Professional Documents

Culture Documents

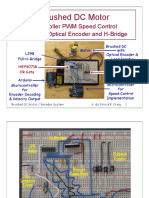

Brushed DC Motor Speed Control with Encoder and H-Bridge

Uploaded by

Mohammed BenlamlihOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brushed DC Motor Speed Control with Encoder and H-Bridge

Uploaded by

Mohammed BenlamlihCopyright:

Available Formats

Brushed DC Motor / Encoder System A. da Silva & K.

Craig 1

Brushed DC Motor

Microcontroller PWM Speed Control with

Optical Encoder and H-Bridge

Brushed DC Motor

with

Optical Encoder &

Load Inertia

Arduino

Microcontroller

for

Speed Control

Implementation

Arduino

Microcontroller

for

Encoder Decoding

& Velocity Output

Flyback

Diodes

L298

Full H-Bridge

HEF4071B

OR Gate

Brushed DC Motor / Encoder System A. da Silva & K. Craig 2

Brushed DC Motor / Encoder System A. da Silva & K. Craig 3

Brushed DC Motor / Encoder System A. da Silva & K. Craig 4

Brushed DC Motor / Encoder System A. da Silva & K. Craig 5

Pittman DC Servo Motor 8322S001

Brushed DC Motor / Encoder System A. da Silva & K. Craig 6

Pittman DC Servo Motor 8322S001

Wire Function Color Pins

1 GND Black GND

2 Index Green -

3 CH A Yellow

4 Vcc Red 5V

5 CH B Blue

Encoder

500 counts/rev

Brushed DC Motor / Encoder System A. da Silva & K. Craig 7

L298

Dual Full Bridge Driver

Brushed DC Motor / Encoder System A. da Silva & K. Craig 8

Brushed DC Motor / Encoder System A. da Silva & K. Craig 9

Topics

Brushed DC Motor

Physical & Mathematical Models, Hardware

Parameters

H-Bridge Operation

Feedback Control Design

MatLab / Simulink Design and Auto-Code

Generation

Brushed DC Motor / Encoder System A. da Silva & K. Craig 10

Brushed DC Motor

Schematic

Brushed DC Motor

Pittman DC

Servo Motor

Brushed DC Motor / Encoder System A. da Silva & K. Craig 11

Physical Modeling

For a permanent-magnet DC

motor i

f

= constant.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 12

Physical Modeling Assumptions

The copper armature windings in the motor are

treated as a resistance and inductance in series.

The distributed inductance and resistance is

lumped into two characteristic quantities, L and R.

The commutation of the motor is neglected. The

system is treated as a single electrical network

which is continuously energized.

The compliance of the shaft connecting the load to

the motor is negligible. The shaft is treated as a

rigid member.

The total inertia J is a single lumped inertia, equal

to the sum of the inertias of the rotor and the

driven load.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 13

There exists motion only about the axis of rotation of

the motor, i.e., a one-degree-of-freedom system.

The parameters of the system are constant, i.e., they

do not change over time.

The damping in the mechanical system is modeled as

viscous damping B, i.e., all stiction and dry friction are

initially neglected.

The optical encoder output is decoded in software.

Position and velocity are calculated and made

available as analog signals for control calculations.

The motor is driven with a PWM control signal to a H-

Bridge. The time delay associated with this, as well

as computation for control, is lumped into a single

system time delay.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 14

Mathematical Modeling Steps

Define System, System Boundary, System Inputs

and Outputs

Define Through and Across Variables

Write Physical Relations for Each Element

Write System Relations of Equilibrium and/or

Compatibility

Combine System Relations and Physical

Relations to Generate the Mathematical Model for

the System

Brushed DC Motor / Encoder System A. da Silva & K. Craig 15

m t m b b

T K i V K = = e

out m t m in b m b m

out t

in b

P T K i P V i K i

P K

P K

= e = e = = e

=

out in

t b m

P P

K K K

=

=

L

L R R B

J motor load

di

V L V Ri T B

dt

T J J J J J

= = = e

= o = e +

t b

3

t b

t b

K (oz in / A) 1.3524K (V/ krpm)

