Professional Documents

Culture Documents

Britain'S Aero Engines (Continued) : NOVEMBER 3, 1938

Uploaded by

seafire47Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Britain'S Aero Engines (Continued) : NOVEMBER 3, 1938

Uploaded by

seafire47Copyright:

Available Formats

NOVEMBER 3,

1938.

FLIGHT.

BRITAIN'S

AERO

ENGINES

(CONTINUED)

well above a 100 deg. C. and should avoid the difficulties of draining and supplying the Glycol. In all essentials the following description of the Merlin will apply to all current models, excepting the Merlin I. The crankcase is an aluminium casting made in two halves bolted together. The upper half is cast integral with the rear half of the reduction gear casing and carries the cylinder blocks in addition to incorporating the seven main bearings and caps, the engine mounting feet, slinging points, etc. In the lower half are the oil pumps and niters together with drives for a hydraulic undercarriage pump or low-pressure air compressor. At the rear end of both halves is a vertical facing for mounting the wheel case which houses the auxiliary drives. The main bearings are split mild steel shells lined with lead-bronze and fitted into recesses machined in the crankcase. They are held in position by caps and bolts passing through the caps and across the whole width of the crankcase. A one-piece forging, the crankshaft has integral balance weights. It is machined all over, nitrogen-hardened, and its crank pins and journals are bored and fitted with oil retaining covers. Oil is fed into the journals and passes through drilled passages into the crankpins to feed the bigend bearings. The drive to the reduction gear pinion is taken from a flange bolted to the front end, and the spring drive to the camshafts, supercharger and all auxiliaries from the rear end. There are two connecting rods to each crankpin. These are of " H " section, and are nickel-steel forgings machined all over, each pair consisting of a plain rod and a forked rod carrying a nickel-steel bearing block lined inside and out with a special lead-bronze mixture. The bearing block is divided across its bore, and bears directly on the crankpin being secured to the forked rod by four bolts, whilst its outer lining forms the bearing for the plain rod. Lubrication of the big-end bearings is by pressure feed from the crankpins, but the small end bush relies upon the oil mist from the cylinder walls and pistons. The forged aluminium alloy pistons are machined all over, and are fitted with three gas and two scraper rings. The hollow gudgeon pins are of the fully floating type, and are retained in position by spring circlips. Each of the two banks of cylinders, which are set in a vee at an angle of 60 deg. on the upper half of the crankcase, is a monobloc aluminium casting with integral heads and water jackets into which are inserted six '' w e t ' ' cylinder liners of high carbon steel. The cylinder head houses the valves, camshaft and rocker gear. At the upper end of each liner is a spigoted flange registering in a recess in the head, a soft aluminium alloy joint ring ensuring gas tightness, while the coolant joint at the base of each cylinder is made by a rubber ring, springloaded in an external groove in the liner. The lower end of the liner is flanged for seating on the crankcase. Fourteen long studs extending from the top of the block castings into the crankcase secure the cylinder assembly in position and maintain the gas tightness of the head joint. Relative movement between the cylinder skirts and the liners is permitted by the springloaded glands, which at the same time ensure coolant-tight joints. A certain degree of flexibility and a reduction in local distortion of each top joint face under sudden temperature changes are allowed by a lateral saw-cut between each combustion head. Further, to improve

this joint and prevent disturbance of the liner during removal of the cylinder block there are six additional studs on each side of the block to secure clamps. These studs abut against the lower face of the top flange of each liner. Renewable valve seatings (aluminium bronze for the inlet and silchrome for the exhaust) are screwed into the. cylinder heads which also house the cast-iron inlet, and the phosphor bronze exhaust-valve guides. The camshafts, which are driven through the spring drive by an inclined shaft and bevel gears from the wheel case at the rear of the engine, are nickel steel forgings machined all over and case-hardened and ground on the cam and bearing surfaces. Each valve is operated by a separate steel rocker having a spherical-headed tappet screw and locknut at the valve end for tappet adjustment. There are four valvestwo inlet and two exhaustfor each cylinder, all working parallel to the axis of the cylinder. Each is fitted with two concentric-coil springs. To damp out irregularities in angular velocity and torque, the drive from the crankshaft to the supercharger, timing gears, and auxiliary components, is taken through a torsionally flexible shaft which provides a spring drive. The twisting of this shaft is limited by a hollow sleeve connected to its outer end by means of a damper clutch, the drive then being taken up by the sleeve. The wheel-casean aluminium alloy castinghouses, apart from the supercharger unit on its rear face, the drives to the camshafts, magnetos, coolant and oil pumps, fuel pumps, supercharger, hand and electric starters and electric generator. Alternative methods of starting are by an electric starter motor or an auxiliary hand-turning gear. A single spur reduction gear is used. The pinion, which is hollow and carried in two roller bearings, is coaxial with, and driven from, the crankshaft by a short hollow shaft, serrated at both ends, engaging the crankshaft flange and the forward end of the pinion internally. This pinion engages with a toothed ring bolted to a flange formed integral with the hollow airscrew shaft, the latter being supported on roller bearings and fitted with a ball bearing which takes axial thrust in either direction. The hollowdrive shaft isolates the pinion bearings from the crankshaft loading. Lubrication of the gears is effected by two jets fed from the low - p r e s s u r e

