Professional Documents

Culture Documents

Incident Invest

Uploaded by

Andy DolmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Incident Invest

Uploaded by

Andy DolmanCopyright:

Available Formats

Root Cause MapTM

.

I

Equipment Equipment Reliability Program Problem

Start here with each causal factor

Personnel

u

Other Difficulty Contract Employee

I

Equipment Design Problem

p-

Installation/ Fabrication

I

Equipment Misuse

Administrative/

F

I

Company Employee

I

Natural Phenomena

11

Sabotage/ Horseplay

12

External Events

13

Other

14

Procedures

Design Input LTA @ Design output 0 LTA

t

I -

Equipment Design Records LTA @ Equipment Operating/ Maintenance History LTA @

No Program @

Program LTA @ Analysis/Design Procedure LTA Inappropriate Type of Maintenance Assigned Q Risk Acceptance Criteria LTA 8 Allocation of Resources LTA

-Corrective Maintenance LTA @ Troubleshooting/ Corrective Action LTA @@ Repair Implementation LTA -Preventive Maintenance LTA @ Frequency LTA Q Scow LTA @ Activity Implementation LTA @ Predictive -Maintenance LTA @ Detection LTA @ Monitoring LTA @ Troubleshooting/ Corrective Action LTA @ Activity Implementation LTA

F I

- Maintenance LTA @

Event Specification LTA @ Monitoring LTA Scope LTA Activity Implementation LTA @ - Failure Finding Maintenance LTA @ Frequency LTA Scope LTA @ Troubleshooting/ Corrective Action LTA Repair Implementation0 - Routine Equipment Rounds LTA 0 Frequency LTA @ Proactive

Engineeringd

L

- Preparation @ No Preparation @

Job Plan LTA @ Instructions to Workers LTA @ Walkthrough LTA @ Scheduling LTA @ Worker Selection/ Assignment LTA @) - Supervision During Work @ Supervision LTA @ Improper Performance & Not Corrected @ Teamwork LTA @ No Communication or Not Timely @ Method Unavailable or LTA @ Communication Between Work Groups LTA Communication Between Shifts and Management LTA @ Communication with Contractors LTA @ Communication with Customers LTA @

1*f,tude/Attention

Problem Detection LTA *Sensory/ Perceptual Capabilities LTA *Reasoning Capabilities LTA *Motor/Physical Capabilities LTA

"RestlSleep LTA (Fatigue)@ *Personal/ Medication Problems

Activity Implementation LTA

Standards, Policies, or Administrative Controls (SPACs) LTA @ No SPACs Not Strict Enough Confusing, Contradictory, or Incomplete 8 *Technical Error 8 Responsibility for Item/Activity Not Adequately Defined 8 Planning, Scheduling, or Trackina of Work Activities LTA Rewards/ Incentives LTA 8 Employee Screening/Hiring LTA @@

Standards, SafetyRlazardlRisk Review @ Policies, or Administrative Review LTA or Not Controls (SPACs) Performed @ Not Used @ Recommendations Communication of Not Yet ' SPACs LTA Implemented Q Recently C h a n g e d m Risk Acceptance Enforcement LTA Criteria LTA 8 Review Procedure LTA

Problem Identification/ Control @ Problem Reporting LTA @ Problem Analysis LTA

*Audits LTA @ Corrective Action LTA @ Corrective Actions Not Yet Implemented @

Product/Material Control @ Handling LTA @ Storage LTA @ Packaging/ Shipping LTA Unauthorized Material Substitution Product Acceptance Criteria LTA @ Product Inspections LTA @

Procurement Document and Customer @ Control Configuration Interface/Services Purchasing Control @ .Customer Specifications LTA @ Change Not Requirements Not Control of Identified @ Identified @ Changes to *Verification of Customer Needs Procurement DesignIField Not Addressdoos) Specifications LTA Changes LTA Implementation Material (NO PSSR) @ LTA Acceptance Documentation Requirements LTA @ Content Not Kept Material Up-to-Date @ Inspections LTA Control of Official Contractor Documents LTA @ Selection LTA @

C B

Standard Terminology Not Used @E) Verification/ Repeat-back Not Used @ Long Message @@

Within Shifts LTA @$ Communication Between Shifts LTA @?)