K (Nm/ A) 9.5493 10 K (V/ krpm)

K (Nm/ A) K (V s / rad)

=

=

=

Physical Relations

Brushed DC Motor / Encoder System A. da Silva & K. Craig 16

System Relations + Equations of

Motion

in R L b

V V V V 0 =

m B J

T T T 0 =

R L m

i i i i = =

in b t

di d

V Ri L K 0 J B K i 0

dt dt

e

e = + e =

t

in

b

d

K

B

0

dt J J

V

1

di i K

R

L

L L

dt

e

(

(

(

(

e

(

(

= +

(

(

(

(

(

(

(

(

KVL

Newtons Law

Brushed DC Motor / Encoder System A. da Silva & K. Craig 17

Steady-State Conditions

in b

in b

t

t t b

in

t

s in

in

0

b

di

V Ri L K 0

dt

T

V R K 0

K

K K K

T V

R R

K

T V

R

V

K

e =

| |

e =

|

\ .

= e

=

e =

Stall Torque

No-Load Speed

Brushed DC Motor / Encoder System A. da Silva & K. Craig 18

Transfer Functions

in b t

di d

V Ri L K 0 J B K i 0

dt dt

e

e = + e =

( ) ( )

in b t

V s (Ls R)I(s) K (s) 0 Js B (s) K I(s) 0 + O = + O =

( )( ) ( ) ( )

t t

2

in t b t b

t

2

t b

K K (s)

V (s) Js B Ls R K K JLs BL JR s BR K K

K

JL

K K B R BR

s s

J L JL JL

O

= =

+ + + + + + +

=

| | | |

+ + + +

| |

\ . \ .

Brushed DC Motor / Encoder System A. da Silva & K. Craig 19

Block Diagram

1

Ls R +

1

Js B +

b

K

t

K

e

m

T

i

in

V

E

Brushed DC Motor / Encoder System A. da Silva & K. Craig 20

Simplification

in b t

d

V Ri K 0 J B K i 0

dt

e

e = + e =

( ) ( )

t

t t in b in b

t b t

in

t

in

motor m

t

in m motor

motor

K d 1

J B K i K V K V K

dt R R

K K K d B

V

dt RJ J RJ

K d 1 1

V

dt RJ

K d 1

V since

dt RJ

e

| |

+ e = = e = e

|

\ .

e

| |

+ + e =

|

\ .

| |

e

+ + e =

|

t t

\ .

| |

e

+ e = t >> t

|

t

\ .

m e

J L

>>

B R

t = t =

Brushed DC Motor / Encoder System A. da Silva & K. Craig 21

Brushed DC Motor / Encoder System A. da Silva & K. Craig 22

Brushed DC Motor / Encoder System A. da Silva & K. Craig 23

Brushed DC Motor / Encoder System A. da Silva & K. Craig 24

Brushed DC Motor / Encoder System A. da Silva & K. Craig 25

Brushed DC Motor / Encoder System A. da Silva & K. Craig 26

Brushed DC Motor / Encoder System A. da Silva & K. Craig 27

Brushed DC Motor / Encoder System A. da Silva & K. Craig 28

Brushed DC Motor / Encoder System A. da Silva & K. Craig 29

MatLab M-File

Brushed DC Motor / Encoder System A. da Silva & K. Craig 30

H-Bridge Operation

For DC electric motors, a power device configuration

called H-Bridge is used to control the direction and

magnitude of the voltage applied to the load. The H-

Bridge consists of four electronic power components

arranged in an H-shape in which two or none of the

power devices are turned on simultaneously.

A typical technique to control the power components is

via PWM (Pulse Width Modulation) signal. A PWM signal

has a constant frequency called carrier frequency.

