Professional Documents

Culture Documents

Alfa 156 Front Suspension V 2

Uploaded by

Danny SabatoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alfa 156 Front Suspension V 2

Uploaded by

Danny SabatoCopyright:

Available Formats

Alfa 156 Front Wishbone Replacement

Alfa 156 Front Wishbone Replacement

Also for 147 and GT that have same suspension. One of the annoying problems you get with a 156 is the squeaking suspension syndrome. This is usually where the rubber bushes in the upper and lower wishbones start to harden. This hints document will hopefully show you how to replace both sets of arms. You dont have to do them at the same time, but if one is worn, you can be pretty sure the other it too. Also the way I did mine means you take the same parts off to do either. You should not need to dismantle the driveshaft, remove the hub nut or split the steering ball joint to complete this. But as will all work on a car, make sure you have all the right tools to hand, the parts you need and bear in mind this is one job where you definitely do reach a point-of-no-return as you are more than liable to damage the old part in trying to remove them, especially when you start splitting the balljoints. Ill also add another caveat here: these tips were written up about a year after I did this on my car. Ive tried to remember exactly how I did everything, but you will need to bear with me if Ive forgotten one or two small items. Just make sure you note where everything goes are you take it off .. so you can put it all back. You will need: Small trolley jack (you might get away with a hydraulic bottle jack!) and axle stands Set of torx keys or sockets (usually 3/8th drive) Set of metric sockets and spanners (ring best) Torque wrench Suitable ball-joint splitter ..heavy-duty scissor type is usually best, although the hammer style can be useful for the lower arm joint 2 Hammers! to help persuade stubborn balljoints. Clap on either side while balljoint is under tension from the splitter ... or simply to whack the fork-style splitter! Parts: Lower wishbones Upper wishbones Roll-bar drop links (optional) Cleaning spray/materials Jack up the car and securely place it on axle stands (this is assuming that you dont have access to a proper workshop and lifting gear!) You will need to have the jack available to support the suspension strut when you start to remove all the fixing bolts. NOTE: The rear arm mounting are threaded into an alloy. Dont overtighten the bolts or you could strip the threads!! Result? Another new arm!! Also check that the balljoint boot isnt trapped in the hole of the hub or you will tear it open the first time you turn the steering wheel. If you are changing the lower arms, remove the anti-roll bar drop-links on BOTH SIDES. This allows you to push the anti-roll bar up and away from the arm, otherwise it can catch on the rear mounting as you try and pull the arm out. It may also help to remove the caliper and disc as this reduces the weight of the strut you need to man-handle. Torque settings in Deca Newton Metres and Newton Metres (Nm = 10 x daNm)

29/3/11 Gazza82 Enterprises Page 1 of 5

Alfa 156 Front Wishbone Replacement

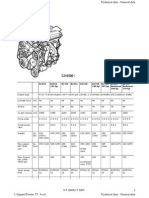

The Strut Assembly

THE STRUT ASSEMBLY

This picture was annoted by someone who was only doing the upper wishbones. But is a useful reference to us for the lower arms as well. It does not show all the cable, pipes and other paraphernalia that are attached to a fully working vehicle. And the parts are clean too .... This is the left/offside/drivers suspension looking backwards.

29/3/11 Gazza82 Enterprises

Page 2 of 5

Alfa 156 Front Wishbone Replacement

Lower Suspension Arms

LOWER SUSPENSION ARMS METHOD 1:

