Professional Documents

Culture Documents

HYSYS Tutorial

Uploaded by

Ehsan AhzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HYSYS Tutorial

Uploaded by

Ehsan AhzCopyright:

Available Formats

66 Process Simulation using HYSYS

Section II: Tutorials

Solution: Follow the step-by-step instructions to solve the problem. 1- Open a new case.

Tutorial 1

Physical Properties

2- Add a new component list Problem 1: Physical Properties of Water Calculate the properties of a stream of water at 25 C and 1 atm with mass flow rate of 125 kg/hr.

Tutorial 1 Physical Properties 67

68 Process Simulation using HYSYS

3- Select water from the Components list and then close the active window by clicking on cross button.

5- Select the Fluid Package (Make sure selecting Component List -1in the component list).

4- The cross button is not seen on the figure and you could move the active window to see the cross button in order to close it.

6- Add a new Fluid Package

Tutorial 1 Physical Properties 69

70 Process Simulation using HYSYS

7- Select the Peng Robinson or SRK equation of state from Property Package.

9- Drag a material stream to the PFD. (Choose the stream from the Object Palette by pressing F4 or by F11). Rename the stream if needed.

8- Close the Fluid Package by clicking on cross button. After this step, it is also possible to import /export the Fluid Package. Enter to Simulation Environment.

10- Save the simulation work (e.g., problem-1).

Tutorial 1 Physical Properties 71

72 Process Simulation using HYSYS

11- For the N components stream, N+2 parameters are needed. Enter 2 out of 3 (temperature, pressure and vapor fraction) and mass flowrate in the Worksheet/Conditions page:

13- The stream properties can now be calculated (seen in the Worksheet/Properties page). Items in blue and black indicate user-defined and calculated properties, respectively.

12- Enter 1 for mole fraction of water in the Worksheet/Composition page.

14- By putting the curser on the stream, the Fly-By window appears showing the main properties of the stream.

Tutorial 1 Physical Properties 73

74 Process Simulation using HYSYS

Problem 2: T-xy diagram Plot the T-xy diagram for the binary mixture of 1-butanol and water.

Solution: Follow the step-by-step instructions to solve the problem. 1- Open a new case.

2- Add a new component list

Tutorial 1 Physical Properties 75

76 Process Simulation using HYSYS

3- Select 1-butanol and water from components list then close the active window by clicking on cross button.

5- Select the Fluid Package (Make sure selecting Component List -1in the component list).

4- The cross button is not seen on the figure and you could move the active window to see the cross button in order to close it.

6- Add a new Fluid Package.

Tutorial 1 Physical Properties 77

78 Process Simulation using HYSYS

7- Select the UNIQUAC activity model from Property Package.

9- Drag a material stream to the PFD. (Choose the stream from the Object Palette by pressing F4 or by F11). Rename the stream to H2O.

8- Close the Fluid Package by clicking on cross button. After this step, it is possible to import/export the Fluid Package. You may now enter to Simulation Environment.

10- Save the simulation work (e.g., problem-2).

Tutorial 1 Physical Properties 79

80 Process Simulation using HYSYS

11- Select another material stream for 1-butanol. Define both streams (100 C and 1 atm) as outlined in the previous problem.

13- Use the set function from the Object Palette to keep the total molar flow of these streams equal to 1. In this way, independent mole fraction variables could be defined for mixture.

12- Enter the molar flow rate for water stream (e.g., 0.7 kmole/hr) and its composition (mole fraction=1) in order to fully define this stream. Enter the composition of 1-butanol stream (mole fraction=1).

14- Double click on the set icon to define the target variable (1-butanol molar flow).

Tutorial 1 Physical Properties 81

82 Process Simulation using HYSYS

15- Choose H2O as a source stream.

17- There are different ways to keep the total molar flow rate of these streams constant instead of using set. For example, use a mixer (from the object pallet) and set the molar flow rate of outlet stream to 1 kmole/hr. The flow rate of 1-butanol stream is adjusted accordingly.

16- Click on the parameters section to define the multiplier and offset in order to keep the total molar flow rate of these streams equal to 1. The molar flow rate of the second stream is adjusted so that the total molar flow rates of these two streams remain constant.

18- Connect the inlet and outlet streams by double clicking on the Mixer. (The stream properties can now be calculated).

