Professional Documents

Culture Documents

XHX

Uploaded by

Matias MancillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XHX

Uploaded by

Matias MancillaCopyright:

Available Formats

Dalamatic

Dust Collectors

Sinjly

tle

est

Dust Collectors Aiailable

1le veisarile Donaluson

1oiir

Dalamaric seiies o uusr collecrois uelivei a oveiul

solurion oi neaily any uusr ilriarion alicarion. 1lese collecrois come in rvo mouels: rle

Dalamaric Caseu (DL^C) is a sranu alone collecroi rlar can Le uucreu ro many uieienr

alicarions, rle Dalamaric InseiraLle (DL^V) is a veisarile collecroi rlar can Le inseireu

inro vaiious alicarions, sucl as Lins, silos, Lunkeis, sroiage vessels oi riansei oinrs.

Borl mouels aie conrinuous-uury uusr collecrois uesigneu ro lanule rle mosr uiiculr

iouucr iecoveiy alicarions.

DLMC 3/7/15

Dalamatic

Dalamatic

Proven Performance, Compact Design

=a~Ji

q==i=c=_~

Continuous collection

Pioviues conrinuous ilriarion o ligl

uusr concenriarions ar ligl ilriarion

velociries anu consranr levels o

iesisrance in almosr any inuusriy anu

alicarion.

Compact desi gn Unique

mouulai uesign allovs oi insrallarion in

rle mosr sace iesriicreu aieas.

Lnveloe-slaeu Lags maximize rle

amounr o meuia in a given sace anu

allov oi incieaseu sace Lerveen Lags,

minimizing rle clances o Liiuging.

Dura-Life

Filter Bags ioviue

Lerrei suiace loauing anu Lerrei ulse

cleaning ieuucing mainrenance anu

oeiaring cosrs.

Versatility A ull iange o sizes anu

ryes o Lags aie availaLle oi a viue

vaiiery o uusr collecrion alicarions.

10-year warranty

Dalamatics Offer:

Efficient Media Design 1le Dalamaric auvanrage is ounu in rle Lieakrliougl

reclnology o Duia-Lie ilrei Lags. Duia-Lie Lags oei longei Lag lie anu ieuuceu

emissions. 1lis unique oeiarion o rle ilrei Lag lels aclieve ligl ilriarion eiciencies.

Dust accumulates on the outer surface of the

filter bag as air penetrates the media.

The blowpipe (jet tube) injects a burst of

compressed air into the filter bag.

Airflow is then briefly reversed, inflating the filter

bag and dislodging dust.

The dislodged dust cake falls into the collection

hopper for final removal or directly back in the

the process. The envelope-shaped filter bag,

which is mounted on a unique wire frame,

ensures optimum airflow and thorough cleaning.

outlet header

sealing flange

and ring

accumulated

dust cake

filter bag

clean-air plenum

dirty-air plenum

air inducted by

force of jet

clean-air plenum

dirty-air plenum

airflow temporarily

reversed, inflating bag

and dislodging

dust cake

Normal Operation Filter Cleaning Operation

clean-air outlet

blow pipe (jet tube)

tubesheet (seal frame)

cage (wire insert)

blow pipe (jet tube)

injecting compressed air

dust cake falls into the

hopper (DLMC)

dust cake falls back into

the silo or process

equipment (DLMV)

Principles of Filtration

Flexible, Effective Filter Media

1

Dalamatic

Dalamatic

DLMV 45/15

Dalamatic Cased (DLMC)

Envelope-shaped bags provide maximum

filter area per given space and ensure

efficient cleaning

Air volumes range from 1500 to 85,000 cfm

Modular design gives dimensional and

capacity flexibility

Downward airflow pattern minimizes dust

re-entrainment

Installed face to face (double-banked)

reduces required platforms and ductwork

for easy access and maintenance.

Standard leg pack meets IBC 2003

requirements

Dalamatic Insertable (DLMV)

Five configurations to suit most process

applications

Uses positive pressure of the conveying air or

can be fan powered for pneumatic conveying

applications

Bags can be installed hanging vertically,

horizontally or any angle in between

Can be inserted into hood enclosures at belt

transfer points, bucket elevator casings, ribbon

blenders and receiving hoppers for clamshell

unloaders

Insertable approach reduces or eliminates

ducting costs; minimized ducting can also result

in reduced energy costs

2

Dalamatic

Dalamatic

Sizes & Operations

leg and

crossbrace

hopper

cabinet ground lug

(opt., not shown)

tubesheet

(seal frame)

filter bag

and cage (insert)

dirty-air

inlet

clean-air

outlet

solenoid

enclosure

top

inspection

panel

blow pipe

(jet tube)

lifting lug

filter bag

and cage

(insert)

clean-air

plenum

blow pipe

(jet tube)

fan

motor

mounting

flange

Normal Operation for Models DLMC Normal Operation for Models DLMV

3

Dalamatic

Dalamatic

Dura-Life bags provide big benefits!

