Professional Documents

Culture Documents

Mill Heat Balance

Uploaded by

Anonymous NxpnI6jCOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mill Heat Balance

Uploaded by

Anonymous NxpnI6jCCopyright:

Available Formats

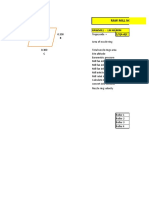

Coal Mill Heat Balance ( Non-Inert : Cooler Gases)

Total wet feed to mill Feed Moisture Residual Moisture False Air

55 18.489 1.5 18 Mass TPH

TPH % % % Sp. Heat (Kcal/kg/oC) Temp oC Heat Cont. (Kcal/h) *1000

INPUT: Material Water Cooler Hot Air Recirculation Air False Air Grinding Heat(Mot. KW)------> Total Input

44.831 10.169 121.49 10 18.532 425 KW

0.27 1.00 0.24 0.24 0.24

25 25 280 60 30

304.6 254.2 8321.1 143.6 132.7 347.7 9504.0

OUTPUT: Material Residual Water Evaporated water Air Radiation Total Output

44.831 0.6625 9.5063 150.02

0.29 1.00 0.45 0.24

70.0

907.9 46.4 5958.5 2498.7 92.5 9504.0

HEAT BALANCE FLAG(Green if Heat Balance is OK)>>>>>

Press To Adjust outlet temperature for Balance

0.0

Press to Adjust Cooler Hot Air Quantity for Balance

Press to Adjust Feed Moisture for Balance

Press to Adjust Cooler Hot Air Temperaturefor Balance

This sheet has been created by Rajiv Sadavarti on November 20, 2008. Rev 0.

1. This sheet is valid only for Non- Inert Coal Mill. 2. While loading the sheet; macros shall be enabled. 3. All the data appearing in yellow boxes can be changed as per the requirements. 4. Buttons at the bottom are "coded" to do an auto heat balance based on the button caption. 5. With changes if the Heat is not balanced the flag will turn red. 6. Pressing any of the Heat Balance buttons at the bottom will do the balancing and turn the flag green. 7. This Heat Balance is Preliminary and will be reviewed.

You might also like

- Raw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesDocument3 pagesRaw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesRamachandrarao MaddaliNo ratings yet

- Vertical Mill CalculationsDocument12 pagesVertical Mill CalculationsAbhijeet Jhankal100% (1)

- Rotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationDocument1 pageRotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationVijay Bhan80% (5)

- Kiln Thermal LoadDocument33 pagesKiln Thermal Loadeng_mhassan1100% (1)

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocument4 pagesA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneNo ratings yet

- How To Measure False AirDocument3 pagesHow To Measure False AirTamer Fathy100% (3)

- Kiln OperationDocument27 pagesKiln Operationrecai100% (1)

- Mill Ventilation MeasurementDocument5 pagesMill Ventilation MeasurementBùi Hắc HảiNo ratings yet

- Process Problem Trouble ShootingDocument13 pagesProcess Problem Trouble ShootingMin Zayar100% (2)

- Kiln Heat Balance 1Document33 pagesKiln Heat Balance 1Bùi Hắc HảiNo ratings yet

- Coal CombustionDocument3 pagesCoal CombustionRahul ChandrawarNo ratings yet

- Cement Kiln Shell Specific Surface Radiation Loss CalculationDocument2 pagesCement Kiln Shell Specific Surface Radiation Loss CalculationvvijaybhanNo ratings yet

- Clinker Vs Kiln Feed FactorDocument3 pagesClinker Vs Kiln Feed FactorSSAC PVT.LTD.No ratings yet

- 6 Bag House BasicsDocument27 pages6 Bag House BasicsPANKAJ AGRAHARI100% (1)

- Heat CalcultionDocument4 pagesHeat CalcultionDgk RajuNo ratings yet

- Loesche Round Table VICAT PDFDocument20 pagesLoesche Round Table VICAT PDFrecaiNo ratings yet

- High VM Coal With 3% SulphurDocument1 pageHigh VM Coal With 3% SulphurIrshad HussainNo ratings yet

- 03 QualityDocument22 pages03 QualityMKPashaPasha67% (3)

- Shree Cement - WHR PPT 15.6.16 - SCLDocument22 pagesShree Cement - WHR PPT 15.6.16 - SCLSivakumaran RajuNo ratings yet

- Coal MillDocument84 pagesCoal MillPartha MisraNo ratings yet

- By Pass SystemDocument56 pagesBy Pass SystemIrshad Hussain100% (2)

