Professional Documents

Culture Documents

Microcontroller Based Automatic Solar Power Tracking System

Uploaded by

IAEME PublicationCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microcontroller Based Automatic Solar Power Tracking System

Uploaded by

IAEME PublicationCopyright:

Available Formats

International Journal of Electrical Engineering and Technology (IJEET), ISSN 0976 INTERNATIONAL JOURNAL OF ELECTRICAL ENGINEERING 6545(Print), ISSN

N 0976 6553(Online) Volume 4, Issue 1, January- February (2013), IAEME & TECHNOLOGY (IJEET)

ISSN 0976 6545(Print) ISSN 0976 6553(Online) Volume 4, Issue 1, January- February (2013), pp. 109-114 IAEME: www.iaeme.com/ijeet.asp Journal Impact Factor (2012): 3.2031 (Calculated by GISI) www.jifactor.com

IJEET

IAEME

MICROCONTROLLER BASED AUTOMATIC SOLAR POWER TRACKING SYSTEM

Hemlata B. Nirmal, 2 Syed A. Naveed 1 P.G. Student, Electronics and Telecommunication Dept. Jawaharlal Nehru Engineering College, Aurangabad, (M.S.) INDIA. 2 Electronics and Telecommunication Dept. Jawaharlal Nehru Engineering College, Aurangabad, (M.S.) INDIA. hemlatanirmal@rediffmail.com, sa_naveed01@rediffmail.com

1

ABSTRACT Renewable energy resources are getting priorities in the whole world in order to provide a sustainable power production and safe world to the future generation. Solar energy is rapidly gaining the focus as an important means of expanding renewable energy uses. Solar trackers are the most appropriate and proven technology to increase the efficiency of solar panels through keeping the panels aligned with suns position. A microcontroller based design methodology of an automatic solar tracker is presented in this paper. The unit controls the movement of solar panel always aligned towards the direction of the sun, due to this maximum thermal energy would be culminated from solar panel. Sun always moves from east to west direction independent of weather condition, so with this concept without using sensors movement of the solar panel from east to west direction is done with the help of programme loaded into the microcontroller. This prototype is designed for single axis as well as for double axis to solve solstice problem. From hardware testing we come to know that solar tracking system tracks the sun precisely and provides more power at the output as compared to that static solar panel. Keywords: Solar panel, solar tracking, microcontroller, stepper motor, liquid crystal display.

109

International Journal of Electrical Engineering and Technology (IJEET), ISSN 0976 6545(Print), ISSN 0976 6553(Online) Volume 4, Issue 1, January- February (2013), IAEME

I. INTRODUCTION Energy is essential factor for the development of any nation. Most of the energy production depends on fossil fuels. The resources of the fossil fuels are limited, so that there is growing demand for energy from renewable resources like solar, geothermal and ocean tidal wave. Among all renewable systems photovoltaic system is the one which has great chance to replace the conventional energy resources. Solar panel directly converts solar radiation into electrical energy. Solar panel is mainly made from semiconductor materials. To enhance the performance of solar panel the only way is to increase the intensity of light falling on it. Solar tracker is the best technology to increase the efficiency of solar panel by keeping panel aligned with the suns position. In this paper a microcontroller based simple and easily programmed automatic solar tracker is presented. II. TECHNOLOGY TO ENHANCE POWER OUTPUT FROM SOLAR PANEL In order to increase the efficiency of photovoltaic system there are three methods. First is increasing the efficiency of solar cell, second is maximizing the power output and third is employing a tracking system. Improvement of solar cell efficiency is an ongoing research work and people throughout the world are actively doing research on this. Maximum power point tracking is the process to maximize the output power from solar panel by keeping the solar panels operation on the knee point of photovoltaic characteristics. A number of maximum power point tracking algorithms have been developed and employed around the world [1]. At particular time, maximum power can be received from a stationary array of solar panel in case of maximum power point tracking technology. However, it cannot increase the power generation when the sun is not aligned with the system. Automatic solar tracker increases the efficiency of the solar panel by keeping the solar panel aligned with the rotating sun. Solar tracking is a basically electromechanical system to track the suns position that increases power output of solar panel 30% to 60% than the stationary system [2]. A few design methodology of solar tracking system has been proposed in recent days [3]-[4]. Maximum rays from the sun reach on the earths surface through interaction of clouds, dusts and water. These rays are called as diffused rays which reduces the output of solar cell. If these rays reflected on the panel through the reflectors it will increase the overall output of the panel [5]. III. PHOTOVOLTAIC TECHNOLOGY Solar energy is most abundant and convenient source of renewable energy. Photovoltaic cells are the basic of solar system. In the word photovoltaic photo means light and voltaic means producing electricity. Therefore the photovoltaic process is producing electricity directly from sunlight. The output power of a photovoltaic cell depends on the amount of light projected on the cell. The output power also depends on the time of day, season, panel position and orientation.