Duia-Lie reclnology ioviues Lerrei suiace loauing anu Lerrei

ulse cleaning, iesulring in:

Two to three times longer bag life

Energy savings due to lower pressure drop

Reduced replacement bag costs due to

fewer bag changeouts

Reduced maintenance and operating costs due

to fewer bag changeouts

30% fewer emissions based on EPA tests

Dura-Life

Filter Bag Technology

Dura-Life A technology breakthrough for bag users.

Polyesrei Lags aie iouuceu virl a neeuling iocess rlar cieares laigei oies vleie uusr

can emLeu inro rle aLiic, inliLiring cleaning anu ieuucing Lag lie. Duia-Lie` Lags aie

engineeieu virl a unique lyuioenranglemenr iocess rlar uses varei ro Llenu rle iLeis.

1lis iocess ioviues a moie unioim mareiial virl smallei oies, Lerrei suiace loauing,

anu Lerrei cleaning. 1lese auvanrages ioviue rvice rle oeiaring lie Leoie Lags

neeu ro Le ielaceu uue ro ligl iessuie uio. Longei lie iom Duia-Lie Lags loveis

mainrenance anu oeiaring cosrs anu iaises Laglouse uusr collecrion ro a vlole nev level.

300X

300X

Tlese jlotos uere talen uitl a scanning electron nicroscoje of bag neJia useJ in a collector tlat uas

filtering fly asl. Tle bags uere renoieJ after 2,00 lours of use. Air-to-neJia ratio uas +.S to 1. ressure

Jroj uas 6 in. on jolyester bags anJ 2 in. on Dura-Iife.

Dura-Life Bag-Clean Air Side Polyester Bag-Clean Air Side

StanJarJ in All DonalJson Torit

Dalanatic aglouse Collectors

* Dura-Life bags are made with Durapex

filter media manufactured by Polymer Group, Inc.

Pyramid

Hopper

*

(2/ 5/15 Model)

Side View

Pyramid Hopper

(2/ 5/15 Model)

UMA

Hopper

(2/ 5/15 Model with 4 cu. ft. Bins)

Trough

Hopper

(2/ 5/15 Model)

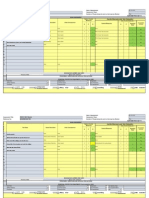

Cased Dimensions & Specifications

DLMC

Model

1/2/15

1/3/15

1/4/15

2/2/15

1/5/15

2/3/15

1/7/15

2/4/15

3/3/15

2/5/15

2/6/15

3/5/15

2/8/15

3/6/15

4/5/15

3/7/15

3/8/15

4/8/15

1,290- 3,550

1,940- 5,335

2,580- 7,095

2,580- 7,095

3,240- 8,910

3,880-10,670

4,520-12,430

5,160-14,190

5,815-15,990

6,480-17,820

7,750-21,315

9,690-26,650

10,335-28,420

11,625-31,975

12,920-35,530

13,565-37,310

15,500-42,635

20,670-56,845

1

1

1

2

1

2

1

2

3

2

2

3

2

3

4

3

3

4

323

485

645

645

810

970

1130

1290

1454

1620

1938

2423

2584

2907

3230

3392

3876

5168

2

3

4

2

5

3

7

4

3

5

6

5

8

6

5

7

8

8

20

30

40

40

50

60

70

80

90

100

120

150

160

180

200

210

240

320

10

10

10

20

10

20

10

20

30

20

20

30

20

30

40

30

30

40

2243

2743

3384

3886

3884

4686

5145

5889

6877

6814

7764

9677

9289

11,077

12,670

12,177

13,302

17,445

2270

2770

3396

3907

3894

4543

4895

5593

6518

6518

7468

9318

8993

10,718

12,185

11,818

12,943

16,960

N/A

N/A

N/A

3967

N/A

4707

N/A

5757

6473

6682

7632

9273

9157

10,673

11,862

11,773

12,898

16,637

Shipping Weight (lbs)

With Pyramid With Hopper for With Trough

Hopper UMA 4 cu. ft. Bin Hopper

No. of

Bags

Cloth

Area (ft

2

)

Nominal

Airflow Range

(cfm)**

No. of

Tiers

No. of

Banks

No. of

Valves

4

Dalamatic

Dalamatic

89.9

43.5

9.6

B

D E

A

29.6

F G

A

48.0

B C

A

48.0

` Wirl orional 55-gallon uium auarei (uium nor incluueu).

`` Baseu on clean ilreis.

