Professional Documents

Culture Documents

Regulator

Uploaded by

Florin GoiaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Regulator

Uploaded by

Florin GoiaCopyright:

Available Formats

Pressure regulator FRS

4.01

16

Technical description The DUNGS pressure regulator, type FRS, has an adjustable setpoint spring. The pressure regulator complies with EN 88 and DIN 3380: - Input pressures up to 500 mbar - High flow rate - Sturdy, precise and sensitive regulation of regulator output pressure - Inlet pressure compensation diaphragms - Safety diaphragms - Internal pulse for regulator output pressure as standard, optional external pulse connection optional on both sides - Rp 3/8 to Rp 2 thread connection - DN 20 to DN 150 flange connection Application Gas pressure regulator for gas burners and gas equipment. It does not contain any nonferrous metals, suitable for gases of up to max. 0.1 vol.% H2S, dry. Suitable for gases of families 1, 2, 3 and other neutral gaseous media.

Approval EU type test approval as per EU Gas Appliance Directive. FRS 503 FRS 505 FRS 507 / 5020 FRS 510 / 5025 FRS 515 / 5040 FRS 520 / 5050 FRS 525 FRS 5065 FRS 5080 FRS 5100 FRS 5125 FRS 5150 CE-0085 AQ 0244 CE-0085 AQ 0245 CE-0085 AQ 0246 CE-0085 AQ 0247 CE-0085 AQ 0264 CE-0085 AQ 0265 CE-0085 AQ 0266 CE-0085 AQ 0267 CE-0085 AQ 0268 CE-0085 AQ 0269 CE-0085 AQ 0270 CE-0085 AQ 0271

Printed in Germany Rsler Druck Edition 08.00 Nr. 214 743

Approvals in other important gasconsuming countries.

FRS

Spring-loaded pressure regulator with adjustable setpoint spring. Internal tap of regulator output pressure. External pulse connections optional, suitable for controlling regulator output pressure.

Specifications Nominal diameters Pipe thread as per ISO 7/1 Flange DN 10 15 20 25 40 50 65 80 100 125 150 Rp 3/8 1/2 3/4 1 1 1/2 2 Connection flange as per DIN 2501 Part 1, to fit preweld flanges as per DIN 2633 (PN 16) DN 40 to DN 150, ISO 7085 - 1 (PN 16), ISO 7005 - 2 (PN 16) up to 500 mbar (50 kPa) Pressure regulator as per EN 88, Class A, Group 2, DIN 3380, RG 10 + 5 mbar or p2 +2.5 mbar up to 500 mbar PN 1 2.5 mbar to 150 mbar as a factor of adjustable setpoint spring Housing: aluminium, steel Seals and diaphragms: NBR -15 C to + 70 C Regulator dome from vertically upright to lying horizontally G 1/4 ISO 228 on both sides in inlet section Internal in outlet section, Optional: external on housing on both sides Blow-off line only required in special cases. Safety diaphragms are installed. Connection: G 1/4 ISO 228 to Rp 1; from Rp 1 1/2, DN 40: G 1/2 ISO 228

Max. operating pressure Pressure regulator Input pressure range Pressure stage Output pressure range Materials of gas-conveying parts

Ambient temperature Installation position Measuring/ignition gas connections Pulse connection

Blow-off line

Pressure taps 1 Breathing plug, blow-off line. 2 Connection for external pulse G 1/4 ISO 228 screw plug on both sides, optional 3 G 1/4 ISO 228 screw plug in input section on both sides

1

26

Spring selection The output pressure is provided by the moving parts. The pressure reguthe force of the installed adjustable lator is equipped with the blue spring spring and the force due to weight of No. 4 as standard. By exchanging the Setpoint spring range [mbar] Spring colour Nominal width Rp/DN Rp 3/8, Rp 1/2 Rp 3/4 Rp 1 Rp 1 1/2, DN 40 Rp 2, DN 50 DN 65, 80 DN 100 DN 125 DN 150 Dimensions 2,59 513 520 Spring 1 Spring 2 Spring 3 brown white orange 069 112 069 195 069 278 058 859 058 925 058 636 083 188 053 082 053 157 069 120 069 203 069 286 058 867 058 933 058 644 083 196 053 090 053 165 069 138 069 211 069 294 058 875 058 941 058 651 083 204 053 108 053 173 1030 Spring 4 blue Standard 069 146 069 229 069 302 058 883 058 958 058 669 083 212 053 116 053 181 2555 Spring 5 red 069 153 069 237 069 310 058 891 058 966 058 677 083 220 053 124 053 199

adjustable spring, other output pressures can be adjusted.