110

International Journal of Electrical Engineering and Technology (IJEET), ISSN 0976 6545(Print), ISSN 0976 6553(Online) Volume 4, Issue 1, January- February (2013), IAEME

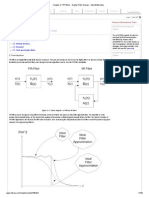

IV. AUTOMATIC SOLAR TRACKING SYSTEM The sun moves across the sky during the day, it is advantageous to have the solar panels track the location of the sun such that the panels are always perpendicular with the position of the sun. But available solar trackers in the market are much more costly to integrate with solar panel system [6]. Solar tracking presented in this paper can provide an effective solution to such problem. The major components those are used in the system are given below. . Microcontroller . Stepper motor . L293D .Liquid crystal display Fig. 1 shows the schematic diagram of automatic solar power tracking system.

Fig.1 Schematic of solar tracker circuitry A. Microcontroller The PIC18F452 microcontroller has been used in the system. Microcontroller is the heart of overall system. PIC 18F452 has some features such as analog comparator(AC), analog to digital converter (ADC), universal synchronous asynchronous receiver transmitter (USART), timers and parallel slave port (PSP).

111

International Journal of Electrical Engineering and Technology (IJEET), ISSN 0976 6545(Print), ISSN 0976 6553(Online) Volume 4, Issue 1, January- February (2013), IAEME

B. Stepper motor Stepper motors are commonly used in precision positioning control applications. Five characteristics of stepper motor have been considered while choosing stepper motor for solar tracker. Stepper motor is brushless, load independent, has open loop positioning capability, good holding torque and excellent response characteristics. The stepper motor that has been used in the system has the specifications of 4.4volts, 4 resistance, 1.8 per step, 2 phases, bipolar. C. L293D L293D is quadruple high-current half-H driver. All inputs are TTL compatible. Each output is a complete totem-pole drive circuit with a Darlington transistor sink and a pseudoDarlington source. The L293D has some features such as wide supply voltage range 4.5V to 36V, separate input logic supply, thermal shutdown, high noise immunity inputs, output current 600mA per channel, peak output current 1.2mA per channel and output clamp diodes for inductive transient suppression. D. Liquid crystal display 16X2 character Liquid crystal display is used in this system to display solar panel voltage and number of cycles completed. V. OPERATION OF THE SOLAR TRACKER Solar tracker provides three ways of operation and control mechanism through the programme written in the microcontroller. The three ways of operation includes normal day light condition, bad weather condition and bidirectional rotation. Whether there is normal day light or bad weather sun always present in the sky. With this programme loaded into the microcontroller to move the panel from east to west direction automatically. Once the day of 24 hours completed panel brought to initial position to start the new day. The entire day is divided into 24x6=144 parts of 10 minute each. The day light is assumed to be present for 10 hours that is 60 parts of 10 minutes. Stepper motor has resolution of 1.8per step. The worm gear ratio that has been used is 30:1. With this the number of steps required by the stepper motor to move the panel through 2.4 is 40. With beginning of the daylight from a reference point the system starts counting the stepping cycles each of 40 steps. Three counters used counter1 for day light, counter2 for whole day and conuter3 for season correction. After every one month the light emitting diode will turned ON to indicate there is need to do correction to solve elevation problem. For this purpose a separate mechanism of fine pitch of lead screw is used for compensating the elevation of the sun. Once the counter1 reaches 60 counts there will be no further movement of the stepper motor. But the counting of the cycles continues up to 144 in counter2. This completes the day of 24 hours. The numbers of days are calculated in counter3. As number of days is not equal to 365 then panel is brought to initial position by counting 60 cycles backward. Then start the new day. But whenever number of days is equal to 365 then resetting of all counters is required. A 6volt lead acid rechargeable cell is used as storage element for the motor drive as well as the power supply for the other circuits. Operational flow of the solar tracker is given in fig.2