NoTrainiAg @ Decision Not to Train @ Training Requirements Not Identified @

Training Records System LTA *Training Records Incorrect @@ *Training Records Not Up-to-Date6

a

I

( >

Shape

Description

Primary Difficulty Source Problem Category

Root Cause Category

Near Root Cause

Not Used @ Not Available or Inconvenient to Obtain @ Procedure Difficult to Use Use Not Required but Should Be No Procedure for Task

Root Cause

Note: LTA = Less Than Adequate

Copyrighted 1995, 1997, 1999, 2000, 2001 Rev. 8 (8101)

MisleadinglConfusing 0 Format Confusing or LTA More Than One Action per Step No Checkoff Space Provided but Should Be Q Inadequate Checklist @ Graphics LTA @ Ambiguous or Confusing Instructions/Requirements@ DatdComputations Wrong/ Incomplete@ Insufficient or Excessive References 8 Identification of Revised Steps LTA @ Level of Detail LTA @@ Difficult to Identify @@

Wrong/lncomplete Typographical Error @ Sequence Wrong Q Facts Wrong/ Requirements Not Correct Q Wrong Revision or Expired Procedure Revision Used @ Inconsistency Between Requirements Q Incomplete/Situation Not Covered 8 Overlap or Gaps Between Procedures @?) *Note:

Workplace Layout @ Work Environment @ Workload @ Intolerait System Controls/Displays Housekeeping LTA @ Excessive Control Errors Not LTA @ *Tools LTA @ Action Detectable 8 ControVDisplay Protective Requirements @ Errors Not Integration/ Clothing/ Unrealistic Correctable G@ Monitoring Arrangement LTA @ Equipment LTA Location of Ambient Requirements Q Knowledge-based ControlslDisplays Conditions LTA @ LTA @ Other Decision Required @ Conflicting Environmental Excessive Layouts ( 3 Stresses Calculation or Equipment Excessive @ Data Manipulation Location LTA @ Required @ Labeling of Equipment or Locations LTA @?)

i

Training LTA @3 Job/Task Analysis LTA Program Design/ Objectives LTA Q Lesson Content LTA @ On-the-Job Training LTA Q Qualification Testing LTA @ Continuing Training LTA Q Training Resources LTA @ Abnormal Events/ Emergency Training LTA @

:V:'.'.-r'i:JJ

IX? m-?ILt.l L

These nodes are for descriptive purposes only. Code Only to Personal Performance (Node 208).

www.absconsulting.com/knoxville

(865) 966-5232

You might also like

- Root Cause Failure Analysis Rev 2Document69 pagesRoot Cause Failure Analysis Rev 2clcoolleo100% (1)

- SUPPLI 4 JDocument69 pagesSUPPLI 4 JkvasudevinK123No ratings yet

- Reliability Centered Maintenance-GaryDocument15 pagesReliability Centered Maintenance-GaryAshwin80% (5)

- Software Test Metrics QADocument23 pagesSoftware Test Metrics QApulsarspNo ratings yet

- TPMDocument32 pagesTPMmanolo6490No ratings yet

- International Social Network Maintenance AssessmentDocument12 pagesInternational Social Network Maintenance Assessmentruayo100% (1)

- Effective Metrics For Managing Test EffortsDocument23 pagesEffective Metrics For Managing Test EffortsSanjeev KumarNo ratings yet

- Xfmea Report Sample - Design FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument9 pagesXfmea Report Sample - Design FMEA: in Addition To This Summary, This Report Includes The Following FormsAlejandro José Poveda GuevaraNo ratings yet

- Analysis Work Procedure - V1.0.2Document23 pagesAnalysis Work Procedure - V1.0.2shaikh100% (1)

- RCFA Report Template For Mechanical EquipmentDocument11 pagesRCFA Report Template For Mechanical EquipmentFaisal Tariq100% (1)

- MFG OPM Advisor Webcast 2016 0105Document61 pagesMFG OPM Advisor Webcast 2016 0105Steffi StevenNo ratings yet

