Professional Documents

Culture Documents

3 Otta Seal

Uploaded by

Priti PaudelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Otta Seal

Uploaded by

Priti PaudelCopyright:

Available Formats

International Focus Group on Rural Road Engineering

Information Note

Otta Seal

Category : Technical Information/On-carriageway/

BACKGROUND

An Otta seal is a thin bituminous seal comprising graded gravel or crushed aggregate containing all sizes and either a cut-back or soft penetration grade bitumen. Otta seals should be considered when;

a road is to be constructed in a remote area where only natural gravels occur; workmanship may be of indifferent quality; flexibility and durability are required to tolerate low quality, low bearing capacity pavements; or there is a low maintenance capability.

GENERAL DESCRIPTION

An Otta seal comprises of a layer of binder followed by a layer of aggregate that is rolled into the binder using a pneumatic tyred roller or loaded trucks. It is different to surface dressing in that an 'all in' graded gravel or crushed aggregate is used instead of single sized chippings. It depends for its success on the binder being squeezed up through the aggregate by the action of extensive rolling. Due to the fines in the aggregate, 2 to 3 days or longer of pneumatic-tyred compaction (rollers or traffic) are required to fully coat all the particles. An Otta seal may be applied in a single or double layer. Evidence on the performance of these types of seal constructed by conventional plant methods has shown them satisfactory for over 12 years on roads carrying up to 300 vehicles per day. Binder and aggregate design is by judgement and must be established through trials. Inadequate trials can give poor results and a loss of confidence in the construction technique. A wide range of aggregate sources and types can be used.

DESIGN ASPECTS

Aggregate The grading of the aggregate material is based on the the level of traffic expected. Recommended grading envelopes are given in Table 1. Generally for roads carrying light traffic (less than 100 vehicles per day), a 'coarse' grading should be chosen while a 'dense' grading should be applied to roads carrying greater than 100 vehicles per day.

Page 1

www.ifgworld.org

International Focus Group on Rural Road Engineering

Information Note

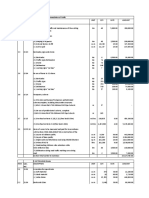

Table 1 Sieve (mm) 19.0 16.0 13.2 9.5 6.7 4.75 2.00 1.180 0.425 0.075 Dense grading Percentage passing1 100 93 - 100 84 - 100 70 - 98 54 - 80 44 - 70 20 - 48 15 - 38 7 - 25 3 - 10 100 84 - 100 68 - 94 44 - 73 29 - 54 19 - 42 3 - 18 1 - 14 0-6 0-2 100 80 - 100 52 - 82 36 - 58 20 - 40 10 - 30 0-8 0-5 0-2 0-1 Medium grading Coarse grading

The amount of fines (<0.075 mm) should not exceed 10 per cent. A higher fines content than this may result in construction problems through the finer particles being coated before the larger ones which can result in a less durable surfacing. Plasticity Index of the aggregate must not exceed 10. No requirement for Flakiness Index is required for natural gravel or a mixture of crushed rock and natural gravel in Otta seals. If crushed rock material is used on its own then the Flakiness Index must not exceed 30. The Flakiness Index is determined on the following fractions; 9.5 13.2 mm, 6.7 9.5 mm and 4.75 6.7 mm. The aggregate strength requirements are shown in Table 2 and spread rates in Table 3.

Page 2

www.ifgworld.org

International Focus Group on Rural Road Engineering

Information Note

Table 2

Vehicles per day <100 >100 Minimum Dry 10% FACT 90 kN 110 kN Minimum Wet/Dry strength ratio 0.60 0.75 Aggregate strength requirements

Table 3 Aggregate spread rate m3/m2 Dense grading Medium grading 0.016 0.020 0.013 0.016 Binder The viscosities of binders used in construction should reflect the grading of aggregate employed and the level of traffic at the time of construction. Normally MC 800, MC 3000 or 150/200 penetration grade bitumen are used. Table 4 shows the recommended binders for Otta seals with different aggregate gradings and traffic levels. Table 4 Annual Average Daily Traffic More than 1000 Aggregate grading Dense Medium MC 3000 MC 800 below 15oC MC 3000 MC 800 below 15oC MC 800 150/200 pen.

