Professional Documents

Culture Documents

GE 2116 Lab Manual-Rev 2012

Uploaded by

lenojerin3486Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GE 2116 Lab Manual-Rev 2012

Uploaded by

lenojerin3486Copyright:

Available Formats

9518 - National College of Engineering

NATIONAL COLLEGE OF ENGINEERING MARUTHAKULAM

GE-2116 ENGINEERING PRACTICES LABORATORY MANUAL GROUP A- CIVIL & MECHANICAL FIRST YEAR FIRST SEMESTER (MECH, EEE, ECE, CSE, IT & CIVIL)

Engineering Practices Laboratory GE 2116

9518 - National College of Engineering

Engineering Practices Laboratory GE 2116

9518 - National College of Engineering

INDEX

Sl.No . CIVIL I 1 2 3 II 4 5 I 6 7 8 9 10 II 11 12 III 13 14 III 15 Carpentry T-joint Dove tail joint Cross lap joint Plumbing Basic pipe connections for wash basin and water heater Basic pipe connections involving the fittings like valves, taps and bends MECHANICAL Welding Lap joint Parallel fillet joint T joint Butt joint Sheet metal work Rectangular tray Frustum Basic machining Stepped Shaft Drilling Fitting V- joint Name of the Experiment Page No.

Engineering Practices Laboratory GE 2116

9518 - National College of Engineering

Engineering Practices Laboratory GE 2116

9518 - National College of Engineering

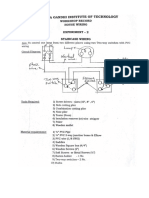

1. BASIC PIPE CONNECTIONS INVOLVING THE FITTINGS LIKE VALVES, TAPS AND BENDS

Aim: To connect the pipes with pipe fittings like valves, bends and taps with main supply pipe using joints. Materials supplied; 1. Pipe wrench 3. Bend 5. Taps 6. Flange Procedure: 1. Two pipes are taken and they are held in vice and they are connected by using a flanged joint as shown in fig. 2. A gate valve is connected to the pipe for controlling the water supply. 3. Then bend is connected to the end of the pipe. Make internal threads using taps in the bend-1. So it can be screwed to the pipe. 4. One more pipe is connected to the bend for extension of the layout. 5. The pipe is then screwed to bend-2 for further extension. 6. A horizontal pipe is connected to this bend-2 as shown in fig. 7. Then tap is fitted to the end of the pipe for closing and opening the water supply.

2. Spanner 4. Valves 6. Cast iron pipes of different length 8. Bench vice

Result: Thus the basic connections of pipes with accessories are made.

Engineering Practices Laboratory GE 2116

9518 - National College of Engineering

Engineering Practices Laboratory GE 2116

9518 - National College of Engineering

2. BASIC PIPE CONNECTIONS FOR WASH BASIN AND WATER HEATER

Aim: To construct a basic pipe connections for wash basin and water heater. Materials required: 1. 2. 3. 4. 5. 6. 7. 8. Plumbing tool kit Taps Wash basin Water heater Elbow Tee Gate valve PVC 1 No. 3 Nos. 1 No. 1 No. 3 Nos. 2 Nos. 1 No. required length

Procedure: 1) 2) 3) 4) 5) 6) 7) 8) Study the given diagram. Mark the location of wash basin, water heater and taps. Fix the wash basin, water heater. Make the tee and elbow connections in the main pipeline to connect it to the wash basin, water heater and taps. Fix the gate valve, near the water tank. Connect all pipe fittings as per diagram. The water tank was filled with water and the gate valve was opened slowly to supply water into pipeline. The taps were opened to check its functions.

Result: Thus the basic connections for wash basin and water heater is made.

Engineering Practices Laboratory GE 2116

9518 - National College of Engineering

All Dimensions are in mm. Not to Scale.