Tutorial 1 Physical Properties 83

84 Process Simulation using HYSYS

19- In order to plot the T-xy diagram, the bubble and dew point should be calculated for the water stream flowrate varying from 0 to 1. A Heater and a Cooler are added to the flow sheet for this purpose.

21- To calculate the bubble and dew point for a given flowrate of water stream (0.7 kmole/hr), set the vapor fraction at the exit of the Heater and Cooler equal to zero and one, respectively.

20- Assume no pressure drop in the Heater and the Cooler (Constant pressure for T-xy).

22- To plot the figure, press Ctrl+D to open Databook.

Tutorial 1 Physical Properties 85

86 Process Simulation using HYSYS

23- Click on insert button in order to sample the variables from the flowsheet.

25- Go to case studies and add a new case.

24- Sample the variables from the flowsheet (temperature for S-bubble stream, S-dew stream and flowrate of water stream).

26- Choose the molar flow as an independent variable (to represent x in T-xy) and the temperatures as dependent variables (to represent T in T-xy) and then press view.

Tutorial 1 Physical Properties 87

88 Process Simulation using HYSYS

27- Specify the low, high bound and step size values of independent variable and press start.

Problem 3 Flash Calculations Consider a stream of gas (T=40 C and P=30 kg/cm2) containing methane, ethane, propane, n-butane and n-pentane with molar flow rates of 60, 25, 15, 10 and 10 kmole/hr, respectively. Calculate: a) Pressure of dew point at 40 C. b) Pressure of bubble point at 40 C. c) Temperature of dew point at 30 kg/cm2. d) Temperature of bubble point at 30 kg/cm2. e) Stream enters to a separator. Calculate properties of outlet streams. f) Plot outlet molar flow rate of ethane in the gas stream as a function of the operating temperature (sensitivity analysis). g) Adjust the drum temperature to reach 50% liquid.

28- After the completion of simulation, press Results button to view the T-xy diagram.

.

Different thermodynamic models may be selected to generate T-xy diagram and to compare the simulation data with the experimental data to figure out the proper physical property models to be employed in simulation.

Tutorial 1 Physical Properties 89

90 Process Simulation using HYSYS

Solution: Follow the step-by-step instructions to solve the problem. 1- Open a new case.

3- Select components from components list, then close the active window.

4- The cross button is not seen on the figure and you could move the active window to see the cross button in order to close it. 2- Add a new component list

Tutorial 1 Physical Properties 91

92 Process Simulation using HYSYS

5- Select the Fluid Package (Make sure selecting Component List -1in the component list).

7- Select the Peng Robinson equation of state from Property Package.

6- Add a new Fluid Package.

8- Close the Fluid Package by clicking on cross button. After this step, it is possible to import/export the Fluid Package. You may now enter to Simulation Environment.

Tutorial 1 Physical Properties 93

94 Process Simulation using HYSYS

9- Drag a material stream to the PFD and enter two out of three properties (temperature, pressure and vapor fraction) in the Worksheet/Conditions page.

11- Enter molar flow rate of components in the Worksheet/Composition page.

10- Save the simulation work (e.g., problem-3).

8- By pressing OK button, the properties of stream will be calculated.

Tutorial 1 Physical Properties 95

96 Process Simulation using HYSYS

a) For calculating the dew point pressure at 40 C, first erase the pressure of the stream. Then enter 1 in vapor/phase fraction of stream. (Pressure of dew point is 1105.5 kPa).

c) For calculating the temperature of dew point, erase the temperature, and then enter 30 kg/cm2 for pressure and 1 for vapor fraction. The dew point temperature is 68.092 C.

b) For calculating the bubble point pressure at 40 C, enter 0 in vapor/phase fraction of stream. Pressure of bubble point is 10775 kPa.

d) For calculating the temperature of bubble point at 30 kg/cm2, enter 0 for vapor/phase fraction of stream. Temperature of bubble point is calculated to be -73.314 C.

Tutorial 1 Physical Properties 97

98 Process Simulation using HYSYS

e) Return the stream conditions (temperature and pressure) to initial conditions (40 C and 30 kg/cm2). Then put a separator on the PFD from the Object Palette (F4).

The properties of streams are seen in the Worksheet/Conditions page.

Double click on the separator to open it. Enter inlet and outlet vapor and liquid streams on the Design/Connections page. The calculation is performed for an adiabatic separator immediately.

f) To complete a sensitivity analysis, go to Tools/Databook or press Ctrl+D.