Coarse grading 0.013 0.016

Coarse Not suitable for Otta seal

100 1000 Less than 100

150/200 pen. MC 3000

150/200 pen. 150/200 pen.

Spray rates are not calculated by design and must be chosen empirically through road trials. The range of spray rates for different levels of traffic that can be employed during trials is given below.

o o o

Average annual daily traffic <100 Average annual daily traffic 100 500 Average annual daily traffic >500

1.8 - 2.2 l/m2 1.8 - 2.0 l/m2 1.6 - 1.8 l/m2

Page 3

www.ifgworld.org

International Focus Group on Rural Road Engineering

Information Note

Best results are achieved by spraying the bituminous binder with a self propelled or tractor drawn bitumen distributor. However application by hand lance, if skilfully carried out, can achieve satisfactory work on small-scale work.

Binder distributor

CONSTRUCTION ASPECTS

It is because of the broad range of materials that may be used and the empirical nature of the design of this type of seal that it is imperative that pre-construction trials be carried out. This strategy will enable any special local conditions concerning the available aggregates and binders to become apparent to the engineer so he can adjust the nominal design. Preparation for otta sealing An Otta seal will not add to the structural strength of the road and therefore the surface to be treated must previously have been prepared to withstand the expected traffic levels. Preparation of the roadbase may include regravelling, reshaping and compaction. Immediately prior to the construction of the Otta seal the roadbase must be broomed free of sand and excess dust, mud or any other material that might hinder bonding between the seal and roadbase. Priming of the roadbase of non-calcareous material is not normally required. Calcareous material does require priming due to its capacity to absorb high amounts of bitumen. MC 30 or MC 70 is normally used for priming and are applied at spray rates between 0.8 and 1.2 l/m2.

Page 4

www.ifgworld.org

International Focus Group on Rural Road Engineering

Information Note

Stockpiles of aggregate must be inspected to see if screening is needed to remove excess fines or over large particles. The spreading of aggregate can be carried out with conventional mechanical methods or by more labour intensive methods. If aggregate is to be spread by hand then small stockpiles must be placed in sufficient quantities on either side of the road to be treated at approximately every 10 metres. The aggregate must be placed so as not to interfere with the binder spraying operation. Otta sealing construction 1. The area of road to be treated must be marked out by some means such as with string or small stones. This will ensure the correct placement of binder and no overspray onto adjoining vergeside areas. 2. Controls must be put in place to prevent traffic encroaching within the area of construction. 3. The binder distributor should be loaded with sufficient binder to complete the work area and be at the correct temperature for spraying. 4. Cut-off sheets of paper or other material must be placed across the road at the start and end of the length of road to be sprayed. This produces a tidy appearance. 5. Check the speed of the distributor will be driven will produce the design binder spray rate. 6. Check the aggregate has been placed correctly and the workforce are ready to spread the aggregate after the distributor run. 7. Check equipment for rolling is positioned ready for rolling. 8. It is recommended the distributor makes a spray run of 100 metres to allow for immediate covering of the binder with aggregate. Rolling will be able to begin within 10 minutes of the binder being applied. 9. Spreading of the aggregate must begin immediately after the spraying of binder has begun. The binder must be covered with aggregate as soon as possible. 10. The supervisor must check no areas are left uncovered or too little aggregate is spread. Aggregate must not be left in heaps and a drag broom pulled manually or by tractor can help ensure an even distribution before rolling begins. 11. 12 tonne pneumatic-tyred rollers must be used in the construction of Otta seals although it is possible to use loaded trucks in their place. The section of treated road may be reopened to traffic after 3 passes of the rollers but on the day of construction, the surface treated must receive a minimum total of 15 passes. 12. Traffic must be restricted in speed to 30 kilometres per hour for two to three weeks after construction to minimise the hazard of loose excess aggregate being thrown up into the air. 13. During this initial period, aggregate that has been displaced by the action of traffic should be broomed back into the wheelpaths. After 2 to 3 weeks the excess aggregate should be swept away and the traffic speed restriction can be lifted. 14. If a second layer is to be constructed to make a double Otta seal, then a minimum of 2 to 3 months should pass before construction takes place.