Engineering Practices Laboratory GE 2116

9518 - National College of Engineering

3. T- JOINT Aim: To make a T-joint from the given wooden piece for the desired dimensions. Material supplied: A wooden piece of size 300x40x40 mm. Tools required: 1. Jack plane 4. Tenon saw 7. Firmer chisel Sequence of operations: 1. Rough planing 4. Chiselling Working steps: 1. The given job is checked to ensure its correct size. 2. The job is firmly clamped in the carpentry vice and any two surfaces are planed by jack plane to get right angle. 3. Using try square, the right angle of the workpiece is checked. 4. All the four sides of the wooden pieces are planed to get the smoother and finished surface. 5. The job is cut into two halves using rip saw then proper marking is done for T-joint on the two pieces using steel rule and marking gauge. 6. One half is taken. Using tenon saw and firmer chisel the unwanted portions are removed as per the drawing. 7. The above procedure is repeated for the other half of the workpiece. 8. Jack plane is used to plane the other two faces upto the marked portion. 9. Now the two pieces are assembled to check proper fitting. 10. The finished job is again checked for its accurate shape and size using try square and steel rule. Result: Thus the desired T-joint is obtained. 2. Marking 5. Finish planing 3. Cutting (or) sawing 2. Try square 5. Carpentry vice 8. Mallet 3. Marking gauge 6. Steel rule 9. Rip saw

Engineering Practices Laboratory GE 2116

9518 - National College of Engineering

All Dimensions are in mm. Not to Scale.

Engineering Practices Laboratory GE 2116

10

9518 - National College of Engineering

4. DOVE-TAIL JOINT Aim: To make a dove-tail joint from the given wooden piece to get the desired dimensions. Material supplied: A wooden piece of size 300x40x40 mm. Tools required: 1. Jack plane 4. Tenon saw 7.Firmer chisel 2. Try square 5. Carpentry vice 8. Mallet 3. Marking gauge 6. Steel rule 9. Rip saw 3. Cutting (or) sawing

Sequence of operations: 1. Rough planning 2. Marking 4. Chiselling 5. Finish planing

Working steps: 1. The given job is checked to ensure its correct size. 2. The job is firmly clamped in the carpentry vice and any two surfaces are planed by jack plane to get right angle. 3. Using try square, the right angle of the workpiece is checked. 4. All the four sides of the wooden pieces are planed to get the smoother and finished surface. 5. The job is cut into two halves using rip saw then proper marking is done for dovetail joint on the two pieces using steel rule and marking gauge. 6. One half is taken. Using tenon saw and firmer chisel the unwanted portions are removed as per the drawing. 7. The above procedure is repeated for the other half of the workpiece. 8. Jack plane is used to plane the other two faces upto the marked portion. 9. Now the two pieces are assembled to check proper fitting. 10. The finished job is again checked for its accurate shape and size using try square and steel rule. Result: Thus the desired dove-tail joint is obtained.

Engineering Practices Laboratory GE 2116

11

9518 - National College of Engineering

All Dimensions are in mm. Not to Scale.

Engineering Practices Laboratory GE 2116

12

9518 - National College of Engineering

5. CROSS LAP JOINT Aim: To make a cross lap joint from the given wooden piece for the desired dimensions. Material supplied: A wooden piece of size 300x40x40 mm. Tools required: 1. Jack plane 4. Tenon saw 7. Firmer chisel Sequence of operations: 1. Rough planning 4. Chiselling 2. Marking 5. Finish planing 3. Cutting (or) sawing 2. Try square 5. Carpentry vice 8. Mallet 3. Marking gauge 6. Steel rule 9. Rip saw

Working steps: 1. The given job is checked to ensure its correct size. 2. The job is firmly clamped in the carpentry vice and any two surfaces are planed by jack plane to get right angle. 3. Using try square, the right angle of the workpiece is checked. 4. All the four sides of the wooden pieces are planed to get the smoother and finished surface. 5. The job is cut into two halves using rip saw then proper marking is done for cross lap joint on the two pieces using steel rule and marking gauge. 6. One half is taken. Using tenon saw and finner chisel the unwanted portions are removed as per the drawing. 7. The above procedure is repeated for the other half of the workpiece. 8. Jack plane is used to plane the other two faces upto the marked portion. 9. Now the two pieces are assembled to check proper fitting. 10. The finished job is again checked for its accurate shape and size using try square and steel rule. Result: Thus the desired cross lap joint is obtained.

Engineering Practices Laboratory GE 2116

13

9518 - National College of Engineering

All Dimensions are in mm. Not to Scale.