Cased Dimensions & Specifications

Dimensions (inches)

DLMC Pyramid UMA Trough

Model A B C D E F G

1/2/15 43.5 171.7 162.7 147.9 138.9 N/A N/A

1/3/15 43.5 185.5 194.5 170.7 161.7 N/A N/A

1/4/15 43.5 216.8 234.2 240.8 193.0 N/A N/A

1/5/15 43.5 241.6 259.0 235.2 217.8 N/A N/A

1/7/15 43.5 287.3 304.7 280.9 263.5 N/A N/A

2/2/15 83.0 171.7 162.7 147.9 138.9 165.7 156.7

2/3/15 83.0 194.5 185.5 170.4 161.7 188.5 179.5

2/4/15 83.0 234.2 216.8 210.4 193.0 228.2 210.7

2/5/15 83.0 259.0 241.6 235.2 217.8 253.0 235.6

2/6/15 83.0 281.9 264.4 258.1 240.7 275.8 258.4

2/8/15 83.0 327.5 310.1 303.7 286.3 321.5 304.1

3/3/15 122.4 194.5 185.5 147.9 138.9 165.7 156.7

3/5/15 122.4 259.0 241.6 235.2 217.8 253.0 235.6

3/6/15 122.4 281.9 264.4 258.0 240.7 275.8 258.4

3/7/15 122.4 304.7 287.3 280.9 263.5 298.7 281.2

3/8/15 122.4 327.5 310.1 303.7 286.3 321.5 304.1

4/5/15 161.9 259.0 241.6 235.2 217.8 253.0 235.6

4/8/15 161.9 327.5 310.1 303.7 286.3 321.5 304.1

Seismic Spectral Acceleration S

s

= 1.5 & S

1

= 0.6

Wind Load Rating (mph) 90

Housing Rating ("wg) 0-20 21-45

Compressed Air Required (psig) 55-90 _

Temperature Range 15F to 140F 140F to 400F

DLMC Operating Conditions Standard Optional

5

Dalamatic

Dalamatic

Insertable Dimensions & Specifications

No. of

Bags

4/7, 6/10, 9/15

7/7, 10/10, 15/15

8/7, 12/10, 18/15

14/7, 20/10

30/15

21/7, 30/10, 45/15

60/15

6

10

12

20

20

30

40

Dimensions (inches)

A

38.3

38.3

62.2

62.3

62.3

85.9

112.2

B

36.8

36.8

36.8

36.8

37.6

42.9

42.9

C

33.8

33.8

44.5

44.5

44.5

68.1

88.8

D

27.5

43.3

27.6

43.3

43.3

43.3

43.3

E

43.1

43.1

64.0

67.0

68.4

93.1

113.3

F

29.1

39.8

29.1

39.8

39.8

39.8

39.8

G

57.4

57.4

71.6

71.7

71.7

100.0

120.7

H

43.3

43.3

43.3

43.3

43.3

46.8

46.8

J

14.7

14.7

15.7

15.8

15.8

15.8

15.8

DLMV Type H

(Type B plus exit header)

Filter with exit header for connection to a fan or discharge ducting.

The filter is weatherproof and suitable for indoor and

outdoor application.

DLMV Type W

(Type H plus weather cowl)

Filter with a weather cowl for pressure systems

where the filter is located outdoors or exposed to

adverse conditions.

DLMV Type FAD

(Type F plus acoustic diffuser)

Weatherproof filter fitted with an integral fan and acoustic

diffuser for quiet operation.

DLMV Type F

(Type H plus integral fan)

Weatherproof filter fitted with an integral fan for

negative pressure applications.

DLMV Type B

Basic filter for pressure systems located indoors.