Page 5

www.ifgworld.org

International Focus Group on Rural Road Engineering

Information Note

Completed Otta seal An important aspect of Otta seal construction that can not be over stressed is the need for extensive rolling by pneumatic rollers for two to three days or longer after construction. The action of rolling ensures the binder is forced upwards, coating the aggregate, and thereby initiating the process, continued by subsequent trafficking, of forming a premix like appearance to the surface.

REFERENCE DATA AND FURTHER INFORMATION

The Design, Construction and Maintenance of Otta Seals, Guideline No.1. Roads Department, Ministry of Works, Transport and Communications. Republic of Botswana, June 1999. A Guide to the Use of Otta Seals, Publication No. 93, Norwegian Public Roads Administration, Directorate of Public Roads, Road Technology Department, International Division, Oslo, August 1999.

Page 6

www.ifgworld.org

You might also like

- 04 LVSR Wshop Kenya Feb06 OttaSeal ChOverbyDocument38 pages04 LVSR Wshop Kenya Feb06 OttaSeal ChOverbyAbdoAbdelNo ratings yet

- Claycrete English v3Document22 pagesClaycrete English v3supernaenergy100% (1)

- Envirotac's Polymers & Applications For Dust Control & Soil StabilizationDocument16 pagesEnvirotac's Polymers & Applications For Dust Control & Soil StabilizationEP&A EnvirotacNo ratings yet

- Manual - Otta SealDocument70 pagesManual - Otta SealJhossep David C. L100% (2)

- Reclaimed Asphalt Pavement (RAP) Management PlanDocument13 pagesReclaimed Asphalt Pavement (RAP) Management Planali ghNo ratings yet

- Catalogo Inglese Iterchimica 2019 PDFDocument38 pagesCatalogo Inglese Iterchimica 2019 PDFBesim QelajNo ratings yet

- Asphaltic MixturesDocument30 pagesAsphaltic MixturesFlorin MatisNo ratings yet

- Man8 PDFDocument72 pagesMan8 PDFCarel De JagerNo ratings yet

- Catalogue of DefectsDocument3 pagesCatalogue of DefectsChoo Fu-KiatNo ratings yet

- Nitoproof 120Document2 pagesNitoproof 120Balasubramanian AnanthNo ratings yet

- K31 Company Profile 2021Document15 pagesK31 Company Profile 2021abdellatifNo ratings yet

- FT GeotextilesDocument2 pagesFT GeotextilesElber Ramiro Olivares BareñoNo ratings yet

- Cold Mix Technology CRRI PDFDocument76 pagesCold Mix Technology CRRI PDFvvt102No ratings yet

- Zydex Nanotechnology For Green Roads-22Aug2014Document39 pagesZydex Nanotechnology For Green Roads-22Aug2014willypraviantoNo ratings yet

- Métodos de Diseño de Mezclas Asfálticas.Document151 pagesMétodos de Diseño de Mezclas Asfálticas.Fernando VaronNo ratings yet

- ProjectDocument58 pagesProjectsanjeet kumar sinhaNo ratings yet

- Resilient Modulus and Dynamic Modulus of Warm Mix AsphaltDocument8 pagesResilient Modulus and Dynamic Modulus of Warm Mix AsphaltJorge LuisNo ratings yet

- Foamed Asphalt MixDocument32 pagesFoamed Asphalt Mixentree4527No ratings yet

- Manual Otta Seal PDFDocument70 pagesManual Otta Seal PDFWambugu MaInaNo ratings yet

- Asphalt Concrete With Encapsulated CbsDocument13 pagesAsphalt Concrete With Encapsulated CbsMariaNilaZaragozaPalacioNo ratings yet

- Use of PET (POLY ETHYLENE TERAPHTALATE) WASTE in Bituminous Road Construction - A Critical ReviewDocument4 pagesUse of PET (POLY ETHYLENE TERAPHTALATE) WASTE in Bituminous Road Construction - A Critical ReviewijeteeditorNo ratings yet

- Argus Americas AsphaltDocument10 pagesArgus Americas AsphaltRvrch FVNo ratings yet