Engineering Practices Laboratory GE 2116

14

9518 - National College of Engineering

6. STEPPED SHAFT Aim: To obtain the required stepped shaft by turning and facing operations. Materials supplied: Cylindrical work piece of diameter 25mm and length 65mm mild steel rod. Tools required: 1. Lathe 4. Try square Sequence of operations: 1. Checking 4. Facing Working steps: 1. The given work piece is checked for its dimensions. 2. The work piece is held in the chuck. Chuck key is used to tighten the job firmly, ensuring centering of work-piece. 3. The single point cutting tool is held in the tool post and tighten the nuts using spanner. 4. Facing is done with cutting tool moving from the centre of workpiece towards outside. It is done until the required length of the job is obtained. 5. Turning is done to reduce the diameter of the job. Sufficient depth of cut is given and it is done until the required diameter of the job is obtained. 6. Finally the dimensions of workpiece are again checked. Result: Thus the required size and shape of the given work piece is obtained. 2.Workpiece setting 5. Turning 3. Tool setting 2. Cutting tool 5. Scriber 3. Vernier Caliper 6. Vernier height gauge

Engineering Practices Laboratory GE 2116

15

9518 - National College of Engineering

All Dimensions are in mm. Not to Scale.

Engineering Practices Laboratory GE 2116

16

9518 - National College of Engineering 7. DRILLING Aim: To drill the holes of required sizes . Material supplied: 50x50x5 nun Mild steel plate - 1 No. Tools required: 1. Bench vice 4. Standard set of filing tools 7. Vernier height gauge 10. Dri11 bit Sequence of operations: 1. Checking 4. Punching Working steps: 1. The raw material is checked for its size 50 x 50 x 5 mm using steel rule. 2. The given workpiece is clamped in a vice and any two surfaces are filed to get right angle. 3. Chalk is applied uniformly on the surfaces of the workpieces. 4. With the help of vernier height gauge, surface plate, angle plate, steel rule, and scriber the given dimensions are marked. 5. The mid point of the required holes is punched by using a dot punch. 6. The punched dots are drilled by drilling machine. 7. Finally the dimensions are again checked. 2. Machine vice 5. Try square 8. Scriber 3. Steel rule 6. Surface plate 9. Dot Punch

2. Filing 5. Drilling

3. Marking

Result: Thus the given work piece is drilled to the required dimensions.

Engineering Practices Laboratory GE 2116

17

9518 - National College of Engineering

All Dimensions are in mm. Not to Scale.

Engineering Practices Laboratory GE 2116

18

9518 - National College of Engineering 9. BUTT JOINT Aim: To make a butt joint using gas welding on the given work pieces. Material supplied: Mild steel plate of size 100 x 50 x 4 mm 2 Nos. Tools required: 1. Oxygen cylinder 4. Tongs 7. Wire brush Sequence of operations: 1. Edge preparation 4. Cooling Working steps: 1. First of all, the workpieces must be thoroughly cleaned to remove rust, scale and other foreign material. 2. Set the neutral flame in welding torch. 3. Set the workpiece in correct position and maintain the gap 3mm and start tack welding at both ends of the workpiece. 4. Now the partially welded plate are inverted and tacked at both ends of the workpiece. 5. Again the welding is carried out throughout the length. 6. As soon as the welding process is finished close the valves of both the oxygen cylinder and acetylene cylinder. Then allow the workpiece to cool. 7. Finally using wire brush, welded portions are cleaned 2. Tacking 5. Chipping 3. Welding 6. Cleaning 2. Acetylene cylinder 5. Safety glasses 8. Gloves 3. Welding torch 6. Chipping hammer 9. Aprons

Result: Thus the desired butt joint is obtained using gas welding.

Engineering Practices Laboratory GE 2116

19

9518 - National College of Engineering

All Dimensions are in mm. Not to Scale.