3070 Spring 6 yellow 069 161 069 245 069 328 058 909 058 974 058 685 083 238 053 132 053 207

60110 Spring 7 black 069 179 069 252 069 336 058 917 058 982 058 693 083 246 053 140 053 215

100150 Spring 8 pink 069 187 069 260 069 344 069 351 069 369 069 377 083 253 223 461 223 462

h g d

DN

DN

f a a

Type

Rp / DN Order No. Order No. pmax. Internal External [mbar] pulse pulse 086 462 070 383 070 391 070 409 058 446 058 628 065 144 065 151 058 792 079 681 082 552 013 250 013 268 220 998 211 817 220 999 210 381 221 000 208 237 214 474 183 600 183 930 183 940 211 019 208 301 208 302 500 500 500 500 500 500 500 500 500 500 500 500 500 Rp 3/8 Rp 1/2 Rp 3/4 Rp 1 Rp 1 1/2 Rp 2 DN 40 DN 50 DN 65 DN 80 DN 100 DN 125 DN 150

Dimensions [mm] a 75 75 100 110 150 170 200 230 290 310 350 400 480 b 115 115 130 145 195 250 195 250 285 285 350 400 480 c 24 24 28 33 40 47 65 75 95 95 105 135 160 d 143 143 165 190 250 310 280 340 405 405 495 635 780 e G 1/4 G 1/4 G 1/4 G 1/4 G 1/2 G 1/2 G 1/2 G 1/2 G 1/2 G 1/2 G 1/2 G 1/2 G 1/2 f G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 g G 1/8 G 1/8 G 1/8 G 1/8 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 G 1/4 h 225 225 245 310 365 450 395 480 590 590 760 1000 1180

Weight [kg]

FRS 503 FRS 505 FRS 507 FRS 510 FRS 515 FRS 520 FRS 5040 FRS 5050 FRS 5065 FRS 5080 FRS 5100 FRS 5125 FRS 5150

0.60 0.60 1.00 1.20 2.50 3.50 3.50 5.00 7.50 10.00 16.00 28.00 38.00

36

Functional description Functions according to the force comparison principle between the force of: - the adjustable setpoint spring - the differential pressure at the working diaphragm - the force due to weight of the moving parts The adjustable spring acts with the force due to weight of the moving parts. The output pressure is adjusted depending on the pretension of the adjustable spring and the installation position.

Instructions Gas-conveying lines, pulse and connection lines must be made of steel and at least PN 1, DN 6. The lines must be resistant to thermal, chemical and mechanical loads. The lines must be durable and resistant to deformation and cracks.

Do not route condensate from lines into the pressure regulator. Protect the pressure regulator from fouling by means of a suitable dirt trap. Do not apply combustion gas or combustion gas air mixtures to the installation chamber of the adjustable spring. Pressure regulators for this application on request only.

FRS 515 sectional drawing Pressure regulator in operating position

10 9

8 7 6

p1

p2

3 2 1

1 2 3

Housing Regulating cup Pulse tap, internal

4 5 6

Compensation diaphragm Diaphragm disk Working diaphragm

7 8 9 10

Safety diaphragm Breathing plug Setpoint spring Adjustment device

46

Equipment preselection, blocked pressure regulators You can preselect the nominal diameter using the volumetric flow pressure drop characteristic of the pressure regulators in mechanically open state. The pressure drop be-

tween input pressure p1 and regulator output pressure p2 in connection with the maximum volumetric flow Vmax determine the nominal width of the pressure regulator. The operating point described by pmin and Vmax is left of the nominal width of the pressure regu-

lator to be selected. The pressure drop over blocked pressure regulators is described by the "mechanically open" characteristic. The final determination is performed according to the dimension specified by the gas appliance manufacturer.

Volumetric flow pressure drop characteristic mechanically open

Rp 21/2 DN 65 DN 80

Rp 11/2

DN 100

DN 125

Rp 3/8

Rp 1/2

Rp 3/4

Rp 1

100 90 80 70 60 50 40 30 20

p [mbar]

10 9 8 7 6 5 4 3 2

Basis Based on Base Base

+ 15 C, 1013 mbar, trocken + 15 C, 1013 mbar, dry + 15 C, 1013 mbar, sec + 15 C, 1013 mbar, secco