Although the frequency of a PWM signal is constant, the

width of the pulses (the duty cycle) varies to obtain the

desired voltage to be applied to the load.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 31

The H-Bridge can be in one of the four states: coasting,

moving forward, moving backward, or braking, as shown

on the next slide.

In the coasting mode, all four devices are turned off and

since no energy is applied to the motor, it will coast.

In the forward direction, two power components are

turned on, one connected to the power supply and one

connected to ground.

In reverse direction, only the opposite power

components are turned on supplying voltage in the

opposite direction and allowing the motor to reverse

direction.

In braking, only the two devices connected to ground

are tuned on. This allows the energy of the motor to

quickly dissipate, which will take the motor to a stop.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 32

Brushed DC Motor / Encoder System A. da Silva & K. Craig 33

The four diodes shown in anti-parallel to the

transistors are for back-EMF current decay when all

transistors are turned off.

These diodes protect the transistors from the voltage

spike on the motor leads due the back-EMF when all

four transistors are turned off. This could could yield

excessive voltage on the transistor terminals and

potentially damage them.

They must be sized to a current higher than the

motor current and for the lowest forward voltage to

reduce junction temperature and the time to dissipate

the motor energy.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 34

Diodes for back-EMF

protection are shown.

The solid line is the

current flow when the

transistors on the upper

left corner and on the

right lower corner are

turned on. The dashed

line shows the motor

current when all

transistors are turned

off.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 35

The approach shown next to generate the PWM

command for an H-Bridge was developed for the

Dual Full Bridge Driver L298 from STMicroelectronics

Each bridge contains two inputs (IN1 and IN2 for the

bridge A and IN3 and IN4 for bridge B) and an enable

for each bridge (ENA for one bridge and ENB for the

other bridge).

The operation of this bridge is shown in the table

below for bridge A. The operation for bridge B is

identical.

Enable Inputs Function

EN = 1 IN1 = 1, IN2 = 0 Forward Move

IN1 = 0, IN2 = 1 Reverse Move

IN1 = IN2 Motor Fast Stop

EN = 0 IN1 = X, IN2 = X Motor Coast

1 = High, 0 = Low, X = Dont care

Brushed DC Motor / Encoder System A. da Silva & K. Craig 36

Block diagram of L298 (Dual Full Bridge Driver)

Brushed DC Motor / Encoder System A. da Silva & K. Craig 37

This approach to generate the PWM command for

the L298 consists of three steps:

Split the analog torque command to the motor into

two PWM signals (one for each input of one of the

bridges of the L298)

Logics to control inputs and enable the L298

Motor connection and protection of the bridge

Brushed DC Motor / Encoder System A. da Silva & K. Craig 38

Step A

The torque command from the control system can be split

into two PWM signals for an Arduino board as shown

below.

A dead-band control is used to avoid short circuits on the

bridge with inductive loads while switching direction, as

the transistor that is commanded to turn off stays

conducting for a short period of time due the motor back-

EMF when the other transistor on the same branch may

be commanded to turn on for the switching in direction.

Spl i tti ng Command to H-Bri dge Dead Zone Control

Product

Product

Pi n 6

PWM REV Di recti on

Pi n 3

PWM FWD Di recti on

< -0.1

DeadBand

> 0.1

DeadBand

Torque Command

Control System

255/8

Anal og to 8 bi ts

-255/8

Anal og to 8 bi ts

Brushed DC Motor / Encoder System A. da Silva & K. Craig 39

Thus, if the torque command is within the dead-band, all

four transistors are turned off. If the torque command is

positive and higher than the dead-band threshold, a

signal is applied to the PWM FWD Direction output as

shown. Similarly, if the torque command is negative and

lower than the dead-band threshold, signal is applied to

the PWM REV Direction output.