112

International Journal of Electrical Engineering and Technology (IJEET), ISSN 0976 6545(Print), ISSN 0976 6553(Online) Volume 4, Issue 1, January- February (2013), IAEME

Fig.2 Operational flow chart of solar tracker VI. HARDWARE TESTING OF SOLAR PANEL Table I shows the data of voltage, current and power received from solar tracking system and static solar panel for a day. Fig. 3 shows the comparison of electric power characteristic curves from solar tracking system and static solar panel. It shows that solar tracking system is able to receive more Sunlight and consequently generate more power as compared to static solar panel. TABLE I Observations of solar panel during hardware testing

113

International Journal of Electrical Engineering and Technology (IJEET), ISSN 0976 6545(Print), ISSN 0976 6553(Online) Volume 4, Issue 1, January- February (2013), IAEME

Fig. 3 Electric Power vs. Hours characteristic curve

VII. CONCLUSION The proposed sun tracker automatically tracks the sun capturing maximum solar power with help of microcontroller. The system tracks the sun both in normal and bad weather condition. The tracker can initialize the starting position itself which reduce the need of any more photo resistor. Summer solstice and winter solstice problem is solved manually by tilting the panel with the help of fine screw arrangement. REFERENCES [1] C. Hua and C. Shen (1998) Comparative study of peak power tracking techniques for solar storage system, Applied Power Electronics Conference and Exposition, vol. 2, pp. 679-685. [2] A. K. Saxena and V. Dutta (1990), A versatile microprocessor based controller for solar tracking, Photovoltaic Specialists Conference, vol. 2, pp. 1105-1109. [3] B. Koyuncu and K. Balasubramanian (1991), A microprocessor controlled automatic sun tracker, IEEE Transactions on Consumer Electronics, vol. 37, no. 4, pp. 913-917. [4] Md. Tanvir Arafat Khan, S. M. Shahrear Tanzil, Rifat Rahman, S M Shafiul Alam (2010) Design and construction of an automatic solar tracking system, international conference on electrical and computer engineering, Dhaka, Bangladesh. [5] R. U. Rahman, D. I. Ahmed, M. A. Fahmi, T. Tasnuva M. F. Khan (2009), Performance Enhancement of PV solar system by diffused refection, Intl. Conf. on the Developments in Renewable Energy Technology, PP. 96-99. [6] WATTSON SOLAR TRACKER RETAIL PRICE AND DATA SHEET. [Online].Available: http://www.wattson.com/prices.html [7] Microcontroller datasheet. [Online] Available: http://www.microchip.com/downloads/en/devicedoc/ 39564c.pdf. [8] L293D datasheet. [Online]. Available: http://idmax.free.fr/Aide/stepper/i293.pdf [9] LM317 datasheet. [Online]. Available: http://www.ee.baffalo.edu/courses/elab/LM117.pdf. [10] Neeraj Tiwari, D. Bhagwan Das and Prabal Pratap Singh, Design, Development And Hardware Realization Of X-Beebased Single Axis Solar Tracking System International Journal of Electrical Engineering & Technology (IJEET), Volume 3, Issue 3, 2012, pp. 8 - 20, Published by IAEME

114

You might also like

- AMA Manual 10th Edition PDFDocument1,014 pagesAMA Manual 10th Edition PDFKannan Fangs S100% (2)

- Design and Development of Single Axis Solar Tracking System Using C8051F120 (CYGNAL) MicrocontrollerDocument8 pagesDesign and Development of Single Axis Solar Tracking System Using C8051F120 (CYGNAL) MicrocontrollerarcherselevatorsNo ratings yet

- Lab Sheet: Faculty of Engineering & TechnologyDocument12 pagesLab Sheet: Faculty of Engineering & TechnologyMun Kit ChokNo ratings yet

- Staircase Climbing TrollyDocument47 pagesStaircase Climbing TrollySathish Royalraja75% (4)

- Chinnamasta Sadhana PDFDocument1 pageChinnamasta Sadhana PDFSayan Majumdar100% (2)

- Bluetooth Modules - Martyn Currey PDFDocument64 pagesBluetooth Modules - Martyn Currey PDFAng Tze Wern100% (1)