Vn [m 3/h] Luft / Air / Aria dv = 1,00

2 4 6 8 10 20 40

8 10

20

40

60 80 100

200

400

600 800 1000

2000

Vn [m 3/h] Erdgas/Natural gas/Gaz Naturel/Gas metano dv = 0,65

60 80 100

200

400

600 800 1000

2000

4000

Vverwendetes Gas/gas used/ gaz utilis/gas utilizzato = V Luft/air/air/aria x f

Gasart Type of gas Type de gaz Tipo di gas

Dichte Density Densit Densit [kg/m3] 0.81

DN 150

4000

DN 40

DN 50

Rp 2

dv

Dichte Luft Air density Densit de l'air Densit dell'aria f= spez. Gweicht des verwendeten Gases Spec. weight of gas used poids spcifique du gaz utilis peso specifico del gas utilizzato

Erdgas/Nat.Gas/ Gaz naturel/Gas metano Stadtgas/City gas/ Gaz de ville/Gas citt Flssiggas/LPG/ Gaz liquide/Gas liquido Luft/Air/ Air/Aria

0.65

1.24

0.58

0.47

1.46

2.08

1.67

0.77

1.24

1.00

1.00

56

Pressure regulator FRS

Flow diagram in regulated state, where p2 = 20 mbar o o Vmin = 0,05 x Vmax

Rp 1 1/2 DN 100 DN 125 DN 150 Rp 3/8 Rp 1/2 Rp 3/4 DN 40 DN 50 DN 65 DN 80 Rp 1 Rp 2

500 400 300 200

Recommended operating range

100 80 60 50 40 30

p [mbar]

20

10 8 6 5 4 3 2

Basis Based on Base Base

1 1 5 6 8 10

DN 150

+ 15 C, 1013 mbar, trocken + 15 C, 1013 mbar, dry + 15 C, 1013 mbar, sec + 15 C, 1013 mbar, secco

150

Vn [m /h] Luft / Air / Aria dv = 1,00

3

20

30

40 50 60

80 100

200

300 400

600 800 1000

2000

4000

5 6

8 10

Vn [m /h] Erdgas/Natural gas/Gaz Naturel/Gas metano dv = 0,65

3

20

30

40 50 60

80 100

200

300 400

600 800 1000

2000

4000

We reserve the right to make any changes in the interest of technical progress. Head Offices and Factory Karl Dungs GmbH & Co. Siemensstrae 6-10 D-73660 Urbach, Germany Telephone +49 (0)7181-804-0 Fax +49 (0)7181-804-166 Postal address Karl Dungs GmbH & Co. Postfach 12 29 D-73602 Schorndorf, Germany e-mail info@dungs.com Internet www.dungs.com

66

You might also like

- PC1250-8R ShopManual PDFDocument1,254 pagesPC1250-8R ShopManual PDFQuy Le Thanh82% (11)

- Re 25402Document8 pagesRe 25402Arturo MendozaNo ratings yet

- Radial TCDocument3 pagesRadial TCArun SNo ratings yet

- Iveco Fault CodesDocument7 pagesIveco Fault CodesEsam Phlipe67% (3)

- Project Title: Solar Rechargeable Electric ScooterDocument23 pagesProject Title: Solar Rechargeable Electric ScooterArsh 837No ratings yet

- BP Hazards of Water PDFDocument69 pagesBP Hazards of Water PDFLuis L100% (2)

- Gas and Air Filter (DUNGS Model GF Catalog)Document8 pagesGas and Air Filter (DUNGS Model GF Catalog)Julio OrtegaNo ratings yet

- Dungs FRS Gas PR RegDocument6 pagesDungs FRS Gas PR RegAdam KowalskiNo ratings yet

- Gas Pressure Regulator FRU DungDocument8 pagesGas Pressure Regulator FRU DungLaiqNo ratings yet

- Uniworld: Series Pneumatic ValvesDocument2 pagesUniworld: Series Pneumatic ValvesSyarif Mutsaqqif100% (1)

- 402 00 GB 0611Document12 pages402 00 GB 0611Branko BabicNo ratings yet

- Fisher 1190 Low-Pressure Gas Blanketing RegulatorDocument20 pagesFisher 1190 Low-Pressure Gas Blanketing Regulatorneurolepsia3790No ratings yet

- EZR RegulatorDocument40 pagesEZR RegulatorBranko BabicNo ratings yet

- ASCO SolenoidDocument10 pagesASCO Solenoidsharib26No ratings yet

- Valvula Borboleta Lug z614 ADocument6 pagesValvula Borboleta Lug z614 AWellington S. FrançaNo ratings yet

- Control Valve System: PN 16 / 40 DN 15 - 150 ApplicationDocument0 pagesControl Valve System: PN 16 / 40 DN 15 - 150 Applicationcico_ctNo ratings yet

- Wafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ADocument4 pagesWafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ARadu GanciuNo ratings yet