The gains 255/8 converts the torque command of a

maximum of 8 Nm in this example into a digital signal of 8

bits (2

8

= 256) which is the resolution of an analog output

on Arduino boards.

The analog output on the Arduino is actually a PWM

signal of approximately 490 Hz. Thus, there is no need

for generating PWM signal from the analog torque

command using Arduino because the analog output is

PWM.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 40

If the torque command is a symmetric sinusoid with

amplitude of 8 Nm, the outputs PWM FWD Direction

and PWM REV Direction would be as shown below.

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2

-10

0

10

T

o

r

q

u

e

C

o

m

m

a

n

d

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2

0

2

4

6

P

W

M

F

W

D

D

i

r

e

c

t

i

o

n

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2

0

2

4

6

P

W

M

R

E

V

D

i

r

e

c

t

i

o

n

Time (sec)

Brushed DC Motor / Encoder System A. da Silva & K. Craig 41

Step B

The logic to control inputs and enable the L298

consists of a single OR gate that allows disabling

all transistors of the H-Bridge when the command

PWM signals are at zero. This logic located

between the Arduino board and the H-Bridge is

shown below.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 42

Step C

The motor is connected to the outputs of the bridge.

Depending on the type of H-Bridge used, internal

protection to the transistor of the bridge may not exist. In

this case, external protection circuitry needs to be

provided. This protection consists of diodes connected in

anti-parallel to the transistors. Shottky diodes are preferred

for inductive loads. The motor rated voltage needs to be

supplied to the bridge in order to allow the motor to

develop rated torque. If the bridge is supplied with voltage

higher than the motor rated voltage, damage may occur to

the motor. A sensing resistor (R

s

) can be used to monitor

the motor current and shutdown the transistors if the motor

rated current or the bridge maximum current is exceeded.

The connection of the motor to the bridge and the diodes

to protect the transistors are shown on the next slide.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 43

Brushed DC Motor / Encoder System A. da Silva & K. Craig 44

Feedback Control Design &

Implementation

Feedback speed control of the DC motor can be

accomplished using several approaches.

The Single-Output, Single-Input (SISO) MatLab tool is

typically used to design classical feedback control

systems. A combination of the root locus approach and

the frequency response approach is most effective.

Once a controller, e.g., PI or PID, is designed, the block

diagram shown can then be used in Simulink with the

Code Generation to create and download to the Arduino

microcontroller the control code for the motor.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 45

DC-Motor - Closed Loop Velocity Control

SampleTime = 0.020 seconds

for data monitoring Velocity

Velocity

Feedback

(rev/sec)

Si ne Wave

Saturation

12V to -12V

In1

In2

Plot data

PI(s)

PID Controller

10

Offset

In1

H-Bridge Control

rps

Control Implementation

with

Arduino and Simulink

Code Generation

1

Vel oci ty

Pi n 0

Motor Speed

(1023=50rps

512 = 0rps

0=-50rps)

50/512

Di gi tal to rps

512

Constant

rps

5V = 1023 = 50 rev/sec

2.5V = 512 = 0 rev/sec

0V = 0 = -50 rev/sec 10-bit A/D

Brushed DC Motor / Encoder System A. da Silva & K. Craig 46

Splitting Command to H-Bridge Dead Zone Control

Product1

Product

Pin 10

PWM REV Direction

Pin 9

PWM FWD Direction

> 0.1

DeadBand1

< -0.1

DeadBand

255/12

Analog to 8 bits

-255/12

Analog to 8 bits

1

In1

H-Bridge Control Subsystem

H-Bridge Control Block

It contains a dead band control to avoid two transistors on

the same side of the H-bridge turning on at the same time and

damaging the H-bridge. It also contain the logic to split the

signal from the PID controller into forward and reverse

direction for the transistors of the H-bridge.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 47

These bl ocks show how you can send mul ti pl e bytes

by combi ni ng di fferent si gnal s i nto a vector usi ng the

Mux bl ock. In thi s case we are addi ng a Header and

Termi nator character to our message.