- Vertical Raw Mill Heat Balance - SolutionDocument3 pagesVertical Raw Mill Heat Balance - SolutionSai Sricharan Reddy80% (5)

- Kiln Control VariablesDocument50 pagesKiln Control VariablesElder A. Gutiérrez Villacorta100% (1)

- Kiln Cooler Heat Mass BalanceDocument84 pagesKiln Cooler Heat Mass BalancePrabhakar Reddy PeramNo ratings yet

- Clinker Vs Kiln Feed FactorDocument3 pagesClinker Vs Kiln Feed Factorvvijaybhan100% (6)

- VRM Heat and Mass BalanceDocument1 pageVRM Heat and Mass BalanceRajeshRockNo ratings yet

- Clinker Drop Test - Kiln 2: ObjectiveDocument10 pagesClinker Drop Test - Kiln 2: ObjectiveJunaid MazharNo ratings yet

- Heat & Mass Equation For CementDocument99 pagesHeat & Mass Equation For Cementamit100% (1)

- Pyro Process Equipment PDFDocument114 pagesPyro Process Equipment PDFMohamedNo ratings yet

- Kiln TrippingDocument13 pagesKiln Tripping7atemmohNo ratings yet

- SOP-Kiln Start Up and OperationDocument4 pagesSOP-Kiln Start Up and OperationJCS100% (3)

- 4 - False Air Profile Dry Preheater KilnDocument1 page4 - False Air Profile Dry Preheater KilnSundara SubramaniyanNo ratings yet

- Cement Kiln Pyro BalanceDocument45 pagesCement Kiln Pyro BalanceirfanNo ratings yet

- CM2 Process Media Mix Up 2014 2015Document31 pagesCM2 Process Media Mix Up 2014 2015Junaid MazharNo ratings yet

- Mod 6Document49 pagesMod 6mkpq100% (1)

- Heat & Mass BalanceDocument65 pagesHeat & Mass BalanceYhaneNo ratings yet

- Combustion ManualDocument60 pagesCombustion ManualPradeep Kumawat100% (1)

- Studies of Cement Mill CircuitDocument3 pagesStudies of Cement Mill CircuitRobson de Freitas Werling100% (1)

- Ball Mill Heat Balance ExplanationDocument4 pagesBall Mill Heat Balance ExplanationVisnu Sankar67% (3)

- What Kiln Operator Should Do in Emergency SituationDocument12 pagesWhat Kiln Operator Should Do in Emergency SituationLe HoangNo ratings yet

- Technological Advancement in Cement Manufacturing Industry: System Length DiameterDocument16 pagesTechnological Advancement in Cement Manufacturing Industry: System Length Diameterfaran100% (3)

- Formulas KilnDocument5 pagesFormulas Kilnzain1400% (1)

- Flame MomentumDocument1 pageFlame Momentumayaskant751001No ratings yet

- Nozzle Ring Area of Raw MillDocument6 pagesNozzle Ring Area of Raw MillMohd Ali100% (7)

- Material Residence Time in KilnDocument2 pagesMaterial Residence Time in KilnVijay Bhan100% (2)

- Loesche Round Table VICATDocument20 pagesLoesche Round Table VICATFirdaus Azizan86% (7)

- False Air - Measuerment OverviewDocument11 pagesFalse Air - Measuerment OverviewVijay BhanNo ratings yet

- Grinding System and Circuit of VRM Process Data Plant DataDocument58 pagesGrinding System and Circuit of VRM Process Data Plant DataFasil Ayele60% (5)

- Pheater Heat BalanceDocument2 pagesPheater Heat BalanceRaji SuriNo ratings yet

- Pyro & Cooler Heat & Mass Balance Ed1Document2 pagesPyro & Cooler Heat & Mass Balance Ed1JCSNo ratings yet

- 007.heat Balance - New - 25072023hoDocument30 pages007.heat Balance - New - 25072023hoGauranka MoranNo ratings yet

- Summaries: Summary Mass BalanceDocument51 pagesSummaries: Summary Mass Balanceirfan100% (1)

- Copy of Model Calculation NKarthickDocument22 pagesCopy of Model Calculation NKarthickHsein WangNo ratings yet

- Heat Balance WriteDocument4 pagesHeat Balance WriteFaimulNo ratings yet

- Pyro Heat Balance 8000TPD @23.03.2023Document2 pagesPyro Heat Balance 8000TPD @23.03.2023harikrushnaNo ratings yet

- Triplex BoilerDocument53 pagesTriplex Boilershahroze mustafaNo ratings yet

- Line I Heat BalanceDocument60 pagesLine I Heat Balancehmaza shakeelNo ratings yet