Tutorial 1 Physical Properties 99

100 Process Simulation using HYSYS

At the first page of Databook, variables appear, use insert to sample variables from flowsheet.

Select molar flow rate of ethane from the vapor outlet stream (stream vap).

From the variable navigator, select the object and variable, e.g., choose 1 as object and its temperature as variable, press add button to select another variable.

Then go to the Case Studies page and add a new case study by clicking on the Add button.

Tutorial 1 Physical Properties 101

102 Process Simulation using HYSYS

Specify temperature as an independent and molar flow rate of ethane as a dependent variable.

Press Start button and then go to the Results page to see the plot or table. The results may be exported to any spreadsheet software for further processing.

Click on the view button and enter low, high bonds and step size values for the independent variable. Number of states will be calculated by HYSYS.

g) In order to adjust the drum temperature to reach the 50% liquid, the duty should be specified for drum to be able to run it isothermally.

Tutorial 1 Physical Properties 103

104 Process Simulation using HYSYS

At this stage, the specifications for the drum are incomplete. The drum temperature (vap stream temperature) is now specified to run it.

Use the spreadsheet to define the new variable being the ratio of liquid stream to feed stream.

Close the active window. The drum temperature is now initiated. It could be changed by the Adjust function to control the bottom flow rate. Drag the adjust function from the object pallet to the PFD.

Double click on spreadsheet and import the flowrate variables from the flowsheet.

Tutorial 1 Physical Properties 105

106 Process Simulation using HYSYS

Click on the spreadsheet button and create a new variable (liquid_to_feed_ratio) and calculate its value (the formula used in cell B4 is the ratio).

The calculation is now completed.

Close the active window and double click on Adjust. Specify the drum temperature (vap stream) as the adjusted variable and the value calculated in spreadsheet as the target value. Then click on start.

Click on the Monitor button to view the Adjusted temperature.

Tutorial 1 Physical Properties 107

108 Process Simulation using HYSYS

Problem 4: Plot the physical and thermodynamic properties Plot vapor pressure and surface tension of dimethylsulphide as a function of temperature in a desired range.

Solution: Follow the step-by-step instructions to solve the problem. 1- Open a new case.

2- Add a new component list.

Tutorial 1 Physical Properties 109

110 Process Simulation using HYSYS

3- Select components from components list.

5- Select the Fluid Package (Make sure selecting Component List -1in the component list).

4- The cross button is not seen on the figure and you could move the active window to see the cross button in order to close it.

6- Add a new Fluid Package.

Tutorial 1 Physical Properties 111

112 Process Simulation using HYSYS

7- Select Peng Robinson equation of state from Property Package.

9- Drag a material stream to the PFD and Rename it to Feed. Enter temperature, pressure and molar flow in the Worksheet/Conditions page.

8- Close the Fluid Package by clicking on cross button. Enter to Simulation Environment.

10- In Worksheet Compositions page, enter mole fraction of the components. The stream is now calculated for a base case.

Tutorial 1 Physical Properties 113

114 Process Simulation using HYSYS

11- Save the simulation work (e.g., problem-4).

13- The first page of the Databook is variables.

12- To plot the surface tension of dimethylsulfide vs. temperature, go to Tools/Databook or press Ctrl-D.

14- Click on Insert button to sample and add the variables from the flowsheet. Herein, temperature of feed stream is sampled from the variable navigator.

Tutorial 1 Physical Properties 115

116 Process Simulation using HYSYS

15- Also, insert the surface tension of the Feed stream.

17- Go to the view page and enter low, high bounds and step size values for independent variables (e.g., -250, 50 and 20).

16- Go to case studies page and add a new case study. Select the temperature as an independent variable and the surface tension as the dependent variable.

18- Click on start button. Then go to the Results page to view the results. The results are shown both in the graph and table format.

Tutorial 1 Physical Properties 117

118 Process Simulation using HYSYS

19- To plot the vapor pressure of dimethylsulfide vs. temperature, drag the spreadsheet function to PFD.

21- Use the Antoine vapor pressure expression where 6 coefficients from a-f are needed as extracted from the scope navigator (Basis).

22- The coefficients are now imported to the spreadsheet. Press spreadsheet button in order to enter the equations.

20- Click on spreadsheet, press add import button to import the vapor pressure equation coefficients (10 coefficients) from the navigator scope Basis.

Tutorial 1 Physical Properties 119

120 Process Simulation using HYSYS

23- Enter the equations in the spreadsheet to complete the calculation. In cell B9, the temperature is calculated in K.