We are al so usi ng the Convert bl ock to take the i nt16

val ue we get from the Anal og Input and convert i t to

a 2-el ement ui nt8 vector.

9600 baud rate

uint8(0)

Terminator

Serial Write

Serial Write

Serial Config

Launch

host side

uint8('A')

Header

10

Convert to

int16

10

Convert to

int16

From Analog InTo Serial

Convert int16 to uint8 Array1

From Analog InTo Serial

Convert int16 to uint8 Array

2

In2

1

In1

Use the "Serial Configuration" block to make sure that the used serial port is the one to which the arduino

is connected.

A value coming from analog "In1" will also be received and displayed.

COM19 Data

Serial Receive

COM19

9600

8,none,1

Serial Configuration

Scope

Launch

target side

Display

Plot Data Subsystem

Since the serial

port only reads

integers, this

gain adds a

decimal point to

the readings. But

the signal will be

10 times the

actual value.

Brushed DC Motor / Encoder System A. da Silva & K. Craig 48

Plot Data: This block reads any data from the Simulink code

and plots it on a Scope. The steps to use this feature are

as follows:

1. Connect the Arduino board to the USB port of your

computer

2. Run the command in the MatLab Command Window:

comPorts=arduino.Prefs.searchForComPort

3. This command will show the number of the COM port that

the Arduino board is connected.

4. Open the block called Launch host side

5. Open the Serial Configuration block and set the

Communication Port to the port number identified in Step

2.

Steps to Use the Plot Data Subsystem

Brushed DC Motor / Encoder System A. da Silva & K. Craig 49

6. Open the block Serial Receive and set the

Communication Port to the port number identified in

Step 2.

7. Run the following command in the Command Window:

SampleTime = 0.02.

8. Download the code to Arduino

9. Hit Play on the

demo_arduino_serial_communication_host

Brushed DC Motor / Encoder System A. da Silva & K. Craig 50

Double click on the

Scope to start

monitoring the data.

The time to capture

data on the Scope can

be changed as shown.

You might also like

- Business Plan For T-SHIRTDocument19 pagesBusiness Plan For T-SHIRTKayode Olorunsola100% (1)

- Novel Method PMDC Motor Speed ControlDocument15 pagesNovel Method PMDC Motor Speed ControlTravis WoodNo ratings yet

- Lesson 1:: Instructables ClassesDocument15 pagesLesson 1:: Instructables ClassesLandy AdianetNo ratings yet

- NES-Famicom - A Visual CompendiumDocument265 pagesNES-Famicom - A Visual CompendiumStephanos7100% (6)

- Stepper Motor & Drivers - USB MACH3 4 Axis Controller - PENTING!Document6 pagesStepper Motor & Drivers - USB MACH3 4 Axis Controller - PENTING!FalahNo ratings yet

- DBMS Questions and AnswersDocument69 pagesDBMS Questions and AnswersAkash Jain81% (16)

- Pic Micro ControllerDocument83 pagesPic Micro ControllerDenise Nelson100% (3)

- PWM Atmega328Document30 pagesPWM Atmega328JUNIOR700No ratings yet

- Arduino 101: Timers and Interrupts GuideDocument10 pagesArduino 101: Timers and Interrupts GuideFabian Monteleone100% (1)

- Arduino Arduino Arduino Arduino 2 2 2 2 Channel Channel Channel Channel Relay Relay Relay Relay Shield Shield Shield ShieldDocument8 pagesArduino Arduino Arduino Arduino 2 2 2 2 Channel Channel Channel Channel Relay Relay Relay Relay Shield Shield Shield ShieldWisnuNo ratings yet

- TB6600 Stepper Motor Driver User Guide SEODocument11 pagesTB6600 Stepper Motor Driver User Guide SEOAnonymous gdJiDHNo ratings yet