- Treatise On Vocal Performance and Ornamentation by Johann Adam Hiller (Cambridge Musical Texts and Monographs) (2001)Document211 pagesTreatise On Vocal Performance and Ornamentation by Johann Adam Hiller (Cambridge Musical Texts and Monographs) (2001)Lia Pestana RocheNo ratings yet

- Intelligent Solar Tracker System Implemented On 8051 MicrocontrollerDocument5 pagesIntelligent Solar Tracker System Implemented On 8051 MicrocontrollerseventhsensegroupNo ratings yet

- How Does A PID Controller Work - Structure & Tuning MethodsDocument12 pagesHow Does A PID Controller Work - Structure & Tuning Methodsmurugan1984No ratings yet

- Fotovoltaic ImprovementsDocument5 pagesFotovoltaic Improvements3dfelixNo ratings yet

- Adaptive Lighting for Automobiles Seminar PresentationDocument18 pagesAdaptive Lighting for Automobiles Seminar Presentationkavitha mNo ratings yet

- Chapter No. Description Page No.: 1.1 Block Diagram 3Document69 pagesChapter No. Description Page No.: 1.1 Block Diagram 3Deekshith Ram50% (2)

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM561/KJP516/470Document4 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM561/KJP516/470Nasri JamaludinNo ratings yet

- Monitoring and Control of Solar Power System Using Reliance SCADADocument4 pagesMonitoring and Control of Solar Power System Using Reliance SCADAEditor IJTSRDNo ratings yet

- Techno-Environmental Feature-Based Sun Tracking Model Fabrication & Optimal Analyses by Precise Position AlgorithmDocument9 pagesTechno-Environmental Feature-Based Sun Tracking Model Fabrication & Optimal Analyses by Precise Position AlgorithmInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chapter 3 - Choppers - PDFDocument75 pagesChapter 3 - Choppers - PDFZahidullah100% (1)

- Automatic Solar Tracker Max EfficiencyDocument17 pagesAutomatic Solar Tracker Max EfficiencyShahnawazNo ratings yet

- Solar Powered Mobile Operated Smart Multifunction Agriculture RobotDocument4 pagesSolar Powered Mobile Operated Smart Multifunction Agriculture RobotVIVA-TECH IJRINo ratings yet

- Design and Fabrication of Stair Climbing Hand Cart: Government Engineering CollegeDocument28 pagesDesign and Fabrication of Stair Climbing Hand Cart: Government Engineering CollegeFayyaz NadeemNo ratings yet

- Lab 9 TransistorDocument8 pagesLab 9 TransistorChing Wai YongNo ratings yet

- Bank Token Display SystemDocument22 pagesBank Token Display Systemsandy_18_sn5879No ratings yet

- Real-Time Monitoring Security System Integrated With Raspberry Pi and E-Mail Communication LinkDocument12 pagesReal-Time Monitoring Security System Integrated With Raspberry Pi and E-Mail Communication LinkIJRASETPublicationsNo ratings yet

- 16 Unit15Document45 pages16 Unit15ZULUNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM560Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM560Muhammad FirdawsNo ratings yet

- Component of ElectricsDocument13 pagesComponent of ElectricsRam Kishore RoyNo ratings yet

- Main Embedded + SoftwareDocument33 pagesMain Embedded + SoftwareChimbhu SubramaniyamNo ratings yet

- Chapter 2 - FIR Filters - Digital Filter DesignDocument100 pagesChapter 2 - FIR Filters - Digital Filter DesignSanjay BalwaniNo ratings yet

- Design & Implementation of Mamdani Fuzzy Inference System On An Automatic Train Braking SystemDocument5 pagesDesign & Implementation of Mamdani Fuzzy Inference System On An Automatic Train Braking SystemijsretNo ratings yet

- Question Bank For EEE 366Document6 pagesQuestion Bank For EEE 366sramukNo ratings yet

- Experience of Delhi Metro with IEC 61850Document36 pagesExperience of Delhi Metro with IEC 61850Bhuvanes WaranNo ratings yet

- Embedded Systems Design Life Cycle and TestingDocument5 pagesEmbedded Systems Design Life Cycle and TestingAnonymous zQOH5ikNo ratings yet