DLMV

Model

6

Dalamatic

Dalamatic

DLMV

Model

4/7

6/10

7/7

8/7

9/15

10/10

12/10

14/7

15/15

18/15

20/10

21/7

30/10

30/15

45/15

60/15

215- 555

320- 830

375- 975

430- 1,115

485- 1,260

540- 1,400

645- 1,675

750- 1,950

805- 2,090

970- 2,520

1,075- 2,795

1,130- 2,935

1,615- 4,195

1,615- 4,195

2,420- 6,290

3,230- 8,395

172

256

300

344

388

432

516

600

644

776

860

904

1292

1292

1936

2584

43

64

75

86

97

108

129

150

161

194

215

226

323

323

484

646

258

384

450

516

582

648

774

900

966

1164

1290

1356

1938

1938

2904

3876

344

512

600

688

776

864

1032

1200

1288

1552

1720

1808

2584

2584

3872

5168

3

3

5

6

3

5

6

5

5

6

5

10

10

10

10

10

F1

F1

F1

K3

F1

K3

F1

K3

F1

K3

K3

K5

K3

K5

K3

K5

K3

K5

K7

K3

K5

K7

K3

K5

K7

K5

K7

K10

K5

K7

K10

K7

K10

K11

K11

1

1

1

2

1

2

1

2

1

2

2

3

2

3

2

3

2

3

5

2

3

5

2

3

5

3

5

7.5

3

5

7.5

5

7.5

10

10

231

251

353

375

273

386

414

606

423

459

672

794

893

750

1003

1323

320

340

474

518

362

507

558

794

545

602

860

1058

1157

935

1268

1878

331

351

485

529

373

519

569

805

556

613

871

1080

1179

946

1290

1900

430

450

584

595

628

640

472

483

617

628

679

712

915

948

666

699

723

756

833

981

1014

1091

1179

1213

1290

1312

1389

1561

1089

1168

1321

1499

1671

1758

2374

523

543

688

699

727

739

565

576

721

732

778

811

1025

1058

770

803

822

855

932

1091

1124

1201

1307

1341

1418

1440

1517

1689

1199

1278

1431

1627

1799

1886

2506

Shipping Weight (lbs)

Type Type Type Type Type

B H W F FAD Fan

Motor

(hp)

8:1

cfm

Cloth

Area (ft

2

)

6:1

cfm

4:1

cfm

No. of

Valves

Insertable Dimensions & Specifications

Pressure Limits Type B, W and H: -16"wg

Type F: As fan performance curves from

shut-off to ambient pressure

Compressed Air Required (psig) 65-90

Temperature Range 14F to 140F 140F to 250F (not Type F)

DLMV Operating Conditions Standard Optional

7

Dalamatic

Dalamatic

Nominal

Airflow Range

(cfm)*

` Baseu on clean ilreis.

With acoustic diffuser*

Without acoustic diffuser

Insertable Performance Selections

1) Determine the air volume flow (cfm) needed to give effective venting and dust control

2) Estimate pressure or suction ("wg) in the housing in which the dust filter is inserted

3) Assess the operational pressure drop ("wg) across the clean side and dirty side of the

filtering element usually between 2 to 4 "wg

4) The sum of 2 and 3 gives the pressure ("wg) required for fan selection purposes

5) Consult graph for fan performance available

Fan Performance Curve

Insertable Weighted Sound Pressure Levels

All ieauings veie raken in semi-ieveiLeianr suiiounuings 3'3" iauius iom rle equimenr

lousing anu 5'3" aLove Lase level, using a iecision sounu level merei anu ocrave ilrei.

oise measuiemenrs o insralleu equimenr may vaiy uue ro sire conuirions.

` 1lese measuiemenrs ieei ro sranuaiu ourler osirion.

`` Lsrimareu uara.

F1 (1 hp)

76 dB(A)

91 dB(A)

K3 (2 hp)

73 dB(A)

89 dB(A)

K5 (3 hp)

74 dB(A)

92 dB(A)

K7 (5 hp)

76 dB(A)

93 dB(A)

K10 (7.5 hp)

79 dB(A)**

94 dB(A)

K11 (10 hp)

84 dB(A)

97 dB(A)

To select tle nost suitable fan for your ajjlications

Air Volume (cfm)

8

Dalamatic

Dalamatic

S

t

a

t

i

c

P

r

e

s

s

u

r

e

a

t

F

a

n

I

n

l

e

t

(

"

w

g

)

` ^agnelelic anu Plorolelic aie iegisreieu riauemaiks o

Dvyei Insriumenrs, Inc.

U.S. Parenr ,015,15S

Inoimarion conraineu in rlis uocumenr is suLjecr ro clange

virlour norice.

Dalamatic

Dalamatic

Standard Features & Equipment Options

Collector Design

Mild Steel Construction

Horizontal Clean-Side Bag Removal

Rear Dirty-Air Plenum Access Door

High Temperature Construction

Stainless Steel Construction

Mountable Fan

Ladders, Cages, & Platform Assemblies

(OSHA compliant)

Bags & Cages

Dura-Life Twice the Life Polyester Felt Bags

Quick-Release Filter Clamps

Variety of Bag Media Options

Anti-Static Filter Bags

Paint System

Powder-Coated Polyester Textured Finish

Blue Exterior Finish Coating Meets 250-Hour Salt

Spray Corrosion Protection Test

Hostile Environment Paint

Custom Colors

Hopper Design

Pyramid Hoppers

Trough Hoppers

2 and 3 Bank Single-Outlet Hopper

UMA Hopper

Support Structure

Standard Leg Pack

Leg Extensions

Electrical Controls, Gauges and Enclosures

Solid-State Control Panels and Valves in NEMA 4 Encl.

Solid-State Control Panels and Valves in NEMA 9 Encl.

Control Panels and Valves with Heater in NEMA 9 Encl.