10. LAP JOINT

Engineering Practices Laboratory GE 2116

20

9518 - National College of Engineering

Aim: To make a lap joint using arc welding on the given work pieces. Material supplied: Mild steel plate of size l00x50x4 mm - 2 Nos. Tools required: 1. Power supply (AC or DC) 3. Electrodes 5. Chipping hammer 7. Gloves 9. Shield 11. Earthing clamps Sequence of operations: 1. Edge preparation (Removal of rust, scale etc.) 2. Tacking 3. Welding 4. Cooling 5. Chipping 6. Cleaning Working steps: 1. First of all, the workpieces must be thoroughly cleaned to remove rust, scale and other foreign material. 2. Now the workpieces are placed on the table in such a way that two workpieces are overlapped one over another as shown in fig. 3. Appropriate power supply should be given to the electrode and the workpieces. 4. Now the welding current output may be adjusted. 5. When current is passed, arc is produced between electrode and the workpieces. 6. Set the two workpieces in correct position like lap joint and tack at both ends of the workpieces as shown in figure. 7. Then the welding is carried out throughout the length of the workpiece. 8. As soon as the welding process is finished switch off the current supply. 9. Then allow the workpiece to cool, after that slags are removed by chipping process with the help of chipping hammer. 10. Finally by using wire brush, welded portions (weldment) are cleaned. Result: Thus the desired lap joint is obtained using arc welding. 2. Welding Torch 4. Tongs 6. Wire brush 8. Apron 10. Safety goggles

Engineering Practices Laboratory GE 2116

21

9518 - National College of Engineering

Engineering Practices Laboratory GE 2116

22

9518 - National College of Engineering 12. Double Parallel Fillet joint

Aim: To make a lap joint using arc welding on the given work pieces. Material supplied: Mild steel plate of size l00x50x4 mm - 2 Nos. Tools required: 1. Power supply (AC or DC) 3. Electrodes 5. Chipping hammer 7. Gloves 9. Shield 11. Earthing clamps Sequence of operations: 2. Edge preparation (Removal of rust, scale etc.) 2. Tacking 3. Welding 4. Cooling 5. Chipping 6. Cleaning Working steps: 11. First of all, the workpieces must be thoroughly cleaned to remove rust, scale and other foreign material. 12. Now the workpieces are placed on the table in such a way that two workpieces are overlapped one over another as shown in fig. 13. Appropriate power supply should be given to the electrode and the workpieces. 14. Now the welding current output may be adjusted. 15. When current is passed, arc is produced between electrode and the workpieces. 16. Set the two workpieces in correct position like lap joint and tack at both ends of the workpieces as shown in figure. 17. Then the welding is carried out throughout the length of the workpiece. 18. As soon as the welding process is finished switch off the current supply. 19. Then allow the workpiece to cool, after that slags are removed by chipping process with the help of chipping hammer. 20. Finally by using wire brush, welded portions (weldment) are cleaned. Result: Thus the desired lap joint is obtained using arc welding. 2. Welding Torch 4. Tongs 6. Wire brush 8. Apron 10. Safety goggles

Engineering Practices Laboratory GE 2116

23

9518 - National College of Engineering

Engineering Practices Laboratory GE 2116

24

9518 - National College of Engineering 13. T joint Aim: To make a T joint using arc welding on the given work pieces. Material supplied: Mild steel plate of size l00x50x4 mm - 2 Nos. Tools required: 1. Power supply (AC or DC) 3. Electrodes 5. Chipping hammer 7. Gloves 9. Shield 11. Earthing clamps Sequence of operations: 3. Edge preparation (Removal of rust, scale etc.) 2. Tacking 3. Welding 4. Cooling 5. Chipping 6. Cleaning Working steps: 21. First of all, the workpieces must be thoroughly cleaned to remove rust, scale and other foreign material. 22. Now the workpieces are placed on the table in such a way that two workpieces are overlapped one over another in the form of a T-shape as shown in fig. 23. Appropriate power supply should be given to the electrode and the workpieces. 24. Now the welding current output may be adjusted. 25. When current is passed, arc is produced between electrode and the workpieces. 26. Set the two workpieces in correct position like tjoint and tack at both ends of the workpieces as shown in figure. 27. Then the welding is carried out throughout the length of the workpiece. 28. As soon as the welding process is finished switch off the current supply. 29. Then allow the workpiece to cool, after that slags are removed by chipping process with the help of chipping hammer. 30. Finally by using wire brush, welded portions (weldment) are cleaned. Result: Thus the desired T joint is obtained using arc welding. 2. Welding Torch 4. Tongs 6. Wire brush 8. Apron 10. Safety goggles

Engineering Practices Laboratory GE 2116

25

9518 - National College of Engineering

All Dimensions are in mm. Not to Scale.