1. 2. 3. Unclip any pipes and wires from the suspension strut to allow more freedom. Remove the anti-roll bar drop link from both sides!. You need a ring spanner on the nut and torx key in the mounting bolt. (PS you might get away with an allen key). Remove the long bolt that goes through the bottom of the strut (through the U shaped mounting) and the lower wishbone. At this point the strut will drop and will rest on the arm. I have read some have chosen to take the lower mounting off the bottom of the strut. I didnt find this was necessary. Now loosen the inner mounting bolts but dont remove them yet. Remove the balljoint mounting nut. Split the lower balljoint. This is where the fun starts. Because the balljoint is actually inside the hub, I ended up using the type of balljoint splitter that you hit (hard!) with a hammer. This will effectively ruin the balljoint, so this is the point-of-no-return. I balanced the hub on the trolly jack at this point as it is coming to the point where it isnt going to be supported by anything. In hindsight it might be worth thinking about taking the brake caliper off as this will reduce the weight as well as you not having to worry about straining the hydraulic pipes. You shouldnt need to split the steering arm. Once the balljoint is split remove the four mounting bolts. Note they are different lengths for when they go back. I managed to pull the strut out far enough to get the mountings out from the chassis. You may need to swing the arm to the rear to get full clearance. By pushing down on the inner ends of the arm, the balljoint mounting bolt pulled clear up out of the hub and out.

4. 5. 6.

7. 8. 9.

10. Now put it back together ... 11. First put the balljoint end back in the hub. Be careful as this where you could damage the threads - take your time and move it back slowly. Put the balljoint nut on loosely at this stage. Make sure the balljoint rubber doesnt get trapped in the hub or it will tear. 12. Locate the ends of the arm in the chassis. Again this can be difficult as you have to pull the bottom of the strut outwards as you push and twist the mounting into place. This is where supporting the hub on the trolley jack helps as its moveable and you are not trying to support all the weight. Put the mounting bolts back loosely. Make sure that the arm is between the two legs of the lower strut bracket. 13. Tighten the balljoint nut and four inner mounting bolts. (Torque them later!) If you are just doing the lower arms you can carry on putting everything back. If you are doing the upper wishbones, leave it like this. 14. Replace the long bolt that goes through the lower strut mounting and the arm and replace the nut. 15. Replace the anti-roll bar drop link in the mounting bracket on the strut. If you are replacing the droplinks, do this now. 16. Replace the caliper (if removed) and any pipes/wires. 17. Torque the various nuts to the specifications: Balljoint nut: 8.6-9.5 daNm 86-95 Nm Cross-bolt: 8.1-8.9 daNm 81-89 Nm (should have the weight of the car on this when tightened)

29/3/11 Gazza82 Enterprises Page 3 of 5

Alfa 156 Front Wishbone Replacement

Method 2:

Wishbone mountings: 6.2-6.8 daNm 62-68 Nm (take care: tighten progressively) Caliper Hex Bolts: 4.8-5.2 daNm 48-52 Nm NOTE: The rear arm bolts are threaded into an alloy mounting. Dont overtighten the bolts or you could strip the threads!! Result: another new arm!!

METHOD 2:

I now tend to take the hub, upright and driveshaft out as one (only because I can't be bothered to get the hut nut off, etc). This means that you can take out the complete suspension and replace the lower arm without forcing the mounting into place, which can result in cross-threaded mounting bolts. It takes a bit longer as you have six 6mm hex bolts to remove at the inner cv joint, but is a lot less hassle that fighting with the suspension assembly and locating the four mounting bolts. I started to do it this way when I had to replace a lower arm (split balljoint cover and wear) and the two CV joint covers on the n/s driveshaft. So the process is similar to this: 1) Support car on axle stands! 2) undo top a/r bar droplink connection and pull brake hose and cable out of fittings 3) remove front caliper and support it (don't let it hang on the brake hose). Optionally remove brake disk and backing plate to reduce weight and improve access to lower ball joint 4) split the lower balljoint 5) split the upper balljoint 6) split the tie-rod ball joint 7) undo the six 6mm hex bolts on the inner driveshaft 8) remove the bolt through the lower arm and shock fork If you can get the lower strut fork off, remove it now, but it is most likely to be well and truly welded together .. the alloy fork and steel bolts corrode together. 9) drop the hub assembly down off the lower arm ball joint and pull assembly towards you carefully until the inner cv joint catches on the strut fork ... it is heavy 10) push down on the balljoint end of the now free lower arm and slip the driveshaft out of the gap between the arm and the fork .. a second person is useful here! put assembly to one side 11) remove the four lower arm mounting bolts and remove old arm 12) give everything a good clean up before mounting new lower arm ... this area is usually full of grit and stones! If you want to change the upper wishbone, now undo the four upper mounting nuts and carefully drop the strut (I support it on a trolley jack and lower slowly) Remove the upper wishbone mounting and wishbone from the top of the strut and replace wishbone When you put it back start with the lower arm and bolt in place, but don't overtighten the mounting bolts. They strip the thread easily in the two mounting.