- Solar Power PlantDocument65 pagesSolar Power PlantHil GloriosoNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/JUN2012/MEM560Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JUN2012/MEM560Muhammad FirdawsNo ratings yet

- WM-75FL1 Washing Machine Service ManualDocument28 pagesWM-75FL1 Washing Machine Service ManualRoby Surya100% (1)

- Electrical Cable GuideDocument19 pagesElectrical Cable GuideatramanathanNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2013/MEM560Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2013/MEM560Shah GrungeNo ratings yet

- Course FileDocument36 pagesCourse FileElakkiya N.SNo ratings yet

- Household AppliancesDocument32 pagesHousehold Appliancesbhaskar51178No ratings yet

- LED flasher using UJT oscillatorDocument5 pagesLED flasher using UJT oscillatorBharathNo ratings yet

- Relay Pin Configuration and Implementation in The CircuitsDocument3 pagesRelay Pin Configuration and Implementation in The CircuitsSandeep KumarNo ratings yet

- IC615 Embedded Systems - 23 - 09 - 2020 PDFDocument154 pagesIC615 Embedded Systems - 23 - 09 - 2020 PDFHussainNo ratings yet

- FIR Using Window MethodDocument24 pagesFIR Using Window MethodModyKing99No ratings yet

- Window Function ComparisonsDocument7 pagesWindow Function ComparisonsHaripriya RadhakrishnanNo ratings yet

- Dee3071 Electronic Computer Aided Design (Ecad) - SDocument6 pagesDee3071 Electronic Computer Aided Design (Ecad) - Skshika meganathanNo ratings yet

- Performance Improvement of Solar PV Cells Using Various Cooling Methods: A ReviewDocument5 pagesPerformance Improvement of Solar PV Cells Using Various Cooling Methods: A ReviewEditor IJRITCCNo ratings yet

- C++ Tokens, Literals, and Short ProgramsDocument17 pagesC++ Tokens, Literals, and Short Programsmehak2106No ratings yet

- Embedded System DesignDocument22 pagesEmbedded System Designtrail meNo ratings yet

- Chapter 6Document38 pagesChapter 6Deivasigamani SubramaniyanNo ratings yet

- Steady State ErrorsDocument13 pagesSteady State ErrorsChetan KotwalNo ratings yet

- Whirlpool Awt 2284Document9 pagesWhirlpool Awt 2284th_gabNo ratings yet

- QB Et7104Document9 pagesQB Et7104JEEVANo ratings yet

- Ai For AutomotivesDocument18 pagesAi For AutomotivesAbhishek SoundaleNo ratings yet

- IT1353 Embedded SystemDocument6 pagesIT1353 Embedded SystemReeshma ApNo ratings yet

- Whirlpool Awt 2284 PDFDocument9 pagesWhirlpool Awt 2284 PDFcriss76No ratings yet

- Matlab-Simulink Controller DesignDocument4 pagesMatlab-Simulink Controller DesignMohamed SomaiNo ratings yet

- Assignment 2Document5 pagesAssignment 2aiao90No ratings yet

- Electrical Bus, Bar and Types of Bus, Bar Arrangements and Advantages and DisadvantagesDocument10 pagesElectrical Bus, Bar and Types of Bus, Bar Arrangements and Advantages and DisadvantagesAlan MuerongNo ratings yet

- A Microcontroller Based Solar Panel Tracking SystemDocument10 pagesA Microcontroller Based Solar Panel Tracking Systemvershakhemka7193100% (1)

- EMG 2505 - Measurement and Instrumentation PDFDocument159 pagesEMG 2505 - Measurement and Instrumentation PDFVasda VinciNo ratings yet

- Ignition Systems: Columbia Basin CollegeDocument23 pagesIgnition Systems: Columbia Basin CollegeKiran S KumarNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Research and Development in Non-Mechanical Electrical Power Sources: Proceedings of the 6th International Symposium Held at Brighton, September 1968From EverandResearch and Development in Non-Mechanical Electrical Power Sources: Proceedings of the 6th International Symposium Held at Brighton, September 1968No ratings yet

- A Study On The Reasons For Transgender To Become EntrepreneursDocument7 pagesA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationNo ratings yet

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsDocument8 pagesDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationNo ratings yet

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyDocument4 pagesVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationNo ratings yet

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNo ratings yet

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNo ratings yet

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNo ratings yet

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsDocument7 pagesAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationNo ratings yet