- PIC Basic Projects: 30 Projects using PIC BASIC and PIC BASIC PROFrom EverandPIC Basic Projects: 30 Projects using PIC BASIC and PIC BASIC PRORating: 1 out of 5 stars1/5 (1)

- R438 Leroy-Somer AVRDocument2 pagesR438 Leroy-Somer AVRThomas Branley100% (2)

- Y Axis AssemblyDocument25 pagesY Axis AssemblyNixonGarciaNo ratings yet

- Delay 1.0K Millis 2.3K Micros 1.0K Delaymicroseconds 359 Analogwrite 274 Tone 1.4K Notone 76 Servo Library 1.6KDocument11 pagesDelay 1.0K Millis 2.3K Micros 1.0K Delaymicroseconds 359 Analogwrite 274 Tone 1.4K Notone 76 Servo Library 1.6KOthmane Bouzarzar100% (1)

- Manual Pic Lab 1Document44 pagesManual Pic Lab 1Mustafa Arif100% (2)

- Elektor Attiny NoiseDocument2 pagesElektor Attiny NoiseKlemensKohlweisNo ratings yet

- Unitec Parts Part 2Document49 pagesUnitec Parts Part 2coco MPNo ratings yet

- BeagleBone BlackDocument117 pagesBeagleBone Blackjupiter8053No ratings yet

- Programming 16 Bit Timer On Atmega328Document9 pagesProgramming 16 Bit Timer On Atmega328VisitOn.T.witte.r100% (1)

- 3500Document54 pages3500Steve da Rivia67% (3)

- MicroPython Libraries For PyBoardDocument184 pagesMicroPython Libraries For PyBoardonæssNo ratings yet

- B&R XP Embedded Pack and Target Designer Export Files Guide V2 33 ENGDocument55 pagesB&R XP Embedded Pack and Target Designer Export Files Guide V2 33 ENGDhana SekarNo ratings yet

- G100 Set Up Guide Rev.1 9-19-07Document34 pagesG100 Set Up Guide Rev.1 9-19-07Milton MarinNo ratings yet

- AXBB E ManualDocument29 pagesAXBB E ManualKenny HebertNo ratings yet

- Computer Architecture NoteDocument10 pagesComputer Architecture Notekazi habibaNo ratings yet

- Jetson Nano Developer Kit User GuideDocument24 pagesJetson Nano Developer Kit User GuideTamires BernoNo ratings yet

- Measurement TECHS For The Cement Industry 03Document50 pagesMeasurement TECHS For The Cement Industry 03Sudheer NairNo ratings yet

- Arduino Timer InterruptsDocument7 pagesArduino Timer Interruptsbugaboo2323100% (1)

- VACON NC1131-3 Engineering: File: 1 03/29/21/KHDocument11 pagesVACON NC1131-3 Engineering: File: 1 03/29/21/KHEugenNo ratings yet

- Mach3 Software Installation GuideDocument9 pagesMach3 Software Installation Guidegabrieldromano1No ratings yet

- Introduction to Computers: Hardware, Software, and BeyondDocument64 pagesIntroduction to Computers: Hardware, Software, and BeyondRuban Rajalingam100% (1)

- Arduino Shield ManualDocument24 pagesArduino Shield Manualzhalim2001No ratings yet

- 28 Project Learning Kit User GuideDocument88 pages28 Project Learning Kit User GuidemayankdgaurNo ratings yet

- Circuit diagram iPad chargerDocument1 pageCircuit diagram iPad chargeraplus guideNo ratings yet

- Arduino Tracking Maze CarDocument2 pagesArduino Tracking Maze CarAmmarALJodah0% (1)

- ET-PIC Training Board GuideDocument101 pagesET-PIC Training Board GuideDev Iker100% (2)

- ME-447 Lab Final Exam Paper BDocument7 pagesME-447 Lab Final Exam Paper BSaad RasheedNo ratings yet