29/3/11 Gazza82 Enterprises

Page 4 of 5

Alfa 156 Front Wishbone Replacement

Upper Wishbones

Now refit the upper wishbone mount, then locate the strut and loosely bolt both in place. Push the lower arm down hard to clear the strut fork and put the driveshaft in place, then let the arm up so the fork straddles the shaft and arm. Now hook the lower balljoint into the hub assembly and fit the nut loosely to stop it falling out. Take car not to scuff the threads or catch the balljoint cover. The rest should be relatively straightforward, with the most annoying part replacing the six inner CV joint bolts as they are a pain to tighten. Remember to use loctite on these. In DTE/ elearn it actually suggests replacing the nuts and bolts. Might be something to do with the thread locking solution Alfa use. But nylok nuts should be replaced when they are no longer gripping the bolt threads ...

UPPER WISHBONES

Complete steps 1-3 for the lower arm instructions. If youve changed the lower arm, it will be in place except for the long cross bolt that goes through the bottom of the strut and arm. 1. 1. Split the upper ball joint now. If this proves difficult, support the bottom or the strut on the jack, or even replace the long bolt to support the strut. It may take a fair whack to do this. Again, using the hammer-type splitter will wreck the balljoint. If you put the crossbolt through, take it out again now as the strut needs to drop. Support the strut on the jack. From inside the engine bar, loosen the four nuts at the top of the strut mounting. Pull the strut down as much as possible. Remove the four nuts and pull the strut down so the bolts clear the body work. The wishbone arm and mounting lift up and off the strut mounting bolts. Pull down on the strut and push the mounting up and it should twist off. Remove the bolt that runs through the mounting and wishbone. Give the mounting a good clean. Replace the new wishbone and put the bolt back. Torque the fitting nut to 4.0-4.9 daNm 40-49 Nm. Wiggle the mounting back over the four mounting bolts, and lift the strut. This is best done with a jack as you can move it up gradually. Take care not to catch the bolts as they pass back through the body work. They make a big bang if you do and they let go as the strut is moved back!! Apart from that you could damage the threads. Once the four bolts are through, put the nuts back and tighten them to pull the strut into place. Torque them when the wheel is back on the ground.

2. 3. 4. 5. 6. 7. 8.

9.

10. Replace the upper balljoint and torque the nut to 4.3-4.7 daNm 43-47 Nm. 11. Replace the anti-roll bar drop links and the crossbolt and tighten. Torque crossbolt to 8.1-8.9 daNm 81-89 Nm. 12. Make sure everything is back in place. Replace the wheel and drop the car to the ground. 13. Torque the strut mounting nuts to 2.4-2.9 daNm 24-29 Nm and wishbone mountings to 4.0-4.9 daNm 40-49 Nm. Now repeat it on the other side!!

Updated: March 29th 2011 with method 2, etc. 29/3/11 Gazza82 Enterprises Page 5 of 5

You might also like

- Alfa RomeoDocument53 pagesAlfa RomeoSneha Chauhan0% (1)

- Repair Instructions - On VehicleDocument96 pagesRepair Instructions - On Vehicleoscar vasquezNo ratings yet

- Acura RSX (02-06) Service Manual - Brakes OnlyDocument27 pagesAcura RSX (02-06) Service Manual - Brakes OnlyWill Wolff-Myren67% (3)

- ME 87 enDocument295 pagesME 87 enUserfabian215No ratings yet

- Car Design Archive IndexDocument18 pagesCar Design Archive IndexAnonymous GKqp4HnNo ratings yet

- 9-5 Aero HirschDocument2 pages9-5 Aero Hirschajjyt100% (1)

- Alfa Romeo GT - Bertone ManualDocument159 pagesAlfa Romeo GT - Bertone ManualOgnjenLazarevic100% (2)