- 75 81 EngDocument84 pages75 81 Engmehrdad_so1981No ratings yet

- 21 Shamim ZafarDocument30 pages21 Shamim ZafarUsman RafiqNo ratings yet

- Zycotherm AsDocument4 pagesZycotherm AsKreesthu ReddyNo ratings yet

- Development of in Situ Mass Stabilization Technique in FinlandDocument6 pagesDevelopment of in Situ Mass Stabilization Technique in Finlandvickneshj9406No ratings yet

- Tire Rubber Modified AsphaltDocument25 pagesTire Rubber Modified Asphaltzeidan111No ratings yet

- Micro Surfacing Process Design Overview - 0Document3 pagesMicro Surfacing Process Design Overview - 0RenugopalNo ratings yet

- Asphalt Reinforcement With ARTER GTA A 50-50-35 GeogridsDocument13 pagesAsphalt Reinforcement With ARTER GTA A 50-50-35 GeogridssgondoschNo ratings yet

- A Road Building Opportunity PURE - CRETE - Eng - 02252011Document48 pagesA Road Building Opportunity PURE - CRETE - Eng - 02252011PAYLEUNo ratings yet

- Austroads Technical ReportDocument27 pagesAustroads Technical ReportelexdosNo ratings yet

- Open Letter To Hon. Narendra Modi On Gross Wastage of Public Funds On Bituminous Resurfacing of Rural RoadsDocument6 pagesOpen Letter To Hon. Narendra Modi On Gross Wastage of Public Funds On Bituminous Resurfacing of Rural RoadsProf. Prithvi Singh KandhalNo ratings yet

- Guidelines For Using Prime and Tack Coats PDFDocument111 pagesGuidelines For Using Prime and Tack Coats PDFHery BudiantoNo ratings yet

- SUPERPLAST - High Performance Polymer-Low ResDocument37 pagesSUPERPLAST - High Performance Polymer-Low ResStanescu Axu AlexandruNo ratings yet

- Perpetual Flexible Pavements: Pavements of Future: Sanjay GargDocument17 pagesPerpetual Flexible Pavements: Pavements of Future: Sanjay GargDidier BellonNo ratings yet

- EB236Document26 pagesEB236mehrdad_so1981No ratings yet

- A Research Paper On Porous Asphalt PavementDocument6 pagesA Research Paper On Porous Asphalt PavementEditor IJTSRDNo ratings yet

- On Modified BitumenDocument19 pagesOn Modified BitumenTejeshwini SNo ratings yet

- Evaluation of Stone Mastic Asphalt Mix by The Bailey Method DesignDocument8 pagesEvaluation of Stone Mastic Asphalt Mix by The Bailey Method DesignLin ChouNo ratings yet

- Creep NCHRPDocument106 pagesCreep NCHRPFranklinNo ratings yet

- T122 TorsionalDocument6 pagesT122 Torsionalprabin kumar ashishNo ratings yet

- Bitumin Modification With Carbon NanotubesDocument6 pagesBitumin Modification With Carbon NanotubesSachith SeneviratnaNo ratings yet

- Asphalt Concrete (Commonly Called Asphalt, Blacktop, Macadam in Great Britain and Ireland) Is A CompositeDocument7 pagesAsphalt Concrete (Commonly Called Asphalt, Blacktop, Macadam in Great Britain and Ireland) Is A CompositeZerotheoryNo ratings yet

- Crumb Rubber Modified Bitumen A ProjectDocument52 pagesCrumb Rubber Modified Bitumen A ProjectAthira RaghavanNo ratings yet

- Effect of Using Ground Waste Tire Rubber As Fine Aggregate On The Behaviour of Concrete MixesDocument9 pagesEffect of Using Ground Waste Tire Rubber As Fine Aggregate On The Behaviour of Concrete MixesMaridil IsidroNo ratings yet

- Viscosity Grading of BitumenDocument2 pagesViscosity Grading of BitumenVenkateswarlu DanduNo ratings yet

- National Institute of Technology, Patna: Submitted To:-Submitted ByDocument57 pagesNational Institute of Technology, Patna: Submitted To:-Submitted ByVipul MishraNo ratings yet