- Create Accounting Entries TroubleshootingDocument5 pagesCreate Accounting Entries Troubleshootingriazahmad82No ratings yet

- LEAN Construction Tools and Methods PATTYDocument19 pagesLEAN Construction Tools and Methods PATTYvikrambakshi67No ratings yet

- Xfmea MfmeaDocument6 pagesXfmea Mfmeabojanmarkovic88No ratings yet

- Process Audit ChecklistDocument6 pagesProcess Audit ChecklistzafeerNo ratings yet

- Skill Enterprise ID Date (MM/DD/YYYY) Task ItemDocument5 pagesSkill Enterprise ID Date (MM/DD/YYYY) Task ItemFedex VijayNo ratings yet

- A Testing Roadmap For Complex Oracle E-Business Suite Projects - v2.4Document30 pagesA Testing Roadmap For Complex Oracle E-Business Suite Projects - v2.4Rai Prashant Kumar RaiNo ratings yet

- I AddenergyassetandintegritywhitepaperFinal1Document22 pagesI AddenergyassetandintegritywhitepaperFinal1Mohammad NajibullahNo ratings yet

- Gap AnalysisDocument6 pagesGap AnalysisrajshakeeNo ratings yet

- 5 Why TrainingDocument22 pages5 Why Trainingcpalfas100% (1)

- IRRBADocument135 pagesIRRBAKathleenNo ratings yet

- Operator Log Application: - (Template Format - Excel?)Document2 pagesOperator Log Application: - (Template Format - Excel?)AJNo ratings yet

- TPMDocument32 pagesTPMvignesh_sundaresan_1No ratings yet

- Osa ExamDocument15 pagesOsa ExamDaniel BibleNo ratings yet

- Business System ReviewDocument12 pagesBusiness System Reviewtito1628No ratings yet

- Acceptance Testing & Documentation To Support Validation-PresentationDocument34 pagesAcceptance Testing & Documentation To Support Validation-PresentationpoketupiNo ratings yet

- Control Charts: by Praveen GuptaDocument4 pagesControl Charts: by Praveen GuptaKlemen StrušnikNo ratings yet

- Learn and Practice The Developing A FMEADocument4 pagesLearn and Practice The Developing A FMEAjballinasNo ratings yet

- FMEADocument52 pagesFMEArhobinangel100% (1)

- 7.2.6 APQP Phase 3 Checklist Dec 2013Document39 pages7.2.6 APQP Phase 3 Checklist Dec 2013Mani Rathinam RajamaniNo ratings yet

- Corrective Preventive Action Package List of 27 Files Rev 4-21-09 UsDocument4 pagesCorrective Preventive Action Package List of 27 Files Rev 4-21-09 UsSUNDRAMNAGANo ratings yet

- Job Safety Analysis (Jsa)Document12 pagesJob Safety Analysis (Jsa)eastNo ratings yet

- Metrics (KPI's) To Assess Process PerformanceDocument47 pagesMetrics (KPI's) To Assess Process PerformanceSergio Quintana Rodriguez88% (8)

- Etl Testing: Data Warehouse ConceptsDocument9 pagesEtl Testing: Data Warehouse ConceptssyellaneniNo ratings yet

- 6sigma - Control PhaseDocument130 pages6sigma - Control Phasesathya_145No ratings yet

- TQM Tools and TechniquesDocument95 pagesTQM Tools and TechniqueshafizNo ratings yet

- Purpose:: Customer's Finished Goods Demand ProcessDocument13 pagesPurpose:: Customer's Finished Goods Demand ProcessLiew Chee KiongNo ratings yet

- Application ControlsDocument19 pagesApplication ControlsBabatunde Abioye100% (1)

- Application Security - Input & Interface ControlsDocument47 pagesApplication Security - Input & Interface ControlsTeddy HaryadiNo ratings yet

- Service Management WorkshopDocument34 pagesService Management WorkshopUsman HamidNo ratings yet

- Fault Tracing IntroductionDocument4 pagesFault Tracing IntroductionjgkuchhadiyaNo ratings yet