- Mass BalanceDocument20 pagesMass BalanceBhaskar BethiNo ratings yet

- Garbage IncineratorDocument59 pagesGarbage IncineratorgsdaundhNo ratings yet

- Determination of Principal Plant Component EfficienciesDocument9 pagesDetermination of Principal Plant Component EfficienciesThabo MosweuNo ratings yet

- Solid Fuel PreperationDocument1 pageSolid Fuel PreperationvvijaybhanNo ratings yet

- Gyratory Screen - LimestoneDocument1 pageGyratory Screen - LimestonevvijaybhanNo ratings yet

- Thermal Equivanlts For Various FuelsDocument1 pageThermal Equivanlts For Various FuelsvvijaybhanNo ratings yet

- Construction - Hammer MillDocument1 pageConstruction - Hammer MillvvijaybhanNo ratings yet

- Hammer Mill OperationDocument1 pageHammer Mill OperationvvijaybhanNo ratings yet

- Cement Kiln Performance CalculationsDocument9 pagesCement Kiln Performance Calculationsvvijaybhan0% (2)

- Mill CIRCUIT SAMPLESDocument2 pagesMill CIRCUIT SAMPLESvvijaybhanNo ratings yet

- Cement Kiln StartupDocument1 pageCement Kiln StartupvvijaybhanNo ratings yet

- Ball Mill CalculationsDocument12 pagesBall Mill Calculationsvvijaybhan80% (15)

- S. Description Symbol Unit No.: F.L. Smidth's ATOX Vertical Roller MillDocument2 pagesS. Description Symbol Unit No.: F.L. Smidth's ATOX Vertical Roller Millvvijaybhan0% (1)

- Conversion Factor For NOx and SOx CalculationsDocument2 pagesConversion Factor For NOx and SOx CalculationsvvijaybhanNo ratings yet

- Fuel and Combustion CalculationsDocument6 pagesFuel and Combustion Calculationsvvijaybhan100% (2)

- Gearbox Reduction RatioDocument1 pageGearbox Reduction RatiovvijaybhanNo ratings yet

- Raw Mix Design SoftwareDocument7 pagesRaw Mix Design Softwarevvijaybhan100% (9)

- Cement Kiln Shell Specific Surface Radiation Loss CalculationDocument2 pagesCement Kiln Shell Specific Surface Radiation Loss CalculationvvijaybhanNo ratings yet

- Screw Conveyor CalculationDocument14 pagesScrew Conveyor Calculationvvijaybhan100% (2)

- Cement Kiln Shell Specific Surface Radiation Loss CalculationDocument2 pagesCement Kiln Shell Specific Surface Radiation Loss CalculationvvijaybhanNo ratings yet

- Tromp Curve CalculationDocument6 pagesTromp Curve Calculationvvijaybhan83% (6)

- Max Ball Size With Respect To Mill Feed SizeDocument3 pagesMax Ball Size With Respect To Mill Feed Sizevvijaybhan100% (1)

- Cement Kiln Shell Specific Surface Radiation Loss CalculationDocument2 pagesCement Kiln Shell Specific Surface Radiation Loss CalculationvvijaybhanNo ratings yet

- BALL MILL - Ball Charge Composition Piece Weight & Specific SurfaceDocument1 pageBALL MILL - Ball Charge Composition Piece Weight & Specific Surfacevvijaybhan100% (1)

- Blaine Vs OutputDocument2 pagesBlaine Vs Outputvvijaybhan100% (1)

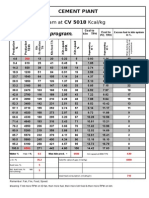

- Clinker Production Caliculation ProgramDocument3 pagesClinker Production Caliculation Programvvijaybhan100% (1)

- Ball Mill Degree of Filling CalculationDocument4 pagesBall Mill Degree of Filling Calculationvvijaybhan100% (2)

- Gera Box CalculationDocument1 pageGera Box CalculationvvijaybhanNo ratings yet

- Ball Mill Grinding Media Max Ball Size CalculationDocument2 pagesBall Mill Grinding Media Max Ball Size Calculationvvijaybhan100% (1)

- Lime Stone Stock Pile CalculationDocument1 pageLime Stone Stock Pile CalculationvvijaybhanNo ratings yet

- Fan Flow CalculationDocument1 pageFan Flow CalculationvvijaybhanNo ratings yet

- Gera Box CalculationDocument1 pageGera Box CalculationvvijaybhanNo ratings yet

- Blaine Apparatus CalibrationDocument1 pageBlaine Apparatus Calibrationvvijaybhan50% (2)