- Brake Pads Removal and Installation PDFDocument7 pagesBrake Pads Removal and Installation PDFMichael Hernandez100% (1)

- Ford FiestaDocument52 pagesFord Fiestalucian07No ratings yet

- Baldor. Pump MotorsDocument550 pagesBaldor. Pump MotorsJavier SumozaNo ratings yet

- Alfa 147 Oil PressureDocument15 pagesAlfa 147 Oil PressureStefan SvenssonNo ratings yet

- YotelredesignDocument129 pagesYotelredesignNone None None100% (2)

- BREMBO CALIPERS ALFA 166 ON THE Alfa Romeo 155Document4 pagesBREMBO CALIPERS ALFA 166 ON THE Alfa Romeo 155Mauricio Lopes de OliveiraNo ratings yet

- Defensive Driving-Driver's Handbook PDFDocument20 pagesDefensive Driving-Driver's Handbook PDFaymenmoatazNo ratings yet

- FLC Sensoren Motormanagement Uk Komplett Final Proofed en PDFDocument370 pagesFLC Sensoren Motormanagement Uk Komplett Final Proofed en PDFMiguel Angel Pavon CarbonellNo ratings yet

- Alfa 147 1.9 JTD - Replacing Glow PlugsDocument3 pagesAlfa 147 1.9 JTD - Replacing Glow PlugsddaaggNo ratings yet

- TempDocument6 pagesTempBrian MelNo ratings yet

- Carte Tehnica Alfa RomeoDocument66 pagesCarte Tehnica Alfa RomeoIndianaJones2000No ratings yet

- Alfa 147 - Gearbox Oil Change GuideDocument7 pagesAlfa 147 - Gearbox Oil Change Guidearnold7894No ratings yet

- Analysis of Cost Benchmarking at JCBDocument76 pagesAnalysis of Cost Benchmarking at JCBAbhishek Kumar100% (1)

- Porsche 356: The Engine Handbook: An Engine Assembly GuideFrom EverandPorsche 356: The Engine Handbook: An Engine Assembly GuideNo ratings yet

- Techno Commercial OfferDocument12 pagesTechno Commercial Offert_syamprasadNo ratings yet

- Alfa 147 - Engine Oil Change GuideDocument9 pagesAlfa 147 - Engine Oil Change Guidearnold7894No ratings yet

- The New Alfa Romeo 147 Technical SpecificationDocument4 pagesThe New Alfa Romeo 147 Technical SpecificationDylan Moodley100% (1)

- Alfa 147 - Brake Pad and Disc Change Guide (Front)Document15 pagesAlfa 147 - Brake Pad and Disc Change Guide (Front)arnold7894100% (3)

- ALFA Romeo 147 OEM CodesDocument108 pagesALFA Romeo 147 OEM CodesDragos Valentin StefanNo ratings yet

- Alfa Romeo Brera-Spider Spare Parts PDFDocument124 pagesAlfa Romeo Brera-Spider Spare Parts PDFMiguel CamachoNo ratings yet

- Aj6 Engineering IgnitionDocument9 pagesAj6 Engineering IgnitionBo BoboNo ratings yet

- Alfa Romeo RZ-SZ Spare Parts PDFDocument41 pagesAlfa Romeo RZ-SZ Spare Parts PDFMiguel CamachoNo ratings yet

- Alfa Romeo TSpark Timing Belt ReplacementDocument3 pagesAlfa Romeo TSpark Timing Belt ReplacementPier Angelo PalumboNo ratings yet

- AlfaRomeo 147 2001 en META AlarmDocument2 pagesAlfaRomeo 147 2001 en META Alarmddamir325hotmail.comNo ratings yet

- Parts News - Unicorn (KSPF)Document16 pagesParts News - Unicorn (KSPF)Jonatan Arango60% (5)

- Slide/tilt Sunroof: Volkswagen New BeetleDocument21 pagesSlide/tilt Sunroof: Volkswagen New BeetleHéctor Morales OrtegaNo ratings yet

- Otocheck2 MODE D EMPLOI PDFDocument27 pagesOtocheck2 MODE D EMPLOI PDFBolinha's Wash ClubNo ratings yet