- Developing A FMEADocument0 pagesDeveloping A FMEAJ Antonio Uribe RiveraNo ratings yet

- 2014 06 23 FMEA SlidesDocument19 pages2014 06 23 FMEA SlidesMadhan RajNo ratings yet

- 2013 - 7QC Story - Brakes Team - Front Pad Worn Out in SumoDocument22 pages2013 - 7QC Story - Brakes Team - Front Pad Worn Out in SumoAvik BanerjeeNo ratings yet

- TPS Checklist UpdatedDocument28 pagesTPS Checklist UpdatedMani Rathinam RajamaniNo ratings yet

- Itil Osa - Exam TipsDocument11 pagesItil Osa - Exam TipsMohammad Faisal AbdulRabNo ratings yet

- MOP For Dell R720 PERC Battery ReplacementDocument7 pagesMOP For Dell R720 PERC Battery ReplacementJP AgcaoiliNo ratings yet

- Test Plan Template Evaluation of Test Results TemplateDocument22 pagesTest Plan Template Evaluation of Test Results Templatemohamed sobhyNo ratings yet

- Statistical Process ControlDocument8 pagesStatistical Process ControlRamchandrarao DeshpandeNo ratings yet

- Techniques for Improving Operational EfficiencyDocument10 pagesTechniques for Improving Operational EfficiencyTripti KhoslaNo ratings yet

- Acl Data Analytics EbookDocument14 pagesAcl Data Analytics Ebookcassiemanok01No ratings yet

- Procurement Process Lean EventDocument23 pagesProcurement Process Lean EventArchana Singh0% (1)

- ITIL® Guide to Software and IT Asset Management - Second EditionFrom EverandITIL® Guide to Software and IT Asset Management - Second EditionRating: 1 out of 5 stars1/5 (1)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Cracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsFrom EverandCracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsNo ratings yet

- Managing the Testing Process: Practical Tools and Techniques for Managing Hardware and Software TestingFrom EverandManaging the Testing Process: Practical Tools and Techniques for Managing Hardware and Software TestingRating: 4 out of 5 stars4/5 (8)

- Customer-Anchored Supply Chains: An Executive’S Guide to Building Competitive Advantage in the Oil PatchFrom EverandCustomer-Anchored Supply Chains: An Executive’S Guide to Building Competitive Advantage in the Oil PatchNo ratings yet

- Reliability - A Shared Responsibility for Operators and Maintenance. 3rd and 4th Discipline of World Class Maintenance Management: 1, #3From EverandReliability - A Shared Responsibility for Operators and Maintenance. 3rd and 4th Discipline of World Class Maintenance Management: 1, #3Rating: 5 out of 5 stars5/5 (1)

- Investigator Name: Event Assessed: Date of Assessment: Investigation Follow-Up Checklist Addressed? Follow-Up Issues Yes NoDocument1 pageInvestigator Name: Event Assessed: Date of Assessment: Investigation Follow-Up Checklist Addressed? Follow-Up Issues Yes NoAndy DolmanNo ratings yet

- Investigator Name: Event Assessed: Date of AssessmentDocument1 pageInvestigator Name: Event Assessed: Date of AssessmentAndy DolmanNo ratings yet

- Investigator Name: Event Assessed: Date of Assessment: Checklist For Formal, Written Reports (See Chapter 11)Document1 pageInvestigator Name: Event Assessed: Date of Assessment: Checklist For Formal, Written Reports (See Chapter 11)Andy DolmanNo ratings yet

- PSM Investigation Compliance ChecklistDocument1 pagePSM Investigation Compliance ChecklistAndy DolmanNo ratings yet

- Incident InvestDocument1 pageIncident InvestAndy DolmanNo ratings yet

- Flashback From Waste Gas Incinerator Into Air Supply Piping: Rohm and Haas Texas Inc Deer Park, TX 77536Document8 pagesFlashback From Waste Gas Incinerator Into Air Supply Piping: Rohm and Haas Texas Inc Deer Park, TX 77536Andy DolmanNo ratings yet

- Sample Investigation Improvement Checklist Incident Investigation GuidelineDocument2 pagesSample Investigation Improvement Checklist Incident Investigation GuidelineAndy DolmanNo ratings yet

