Professional Documents

Culture Documents

Quality: Astm A 105

Uploaded by

lavius_mOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality: Astm A 105

Uploaded by

lavius_mCopyright:

Available Formats

Quality

According to standards Number

ASTM A 105

ASTM A 105M - 03 -Mn% 0,60-1,05 P% max 0,035 S% max 0,040 Cu% max 0,40 Ni% 0,40 Cr% max 0,30 Mo% max 0,12 V% max 0,08 Nb% max 0,02

Chemical composition

C% max 0,35 Si% 0,10-0,35

The sum of copper (Cu), chromium (Cr), nickel (Ni) and molybdenum (Mo) shall not exceed 1,00% The sum of chromium (Cr) and molybdenum (Mo) shall not exceed 0,32% For each reduction of 0,01% below the specified carbon maximum (0,35), an increase of 0,06% manganese above the specific maximum (1,05%) will be permitted up to a maximum of 1,35% Calcium (Ca) treatment may be supplied on request Al min 0,020% Carbon Equivalent CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/ 15 max 0,47

Temperature C

Hot forming 1150-850 Soft annealing 700 air cooling Normalizing . 843-927 air cooling Normalizing and Tempering 843-927 air 593 air Quenching 880-930 oil / polymer water Isothermal annealing 860 furnace cooling to 660 after, air Tempering 593 air cooling Stress relieving 50 under the temperature of tempering Preheating welding 250 AC1 AC3 --Stress relieving after welding (PWHT) 590 furnace cooling MS Mf ---

Mechanical properties Steel Forgings

make reference the values of Forgeds Heat treatments must grant below mentioned values ASTM A 105M: 03 dimension Testing at room temperature (longitudinal) mm R Rp 0.2% A% L A% T C% L C% T Kv over to N/mm2 min N/mm2 min. min. min. min. min. J min. -T 485 250 22 -30 --Forged over 4540 Kg may be ordered to ASTM A 266/A 266M 03a R Rp 0.2% A% N/mm2 min. min. N/mm2 -T 415-585 205 23 Product tests ( longitudinal ) TRAFILIX esperience Heat treatment product test at R mm C N/mm2 Normalizing 920C 90 +20 603 Normalizing 920C 90 +400 312 Normalizing 900C 240 +20 578 Normalizing 900C 240 +400 506 Normalizing 900C 400 +20 470 Normalizing 900C 400 +400 424 Quenched end tempered 95 +20 579 Quenched and tempered 95 +400 520 Natural 90 +20 580

EUROPE EN -ITALY UNI -CHINA --

HB max 187

A% T min. 20

C% L min. 38

C% T min. 30

Kv J min. --

HB 121-170

T= is the maximum heat-treated thickness. Ttest specimen shall correspond to the T Rp 0.2 N/mm2 485 217 417 248 309 206 403 325 400 A % 30 -32.4 -39.2 -35.6 -28.0 C-Z % 69.5 -63.8 -69.0 -68.6 -63.0 Kv 0C J 66-64-60 -111-136-133 -181-222-220 -210-203-207 -20-18-18

U.K. B.S. --

Kv18C J --------14-12-12

RUSSIA 20G

Kv -46C J --------10-8-8

product Hot-rolled Hot-rolled Hot-rolled Hot-rolled Forged Forged Hot-rolled Hot-rolled Hot-rolled

GERMANY DIN C21

FRANCE AFNOR --

USA AISI/SAE A 105

You might also like

- Snadi Puresine PDFDocument6 pagesSnadi Puresine PDFPMV Dept0% (5)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFAna Raquel SantosNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- TECHNICAL DATA ON SURFACE ROUGHNESS AND TEXTURE INDICATIONDocument1 pageTECHNICAL DATA ON SURFACE ROUGHNESS AND TEXTURE INDICATIONdmayhillNo ratings yet

- Specifications For Aluminum Ingot Alloys (ASTM B179-03) : Alloy SI FE CU MN MG CR NI ZN TI SN OE OTDocument1 pageSpecifications For Aluminum Ingot Alloys (ASTM B179-03) : Alloy SI FE CU MN MG CR NI ZN TI SN OE OTlavius_mNo ratings yet

- Bobcat Battery Reference GuideDocument2 pagesBobcat Battery Reference GuideFrancisco Godoy Kutzbach67% (3)

- Problems PDFDocument246 pagesProblems PDFJasdeep singhNo ratings yet

- Astm A105Document1 pageAstm A105Betto Arriaga100% (1)

- 1 4571a316ti69Document2 pages1 4571a316ti69Admir TalicNo ratings yet

- En10083-2 - 1996 - C35eDocument3 pagesEn10083-2 - 1996 - C35ealextentwentyNo ratings yet