- Kandhal Q and A Part 1 On Confusion From Overlapping Viscosity Ranges of VG-30 and VG-40 Bitumen - 16 August 2017Document4 pagesKandhal Q and A Part 1 On Confusion From Overlapping Viscosity Ranges of VG-30 and VG-40 Bitumen - 16 August 2017Prof. Prithvi Singh Kandhal100% (1)

- Laboratory Performance Characteristics of High Modulus Asphalt Mixture With High-Content RAPDocument8 pagesLaboratory Performance Characteristics of High Modulus Asphalt Mixture With High-Content RAPOscar Javier Lozano PinedaNo ratings yet

- Nanotechnology On Pavement: AbstractDocument6 pagesNanotechnology On Pavement: AbstractVarunNo ratings yet

- Evaluation of Baghouse Fines in Hot Mix Asphalt - Part IDocument18 pagesEvaluation of Baghouse Fines in Hot Mix Asphalt - Part IProf. Prithvi Singh Kandhal100% (1)

- Bituminous Pavement ConstructionDocument24 pagesBituminous Pavement ConstructionSatish SajjaNo ratings yet

- Microsurfacing FHWA SA 94 051Document66 pagesMicrosurfacing FHWA SA 94 051RogerMoleroNo ratings yet

- Ap T240 13Document92 pagesAp T240 13mehdiNo ratings yet

- Roughometer 3Document2 pagesRoughometer 3Angel Nahun RiveraNo ratings yet

- Road Note 8 (Sub Soil Drainage)Document25 pagesRoad Note 8 (Sub Soil Drainage)Someshwar Rao ThakkallapallyNo ratings yet

- Are Two Separate Test Samples Are Used in India To Determine The Flaky (Flat) and Elongated Particles in Each Aggregate Size Fraction? AnswerDocument5 pagesAre Two Separate Test Samples Are Used in India To Determine The Flaky (Flat) and Elongated Particles in Each Aggregate Size Fraction? AnswerProf. Prithvi Singh KandhalNo ratings yet

- Research and Application of Hot In-Place Recycling Technology for Asphalt PavementFrom EverandResearch and Application of Hot In-Place Recycling Technology for Asphalt PavementNo ratings yet

- Upgrading of Approximately 104Km of Road D104/D791 Chipata To Mfuwe in Eastern Province Surfacing PlanDocument8 pagesUpgrading of Approximately 104Km of Road D104/D791 Chipata To Mfuwe in Eastern Province Surfacing PlanSidney MusondaNo ratings yet

- Materi Bab 10 Kelompok 8Document33 pagesMateri Bab 10 Kelompok 8Hartata Putra Mai Marta100% (1)

- PointsDocument1 pagePointsPriti PaudelNo ratings yet

- NEA Load Shedding Schedule December 2012 (2069 Mangsir)Document2 pagesNEA Load Shedding Schedule December 2012 (2069 Mangsir)iAmSMSDNo ratings yet

- List UntitledDocument2 pagesList UntitledPriti PaudelNo ratings yet

- Funny GoDocument1 pageFunny GoPriti PaudelNo ratings yet

- Load Shedding Notice BhadraDocument1 pageLoad Shedding Notice BhadraPriti PaudelNo ratings yet

- Wham TestDocument1 pageWham TestPriti PaudelNo ratings yet

- 4 2Document10 pages4 2Priti PaudelNo ratings yet

- Trends in EnggDocument1 pageTrends in EnggPriti PaudelNo ratings yet

- DyDocument1 pageDyPriti PaudelNo ratings yet

- Wham TestDocument1 pageWham TestPriti PaudelNo ratings yet

- 13 eDocument1 page13 ePriti PaudelNo ratings yet

- DGDocument1 pageDGPriti PaudelNo ratings yet

- Read MeDocument5 pagesRead MeKairenNo ratings yet

- InstallDocument1 pageInstallPriti PaudelNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Read MeDocument5 pagesRead MeKairenNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- IRC 5 - 1998 Road Bridges Section 1Document25 pagesIRC 5 - 1998 Road Bridges Section 1Vahabshaik ShaiNo ratings yet

- Tanzania Pavement and Materials Design Manual 1999 Chapter 1Document25 pagesTanzania Pavement and Materials Design Manual 1999 Chapter 1ryanp4480% (25)