- Investigator Name: Event Assessed: Date of AssessmentDocument1 pageInvestigator Name: Event Assessed: Date of AssessmentAndy DolmanNo ratings yet

- Checklist For Developing An Incident Investigation PlanDocument1 pageChecklist For Developing An Incident Investigation PlanAndy DolmanNo ratings yet

- Comprehensive List of CausesDocument1 pageComprehensive List of CausesAndy DolmanNo ratings yet

- Investigator Name: Event Assessed: Date of Assessment:: Sample Human Factors Checklist Incident Investigation GuidelineDocument1 pageInvestigator Name: Event Assessed: Date of Assessment:: Sample Human Factors Checklist Incident Investigation GuidelineAndy DolmanNo ratings yet

- Incident InvestDocument5 pagesIncident InvestAndy DolmanNo ratings yet

- Investigator Name: Event Assessed: Date of Assessment:: Sample Human Factors Checklist Incident Investigation GuidelineDocument1 pageInvestigator Name: Event Assessed: Date of Assessment:: Sample Human Factors Checklist Incident Investigation GuidelineAndy DolmanNo ratings yet

- Sample Formal Report Outline Incident Investigation GuidelineDocument1 pageSample Formal Report Outline Incident Investigation GuidelineAndy DolmanNo ratings yet

- Quick Checklist For Investigators: Physical ItemsDocument4 pagesQuick Checklist For Investigators: Physical ItemsAndy DolmanNo ratings yet

- Customize This List For Your Use. See The CCPS Guideline For Investigating Chemical InformationDocument4 pagesCustomize This List For Your Use. See The CCPS Guideline For Investigating Chemical InformationAndy DolmanNo ratings yet

- Appendix C: Photography Guidelines For Maximum ResultsDocument3 pagesAppendix C: Photography Guidelines For Maximum ResultsAndy DolmanNo ratings yet

- Quick checklist for incident investigatorsDocument5 pagesQuick checklist for incident investigatorsAndy DolmanNo ratings yet

- Incident InvestDocument16 pagesIncident InvestAndy DolmanNo ratings yet

- Appendix B: Professional Assistance DirectoryDocument2 pagesAppendix B: Professional Assistance DirectoryAndy DolmanNo ratings yet

- Propane Tank Flare Off in Topeka Cause and Effect Chart: (Simplified Version) 12-2-02Document2 pagesPropane Tank Flare Off in Topeka Cause and Effect Chart: (Simplified Version) 12-2-02Andy DolmanNo ratings yet

- Appendix F: Selected OSHA and EPA Incident Investigation RegulationsDocument3 pagesAppendix F: Selected OSHA and EPA Incident Investigation RegulationsAndy DolmanNo ratings yet

- Relevant Organizations GuideDocument3 pagesRelevant Organizations GuideAndy DolmanNo ratings yet

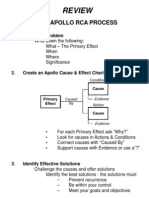

- Review: The Apollo Rca ProcessDocument1 pageReview: The Apollo Rca ProcessAndy DolmanNo ratings yet

- Checklist To Prepare For An Inspection Incident Investigation GuidelineDocument1 pageChecklist To Prepare For An Inspection Incident Investigation GuidelineAndy DolmanNo ratings yet

- Incident InvestDocument21 pagesIncident InvestAndy DolmanNo ratings yet

- Continuous Improvement For The Incident Investigation SystemDocument10 pagesContinuous Improvement For The Incident Investigation SystemAndy DolmanNo ratings yet

- Incident InvestDocument17 pagesIncident InvestAndy DolmanNo ratings yet

- Incident InvestDocument17 pagesIncident InvestAndy DolmanNo ratings yet

- FDP 21-30 SuDocument2 pagesFDP 21-30 SuAmit ModiNo ratings yet

- 95 8657 2.3 FlexSonic AcousticDocument37 pages95 8657 2.3 FlexSonic Acousticsudipta_kolNo ratings yet