Engineering Practices Laboratory GE 2116

26

9518 - National College of Engineering

14. RECTANGULAR TRAY Aim: To make a rectangular tray from the given sheet metal. Material supplied: 22 gauge Galvanized Iron (G. I) sheet. Tools required: 1. Steel rule 4. Divider 7. Stakes Sequence of operations: 1. Checking 4. Cutting 6. Rivetting Working steps: 1. The size of the given sheet is checked for its dimensions Using a steel rule. 2. Then the sheet is levelled on the levelling plate using a mallet. 3. The development procedure is followed same as square taper tray. 4. The dimensions are marked as shown in fig. 5. The sheet is cut as per the marked dimensions by straight snips. 6. Then a single hemming is made on the four sides of the tray as shown In fig. 7. The four sides of the tray are bent to 90 using stakes anvil. 8. Finally all the corners of the tray are joined by riveting. Result: Thus the desired rectangular tray is made from the given sheet metal. 2. Levelling 5. Bending 3. Levelling 6. Hemming 2. Mallet 5. Protractor 8. Rivet set 3. Scriber 6. Snips 9. Ball peen hammer

MAKING OF A CONE FUNNEL

Engineering Practices Laboratory GE 2116

27

9518 - National College of Engineering

Aim To make a funnel from the given sheet metal. Tools required Steel rule Mallet Scriber Divider Protractor Snips Stakes Ball peen hammer Solder Procedure 1. The size of the given sheet is checked for its dimension using steel rule. 2. The required development of surface is being made on the white paper which is overlapped on the sheet metal. 3. The marking is done on the sheet metal as per the development being done on the paper. 4. Now using straight snips, unwanted material are removed. 5. Now fold and bend the workpiece to make the funnel shape and joint is made on the workpieces. 6. Then using a groove, a locked grooved joint is made for about 5mm. also; hemming is done in the bottom of the funnel. 7. In between top face and bottom face, a butt joint is made using a solder. 8. Finally, trimming and finishing operations are carried out.

Result Thus desired cone funnel is made from the given sheet metal.

Engineering Practices Laboratory GE 2116

28

9518 - National College of Engineering

All Dimensions are in mm. Not to Scale.

17. V- JOINT Engineering Practices Laboratory GE 2116 29

9518 - National College of Engineering

Aim: To make a v-joint on the given work piece. Material supplied: 50 x 50 x.5 mm Mild steel plate - 2 Nos. Tools required: 1. Bench vice 3. Standard set of filing tools 5. Scriber 7. Surface plate 9. Dot punch Sequence of operations : 1. Checking 3. Marking 5. Sawing 7. Finish Filing Working steps: 1. The given material is checked for its size 50 x 50 x 5mm after deburring. 2. The given pieces are fixed rigidly on the vice separately and all edges are filed using flat file so that they are at right angles. 3. Then chalk is applied uniformly on the surfaces of the workpieces. 4. The workpiece is marked to given dimensions as per drawing with reference to the datum using surface plate and vernier height gauge. 5. Now using dot punch, dots are punched along the marked line. 6. Using Hacksaw frame, the unwanted portions are removed. 7. Cutting edges are filed by using half round and triangular files. 8. Finally, the assembly is checked for the required class of fit. Result: Thus the required V- joint is obtained from the given work piece. 2. Rough Filing 4. Punching 6. Rough Filing 2. Steel rule 4. Try square 6. Vernier Height gauge 8. Angle Plate 10. Fixed Hacksaw

Engineering Practices Laboratory GE 2116

30

You might also like

- Unit 6Document13 pagesUnit 6VeronicaNo ratings yet

- Scania 12L - EMS - Operator - Manual - enDocument60 pagesScania 12L - EMS - Operator - Manual - enАнатолий ЩербаковNo ratings yet

- Generation of Electrical Energy - B. R. GuptaDocument171 pagesGeneration of Electrical Energy - B. R. GuptaIbrahim Ahmed43% (23)

- Variable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)Document227 pagesVariable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)miladNo ratings yet

- Fundamentals of Compressible Fluid FlowDocument335 pagesFundamentals of Compressible Fluid Flowlenojerin3486100% (3)

- Fundamentals of Compressible Fluid FlowDocument335 pagesFundamentals of Compressible Fluid Flowlenojerin3486100% (3)

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- JUS StandardsDocument28 pagesJUS StandardsgarejkaNo ratings yet

- Thirukkural With MeaningDocument164 pagesThirukkural With Meaningவினோத்94% (88)

- 3 Phase Induction Motors Objective Questions With AnswersDocument3 pages3 Phase Induction Motors Objective Questions With AnswersMohan Raj0% (2)