- Esp 32 NotesDocument4 pagesEsp 32 NotesChuck_YoungNo ratings yet

- Introduction To Arduino PowerPoint Presentation On ArduinoDocument16 pagesIntroduction To Arduino PowerPoint Presentation On ArduinoYogesh SahuNo ratings yet

- DC Motor With Encoder Manual (1.1 W)Document7 pagesDC Motor With Encoder Manual (1.1 W)Saad NajibNo ratings yet

- Component IdentificationDocument22 pagesComponent Identificationjactopple0% (1)

- Analog Inputs With Arduino & Mach3Document8 pagesAnalog Inputs With Arduino & Mach3Francisco Campoverde100% (2)

- Voltmeter and Ammeter Using PIC Microcontroller PDFDocument11 pagesVoltmeter and Ammeter Using PIC Microcontroller PDFMohd Waseem Ansari100% (1)

- Bluetooth HC-05, HC-06 Commands Mode and AT CommandsDocument5 pagesBluetooth HC-05, HC-06 Commands Mode and AT CommandsOnofre Enriquez Fercito Leito100% (1)

- Arduino Timer InterruptsDocument1 pageArduino Timer InterruptseduardohcmendesNo ratings yet

- The Tutorial On Motors PDFDocument11 pagesThe Tutorial On Motors PDFPavan DaddimaniNo ratings yet

- Board SchematicDocument1 pageBoard SchematicJOSE LENIN RIVERA VILLALOBOS0% (1)

- LCR-Meter ElektorDocument5 pagesLCR-Meter ElektorFernando VidalNo ratings yet

- How To Make A Humanoid RobotDocument9 pagesHow To Make A Humanoid RobotC SYAHBANANo ratings yet

- 10ah 200ah Battery ChargerDocument9 pages10ah 200ah Battery Chargerdraj1968100% (1)

- CNC Controller RZNC 0901 User Manual RuDocument34 pagesCNC Controller RZNC 0901 User Manual RuEmill CncNo ratings yet

- 6520-3902004РТ ENGL. (ЕВРО -2, 3, 4)Document1,445 pages6520-3902004РТ ENGL. (ЕВРО -2, 3, 4)kiên HoangNo ratings yet

- Robot OttoDocument17 pagesRobot OttoMarcio ScarduaNo ratings yet

- NRF24L01 Wireless Keyboard SystemDocument4 pagesNRF24L01 Wireless Keyboard SystemHassan AllawiNo ratings yet

- Delta+DPS-205CP TIVIDocument3 pagesDelta+DPS-205CP TIVINgoc Tuy NguyenNo ratings yet

- Nokia 2220 Slide - RM590 - RM591 - Schematics PDFDocument5 pagesNokia 2220 Slide - RM590 - RM591 - Schematics PDFEdgar Jose Aranguibel MorilloNo ratings yet

- KEMPPI MINARC 150 A001 Si Partial Z001 OKDocument1 pageKEMPPI MINARC 150 A001 Si Partial Z001 OKDimitar ValchevNo ratings yet

- CNC by SourabhDocument7 pagesCNC by SourabhsaurabhNo ratings yet

- Easy Start Guide LS Ic5 PDFDocument15 pagesEasy Start Guide LS Ic5 PDFMarina Cecilia TorresNo ratings yet

- Antminer S9 Hash Board Repair GuideDocument20 pagesAntminer S9 Hash Board Repair GuidePedro PaezNo ratings yet

- Wind Turbine MPPT Regulator v2.3 120120Document36 pagesWind Turbine MPPT Regulator v2.3 120120EdwinDuranJr.100% (1)

- Gristleizer Build Notes Updated 121709Document4 pagesGristleizer Build Notes Updated 121709smonkeyNo ratings yet