- Brochure Asphalt Surface Dressing ChipsealDocument20 pagesBrochure Asphalt Surface Dressing ChipsealOjullaIsaac100% (1)

- Abstract Otta Seals TanzaniaDocument1 pageAbstract Otta Seals TanzaniaDavid RiveraNo ratings yet

- Best Practice Manual For Thin Bituminous Surfacings 2013 PDFDocument145 pagesBest Practice Manual For Thin Bituminous Surfacings 2013 PDFashe zinabNo ratings yet

- Guideline 1 Design, Construction and Maintenance of Otta SealsDocument49 pagesGuideline 1 Design, Construction and Maintenance of Otta SealshiltonrjNo ratings yet

- TRH 14 ManualDocument22 pagesTRH 14 ManualNelson KachaliNo ratings yet

- 3 Otta SealDocument6 pages3 Otta SealPriti PaudelNo ratings yet

- Procedimiento Otta SealDocument18 pagesProcedimiento Otta SealJORGE SILVANo ratings yet

- Kang HukuntsiDocument8 pagesKang HukuntsimbutaleNo ratings yet

- Design and Construction Procedure of Otta Seal LatestDocument44 pagesDesign and Construction Procedure of Otta Seal LatestSujit DhitalNo ratings yet

- Bagmati - Pavement Design Final 17 Jan 2022 - 1643008325Document73 pagesBagmati - Pavement Design Final 17 Jan 2022 - 1643008325AnilNo ratings yet

- Bulletin81 Article-2Document13 pagesBulletin81 Article-2Suvash AcharyaNo ratings yet

- Suitability of Natural Gravels in Ghana For Otta Seal ConstructionDocument8 pagesSuitability of Natural Gravels in Ghana For Otta Seal ConstructionIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- SAPEM Chapter 04 2nd Edition 2014Document89 pagesSAPEM Chapter 04 2nd Edition 2014Rob DamhuisNo ratings yet

- Manual Otta Seal PDFDocument70 pagesManual Otta Seal PDFWambugu MaInaNo ratings yet

- Low Cost Sealing of Low Volume Roads EditedDocument22 pagesLow Cost Sealing of Low Volume Roads Editedhaumbamil100% (3)

- Western Cape Provincial Administration Chapter06 Revision 3.0 LatestDocument109 pagesWestern Cape Provincial Administration Chapter06 Revision 3.0 LatestpettisyangNo ratings yet

- Otta Seal PDFDocument2 pagesOtta Seal PDFLuis PilaresNo ratings yet

- Eng. Kitonsa The Future of Low Cost Sealing in Uganda - July 2016Document23 pagesEng. Kitonsa The Future of Low Cost Sealing in Uganda - July 2016haumbamil100% (1)

- Otta Seal Construction For Asphalt Pavement Resurfacing: July 2018Document12 pagesOtta Seal Construction For Asphalt Pavement Resurfacing: July 2018Alex del PinoNo ratings yet

- Low Volume Seal Roads Manual MOWDocument257 pagesLow Volume Seal Roads Manual MOWRichard SendagireNo ratings yet

- Compound Wall EstimatesDocument132 pagesCompound Wall EstimatesLearn & teachNo ratings yet

- Working Methodology For Otta SealDocument2 pagesWorking Methodology For Otta Sealpandey_baibhavNo ratings yet

- DBSTDocument118 pagesDBSTBihanChathuranga100% (6)

- Construction Manual - Oct 2014Document56 pagesConstruction Manual - Oct 2014Sakaria JonasNo ratings yet

- Adapting The Impact of Climate Change On Gravel Roads Network in Tanzania by Otta Seal TechnologyDocument22 pagesAdapting The Impact of Climate Change On Gravel Roads Network in Tanzania by Otta Seal TechnologyFrank NgoiyaNo ratings yet

- Overseas Road Note 03Document46 pagesOverseas Road Note 03Amadu FarrowNo ratings yet

- Performance Assessment of Otta Seals On Low Traffic Volume RoadsDocument63 pagesPerformance Assessment of Otta Seals On Low Traffic Volume RoadsRonald WaiswaNo ratings yet