence and BCS System: by Dr. Ashwani Kumar Vermagopal jhaNo ratings yet

- Dosage Form: Pre-Formulation StudiesDocument7 pagesDosage Form: Pre-Formulation StudiesNimra AmeenNo ratings yet

- Parenteral and Ophthalmic Drug Products (PODP) Leachables and Extractables Experimental Protocol For Simulation Study of BFS CCSDocument1 pageParenteral and Ophthalmic Drug Products (PODP) Leachables and Extractables Experimental Protocol For Simulation Study of BFS CCSvg_vvgNo ratings yet

- Comparision of SCANRDI Vs Pharmacopiea MethodDocument10 pagesComparision of SCANRDI Vs Pharmacopiea MethodUmair ShekhaniNo ratings yet

- Dermato ToxicologyDocument1,121 pagesDermato ToxicologyBella LunaNo ratings yet

- Transdermal Drug Delivery: BackingDocument32 pagesTransdermal Drug Delivery: BackingmurtazaNo ratings yet

- Gastro Retentive DELIVERY SYSTEMSDocument77 pagesGastro Retentive DELIVERY SYSTEMSAnirudh Jain ChampawatNo ratings yet

- Prism 5 StatsDocument255 pagesPrism 5 StatsDr. ANUJ TEWARINo ratings yet

- From The SAGE Social Science Collections. All Rights ReservedDocument10 pagesFrom The SAGE Social Science Collections. All Rights ReservedMuthu VenkateshNo ratings yet

- All Keyboard ShortcutsDocument8 pagesAll Keyboard ShortcutsMuthu VenkateshNo ratings yet

- Society of NeurochemistryDocument14 pagesSociety of NeurochemistryMuthu VenkateshNo ratings yet

- Vocational Training For Medicinal ChemistsDocument14 pagesVocational Training For Medicinal ChemistsMuthu VenkateshNo ratings yet

- Methods For The Synthesis of Haloimidazoles (Reveiw)Document23 pagesMethods For The Synthesis of Haloimidazoles (Reveiw)Muthu VenkateshNo ratings yet

- Should Medicinal Chemists Do Molecular ModellingDocument4 pagesShould Medicinal Chemists Do Molecular ModellingMuthu VenkateshNo ratings yet

- Plate Reader ProtocolDocument2 pagesPlate Reader ProtocolMuthu VenkateshNo ratings yet

- Articles of Confederation LessonDocument2 pagesArticles of Confederation Lessonapi-233755289No ratings yet

- Calibration Procedure FOR Surface Plates Planekator Method: Technical ManualDocument11 pagesCalibration Procedure FOR Surface Plates Planekator Method: Technical Manualentico100% (1)

- Sequential StatementDocument12 pagesSequential Statementdineshvhaval100% (1)

- HR Associate - Job Description VFinalDocument2 pagesHR Associate - Job Description VFinalPamela CardozoNo ratings yet

- Performance in MarxismDocument226 pagesPerformance in Marxismdeanp97No ratings yet

- Olszewski ClusteringDocument4 pagesOlszewski ClusteringkalokosNo ratings yet

- Existentialism EducationDocument40 pagesExistentialism EducationBulqia Mas'udNo ratings yet

- Qualifications Recruitment Promotions Scheme - University AcademicsDocument10 pagesQualifications Recruitment Promotions Scheme - University Academicsuteachers_slNo ratings yet

- Dos and DontsDocument1 pageDos and DontsLeah GlickNo ratings yet

- 240-2 - Review Test 2 - 2Document4 pages240-2 - Review Test 2 - 2Nathaniel McleodNo ratings yet

- Regional Directorate General of Public Finance of BucharestDocument8 pagesRegional Directorate General of Public Finance of BucharestAnna MarissNo ratings yet

- Faiscp MK2 Om Eng 44311D PDFDocument60 pagesFaiscp MK2 Om Eng 44311D PDFJiso JisoNo ratings yet

- Graph Theory (B)Document2 pagesGraph Theory (B)Waqar RoyNo ratings yet

- Angular With Web ApiDocument32 pagesAngular With Web ApiAnonymous hTmjRsiCp100% (1)

- Effects of Temperature and Moisture On SMCDocument20 pagesEffects of Temperature and Moisture On SMCsenencostasNo ratings yet

- Baird, A. Experimental and Numerical Study of U-Shape Flexural Plate.Document9 pagesBaird, A. Experimental and Numerical Study of U-Shape Flexural Plate.Susana Quevedo ReyNo ratings yet

- OP-COM Fault Codes PrintDocument2 pagesOP-COM Fault Codes Printtiponatis0% (1)

- T50 - SVPM - 2014 - 13 - Risk Assessment in Ship Hull Structure Production Using FMEADocument13 pagesT50 - SVPM - 2014 - 13 - Risk Assessment in Ship Hull Structure Production Using FMEACiutacu AndreiNo ratings yet

- Essay Plan and StructureDocument3 pagesEssay Plan and StructureNinaNCNo ratings yet

- Conductivity On Animal SpermDocument8 pagesConductivity On Animal SpermAndrew AdamsNo ratings yet

- Verification ofDocument14 pagesVerification ofsamuel-kor-kee-hao-1919No ratings yet

- Ascc Catalog 2014-2016Document157 pagesAscc Catalog 2014-2016api-261615090No ratings yet

- Binary RelationDocument9 pagesBinary RelationDavidNo ratings yet

- Microelectronic CircuitsDocument22 pagesMicroelectronic CircuitsarunnellurNo ratings yet