Magnehelic

* Gauge

Solenoid Enclosure NEMA 9

Photohelic

* Gauge

Delta P Control, Delta P Plus Control

Compressed Air Filter and Regulator

Safety Features

Sprinkler Pack

Explosion Vents

Warranty

10-Year Warranty

Collector Design

Mild Steel Construction

Horizontal or Vertical Bag Removal

High Temperature Construction

Stainless Steel Construction

Acoustic Diffuser Silencers

Fans (AMCA C Rated) and Motors

Bags & Cages

Dura-Life Twice the Life Polyester Felt Bags

Clean-Side Bag Removal

Quick-Release Filter Clamps

Variety of Bag Media Options

Anti-Static Filter Bags

Paint System

Powder-Coated Polyester Texture

Blue Exterior Finish Coating Meets 250-Hour Salt

Spray Corrosion Protection Test

Hostile Environment Paint

Custom Colors

Support Structure

Vertical or Horizontal Upstands

Electrical Controls, Gauges and Enclosures

Solid-State Control Panels and Valves in NEMA 4 Encl.

Solid-State Control Panels and Valves in NEMA 9 Encl.

Control Panels and Valves with Heater in NEMA 9 Encl.

Magnehelic

* Gauge

Solenoid Enclosure NEMA 9

Photohelic

* Gauge

Delta P Control, Delta P Plus Control

Compressed Air Filter and Regulator

Safety Features

Explosion Proof Motors

Warranty

10-Year Warranty

O

p

tio

n

a

l

Dalamatic Cased (DLMC)

S

ta

n

d

a

r

d

O

p

tio

n

a

l

S

ta

n

d

a

r

d

Dalamatic Insertable (DLMV)

Printed in USA Donaldson Company, 2002 Dalamatic 12-2007

Facilities in 35 countries

37 manufacturing plants and

11 distribution centers

49 sales offices worldwide

Broad range of innovative collectors and filters

Ready-to-ship filters and parts within 24 hours

Technical expertise and support

Knowledgeable Service

Global Support

Better Technology

550 engineers worldwide

More than 500 patents held by

Donaldson employees

Custom designed solutions

750,000

+

units sold

Cleaner Air

Worldwide

Donaluson Comany, Inc.

Inuusriial Aii Iilriarion

P.O. Box 1299

^inneaolis, ^

55440-1299 U.S.A.

1el S00.365.1331 (USA)

1el S00.343.3639 (virlin ^exico)

uonalusonroiir@mail.uonaluson.com

vvv.uonalusonroiir.com

Call Donaldson Torit

to get Cleaner Air today

800-365-1331

Call Donaldson Torit

to get Cleaner Air today

800-365-1331

You might also like

- Packed Bed Tower ScrubbersDocument8 pagesPacked Bed Tower Scrubberssumit_waghmareNo ratings yet

- VERTI-G Cuttings DryerDocument4 pagesVERTI-G Cuttings DryerLoganBohannon100% (1)

- Design Guideline For Hydraulic Fluid CleanlinessDocument24 pagesDesign Guideline For Hydraulic Fluid CleanlinessCarlosNo ratings yet

- Amca Publication 11-03: Certified Ratings Program Operating ManualDocument30 pagesAmca Publication 11-03: Certified Ratings Program Operating ManualMatias MancillaNo ratings yet

- Task Based Risk Assesment FormDocument2 pagesTask Based Risk Assesment FormKolluri SrinivasNo ratings yet

- WIL Cement Separators Brochure PDFDocument12 pagesWIL Cement Separators Brochure PDFPaulo Vidas100% (3)

- Damper Guide BookDocument21 pagesDamper Guide Booksbmmla100% (1)

- SPT High Efficiency Phase Separation Internals BrochureDocument8 pagesSPT High Efficiency Phase Separation Internals BrochurefunctionlakeNo ratings yet

- Separators: For Steam, Air and Gas SystemsDocument16 pagesSeparators: For Steam, Air and Gas SystemsmrazamudinishakNo ratings yet

- 045156-200 GBR - Operating & Maintenance ManualDocument56 pages045156-200 GBR - Operating & Maintenance ManualEdwin Yohn Alvarado Aroca100% (2)

- Jet III Pulse Jet Dust CollectorDocument12 pagesJet III Pulse Jet Dust CollectorAnonymous YzSzB0rpNKNo ratings yet

- MBR DesignDocument52 pagesMBR Designpragatheesk100% (2)

- OilField Review 2016 Cement EvaluationDocument10 pagesOilField Review 2016 Cement EvaluationLuisNo ratings yet

- MODEL QUESTION PAPER OF HRM Open CourceDocument2 pagesMODEL QUESTION PAPER OF HRM Open CourceTitus Clement100% (3)