- 1 4305a30365Document2 pages1 4305a30365skidanjeNo ratings yet

- 1.4125 440c PDFDocument2 pages1.4125 440c PDFsuntansueNo ratings yet

- 1330 Crni Mo 831Document2 pages1330 Crni Mo 831sajay_suryaNo ratings yet

- S355J2 Steel Grade Sheet for Engineering ApplicationsDocument1 pageS355J2 Steel Grade Sheet for Engineering ApplicationssergonNo ratings yet

- C45EDocument3 pagesC45ETrương Định100% (1)

- Quality: Astm A 105Document1 pageQuality: Astm A 105Venkat NarasimmanNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4niladriprasadrNo ratings yet

- 39NiCrMo3 steel technical cardDocument2 pages39NiCrMo3 steel technical cardLokesh Krishnappa100% (1)

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- 42 Crmo 4Document2 pages42 Crmo 4Shiva Kumar MNo ratings yet

- AISI304Document2 pagesAISI304tony_abNo ratings yet

- Quality E335Document1 pageQuality E335Sivanaga DantuluriNo ratings yet

- Quality 1.4021 Chemical Composition: Lucefin GroupDocument2 pagesQuality 1.4021 Chemical Composition: Lucefin Groupmohamedbadawy0% (1)

- SAE1018Document1 pageSAE1018arunas1081No ratings yet

- Quality 42crmo4: Lucefin GroupDocument1 pageQuality 42crmo4: Lucefin GroupAnonymous Gbers2ENo ratings yet

- 18 Ni CR Mo 5Document2 pages18 Ni CR Mo 5lavius_mNo ratings yet

- SMS001R0Document1 pageSMS001R0PRASANTH PRASANTHNo ratings yet

- Quality SAE 1018: Lucefin GroupDocument1 pageQuality SAE 1018: Lucefin GrouponeakshayNo ratings yet

- Sae1045 1018Document2 pagesSae1045 1018kevinjunNo ratings yet

- S275JRDocument1 pageS275JRShahzad QamarNo ratings yet

- Temperature SensorDocument51 pagesTemperature SensorElxan HacinskiNo ratings yet

- X8CrNiS18-9 austenitic stainless steel technical cardDocument1 pageX8CrNiS18-9 austenitic stainless steel technical cardshahid khanNo ratings yet

- DI-MC 355: Product DescriptionDocument4 pagesDI-MC 355: Product DescriptionvinodNo ratings yet

- Metalshield MC - 80NI1 SUITEDocument1 pageMetalshield MC - 80NI1 SUITEH_DEBIANENo ratings yet

- Grades of Steel Used in Ship BuildingDocument1 pageGrades of Steel Used in Ship BuildingAnkit MauryaNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- G42CrMo4+QT Cast Steel Properties and SpecificationsDocument2 pagesG42CrMo4+QT Cast Steel Properties and Specificationsbhavin178No ratings yet

- ASTM A335 Pipe Specification1 PDFDocument8 pagesASTM A335 Pipe Specification1 PDFRoberto EliasNo ratings yet

- ASTM A335 Pipe Specification1Document8 pagesASTM A335 Pipe Specification1Rupam BaruahNo ratings yet

- 42CrMo4 Datos Tecnicos PDFDocument2 pages42CrMo4 Datos Tecnicos PDFjlplazaolaNo ratings yet

- ASTM Materials - CHINA MaterialsDocument29 pagesASTM Materials - CHINA MaterialsHema HemaNo ratings yet

- Type KC TableDocument0 pagesType KC TablemjinspectorNo ratings yet

- minfm33419-en-10028-2-grade-p355gh-normalized-or-normalized-formed-n-Document4 pagesminfm33419-en-10028-2-grade-p355gh-normalized-or-normalized-formed-n-Mert EmremNo ratings yet

- 1.4305 Sae303 DatasheetDocument2 pages1.4305 Sae303 Datasheetehudingram6535No ratings yet

- C55EDocument2 pagesC55EniranjanbmazireNo ratings yet

- Quality steel E295 technical data sheetDocument1 pageQuality steel E295 technical data sheetNunoAfonsoNo ratings yet

- S235JR Sau OL 37Document1 pageS235JR Sau OL 37Pișta GonzalesNo ratings yet

- EN 10025 Grade S355J2C Normalized or Normalized Formed (+N)Document3 pagesEN 10025 Grade S355J2C Normalized or Normalized Formed (+N)melvin ekboteNo ratings yet