- Catalogo Regulador Watts Mod 152-ADocument2 pagesCatalogo Regulador Watts Mod 152-AGuatemalan1979No ratings yet

- Suction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsDocument2 pagesSuction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsZMCONTROLNo ratings yet

- Gemu Saunders ValvecataloqueDocument8 pagesGemu Saunders ValvecataloqueRavi ChaurasiaNo ratings yet

- Bulletin 1301Document8 pagesBulletin 1301Syed Haris Bin AkhterNo ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Big Joe Type 630 d100121x012Document16 pagesBig Joe Type 630 d100121x012lorgio_moroNo ratings yet

- FG-FGS enDocument9 pagesFG-FGS enAnonymous DPkjxLvYmRNo ratings yet

- Butterfly Valve Lug TypeDocument6 pagesButterfly Valve Lug TypeMr. ANo ratings yet

- Model 496 Service Regulator: Technical DataDocument2 pagesModel 496 Service Regulator: Technical DatavirgolostNo ratings yet

- Pressure Regulator FRSDocument6 pagesPressure Regulator FRSTobiasAngererNo ratings yet

- Filter Regulator TPC Series 2000-4000Document5 pagesFilter Regulator TPC Series 2000-4000Antonius Dwi Putranto NNo ratings yet

- Diaphragm Valve, Metal: ConstructionDocument4 pagesDiaphragm Valve, Metal: ConstructionDenial BasanovicNo ratings yet

- Filteri Za Gas - Fini Sa Izmenjivim Ulo (CimaDocument6 pagesFilteri Za Gas - Fini Sa Izmenjivim Ulo (Cimamicaziv4786No ratings yet

- Re26892 2003-02Document10 pagesRe26892 2003-02DANIZACHNo ratings yet

- Flow MeterDocument6 pagesFlow MeterYvoSteentjes100% (1)

- จำหน่าย Danfoss Type RTDocument11 pagesจำหน่าย Danfoss Type RTParinpa KetarNo ratings yet

- 2040 2e6Document6 pages2040 2e6Jaikishan KumaraswamyNo ratings yet

- Odular YPE A F S AF: IR Ilter EriesDocument9 pagesOdular YPE A F S AF: IR Ilter ErieshadeNo ratings yet

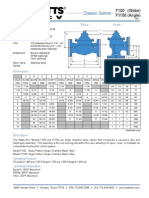

- Classic Series F100 (Globe), F1100 (Angle) Specification SheetDocument2 pagesClassic Series F100 (Globe), F1100 (Angle) Specification SheetWattsNo ratings yet

- Amco CR4000Document4 pagesAmco CR4000Arwin TroconisNo ratings yet

- Regulador American Meter PDFDocument6 pagesRegulador American Meter PDFjmcg1974No ratings yet

- DMK RP 3 - 4 - 2Document6 pagesDMK RP 3 - 4 - 2Vlad Stefan CristianNo ratings yet

- Unitor Cylinder RegulatorDocument8 pagesUnitor Cylinder RegulatorChristis SavvaNo ratings yet

- Fig. 1 Type 3351-1 Pneumatic On/off ValveDocument6 pagesFig. 1 Type 3351-1 Pneumatic On/off ValveZoran DanilovNo ratings yet

- Re 10039Document10 pagesRe 10039Ahmed Abd ElhakeemNo ratings yet

- Es LF289Document2 pagesEs LF289WattsNo ratings yet

- Pressure Reducing Regulator: PR, PM, PH, PD, PLDocument12 pagesPressure Reducing Regulator: PR, PM, PH, PD, PLadventure11111No ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- RFQDocument1 pageRFQAditya TapkirNo ratings yet

- Filter Regulator SMC PDFDocument27 pagesFilter Regulator SMC PDFTuấn Anh NguyễnNo ratings yet

- 1382026533-Plastic Fans Catalogue PDFDocument6 pages1382026533-Plastic Fans Catalogue PDFNicole FelicianoNo ratings yet

- Principle of Operation: Target Inline FlowmeterDocument7 pagesPrinciple of Operation: Target Inline Flowmeterابزار دقیقNo ratings yet

- Ac PDFDocument95 pagesAc PDFCarlos TorresNo ratings yet

- SDM 102 eDocument24 pagesSDM 102 eseaqu3stNo ratings yet

- Elster G-400 PDFDocument8 pagesElster G-400 PDFalexrm12No ratings yet

- Re92060 2014-04Document28 pagesRe92060 2014-04Ibrahim GökmenNo ratings yet

- Sauter B6R Three-Way Valve With Female Thread, PN 16Document4 pagesSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991No ratings yet