The Pobjoy Niagara III in its standardised cowling which ensures not only h a n d s o m e externa] appearance but efficient cooling.

You might also like

- LAA - Light Aviation - FRED G-BWAP at Last! - November 2013Document1 pageLAA - Light Aviation - FRED G-BWAP at Last! - November 2013cluttonfredNo ratings yet

- Sonerai Structure FrameDocument1 pageSonerai Structure Frame69x40% (1)

- Inverse Pressure Gradient Matching Lowers Wing Interference DragDocument7 pagesInverse Pressure Gradient Matching Lowers Wing Interference DragredxusNo ratings yet

- Flight.: PobjoyDocument1 pageFlight.: Pobjoyseafire47No ratings yet

- 1938 - 0824Document1 page1938 - 0824seafire47No ratings yet

- X-57 Power and Command System DesignDocument8 pagesX-57 Power and Command System DesignaircarmediaNo ratings yet

- Blue Edge: The Design, Development and Testing of A New Blade ConceptDocument14 pagesBlue Edge: The Design, Development and Testing of A New Blade ConceptKevinNo ratings yet

- 0117Document79 pages0117Hugo Machado Silva NetoNo ratings yet

- LAA - Light Aviation - October 2012 - Over The HedgeDocument2 pagesLAA - Light Aviation - October 2012 - Over The HedgecluttonfredNo ratings yet

- TL 3.17 List of Approved Prototype Mods PDFDocument143 pagesTL 3.17 List of Approved Prototype Mods PDFomid omidiNo ratings yet

- Eaa Flight Reports - Aeronca ChampDocument4 pagesEaa Flight Reports - Aeronca ChampIdiosocraticNo ratings yet

- Vintage Airplane - Jan 1988Document32 pagesVintage Airplane - Jan 1988Aviation/Space History LibraryNo ratings yet

- Design and Structural Analyses of A ReciprocatingDocument15 pagesDesign and Structural Analyses of A ReciprocatingangelNo ratings yet

- Type Cert A718Document6 pagesType Cert A718skatterbrainkidNo ratings yet

- Eta (Glider) - WikipediaDocument2 pagesEta (Glider) - Wikipediajordanfakes.psdNo ratings yet

- 02 Airfoil ADocument23 pages02 Airfoil Abecool_bcn75No ratings yet

- Economics of Sustainable Regional Air MobilityDocument16 pagesEconomics of Sustainable Regional Air MobilityPablo De FelipeNo ratings yet

- Vintage Airplane - Dec 1987Document32 pagesVintage Airplane - Dec 1987Aviation/Space History LibraryNo ratings yet

- Archer Investor PresentationDocument53 pagesArcher Investor PresentationAlexeyNo ratings yet

- Ostiv Book Long FinalDocument126 pagesOstiv Book Long FinalkurionNo ratings yet

- Section 45: Firewall Forward Wiring Harness: Van'S Aircraft, IncDocument1 pageSection 45: Firewall Forward Wiring Harness: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- Ncrit Thesis - Implementation of A New Transition Prediction Method in XfoilDocument168 pagesNcrit Thesis - Implementation of A New Transition Prediction Method in XfoilDavid Jiménez MenaNo ratings yet

- Rotary Wing Aircraft Handbooks and History Volume 10 Stability and Control of Rotary Wing AircraftDocument67 pagesRotary Wing Aircraft Handbooks and History Volume 10 Stability and Control of Rotary Wing Aircraftpiolenc@archivale.comNo ratings yet