25- Go to Tools/databook or press Ctrl-D.

24- By clicking on the Formula button, all equations used in the spreadsheet are shown.

26- The first page of Databook is variables.

Tutorial 1 Physical Properties 121

122 Process Simulation using HYSYS

27- Click on Insert button to sample and add the variables. Herein, the vapor pressure of methylsulfide is sampled from the Spreadsheet object.

29- Go to Case Studies page and add a new case study. Select the temperature as an independent variable and the vapor pressure as the dependent variable.

30- Go to the view page and enter low, high bounds and step size values for independent variables (e.g., 0, 250 and 12.5). 28- Press OK. The variable is now added to the Databook. Click on Case Studies.

Tutorial 1 Physical Properties 123

124 Process Simulation using HYSYS

31- Click on the Start button. After the completion of simulation, go to the Results page to view the results. The results are shown both in the Graph and Table format.

You might also like

- Florida Motor Fuel Tax Relief Act of 2022Document9 pagesFlorida Motor Fuel Tax Relief Act of 2022ABC Action NewsNo ratings yet

- 4528.R380.02 Slide Handout For StudentsDocument62 pages4528.R380.02 Slide Handout For StudentsCiputra 'Boy' TampubolonNo ratings yet

- Vapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodFrom EverandVapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodNo ratings yet

- The Invisible SunDocument7 pagesThe Invisible SunJay Alfred100% (1)

- Phase Equilibria: Basic Principles, Applications, Experimental TechniquesFrom EverandPhase Equilibria: Basic Principles, Applications, Experimental TechniquesNo ratings yet

- 1.3.10 Optimization Crude ColumnDocument12 pages1.3.10 Optimization Crude ColumnflowealthNo ratings yet

- Design Calculation FOR Rigid Pavement/RoadDocument5 pagesDesign Calculation FOR Rigid Pavement/RoadghansaNo ratings yet

- HYSYS Training 2013Document27 pagesHYSYS Training 2013Kokil JainNo ratings yet

- Assay BachaqueroDocument12 pagesAssay BachaqueroGinis MrcNo ratings yet

- Working Guide to Vapor-Liquid Phase Equilibria CalculationsFrom EverandWorking Guide to Vapor-Liquid Phase Equilibria CalculationsRating: 5 out of 5 stars5/5 (1)

- Simple Dew Point Control (HYSYS v10)Document35 pagesSimple Dew Point Control (HYSYS v10)digeca100% (1)

- Risk Assessment For Harmonic Measurement Study ProcedureDocument13 pagesRisk Assessment For Harmonic Measurement Study ProcedureAnandu AshokanNo ratings yet

- Plant Engineering and Design The Ultimate Step-By-Step GuideFrom EverandPlant Engineering and Design The Ultimate Step-By-Step GuideNo ratings yet

- Native Instruments Sibelius Sound Sets - The Sound Set ProjectDocument3 pagesNative Instruments Sibelius Sound Sets - The Sound Set ProjectNicolas P.No ratings yet

- DLP - CO#1-for PandemicDocument4 pagesDLP - CO#1-for PandemicEvelyn CanoneraNo ratings yet

- Adv 8 1Document10 pagesAdv 8 1Micu Ionut BogdanNo ratings yet

- Using Aspen To Evaluate Process EconomicsDocument15 pagesUsing Aspen To Evaluate Process EconomicspallaviNo ratings yet

- HYSYS2016Document254 pagesHYSYS2016Lizet Daniela Chambi100% (1)

- Hysys Tutorials RevisedDocument33 pagesHysys Tutorials RevisedAkhi Sofi100% (2)

- Natural Gas Hydrates in Flow AssuranceFrom EverandNatural Gas Hydrates in Flow AssuranceCarolyn Ann KohRating: 5 out of 5 stars5/5 (1)

- Blowdown ReportDocument26 pagesBlowdown ReportPaul OhiorNo ratings yet

- Multiphase Flow 1995From EverandMultiphase Flow 1995A. SerizawaNo ratings yet

- HYSYS TutorialDocument30 pagesHYSYS TutorialEhsan AhzNo ratings yet

- 06 Approximate Methods For Multi-Component DistillationDocument61 pages06 Approximate Methods For Multi-Component DistillationNagwa Mansy100% (1)

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- Event Scheduler & Spreadsheet 1Document18 pagesEvent Scheduler & Spreadsheet 1Kajer quemarNo ratings yet