- Refractories For Heat Treating: Industrial CeramicsDocument6 pagesRefractories For Heat Treating: Industrial CeramicsMatias MancillaNo ratings yet

- Envirenmental EngineeringDocument87 pagesEnvirenmental Engineering4919404No ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- OMEGA AIR - Process and Sterile Filtration - EnglishDocument12 pagesOMEGA AIR - Process and Sterile Filtration - EnglishOMEGA AIR d.o.o. LjubljanaNo ratings yet

- Xu10j4 PDFDocument80 pagesXu10j4 PDFPaulo Luiz França100% (1)

- Sustainable drainage systems made simple with MarleyDocument19 pagesSustainable drainage systems made simple with MarleyIrfan Siddiqui100% (1)

- Dal Am A TicDocument12 pagesDal Am A TicMiguelAngelDavilaNo ratings yet

- Jet Pulse FilterDocument12 pagesJet Pulse FilterAkshay KadbeNo ratings yet

- Keller VDN VenturiDocument8 pagesKeller VDN Venturijpdavila205No ratings yet

- 7539 Rev E Air FiltrationDocument36 pages7539 Rev E Air Filtrationatia2kNo ratings yet

- Cuno ZPC Zeta Plus Sanitary HousingDocument4 pagesCuno ZPC Zeta Plus Sanitary Housinggeorgadam1983No ratings yet

- Doneldson Air Breather FilterDocument14 pagesDoneldson Air Breather FilterParinpa KetarNo ratings yet

- Vru100 PDFDocument4 pagesVru100 PDFSasaNo ratings yet

- Vacuum CollectionDocument4 pagesVacuum CollectionLoganBohannonNo ratings yet

- Maskell Venturi Scrubbers 770 SeriesDocument2 pagesMaskell Venturi Scrubbers 770 Seriesjerome42nNo ratings yet

- Superior Gas Chlorinators BrochureDocument16 pagesSuperior Gas Chlorinators BrochureAqua Technology GroupNo ratings yet

- Atmosbag SpecificationDocument12 pagesAtmosbag Specificationsilvership2291100% (1)

- Enhancing Rotary Vacuum Drum Filter PerformanceDocument8 pagesEnhancing Rotary Vacuum Drum Filter PerformanceSiska MilalaNo ratings yet

- Vru 100Document4 pagesVru 100Muh HabzNo ratings yet

- Enhancing The Performance of Rotary Vacuum Drum Filter: November 2011Document8 pagesEnhancing The Performance of Rotary Vacuum Drum Filter: November 2011Nitu VohraNo ratings yet

- Vakuumbandfilter enDocument14 pagesVakuumbandfilter enFrank Vega OrtegaNo ratings yet

- Revolutionary ALDRUM G3 Drum ThickenerDocument4 pagesRevolutionary ALDRUM G3 Drum ThickenerDito KristaNo ratings yet

- Rotary valves and airlocks guideDocument6 pagesRotary valves and airlocks guidegallowdrNo ratings yet

- Filters Ingersoll-RandDocument4 pagesFilters Ingersoll-RandAnonymous bcdUbxoNo ratings yet

- Tee Type StrainersDocument3 pagesTee Type StrainersSrinu AmulojuNo ratings yet

- Enhancing The Performance of Rotary Vacuum Drum FilterDocument8 pagesEnhancing The Performance of Rotary Vacuum Drum FilterBernardo RodriguesNo ratings yet

- Solar 1Document4 pagesSolar 1api-221502147No ratings yet

- Backdraft Dampers CatalogDocument12 pagesBackdraft Dampers CatalogTed K NagaraNo ratings yet

- CamSafe BrochureDocument9 pagesCamSafe BrochureArshavin Watashi WaNo ratings yet

- D85 D275Document8 pagesD85 D275ssinokrotNo ratings yet

- Compressed Air Filters and Water Separators: Intelligent Air TechnologyDocument6 pagesCompressed Air Filters and Water Separators: Intelligent Air TechnologyOliver CambelNo ratings yet

- Dynamelt PUR Series Adhesive Bag MelterDocument2 pagesDynamelt PUR Series Adhesive Bag MelterITWDynatecNo ratings yet

- Inlet Fogging of Gas Turbine EnginesDocument7 pagesInlet Fogging of Gas Turbine EnginesReza Razmjou100% (1)

- Don GTS BrochureDocument8 pagesDon GTS BrochuresanigzlNo ratings yet

- Glass Lined BrochureDocument8 pagesGlass Lined BrochureKarna2504No ratings yet

- Drying Automatik PelletizerDocument8 pagesDrying Automatik PelletizerSharad NaikNo ratings yet

- Column PresentationDocument27 pagesColumn PresentationTaifurNo ratings yet

- Decanter SiebtechnikDocument16 pagesDecanter SiebtechnikzamburittiNo ratings yet