- Electric aircraft concepts, technologies and challengesDocument74 pagesElectric aircraft concepts, technologies and challengesOSCARDELTANo ratings yet

- Scottish RotorDocument8 pagesScottish Rotoraravisara5100% (1)

- MS-343 - WACO Aircraft CompanyDocument38 pagesMS-343 - WACO Aircraft CompanyStargazerNo ratings yet

- R/C Soaring Digest - Apr 2006Document48 pagesR/C Soaring Digest - Apr 2006Aviation/Space History LibraryNo ratings yet

- NACA ACR L4L07 - Tests of A Curtiss Propeller On P47CDocument36 pagesNACA ACR L4L07 - Tests of A Curtiss Propeller On P47CAnonymous xD8wUeMyNo ratings yet

- Hondajet BrochureDocument17 pagesHondajet BrochureranoNo ratings yet

- Aircraft Propellers (PDFDrive)Document162 pagesAircraft Propellers (PDFDrive)Siddarth NandNo ratings yet

- Besi Dalam Perspektif HadisDocument627 pagesBesi Dalam Perspektif Hadiswahyudi5758No ratings yet

- 1407 Sport Aviation 201407Document140 pages1407 Sport Aviation 201407JoseNo ratings yet

- Teaching With Experimentals 2018 PDFDocument33 pagesTeaching With Experimentals 2018 PDFBlockFace08No ratings yet

- Flight of The Falcon - Demolishing Myths of Indo Pak Wars 1965-1971 - Sajad S. Haider PDFDocument185 pagesFlight of The Falcon - Demolishing Myths of Indo Pak Wars 1965-1971 - Sajad S. Haider PDFOsman MustafaNo ratings yet

- Drag of Airplane Wheels, Wheel Fairings and Landing Gear I - NACA RPT 485 PDFDocument35 pagesDrag of Airplane Wheels, Wheel Fairings and Landing Gear I - NACA RPT 485 PDFLysterNo ratings yet

- I Got Wings To Fly and Feel That I'M AliveDocument22 pagesI Got Wings To Fly and Feel That I'M AliveOnce AgainsNo ratings yet

- Naca TN 1670Document134 pagesNaca TN 1670Alma BravoNo ratings yet

- Analysis of The Cricri MC 15Document6 pagesAnalysis of The Cricri MC 15Albaz DarwishNo ratings yet

- C-130 Hercules: Instruction Manual Semi Scale Model of The World Famous Military Transport AircraftDocument19 pagesC-130 Hercules: Instruction Manual Semi Scale Model of The World Famous Military Transport AircraftTom PymNo ratings yet

- Agard R 783Document254 pagesAgard R 783John Alberto Gomez UsedaNo ratings yet

- DesignDocument9 pagesDesignSamx80No ratings yet

- Vintage Airplane - Jan 1998Document36 pagesVintage Airplane - Jan 1998Aviation/Space History LibraryNo ratings yet

- Naca Report 640Document23 pagesNaca Report 640Arturo ValenciaNo ratings yet

- ATF3-3 Single-Stage Geared Fan, Five-Stage I-P Compressor,: Garrett-Airesearch (Usa)Document1 pageATF3-3 Single-Stage Geared Fan, Five-Stage I-P Compressor,: Garrett-Airesearch (Usa)ValBMSNo ratings yet

- Flap System RiginDocument12 pagesFlap System RiginHarold Reyes100% (1)

- Local HeroDocument371 pagesLocal HeroNikhil MohiteNo ratings yet

- NASA Technical Paper 2256Document145 pagesNASA Technical Paper 2256Anonymous QFTSj1YNo ratings yet

- Yugoslav School Glider INKADocument7 pagesYugoslav School Glider INKAslavikpNo ratings yet

- Zenith Ch650Document31 pagesZenith Ch650Aravinthan VarunNo ratings yet

- Agardag300 RevoDocument31 pagesAgardag300 RevocmpmarinhoNo ratings yet

- 19 Steps To Legal Eagle XL Frame Build 1Document14 pages19 Steps To Legal Eagle XL Frame Build 1Ennocent MugabeNo ratings yet

- Vintage Airplane - Jan 1997Document36 pagesVintage Airplane - Jan 1997Aviation/Space History LibraryNo ratings yet