- Science TG Grade 8Document225 pagesScience TG Grade 8Aabdu Zhaif Andal100% (1)

- Corken ManualDocument24 pagesCorken Manualطارق سويد100% (1)

- AS LEVEL IT 9626 A LEVEL IT 9626 Monitoring and ControlDocument17 pagesAS LEVEL IT 9626 A LEVEL IT 9626 Monitoring and ControlTooba Farooq100% (1)

- Chapter 5b Crystal Imperfections Dislocations PDFDocument94 pagesChapter 5b Crystal Imperfections Dislocations PDFManjeet SinghNo ratings yet

- BBBBDocument16 pagesBBBBLidetu AbebeNo ratings yet

- Solution # 2: Department of Physics IIT Kanpur, Semester II, 2022-23Document4 pagesSolution # 2: Department of Physics IIT Kanpur, Semester II, 2022-23darshan sethiaNo ratings yet

- Us 3871298Document13 pagesUs 3871298Phúc DuyNo ratings yet

- Kryotech Problem StatementDocument2 pagesKryotech Problem StatementMohammed MohsinNo ratings yet

- Pig Launcher and ReceiverDocument2 pagesPig Launcher and ReceiverDhanushNo ratings yet

- Renewable and Sustainable Energy Reviews: Wei-Bo ZhangDocument11 pagesRenewable and Sustainable Energy Reviews: Wei-Bo ZhangFredy Akenaton ArroyoNo ratings yet

- REL650Document79 pagesREL650denisseNo ratings yet

- JSA TemplateDocument3 pagesJSA TemplateJob MateusNo ratings yet

- Current Issues: Report OutlineDocument6 pagesCurrent Issues: Report OutlinePangihutan HutaurukNo ratings yet

- Rebuilding The 6.6L Duramax Diesel PDFDocument13 pagesRebuilding The 6.6L Duramax Diesel PDFJuan Contreras100% (3)

- ch-1 Basics of Railway System CIVILDocument61 pagesch-1 Basics of Railway System CIVILmamaNo ratings yet

- Turbine Operation and Maintenance ManualDocument31 pagesTurbine Operation and Maintenance ManualTaufik TajudinNo ratings yet

- Osmium - Os: Chemical Properties of Osmium Health Effects of Osmium Environmental Effects of OsmiumDocument15 pagesOsmium - Os: Chemical Properties of Osmium Health Effects of Osmium Environmental Effects of Osmiumshoaibansari641No ratings yet

- Assignment 2 V2 TM 18ME54Document1 pageAssignment 2 V2 TM 18ME54rudresh JmNo ratings yet

- Deep Trouble - Oil Spills RAZDocument9 pagesDeep Trouble - Oil Spills RAZJaime PDNo ratings yet

- Recirculation of Lab AirDocument1 pageRecirculation of Lab AirAhmed LabibNo ratings yet

- Contents Electronic Circuits For AllDocument8 pagesContents Electronic Circuits For AllmoiNo ratings yet

- Pim1Strun BR: Product DocumentationDocument9 pagesPim1Strun BR: Product DocumentationRílammis SantosNo ratings yet

- NIMONIC263 UNS N07263 Sheets & Plates in IndiaDocument3 pagesNIMONIC263 UNS N07263 Sheets & Plates in IndiaOZAIRTRADELINKNo ratings yet

- Discussion Tray DryerDocument3 pagesDiscussion Tray DryerNoor Fatihah100% (1)

- NASA Surface Meteorology and Solar Energy - Available Tables PDFDocument12 pagesNASA Surface Meteorology and Solar Energy - Available Tables PDFJoshua RealsteelNo ratings yet

- CAT 3126 Parts Manuals PDFDocument1,040 pagesCAT 3126 Parts Manuals PDFDavid B100% (5)

- Basic Ideas: 1.1. The Born-Oppenheimer ApproximationDocument3 pagesBasic Ideas: 1.1. The Born-Oppenheimer ApproximationWafaa NNo ratings yet

- Shell Turbo Oil T32: Performance, Features & BenefitsDocument2 pagesShell Turbo Oil T32: Performance, Features & BenefitsElias GabrielNo ratings yet

- Schwab Family ValuesDocument18 pagesSchwab Family ValuesguingooNo ratings yet

- Ashrae D 90405 20100120 PDFDocument233 pagesAshrae D 90405 20100120 PDFrgopikrishna313No ratings yet