- FlowPak - V725 - ANSI - English Veersion Free For ClientDocument12 pagesFlowPak - V725 - ANSI - English Veersion Free For ClientMisael Castillo CamachoNo ratings yet

- LF 251-1100 - D300483Document2 pagesLF 251-1100 - D300483Anshuman AgrawalNo ratings yet

- TS RTG 320 enDocument17 pagesTS RTG 320 enCristi SoareceNo ratings yet

- Valv Y AscoDocument12 pagesValv Y Ascojoticamario123No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Session Plan-Gas Engine Tune UpDocument16 pagesSession Plan-Gas Engine Tune UpJeffrey RamirezNo ratings yet

- Prirucnik Citroen c3Document450 pagesPrirucnik Citroen c3Komarac DzemilNo ratings yet

- Celdas Flotacion Outotec ModuloDocument76 pagesCeldas Flotacion Outotec ModuloarcelitasNo ratings yet

- Lab Manual Manufacturing Proccesses IIDocument80 pagesLab Manual Manufacturing Proccesses IIEntertainment Club100% (1)

- The "New Energy Economy": An Exercise in Magical ThinkingDocument24 pagesThe "New Energy Economy": An Exercise in Magical ThinkingManhattan InstituteNo ratings yet

- MEP Planning ManualDocument197 pagesMEP Planning Manualsmshaidr50% (2)

- 1 9 7 6 Volvo 262 264 265: Notice To Owner: Your Volvo Has Been Built To Comply With All North American Safety and AntiDocument103 pages1 9 7 6 Volvo 262 264 265: Notice To Owner: Your Volvo Has Been Built To Comply With All North American Safety and AntiJohn DaneNo ratings yet

- QSK50-G4: EPA Tier 2 and TA Luft CompliantDocument3 pagesQSK50-G4: EPA Tier 2 and TA Luft CompliantMehrdad saeediNo ratings yet

- B1e 001Document21 pagesB1e 001Mario HanamiciNo ratings yet

- 14D4K3 Fire Fighting System Process Description (System01)Document12 pages14D4K3 Fire Fighting System Process Description (System01)Ratna LailiaNo ratings yet

- GEDocument36 pagesGEGiulio AlessandroniNo ratings yet

- Description of Parameters, Engine Control Module (ECM)Document19 pagesDescription of Parameters, Engine Control Module (ECM)rahmat sanusiNo ratings yet

- Exp 2 Performance Parameter of Diesel EngineDocument7 pagesExp 2 Performance Parameter of Diesel EngineShashwat JainNo ratings yet

- Itinerary Depart Bulawayo For Zvishavane On 28 March 2023 at 0600 Hrs Date Arrive Depart CompanyDocument4 pagesItinerary Depart Bulawayo For Zvishavane On 28 March 2023 at 0600 Hrs Date Arrive Depart CompanyObrian TandiNo ratings yet

- Electric Cars InformationDocument8 pagesElectric Cars InformationCharger Point CallNo ratings yet

- Hawk Ha240 Lite Installation ManualDocument11 pagesHawk Ha240 Lite Installation Manualronal552No ratings yet

- 7" Liner Running ProcedureDocument2 pages7" Liner Running ProcedureYougchu Luan100% (2)

- Circulation System: Fundamental PetroleumDocument11 pagesCirculation System: Fundamental PetroleumDAWOD SALiNo ratings yet

- SCR All Purpose Engineering Support Excel Sheet - 2016Document92 pagesSCR All Purpose Engineering Support Excel Sheet - 2016scranderiNo ratings yet

- Mil DTL 5593dDocument13 pagesMil DTL 5593dSenthil KumarNo ratings yet

- Crude Oil Pipeline CalculationDocument104 pagesCrude Oil Pipeline CalculationHendra Yudistira100% (3)

- Elemax General2014Document8 pagesElemax General2014Nguyễn Đức LợiNo ratings yet

- OTC-27226-MS Prediction of Asphaltene Onset Pressure From Dead Oil StabilityDocument10 pagesOTC-27226-MS Prediction of Asphaltene Onset Pressure From Dead Oil StabilityAnonymous 8te2h1No ratings yet

- Manual de Taller: Principios de Funcionamiento (Sistema Common Rail) DDGX131 (E)Document35 pagesManual de Taller: Principios de Funcionamiento (Sistema Common Rail) DDGX131 (E)Juan Pablo Duque Rodríguez100% (1)

- FP Diesel BrochureDocument2 pagesFP Diesel BrochureRajesh SoundararajanNo ratings yet