- LR 326 1Document49 pagesLR 326 1RAHULNo ratings yet

- Historical Overview of v-STOL Aircraft TechnologyDocument20 pagesHistorical Overview of v-STOL Aircraft TechnologyMarioNo ratings yet

- FQ Breguet MD 188Document84 pagesFQ Breguet MD 188dagger21100% (2)

- NASA Aeroelasticity Handbook Volume 2 - Design Guides Part 2 PDFDocument596 pagesNASA Aeroelasticity Handbook Volume 2 - Design Guides Part 2 PDFBrunno VasquesNo ratings yet

- PH - Carolina's Chorizo Carbonara With Garden SaladDocument2 pagesPH - Carolina's Chorizo Carbonara With Garden Saladseafire47No ratings yet

- PH - Almond & Garlic Crusted Chicken With Cherry Tomato SaladDocument2 pagesPH - Almond & Garlic Crusted Chicken With Cherry Tomato Saladseafire47No ratings yet

- Flight.: Final Gliding Contest ResultsDocument1 pageFlight.: Final Gliding Contest Resultsseafire47No ratings yet

- Commercial Aviation and Airlines Updates in 1935Document1 pageCommercial Aviation and Airlines Updates in 1935seafire47No ratings yet

- 1938 - 2869Document1 page1938 - 2869seafire47No ratings yet

- 598 Flight.: DECEMBER I 6, 1937Document1 page598 Flight.: DECEMBER I 6, 1937seafire47No ratings yet

- Shor BRQS.: of RochesterDocument1 pageShor BRQS.: of Rochesterseafire47No ratings yet

- Gtsac : Flight Engineering SectionDocument1 pageGtsac : Flight Engineering Sectionseafire47100% (1)

- Short S.20 Mercury SDocument3 pagesShort S.20 Mercury Sseafire47No ratings yet

- East To West Record: 13% HOURSDocument1 pageEast To West Record: 13% HOURSseafire47No ratings yet

- Second Parting: Short-Mayo Compo-Site Separated "In Public"Document1 pageSecond Parting: Short-Mayo Compo-Site Separated "In Public"seafire47No ratings yet

- "Mercury" Makes GoodDocument1 page"Mercury" Makes Goodseafire47No ratings yet

- 1937 - 3487Document1 page1937 - 3487seafire47No ratings yet

- 74-A-23 Se5a F938Document4 pages74-A-23 Se5a F938seafire47No ratings yet

- 203 Sample ArticleDocument8 pages203 Sample Articleseafire47No ratings yet

- 1937 - 3485Document1 page1937 - 3485seafire47No ratings yet

- 95 Sample ArticleDocument5 pages95 Sample Articleseafire47No ratings yet

- Percival Q4,6 1937 - 3486Document1 pagePercival Q4,6 1937 - 3486seafire47No ratings yet

- 8 Ross RS1 93Document4 pages8 Ross RS1 93seafire47No ratings yet

- 7 Moundsville Lone Eagle 94Document9 pages7 Moundsville Lone Eagle 94seafire47No ratings yet

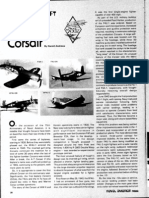

- Chance Vought F4u CorsairDocument6 pagesChance Vought F4u Corsairseafire47100% (3)

- 4 Worlds FairDocument5 pages4 Worlds Fairseafire47No ratings yet

- Splash 1Document4 pagesSplash 1seafire47100% (1)

- Wright Flyer 1903 EngineDocument3 pagesWright Flyer 1903 Engineseafire47No ratings yet

- VS-10001 GA 02 F4U-1 CorsairDocument0 pagesVS-10001 GA 02 F4U-1 Corsairseafire47No ratings yet

- b47 v3Document4 pagesb47 v3seafire47100% (1)

- SB2U VindicatorDocument11 pagesSB2U Vindicatorseafire47100% (1)

- F4u 4Document8 pagesF4u 4seafire47100% (1)

- Raid On Regensburg2Document8 pagesRaid On Regensburg2seafire47100% (1)

- Designation OF USA AIRCRAFTDocument9 pagesDesignation OF USA AIRCRAFTseafire47No ratings yet

- HP 5973 Quick ReferenceDocument28 pagesHP 5973 Quick ReferenceDavid ruizNo ratings yet