- Chemical Engineering 422 Simulation With Hysys: NotesDocument9 pagesChemical Engineering 422 Simulation With Hysys: NotesNoor Ul HaqNo ratings yet

- AspenHYSYSRefiningV7 2 OpsDocument478 pagesAspenHYSYSRefiningV7 2 Opsnguyennha1211100% (1)

- Advanced Simulation Case Using HysysDocument232 pagesAdvanced Simulation Case Using HysysridhajamelNo ratings yet

- Expanding The Column Overhead System: Instructor: Eng. Ahmed Deyab Fares Mobile: 0127549943Document14 pagesExpanding The Column Overhead System: Instructor: Eng. Ahmed Deyab Fares Mobile: 0127549943TayebASherifNo ratings yet

- Problem 2. Production of Bean Oil. Solution:: Steady State Process Simulation Using HYSYS Tutorial 1 Process SimulationDocument9 pagesProblem 2. Production of Bean Oil. Solution:: Steady State Process Simulation Using HYSYS Tutorial 1 Process SimulationEhsan AhzNo ratings yet

- ColumnA RadFrac ABCDocument5 pagesColumnA RadFrac ABCGaby HdzNo ratings yet

- Computational Techniques for Chemical Engineers: International Series of Monographs in Chemical EngineeringFrom EverandComputational Techniques for Chemical Engineers: International Series of Monographs in Chemical EngineeringNo ratings yet

- Fluid Flow and Simulation SoftwaresDocument57 pagesFluid Flow and Simulation Softwaressri9987100% (1)

- Alex University Dynamics HYSYS Course20190614-125372-1rwitpy PDFDocument24 pagesAlex University Dynamics HYSYS Course20190614-125372-1rwitpy PDFSirajNo ratings yet

- Thermodynamic Models for Chemical Engineering: Design, Develop, Analyse and OptimizeFrom EverandThermodynamic Models for Chemical Engineering: Design, Develop, Analyse and OptimizeNo ratings yet

- Ptt156 - Hysys Lab ManualDocument41 pagesPtt156 - Hysys Lab ManualNguyễn Quyết100% (1)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Lecture 1 - Intro To Process SimulationDocument48 pagesLecture 1 - Intro To Process SimulationSJ ChuaNo ratings yet

- Hysys TascDocument10 pagesHysys TascMariano PodestáNo ratings yet

- Phase DiagramDocument3 pagesPhase DiagramTing TCNo ratings yet

- Aspen Hysys Dynamics Process ControlDocument6 pagesAspen Hysys Dynamics Process ControlAkhi Sofi0% (1)

- Aspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACDocument13 pagesAspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACRavi Kant TripathiNo ratings yet

- 1.3.9 Rating Heat ExchangerDocument18 pages1.3.9 Rating Heat ExchangerMelva NainggolanNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Modeling and Simulation of A Distillation Column Using ASPEN PLUS Libre PDFDocument9 pagesModeling and Simulation of A Distillation Column Using ASPEN PLUS Libre PDFmehul10941No ratings yet

- Lecture 4 - Simulation of Recycle StreamsDocument57 pagesLecture 4 - Simulation of Recycle StreamsKin Wai Cheah75% (4)

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- Brunet (Dynamic Simulation and Process Control)Document79 pagesBrunet (Dynamic Simulation and Process Control)Camilo Diaz100% (1)

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Lec SimulationDocument80 pagesLec SimulationDr Tajammal MunirNo ratings yet

- Module#3-Heat ExchangersDocument19 pagesModule#3-Heat ExchangersLa Casa JordanNo ratings yet

- Dynamic Depressuring PDFDocument16 pagesDynamic Depressuring PDFAsimNo ratings yet

- HYSYS TutorialDocument15 pagesHYSYS TutorialEhsan Ahz100% (1)

- Construct A Pre-Heat Train Model Workshop: ObjectiveDocument26 pagesConstruct A Pre-Heat Train Model Workshop: Objectivemiri-256No ratings yet

- Lab # 15Document13 pagesLab # 15Kashaf TehreemNo ratings yet

- Aspen ConvergenceDocument40 pagesAspen ConvergenceKaushal SampatNo ratings yet

- Aspentech Course Catalog Fy18Document27 pagesAspentech Course Catalog Fy18Waseem AkramNo ratings yet