- Rigid Sportster Frame Assembly GuideDocument14 pagesRigid Sportster Frame Assembly GuideMalcolm DiamondNo ratings yet

- Challenges in PavementsDocument23 pagesChallenges in PavementsSomeshwar Rao ThakkallapallyNo ratings yet

- Shop Practice Number 6Document9 pagesShop Practice Number 6JantzenCaliwliwNo ratings yet

- MT-II LabDocument7 pagesMT-II LabAjay Vikram0% (1)

- False Ceiling Construction Details PDFDocument2 pagesFalse Ceiling Construction Details PDFAlexis17% (6)

- Workshop Hammer ReportDocument14 pagesWorkshop Hammer ReportJoshua Chong67% (3)

- Boundary Layer Thickness and Heat Transfer CalculationsDocument9 pagesBoundary Layer Thickness and Heat Transfer Calculationsannie100% (1)

- Lab Exp Manual Workshop 2018 19Document32 pagesLab Exp Manual Workshop 2018 19Babeet JaatNo ratings yet

- SHB 2503-3703 en 1000081433Document192 pagesSHB 2503-3703 en 1000081433Alberto100% (1)

- GE2152 Basic Civil & Mechanical EngineeringDocument30 pagesGE2152 Basic Civil & Mechanical EngineeringThulasi RamNo ratings yet

- Ep Lab Manual Civil & ElectricalDocument62 pagesEp Lab Manual Civil & ElectricalraghulNo ratings yet

- SSN EPL Mechanical - ManualDocument84 pagesSSN EPL Mechanical - ManualThejaswar TejaNo ratings yet

- Basic Machining Facing and TurningDocument17 pagesBasic Machining Facing and TurningKedar NathNo ratings yet

- AICTE Approved Mechanical Engineering Lab RecordsDocument76 pagesAICTE Approved Mechanical Engineering Lab RecordsSathish KNo ratings yet

- Mechanical Engineering Lab Manual from National Institute of Technology, APDocument44 pagesMechanical Engineering Lab Manual from National Institute of Technology, APSaurav KumarNo ratings yet

- Institutional Activity: GuideDocument9 pagesInstitutional Activity: GuideUttu_DasNo ratings yet

- Airframe and Aero Engine Lab FinalDocument25 pagesAirframe and Aero Engine Lab FinalAravind Phoenix50% (2)

- Vsa Scholl of Engineering: Iv Semester Mechanical EngineeringDocument43 pagesVsa Scholl of Engineering: Iv Semester Mechanical EngineeringDmj Anbu RajNo ratings yet

- WorkshopDocument5 pagesWorkshopJoseph NjugunaNo ratings yet

- Workshop - List of Experements and Its Procedure PDFDocument29 pagesWorkshop - List of Experements and Its Procedure PDFAdhi SheshuNo ratings yet

- Sem Workshop ManualDocument22 pagesSem Workshop ManualSaikat BanerjeeNo ratings yet

- Step-by-Step Guide to Taper TurningDocument36 pagesStep-by-Step Guide to Taper TurningLEAGUE OF WARLORDSNo ratings yet

- Fitting ShopDocument4 pagesFitting ShopAmarjeet Singh (Assistant Professor- Mechanical Engineer)No ratings yet

- Fabrication ProcessDocument6 pagesFabrication ProcessSounak ChakrabortyNo ratings yet

- Workshop Practice Course DetailsDocument27 pagesWorkshop Practice Course DetailsRajib Mandal100% (1)

- C-Clamp: Fundamental of ManufacturingDocument35 pagesC-Clamp: Fundamental of ManufacturingBikash Chandra DasNo ratings yet

- ME2258 Manufacturing Technology Lab IIDocument14 pagesME2258 Manufacturing Technology Lab IIதியாகராஜன் அரிதாஸ்No ratings yet

- N 51 e 62 e 9 Ea 2045Document28 pagesN 51 e 62 e 9 Ea 2045TECH RISHABH 07No ratings yet

- Mec 123 PracticalDocument41 pagesMec 123 Practicalsanialiu2711No ratings yet

- 1 CarpentryDocument5 pages1 CarpentryMa NojNo ratings yet

- Carpentary 2 Workshop LabDocument1 pageCarpentary 2 Workshop Labsyed azeemNo ratings yet