- IALA Maritime Buoyage System 2010Document24 pagesIALA Maritime Buoyage System 2010emile jobity100% (1)

- Components of Railway Track 1Document21 pagesComponents of Railway Track 1Mudasar HussainNo ratings yet

- Quaife ATB DiffDocument5 pagesQuaife ATB DiffMaxim MackenzyNo ratings yet

- Alfa 164 Electronic Suspension Rebuild ManualDocument29 pagesAlfa 164 Electronic Suspension Rebuild ManualJavier0043No ratings yet

- Giulietta ALFA TCT-November 2011Document2 pagesGiulietta ALFA TCT-November 2011Kadir CeranNo ratings yet

- Fuel Pump Flow RatesDocument6 pagesFuel Pump Flow Rateshenry0% (1)

- Catalogo Brembo RacingDocument134 pagesCatalogo Brembo Racingblow100% (1)

- Alfa 156 BrakesDocument6 pagesAlfa 156 BrakesAlexTocuNo ratings yet

- Alfa 147 - GTA Lights Conversion GuideDocument12 pagesAlfa 147 - GTA Lights Conversion Guidearnold7894100% (1)

- Alfa Romeo 156 TS Engine CoolingDocument7 pagesAlfa Romeo 156 TS Engine CoolingSteven Landry100% (1)

- Alfa 166 BrochureDocument12 pagesAlfa 166 BrochureTAZ6416100% (1)

- BMW N47 Intake Inlet Manifold Swirl Flap Removal Delete Blanking Install Instruction Guide RepairDocument12 pagesBMW N47 Intake Inlet Manifold Swirl Flap Removal Delete Blanking Install Instruction Guide RepairUlrik HjalberNo ratings yet

- Alfa Romeo 166 - Road TestDocument1 pageAlfa Romeo 166 - Road TesteephantomNo ratings yet

- Vehicle List - SW Flex Motorola MPC5xx Ver.4.0.0.0: Vehicle Brand Model Engine Engine Type Fuel PS MY ECU Brand ECU TypeDocument33 pagesVehicle List - SW Flex Motorola MPC5xx Ver.4.0.0.0: Vehicle Brand Model Engine Engine Type Fuel PS MY ECU Brand ECU TypeWillian BrucaloNo ratings yet

- 2003-2005 Jaguar XK8Document26 pages2003-2005 Jaguar XK8Anonymous KEIPUEgeMNo ratings yet

- Ksuite 2.24 !Document630 pagesKsuite 2.24 !Fabricio GoulartNo ratings yet

- 2005 9-5 EnginesDocument2 pages2005 9-5 Enginessnappydressedotter100% (1)

- Newman-Cams Pricedata Catalogue2016-1Document72 pagesNewman-Cams Pricedata Catalogue2016-1stalinNo ratings yet

- Fiat Lancia Alfa Romeo 3 Pin ToDocument1 pageFiat Lancia Alfa Romeo 3 Pin ToT_R_E_X_1100% (1)

- Luxury Cars and Its Engie ModelsDocument32 pagesLuxury Cars and Its Engie ModelsArunkumaarPunniamurtNo ratings yet

- Opel Corsa C Oil Filter ReplacementDocument12 pagesOpel Corsa C Oil Filter ReplacementAndrásBakosNo ratings yet

- Lexi 239Document2 pagesLexi 239Ashok Kumar RamuNo ratings yet

- Alfa Romeo LinksDocument4 pagesAlfa Romeo LinksSmolovic Srdjan0% (1)

- Compatibilitate TyresDocument10 pagesCompatibilitate TyresArocoraCababacNo ratings yet

- HID Retrofit For Halogen HeadlightsDocument32 pagesHID Retrofit For Halogen Headlightsanon9114095No ratings yet

- Glyco 1314 - 2 PDFDocument1,284 pagesGlyco 1314 - 2 PDFgume pesaNo ratings yet

- CatalogDocument100 pagesCatalogFrancis Lebel100% (1)