- 01 GettingStartedDocument34 pages01 GettingStartedRyan GonzalesNo ratings yet

- 4528 - CourseManual DynamicDocument362 pages4528 - CourseManual DynamicMuntaser YousifNo ratings yet

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28From EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28No ratings yet

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- Pipe Flow in Ansys FluentDocument32 pagesPipe Flow in Ansys Fluentochenapothik2012No ratings yet

- Tut 01Document56 pagesTut 01Andreea Cristina PetcuNo ratings yet

- Pipe Flow in Ansys FluentDocument32 pagesPipe Flow in Ansys Fluentochenapothik2012No ratings yet

- Oil ManagementDocument12 pagesOil ManagementEhsan AhzNo ratings yet

- Mae5230 CFD Intro Notes PDFDocument17 pagesMae5230 CFD Intro Notes PDFDebabrata PaulNo ratings yet

- HYSYS TutorialDocument26 pagesHYSYS TutorialEhsan AhzNo ratings yet

- HYSYS TutorialDocument30 pagesHYSYS TutorialEhsan Ahz100% (2)

- Class I Water Well: DescriptionDocument10 pagesClass I Water Well: DescriptionJavier Andrés Acevedo GarcíaNo ratings yet

- Case Study III - MichelinDocument15 pagesCase Study III - MichelinfreitzNo ratings yet

- Contoh Label Sensus 2022Document313 pagesContoh Label Sensus 2022Ajenk SablackNo ratings yet

- Sample File: The Ultimate Adventurers Guide IDocument6 pagesSample File: The Ultimate Adventurers Guide IDingusbubmisNo ratings yet

- AT ChapIDocument48 pagesAT ChapIvigneshwaranbeNo ratings yet

- Corometrics 170 Series BrochureDocument3 pagesCorometrics 170 Series BrochureCesar MolanoNo ratings yet

- DD 3334Document2 pagesDD 3334FAQMD2No ratings yet

- Focal Length of Convex LensDocument5 pagesFocal Length of Convex LensHey AnuragNo ratings yet

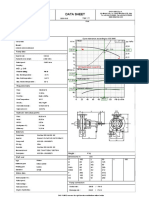

- Data Sheet: Item N°: Curve Tolerance According To ISO 9906Document3 pagesData Sheet: Item N°: Curve Tolerance According To ISO 9906Aan AndianaNo ratings yet

- 3.15.E.V25 Pneumatic Control Valves DN125-150-EnDocument3 pages3.15.E.V25 Pneumatic Control Valves DN125-150-EnlesonspkNo ratings yet

- Column Buckling TestDocument8 pagesColumn Buckling TestWiy GuomNo ratings yet

- BS 07533-3-1997Document21 pagesBS 07533-3-1997Ali RayyaNo ratings yet

- Graduate Macro Theory II: The Real Business Cycle Model: Eric Sims University of Notre Dame Spring 2017Document25 pagesGraduate Macro Theory II: The Real Business Cycle Model: Eric Sims University of Notre Dame Spring 2017Joab Dan Valdivia CoriaNo ratings yet

- AE HM6L-72 Series 430W-450W: Half Large CellDocument2 pagesAE HM6L-72 Series 430W-450W: Half Large CellTaso GegiaNo ratings yet

- RV900S - IB - Series 3Document28 pagesRV900S - IB - Series 3GA LewisNo ratings yet

- Assistant Bookkeeper Resume Sample - Best Format - Great Sample ResumeDocument4 pagesAssistant Bookkeeper Resume Sample - Best Format - Great Sample ResumedrustagiNo ratings yet

- Power Quality Lab Manual (EE-801)Document12 pagesPower Quality Lab Manual (EE-801)ASHU KNo ratings yet

- Mi Account ေက်ာ္နည္းDocument16 pagesMi Account ေက်ာ္နည္းamk91950% (2)

- Puratattva No 41Document3 pagesPuratattva No 41ultimategoonNo ratings yet

- Dady - Piernas LargasDocument12 pagesDady - Piernas LargasSarha NietoNo ratings yet

- EE360 - Magnetic CircuitsDocument48 pagesEE360 - Magnetic Circuitsبدون اسمNo ratings yet

- Online Dynamic Security Assessment of Wind Integrated Power System UsingDocument9 pagesOnline Dynamic Security Assessment of Wind Integrated Power System UsingRizwan Ul HassanNo ratings yet

- HyperconnectivityDocument5 pagesHyperconnectivityramNo ratings yet