- C4570HADocument12 pagesC4570HAAngel QuiñonesNo ratings yet

- Kukri DimensionsDocument11 pagesKukri DimensionsdiamantebarrocasNo ratings yet

- GT S6312 Tshoo 7 PDFDocument57 pagesGT S6312 Tshoo 7 PDFCelublack Ck100% (1)

- Maximizing power density of BLDC machines through advanced control techniquesDocument54 pagesMaximizing power density of BLDC machines through advanced control techniquesM A InayathullaahNo ratings yet

- Arduino PWM MotorDocument56 pagesArduino PWM MotormartinNo ratings yet

- DC - Machines - IDocument23 pagesDC - Machines - IKevinXavierNo ratings yet

- Speed Control of Separately Excited D.C. Motor: Chayan Kumar, Prof. (DR.) Deoraj Kumar TantiDocument11 pagesSpeed Control of Separately Excited D.C. Motor: Chayan Kumar, Prof. (DR.) Deoraj Kumar TantiWieNo ratings yet

- Dcservo NewkitDocument11 pagesDcservo NewkitNikita MalikNo ratings yet

- PMSM ControlDocument35 pagesPMSM Controldhaval2430No ratings yet

- Mobile SystemsDocument89 pagesMobile SystemsMwungura EspoirNo ratings yet

- 4 Radio Propagation - FadingDocument42 pages4 Radio Propagation - FadingMohammed BenlamlihNo ratings yet

- Point To Point Link PlanningDocument177 pagesPoint To Point Link PlanningMohammed BenlamlihNo ratings yet

- 2N3904Document7 pages2N3904api-3697683No ratings yet

- UNIT-III BJT, FET (Completed) PDFDocument35 pagesUNIT-III BJT, FET (Completed) PDFRachananjali Kunamneni Kethineni100% (1)

- Finepix S200exr Manual 01Document144 pagesFinepix S200exr Manual 01Jairo QuevedoNo ratings yet

- 08 Engine MechanicalDocument80 pages08 Engine MechanicalmadcostaNo ratings yet

- AD10 Updates Release NotesDocument44 pagesAD10 Updates Release Notesomidlove84No ratings yet

- Sig View User ManualDocument150 pagesSig View User ManualJosé Ramón IglesiasNo ratings yet

- Elements of Processor Management: CIS 250 Operating SystemsDocument36 pagesElements of Processor Management: CIS 250 Operating SystemsAsawari SurveNo ratings yet

- "Antonia Polygon - Standard" Documentation: (Render by Glitterati3D)Document22 pages"Antonia Polygon - Standard" Documentation: (Render by Glitterati3D)Robin StaceyNo ratings yet

- 11A32 ServiceDocument71 pages11A32 Servicericks69No ratings yet

- Learning Module Computer: Grade 7Document10 pagesLearning Module Computer: Grade 7Steven Prado0% (1)

- WEG SRW 01 Hmi Interface Homem Maquina 0899.5827 Guia de Instalacao Portugues BRDocument16 pagesWEG SRW 01 Hmi Interface Homem Maquina 0899.5827 Guia de Instalacao Portugues BRDavid PalhanoNo ratings yet

- Np540u3c PDFDocument87 pagesNp540u3c PDFCid Patrick HwfNo ratings yet

- 250W Power InverterDocument3 pages250W Power Inverterapi-3731916100% (2)

- Stonesoft 1065 Next Gen Firewall ApplianceDocument3 pagesStonesoft 1065 Next Gen Firewall Appliancealech06No ratings yet

- C Program Compilation StepsDocument46 pagesC Program Compilation StepsAbhishekSharmaNo ratings yet

- EX1Document4 pagesEX1mohamedmusarafNo ratings yet

- Dell Incorporated Form 10-K FY2011-12Document202 pagesDell Incorporated Form 10-K FY2011-12techtrendentropyNo ratings yet

- QSK60 Spec SheetDocument6 pagesQSK60 Spec Sheetbacuoc.nguyen356No ratings yet