- me8361-MT 1 LabmanualDocument37 pagesme8361-MT 1 LabmanualHOD ITNo ratings yet

- What Is Fitting Shop?Document4 pagesWhat Is Fitting Shop?Er Indraj Kumar SudiaNo ratings yet

- Lab 4Document5 pagesLab 4eimaan afrozNo ratings yet

- Progress Report Shop ProjectDocument3 pagesProgress Report Shop Projectapi-550048875No ratings yet

- Vertical Lift Bridge ProjectDocument17 pagesVertical Lift Bridge ProjectPrankur Sharma82% (11)

- MFT Lab Manual 2017-18 Even UpdatedDocument63 pagesMFT Lab Manual 2017-18 Even UpdatedPrakash ThangavelNo ratings yet

- Epl RecordDocument63 pagesEpl RecordTishbian MeshachNo ratings yet

- Experiment - Arc WeldingDocument5 pagesExperiment - Arc WeldingAl Anood Al AmeriNo ratings yet

- Workshop Lab ManualDocument92 pagesWorkshop Lab ManualRajuNo ratings yet

- PRIR11 - Engineering Practice Lab Manual: Tiruchirappalli-620015Document21 pagesPRIR11 - Engineering Practice Lab Manual: Tiruchirappalli-620015pranav kumarNo ratings yet

- Mya Myint Mo (Workshop)Document12 pagesMya Myint Mo (Workshop)ytzqddnd58No ratings yet

- MT-II LAB ManualDocument44 pagesMT-II LAB ManualGANESH KUMARNo ratings yet

- Performing marking, cutting, filing, drilling and threading operationsDocument5 pagesPerforming marking, cutting, filing, drilling and threading operationsKashif SultanNo ratings yet

- ME2258 Lab ManualDocument14 pagesME2258 Lab ManualMURALIGOCAM_29070605No ratings yet

- Government College of Engineering, Kalahandi, BhawanipatnaDocument20 pagesGovernment College of Engineering, Kalahandi, BhawanipatnaManoranjan KumarNo ratings yet

- Diploma Workshop Practice IDocument20 pagesDiploma Workshop Practice Ieighteen plusNo ratings yet

- M.Kumarasamy: Basic Civil and Mechanical Engineering LaboratoryDocument21 pagesM.Kumarasamy: Basic Civil and Mechanical Engineering LaboratoryAravindNo ratings yet

- A Low-Cost Energy Efficient Greenhouse: Construction ManualDocument17 pagesA Low-Cost Energy Efficient Greenhouse: Construction ManualNestor LopezNo ratings yet

- The Cylinder Vessel of Inner Diameter 8 Inch With Hemispherical End Caps. The Vessel Has A Wall Thickness of 0.5 Inch Where The Centers of Hemisphere Are 15 Inch ApartDocument3 pagesThe Cylinder Vessel of Inner Diameter 8 Inch With Hemispherical End Caps. The Vessel Has A Wall Thickness of 0.5 Inch Where The Centers of Hemisphere Are 15 Inch ApartmdahasanNo ratings yet

- Cam Projectt.Document16 pagesCam Projectt.fu MozaNo ratings yet

- Stationary Clamp ReportDocument21 pagesStationary Clamp Reportapi-233198198No ratings yet

- EPL 2019 New ManualDocument44 pagesEPL 2019 New ManualNigileshNo ratings yet

- GegasDocument18 pagesGegasPiraven Casanova II50% (2)

- Ews Lab Manual - Au - 18.1.20241Document47 pagesEws Lab Manual - Au - 18.1.20241Priya SurvacyNo ratings yet

- Assignment 2Document17 pagesAssignment 2AakarshNo ratings yet

- Mannual Narayana 2023-02Document51 pagesMannual Narayana 2023-02pallahemahimaja123No ratings yet

- Metal Bending Machine 1978Document24 pagesMetal Bending Machine 1978Adrian CocisNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Paper2 PDFDocument12 pagesPaper2 PDFlenojerin3486No ratings yet

- A Coevolutionary Algorithm For A Facility Layout ProblemDocument32 pagesA Coevolutionary Algorithm For A Facility Layout Problemlenojerin3486No ratings yet