- Alfa MiTo BrochureDocument34 pagesAlfa MiTo BrochureAugusto GerardiNo ratings yet

- 2011-09-16 Amarok Aufbaurichtlinien enDocument80 pages2011-09-16 Amarok Aufbaurichtlinien enJosé Julio Pantac LiNo ratings yet

- Vorschau Dwa A 139e Din en 1610 PDFDocument12 pagesVorschau Dwa A 139e Din en 1610 PDFMuhamed RiskhanNo ratings yet

- Cfe2 L 341 United Kingdom Differentiated Reading Comprehension Activity - Ver - 4Document14 pagesCfe2 L 341 United Kingdom Differentiated Reading Comprehension Activity - Ver - 4makaNo ratings yet

- Volkswagen 5 Speed Manual Gearbox 0af Workshop Manual Edition 062010 D3e801cbf24Document168 pagesVolkswagen 5 Speed Manual Gearbox 0af Workshop Manual Edition 062010 D3e801cbf24thomaskarak100% (1)

- Finite Element Analysis and Optimization of Commercial Bus Body StructureDocument4 pagesFinite Element Analysis and Optimization of Commercial Bus Body StructureerpublicationNo ratings yet

- Application For Shipping Instructions and Notice of AvailabilityDocument2 pagesApplication For Shipping Instructions and Notice of AvailabilityjwmsscribdNo ratings yet

- Length of Lap of Bars To Be Provided As Per Table 15.4 of Irc 112:2011 (For Fe550D Grade Steel)Document1 pageLength of Lap of Bars To Be Provided As Per Table 15.4 of Irc 112:2011 (For Fe550D Grade Steel)Satyavijet ChilakapatiNo ratings yet

- Smart Drive Two Wheeler Insurance Policy: Certificate of Insurance Cum ScheduleDocument2 pagesSmart Drive Two Wheeler Insurance Policy: Certificate of Insurance Cum ScheduleSHILADITYA DEYNo ratings yet

- JVC DR-MV1S VCR-DVDDocument75 pagesJVC DR-MV1S VCR-DVDCaptain444100% (1)

- Track Circuit (Hindi, Eng, Beng)Document17 pagesTrack Circuit (Hindi, Eng, Beng)Kamal KarNo ratings yet

- Approved RAV DWGDocument3 pagesApproved RAV DWGKartik MendirattaNo ratings yet

- RMC 35-2006 Taxation For Freight ForwardersDocument23 pagesRMC 35-2006 Taxation For Freight ForwardersremoveignoranceNo ratings yet

- Pentagon & Boeing 757 Ground Effect: - Question From EricDocument10 pagesPentagon & Boeing 757 Ground Effect: - Question From Ericbalu119No ratings yet

- Despiece Estanque CombustibleDocument3 pagesDespiece Estanque CombustibleRicardo HarringtonNo ratings yet

- Joint Affidavit PDFDocument2 pagesJoint Affidavit PDFRobert Adrian De RuedaNo ratings yet

- KI0120182ENN enDocument2,290 pagesKI0120182ENN enDaiuk.DakNo ratings yet

- BM3Document3 pagesBM3Romeo RajaNo ratings yet

- An Assessment of Maritime Transport Facilities Along The Fako Coastal Belt of CameroonDocument12 pagesAn Assessment of Maritime Transport Facilities Along The Fako Coastal Belt of CameroonInternational Journal of Innovative Science and Research Technology100% (1)

- Freight Report National LevelDocument140 pagesFreight Report National LevelNitin ChandraNo ratings yet

- Sew Movidrive Setup PositioningDocument46 pagesSew Movidrive Setup Positioningnagaraj5581No ratings yet

- Epicyclic Gear TrainDocument12 pagesEpicyclic Gear TrainAmeer ShNo ratings yet

- Retail Brochure 2011Document176 pagesRetail Brochure 2011Oliver GunnellNo ratings yet

- FMG Marine Notice 01-2021 Fortescue Port Hedland Mooring Line StandardsDocument3 pagesFMG Marine Notice 01-2021 Fortescue Port Hedland Mooring Line StandardsShivram VoletyNo ratings yet