- Francis turbines optimizedDocument5 pagesFrancis turbines optimizedmamok supraptoNo ratings yet

- Thor Hanks ResumeDocument1 pageThor Hanks ResumethorhanksNo ratings yet

- 7 Things You Should Know About Augmented Reality PDFDocument2 pages7 Things You Should Know About Augmented Reality PDFKartika LesmanaNo ratings yet

- Intuit Case Study - Analyzing Opportunities for QuickBooks Platform ExpansionDocument6 pagesIntuit Case Study - Analyzing Opportunities for QuickBooks Platform ExpansionAndrés Pérez100% (1)

- Best of SQL Server Central Vol 2Document195 pagesBest of SQL Server Central Vol 2madhavareddy29100% (3)

- Sonet SDH LectureDocument36 pagesSonet SDH LectureStar LightNo ratings yet

- Benchtop Water Quality Meters 1000 SeriesDocument12 pagesBenchtop Water Quality Meters 1000 Serieschaerul.anwar554No ratings yet

- CHAPTER 2 Product DesignDocument20 pagesCHAPTER 2 Product DesignAkash JainNo ratings yet

- Build a 5W 40M CW TransmitterDocument2 pagesBuild a 5W 40M CW TransmitterRicardo MorimNo ratings yet

- Account Summary: Total Due $670.47Document4 pagesAccount Summary: Total Due $670.47Susan Stanley100% (4)

- Kidde - Spec - ECS - Novec 1230 - 8-14 PDFDocument7 pagesKidde - Spec - ECS - Novec 1230 - 8-14 PDFMarcio BritoNo ratings yet

- B15-Content - Analysis - in - Social - Media (1) - BbhavaniDocument59 pagesB15-Content - Analysis - in - Social - Media (1) - Bbhavanigandhambhavani2003No ratings yet

- Tariq Javed's Resume for Accounts Executive RoleDocument3 pagesTariq Javed's Resume for Accounts Executive RoleTariq Javed100% (1)

- Hps 21avp EeDocument1 pageHps 21avp EeSekoNo ratings yet

- Lecture 8Document34 pagesLecture 8Anonymous rcmeSfj5No ratings yet

- Optimum 4-Cylinder Engine Design via 1D CFD SimulationDocument7 pagesOptimum 4-Cylinder Engine Design via 1D CFD SimulationZohaib AliNo ratings yet

- Beyerdynamic Accessories 1Document6 pagesBeyerdynamic Accessories 1Mario HdezNo ratings yet

- Epson L1300 A3 Colour Inkjet Tank System Printer DatasheetDocument2 pagesEpson L1300 A3 Colour Inkjet Tank System Printer DatasheetWebAntics.com Online Shopping StoreNo ratings yet

- Science, Technology As A Way of RevealingDocument6 pagesScience, Technology As A Way of RevealingJonas Boadilla100% (1)

- Ahmadu Bello University Zaria: COSC 801: Operating System Assignment REG: P18PSCS8037Document4 pagesAhmadu Bello University Zaria: COSC 801: Operating System Assignment REG: P18PSCS8037JoshuaNo ratings yet

- Basic Computer SkillDocument61 pagesBasic Computer SkillSyed Umar Shirazi Hashmi100% (2)

- Catalogue AMF Standard Clamping ElementsDocument168 pagesCatalogue AMF Standard Clamping ElementsLang AwNo ratings yet

- Module Week 7 - 8Document13 pagesModule Week 7 - 8Maden betoNo ratings yet

- Leading The Industry In: Solar Microinverter TechnologyDocument2 pagesLeading The Industry In: Solar Microinverter TechnologydukegaloNo ratings yet

- Manual OfcDocument38 pagesManual OfcAnonymous eWMnRr70qNo ratings yet

- Water Cooled Chiller GuideDocument5 pagesWater Cooled Chiller GuideMUHAMMAD TAHANo ratings yet

- SB286 Update For EMV Book C 5Document4 pagesSB286 Update For EMV Book C 5Raven 83No ratings yet

- W441 - Mustang Power Wheel ManualDocument26 pagesW441 - Mustang Power Wheel ManualMarcos JuarezNo ratings yet