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNo ratings yet

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNo ratings yet

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNo ratings yet

- Gandhi On Non-Violent PoliceDocument8 pagesGandhi On Non-Violent PoliceIAEME PublicationNo ratings yet

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNo ratings yet

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNo ratings yet

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 pagesA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNo ratings yet

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 pagesEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNo ratings yet

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNo ratings yet

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNo ratings yet

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNo ratings yet

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNo ratings yet

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNo ratings yet

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNo ratings yet

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNo ratings yet

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNo ratings yet

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNo ratings yet

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 pagesAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNo ratings yet

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 pagesAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNo ratings yet

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 pagesModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNo ratings yet

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 pagesPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNo ratings yet

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNo ratings yet

- EDU101 Solution FileDocument2 pagesEDU101 Solution FileTahaNo ratings yet

- StructDocument2 pagesStructandriessebastianNo ratings yet

- Kerala Dinesh Beedi - WikipediaDocument12 pagesKerala Dinesh Beedi - Wikipediaaymanamna2016No ratings yet

- Chapter 018Document12 pagesChapter 018api-281340024No ratings yet

- Sawmill Safety 3-Trim SawsDocument51 pagesSawmill Safety 3-Trim SawsramptgdNo ratings yet

- Lauritzen 1964Document10 pagesLauritzen 1964Priyanka GandhiNo ratings yet

- English 2Document53 pagesEnglish 2momonunu momonunuNo ratings yet

- Impact of Agile On IT and BusinessDocument6 pagesImpact of Agile On IT and BusinessPurva RaneNo ratings yet

- Minotaur Transformation by LionWarrior (Script)Document7 pagesMinotaur Transformation by LionWarrior (Script)Arnt van HeldenNo ratings yet

- Final Script Tokoh NilamDocument1 pageFinal Script Tokoh NilamrayyanNo ratings yet

- Checklist For HR Audit Policy and ProceduresDocument3 pagesChecklist For HR Audit Policy and ProcedureskrovvidiprasadaraoNo ratings yet

- A Story Behind..: Dimas Budi Satria Wibisana Mario Alexander Industrial Engineering 5Document24 pagesA Story Behind..: Dimas Budi Satria Wibisana Mario Alexander Industrial Engineering 5Owais AwanNo ratings yet

- Masters of Death: The Assassin ClassDocument5 pagesMasters of Death: The Assassin Classjbt_1234No ratings yet

- The Rescue FindingsDocument8 pagesThe Rescue FindingsBini Tugma Bini Tugma100% (1)

- First State of The Nation Address of ArroyoDocument9 pagesFirst State of The Nation Address of ArroyoJennifer Sisperez Buraga-Waña LptNo ratings yet

- Promotion From Associate Professor To ProfessorDocument21 pagesPromotion From Associate Professor To ProfessorKamal KishoreNo ratings yet

- 2009 WORD White Paper TemplateDocument4 pages2009 WORD White Paper Templateomegalpha777No ratings yet

- 5528 L1 L2 Business Admin Unit Pack v4Document199 pages5528 L1 L2 Business Admin Unit Pack v4Yousef OlabiNo ratings yet

- Motivate! 2 End-Of-Term Test Standard: Units 1-3Document6 pagesMotivate! 2 End-Of-Term Test Standard: Units 1-3Oum Vibol SatyaNo ratings yet

- Heritageoil Corporategovernance AwDocument68 pagesHeritageoil Corporategovernance AwbeqsNo ratings yet

- Swot AnalysisDocument6 pagesSwot AnalysisSneha SinhaNo ratings yet

- PeripheralDocument25 pagesPeripheralMans FansNo ratings yet

- Review Activity For The Final Test - 6 Level: 1. Match Phrasal Verbs and Match To The MeaningDocument3 pagesReview Activity For The Final Test - 6 Level: 1. Match Phrasal Verbs and Match To The MeaningGabrielle CostaNo ratings yet

- KNJN Fpga Pluto-P BoardDocument15 pagesKNJN Fpga Pluto-P Boardgandalf1024No ratings yet

- Homeroom Guidance - Activity For Module 1Document3 pagesHomeroom Guidance - Activity For Module 1Iceberg Lettuce0% (1)

- PersonalDevelopment Q1 Module 2Document7 pagesPersonalDevelopment Q1 Module 2Stephanie DilloNo ratings yet