- Ogl422 Milestone Three Team 11 Intro Training Session For Evergreen MGT Audion Recording Due 2022apr18 8 30 PM PST 11 30pm EstDocument14 pagesOgl422 Milestone Three Team 11 Intro Training Session For Evergreen MGT Audion Recording Due 2022apr18 8 30 PM PST 11 30pm Estapi-624721629No ratings yet

- Hencher - Interpretation of Direct Shear Tests On Rock JointsDocument8 pagesHencher - Interpretation of Direct Shear Tests On Rock JointsMark2123100% (1)

- 9 - NCP Computer Science PGDocument19 pages9 - NCP Computer Science PGM AmbreenNo ratings yet

- LAC-Documentation-Tool Session 2Document4 pagesLAC-Documentation-Tool Session 2DenMark Tuazon-RañolaNo ratings yet

- Hardware Purchase and Sales System Project ProfileDocument43 pagesHardware Purchase and Sales System Project Profilesanjaykumarguptaa100% (2)

- StsDocument10 pagesStsSamonte, KimNo ratings yet

- Youth, Time and Social Movements ExploredDocument10 pagesYouth, Time and Social Movements Exploredviva_bourdieu100% (1)

- The Emperor Jones: What's Inside in ContextDocument27 pagesThe Emperor Jones: What's Inside in ContextHarshvardhan RaiNo ratings yet

- 153C Final Exam Study Guide-2Document6 pages153C Final Exam Study Guide-2Soji AdimulaNo ratings yet

- CCEE SWD Basic Levers ToolDocument28 pagesCCEE SWD Basic Levers ToolDivina Margarita Gómez AlvarengaNo ratings yet

- Jesus - The Creator Unleashes Our Creative PotentialDocument1 pageJesus - The Creator Unleashes Our Creative PotentialKear Kyii WongNo ratings yet

- Center of Gravity and Shear Center of Thin-Walled Open-Section Composite BeamsDocument6 pagesCenter of Gravity and Shear Center of Thin-Walled Open-Section Composite Beamsredz00100% (1)

- Learn Square Roots & Plot on Number LineDocument11 pagesLearn Square Roots & Plot on Number LineADAM CRISOLOGONo ratings yet

- City of Brescia - Map - WWW - Bresciatourism.itDocument1 pageCity of Brescia - Map - WWW - Bresciatourism.itBrescia TourismNo ratings yet

- Bitcoin MambaDocument17 pagesBitcoin MambaJean MilenixNo ratings yet

- Aircraft ChecksDocument10 pagesAircraft ChecksAshirbad RathaNo ratings yet

- Dell EMC VPLEX For All-FlashDocument4 pagesDell EMC VPLEX For All-Flashghazal AshouriNo ratings yet

- Principles of Cost Accounting 1Document6 pagesPrinciples of Cost Accounting 1Alimamy KamaraNo ratings yet

- The Graduation Commencement Speech You Will Never HearDocument4 pagesThe Graduation Commencement Speech You Will Never HearBernie Lutchman Jr.No ratings yet

- All MeterialsDocument236 pagesAll MeterialsTamzid AhmedNo ratings yet

- STEM Spring 2023 SyllabusDocument5 pagesSTEM Spring 2023 SyllabusRollins MAKUWANo ratings yet

- 7 Tactical Advantages of Explainer VideosDocument23 pages7 Tactical Advantages of Explainer Videos4ktazekahveNo ratings yet

- Marijuana Grow Basics - Jorge CervantesDocument389 pagesMarijuana Grow Basics - Jorge CervantesHugo Herrera100% (1)

- Wsi PSDDocument18 pagesWsi PSDДрагиша Небитни ТрифуновићNo ratings yet

- 2.0 - SITHKOP002 - Plan and Cost Basic Menus Student GuideDocument92 pages2.0 - SITHKOP002 - Plan and Cost Basic Menus Student Guidebash qwertNo ratings yet

- Compare and Contrast High School and College EssayDocument6 pagesCompare and Contrast High School and College Essayafibkyielxfbab100% (1)

- Analysis of VariancesDocument40 pagesAnalysis of VariancesSameer MalhotraNo ratings yet

- Future Design of Accessibility in Games - A Design Vocabulary - ScienceDirectDocument16 pagesFuture Design of Accessibility in Games - A Design Vocabulary - ScienceDirectsulaNo ratings yet

- English Skills BookDocument49 pagesEnglish Skills BookAngela SpadeNo ratings yet