- Sepura Oil Water Separator 4ppDocument4 pagesSepura Oil Water Separator 4ppmuppetscrapNo ratings yet

- KSWG BruchureDocument4 pagesKSWG BruchureJack AboutboulNo ratings yet

- Aldrum g3 enDocument4 pagesAldrum g3 enmucukilinNo ratings yet

- Drain CoilDocument12 pagesDrain CoilBerlinNo ratings yet

- Enhancing The Performance of Rotary VacuDocument7 pagesEnhancing The Performance of Rotary VacuAbdulrahman zawia (talonLOL)No ratings yet

- Eco Drain condensate drainDocument7 pagesEco Drain condensate drainCatalin Frincu100% (1)

- Eco Micron FitDocument4 pagesEco Micron FitNicholas Jeffrey DaviesNo ratings yet

- A Ire PleatDocument3 pagesA Ire PleatavacansNo ratings yet

- Shanghai Test Results - Filtersafe White PaperDocument21 pagesShanghai Test Results - Filtersafe White PaperBlack PantherNo ratings yet

- CORRUGADODocument4 pagesCORRUGADOOwen Beni SerNo ratings yet

- Peerless Blowers Direct Drive Blowers Forward CurveDocument6 pagesPeerless Blowers Direct Drive Blowers Forward CurveLuis Alonso Zavala GuerraNo ratings yet

- ERG Venturi ScrubbersDocument2 pagesERG Venturi ScrubberscsreyeroNo ratings yet

- Mülheim an der Ruhr company profiles decanter centrifugesDocument14 pagesMülheim an der Ruhr company profiles decanter centrifugeszeppilli23No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Amca Publication 11-03: Certified Ratings Program Operating ManualDocument30 pagesAmca Publication 11-03: Certified Ratings Program Operating ManualMatias MancillaNo ratings yet

- p-100 Vol2 1935 Part5Document132 pagesp-100 Vol2 1935 Part5Matias MancillaNo ratings yet

- Chapter 21Document25 pagesChapter 21Matias MancillaNo ratings yet

- Catalago Resumen de ValvulasDocument21 pagesCatalago Resumen de ValvulasMatias MancillaNo ratings yet

- CA3000A Dodge BearingDocument708 pagesCA3000A Dodge BearingSuphi YükselNo ratings yet

- Hamada Boiler Catalogue Page 57 Coalmac 1Document1 pageHamada Boiler Catalogue Page 57 Coalmac 1Matias MancillaNo ratings yet

- Carter Variator CatDocument40 pagesCarter Variator CatMatias MancillaNo ratings yet

- CA3000A Dodge BearingDocument708 pagesCA3000A Dodge BearingSuphi YükselNo ratings yet

- Hamada Boiler Catalogue Page 56 Heavy Duty Chain GrateDocument1 pageHamada Boiler Catalogue Page 56 Heavy Duty Chain GrateMatias MancillaNo ratings yet

- Technical Documents of The BoilerDocument20 pagesTechnical Documents of The BoilerMatias Mancilla0% (1)

- CA3000A Dodge BearingDocument708 pagesCA3000A Dodge BearingSuphi YükselNo ratings yet

- Hamada Boiler Catalogue Page 47 Rotary Furnace For AMPDocument1 pageHamada Boiler Catalogue Page 47 Rotary Furnace For AMPMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 60 Coalmac 4Document1 pageHamada Boiler Catalogue Page 60 Coalmac 4Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 22 Coal Storage and PLC ControlDocument1 pageHamada Boiler Catalogue Page 22 Coal Storage and PLC ControlMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 58 Coalmac 2Document1 pageHamada Boiler Catalogue Page 58 Coalmac 2Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 65 Rice Husk Firing Boiler 4Document1 pageHamada Boiler Catalogue Page 65 Rice Husk Firing Boiler 4Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 59 Coalmac 3Document1 pageHamada Boiler Catalogue Page 59 Coalmac 3Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 60 Coalmac 4Document1 pageHamada Boiler Catalogue Page 60 Coalmac 4Matias MancillaNo ratings yet