- QB Iat 1 GDJPDocument2 pagesQB Iat 1 GDJPlenojerin3486No ratings yet

- University CadcamDocument4 pagesUniversity Cadcamlenojerin3486No ratings yet

- Young Scientist FormatDocument3 pagesYoung Scientist FormatdevendrakphyNo ratings yet

- University CadcamDocument4 pagesUniversity Cadcamlenojerin3486No ratings yet

- 2MARKSDocument21 pages2MARKSmuthupecmec4908No ratings yet

- QB Iat 1 GDJPDocument2 pagesQB Iat 1 GDJPlenojerin3486No ratings yet

- NPTEL Course ContentsDocument40 pagesNPTEL Course Contentslenojerin3486No ratings yet

- University CadcamDocument4 pagesUniversity Cadcamlenojerin3486No ratings yet

- MT-2 Lab Manual Rajalaksmi PDFDocument11 pagesMT-2 Lab Manual Rajalaksmi PDFlenojerin3486No ratings yet

- Thermoplastics - Properties and ApplicationsDocument19 pagesThermoplastics - Properties and Applicationslenojerin3486No ratings yet

- Lab Manual For Me1151Document16 pagesLab Manual For Me1151lenojerin3486No ratings yet

- MT I Lab ManualDocument20 pagesMT I Lab Manuallenojerin3486No ratings yet

- Pset 5Document4 pagesPset 5lenojerin3486No ratings yet

- Advance Machinig Process MaterialDocument49 pagesAdvance Machinig Process MaterialDhiliban SubramaniyanNo ratings yet

- 2010 Kinematic Feature MIL IeeeDocument16 pages2010 Kinematic Feature MIL Ieeelenojerin3486No ratings yet

- Hit-Re 500 With Hit-V Has RodsDocument3 pagesHit-Re 500 With Hit-V Has RodsMKNo ratings yet

- Customer Targeted E-CommerceDocument4 pagesCustomer Targeted E-CommercepriyaNo ratings yet

- Civil Engineering Reference BooksDocument2 pagesCivil Engineering Reference Booksdevbrat boseNo ratings yet

- Method Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksDocument16 pagesMethod Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksAn-an ChanNo ratings yet

- Correlation Study and Regression Analysis of Water Quality Assessment of Nagpur City, IndiaDocument5 pagesCorrelation Study and Regression Analysis of Water Quality Assessment of Nagpur City, IndiaShakeel AhmadNo ratings yet

- Staircase Preliminary Design Based On NBC and IS CodeDocument10 pagesStaircase Preliminary Design Based On NBC and IS CodeEducation. HubNo ratings yet

- Strength and Insulating Properties of Building Blocks Made From Waste MaterialsDocument7 pagesStrength and Insulating Properties of Building Blocks Made From Waste Materialsmjrobust05No ratings yet

- Final ReportDocument33 pagesFinal ReporttsutsenNo ratings yet

- W 7570 enDocument276 pagesW 7570 enthedoors89No ratings yet

- AASHTO T283-22 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced DamageDocument11 pagesAASHTO T283-22 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced DamageErnesto Oscar VidelaNo ratings yet

- ReleDocument3 pagesRelevitor4santos_6No ratings yet

- Easygen-3000 Series (Package P1) Genset Control: InterfaceDocument102 pagesEasygen-3000 Series (Package P1) Genset Control: InterfacejinameNo ratings yet

- 2009 Energy Storage-U.S. Department of EnergyDocument380 pages2009 Energy Storage-U.S. Department of EnergydiwhiteNo ratings yet

- Smarter and Safer: Cordless Endodontic HandpieceDocument2 pagesSmarter and Safer: Cordless Endodontic Handpiecesonu1296No ratings yet

- 1986 Lobel RobinsonDocument18 pages1986 Lobel RobinsonNathallia SalvadorNo ratings yet

- Assessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Document12 pagesAssessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Ma Liu Hun VuiNo ratings yet

- 95 - 737-General-InformationDocument3 pages95 - 737-General-InformationffontanaNo ratings yet

- Seminar ReportDocument30 pagesSeminar Reportshashank_gowda_7No ratings yet

- Essential Roof Truss Design TermsDocument45 pagesEssential Roof Truss Design TermsAnkit SuriNo ratings yet

- Manual Service Aoc - E943fwskDocument51 pagesManual Service Aoc - E943fwskEduardo BentoNo ratings yet