- Solid Fuel Combustion On Water-Cooled Vibrating Grate: Plant Equipment and ComponentsDocument2 pagesSolid Fuel Combustion On Water-Cooled Vibrating Grate: Plant Equipment and ComponentsMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 63 Rice Husk Firing Boiler 2Document1 pageHamada Boiler Catalogue Page 63 Rice Husk Firing Boiler 2Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 59 Coalmac 3Document1 pageHamada Boiler Catalogue Page 59 Coalmac 3Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 61 EFB Palm Waste FiringDocument1 pageHamada Boiler Catalogue Page 61 EFB Palm Waste FiringMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 62 Rice Husk Firing Boiler 1Document1 pageHamada Boiler Catalogue Page 62 Rice Husk Firing Boiler 1Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 64 Rice Husk Firing Boiler 3Document1 pageHamada Boiler Catalogue Page 64 Rice Husk Firing Boiler 3Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 8 Model DF Series General ViewDocument1 pageHamada Boiler Catalogue Page 8 Model DF Series General ViewMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 67 TVTB 3Document1 pageHamada Boiler Catalogue Page 67 TVTB 3Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 7 Fluidizing Fire and Biomass FuelDocument1 pageHamada Boiler Catalogue Page 7 Fluidizing Fire and Biomass FuelMatias MancillaNo ratings yet

- OTA710C User ManualDocument32 pagesOTA710C User ManualEver Daniel Barreto Rojas100% (2)

- Pg-586-591 - Annexure 13.1 - AllEmployeesDocument7 pagesPg-586-591 - Annexure 13.1 - AllEmployeesaxomprintNo ratings yet

- G C Reddy ProfileDocument3 pagesG C Reddy ProfileG.C.ReddyNo ratings yet

- Project 863 EvidenceDocument5 pagesProject 863 EvidenceMilan TolhuisenNo ratings yet

- Communication Box Specification V1.0Document3 pagesCommunication Box Specification V1.0Natan VillalonNo ratings yet

- Philips Lighting Annual ReportDocument158 pagesPhilips Lighting Annual ReportOctavian Andrei NanciuNo ratings yet

- Reconciling Informal and Formal TradeDocument194 pagesReconciling Informal and Formal TradeBaterias BateriasNo ratings yet

- Routine E-Mail Messages and Memos-Ch 8Document43 pagesRoutine E-Mail Messages and Memos-Ch 8Faryal ArifNo ratings yet

- Sonydsp v77 SM 479622 PDFDocument41 pagesSonydsp v77 SM 479622 PDFmorvetrNo ratings yet

- z2OrgMgmt FinalSummativeTest LearnersDocument3 pagesz2OrgMgmt FinalSummativeTest LearnersJade ivan parrochaNo ratings yet

- 6 Hagonoy V NLRCDocument2 pages6 Hagonoy V NLRCChristiane Marie Bajada0% (1)

- Letter Advocating For Hazard PayDocument2 pagesLetter Advocating For Hazard PayQueens PostNo ratings yet

- Built For Your Business and The Environment.: WORKFORCE PRO WF-C5290/C5790Document4 pagesBuilt For Your Business and The Environment.: WORKFORCE PRO WF-C5290/C5790abe cedeevNo ratings yet

- SESSON 1,2 AND 3 use casesDocument23 pagesSESSON 1,2 AND 3 use casessunilsionNo ratings yet

- Customer Channel Migration in Omnichannel RetailingDocument80 pagesCustomer Channel Migration in Omnichannel RetailingAlberto Martín JiménezNo ratings yet

- TT1 2lecture SpinningDocument29 pagesTT1 2lecture SpinninghaiNo ratings yet

- In Gov cbse-SSCER-191298202020 PDFDocument1 pageIn Gov cbse-SSCER-191298202020 PDFrishichauhan25No ratings yet

- GIS BasedLandSuitabilityAnalysistoSupportTransit OrientedDevelopmentTODMasterPlanACaseStudyoftheCampusStationofThammasatUniversityandItsSurroundingCommunitiesDocument13 pagesGIS BasedLandSuitabilityAnalysistoSupportTransit OrientedDevelopmentTODMasterPlanACaseStudyoftheCampusStationofThammasatUniversityandItsSurroundingCommunitiesAzka RamadhanNo ratings yet

- Akriti Shrivastava CMBA2Y3-1906Document6 pagesAkriti Shrivastava CMBA2Y3-1906Siddharth ChoudheryNo ratings yet

- ION8650 DatasheetDocument11 pagesION8650 DatasheetAlthaf Axel HiroshiNo ratings yet

- Resume DaniellaAmatoDocument2 pagesResume DaniellaAmatoDaniellaNo ratings yet

- Priceliost Ecatalog 2021 Div. DiagnosticDocument2 pagesPriceliost Ecatalog 2021 Div. Diagnosticwawan1010No ratings yet

- Yale Smart Door Locks GuideDocument50 pagesYale Smart Door Locks GuidejaganrajNo ratings yet

- Inner RingDocument16 pagesInner RingService - Anda Hydraulics Asia Pte LtdNo ratings yet

- Mphasis Placement PaperDocument3 pagesMphasis Placement PapernagasaikiranNo ratings yet

- Acuite-India Credit Risk Yearbook FinalDocument70 pagesAcuite-India Credit Risk Yearbook FinalDinesh RupaniNo ratings yet