- 1.225V Micropower Shunt Voltage Reference: DescriptionDocument9 pages1.225V Micropower Shunt Voltage Reference: DescriptionRicardo MosqueiraNo ratings yet

- RTD Thermistor Z202030 0NDocument1 pageRTD Thermistor Z202030 0NKolega Sa FakultetaNo ratings yet

- Grades of Steel Used in Ship BuildingDocument1 pageGrades of Steel Used in Ship Buildingnpankaj1No ratings yet

- Engineering Data Chapter Provides Valve Material SpecificationsDocument93 pagesEngineering Data Chapter Provides Valve Material SpecificationsBhuidhar VermaNo ratings yet

- Quality 1.4021 Chemical Composition: Lucefin GroupDocument2 pagesQuality 1.4021 Chemical Composition: Lucefin GroupSonNguyenNo ratings yet

- Plates - S420G2 MDocument2 pagesPlates - S420G2 MAdisak AumpiemNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- Specifications For PlatesDocument4 pagesSpecifications For PlatesRv VaghasiaNo ratings yet

- Materialcomprison GHISADocument3 pagesMaterialcomprison GHISAlavius_mNo ratings yet

- FoxitPDFEditor20 ManualDocument204 pagesFoxitPDFEditor20 Manuallavius_mNo ratings yet

- A3 Carbon Steel SheetDocument1 pageA3 Carbon Steel Sheetlavius_mNo ratings yet

- Rockwell Brin Dell Hardness ConvDocument1 pageRockwell Brin Dell Hardness Convlavius_mNo ratings yet

- Quality 18nicrmo5: Applications: High-Stress Gearwheels Components and CamshaftsDocument1 pageQuality 18nicrmo5: Applications: High-Stress Gearwheels Components and Camshaftslavius_mNo ratings yet

- CuZn 39 PB 3Document2 pagesCuZn 39 PB 3lomas34No ratings yet

- PA12GDocument1 pagePA12Glavius_mNo ratings yet

- JIG Level-A Banned Substances Threshold, Homogeneous LevelDocument1 pageJIG Level-A Banned Substances Threshold, Homogeneous Levellavius_mNo ratings yet

- Hostaform® POM Processing: Automotive IndustryDocument1 pageHostaform® POM Processing: Automotive Industrylavius_mNo ratings yet

- 18 Ni CR Mo 5Document2 pages18 Ni CR Mo 5lavius_mNo ratings yet

- Grey Cast Iron As FollowingDocument1 pageGrey Cast Iron As Followinglavius_mNo ratings yet

- 20NiCrMo2 2 PDFDocument2 pages20NiCrMo2 2 PDFlavius_mNo ratings yet

- CFBC Boilers & TG Set Auxillaries SpecificationsDocument18 pagesCFBC Boilers & TG Set Auxillaries SpecificationsJAY PARIKHNo ratings yet

- Steam Turbines Basic Information - Power Generation in PakistanDocument12 pagesSteam Turbines Basic Information - Power Generation in Pakistannomi607No ratings yet

- Wires The Politics of Climate Change in India Narratives of Equity and Co-Benefits Dubash PDFDocument11 pagesWires The Politics of Climate Change in India Narratives of Equity and Co-Benefits Dubash PDFShubham Kumar JhaNo ratings yet

- RLA Test FormatDocument11 pagesRLA Test Formatmayur dhandeNo ratings yet

- IB Physics Climate ModellingDocument11 pagesIB Physics Climate ModellingAnara Noelle Chiongbian100% (1)

- The Changes of Leaves in AutumnDocument9 pagesThe Changes of Leaves in AutumnKei's EntertainmentNo ratings yet

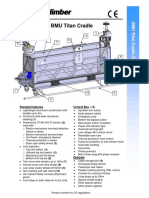

- BMU Titan Cradle: Standard Features Control BoxDocument2 pagesBMU Titan Cradle: Standard Features Control BoxKashyapNo ratings yet

- Catalytic LEL SensorsDocument9 pagesCatalytic LEL Sensorsvibhor_748408347No ratings yet

- Hazardous Areas: European & IEC Classification Definition of Zone or Division North American ClassificationDocument3 pagesHazardous Areas: European & IEC Classification Definition of Zone or Division North American Classificationmuddisetty umamaheswarNo ratings yet

- BE 2008 Petroleum EnggDocument54 pagesBE 2008 Petroleum Engg1234abcdNo ratings yet

- Accident Radio Logic GOIANIADocument157 pagesAccident Radio Logic GOIANIACatalin CuraliucNo ratings yet

- TSSR 2g Grahafamily3 PKMDocument43 pagesTSSR 2g Grahafamily3 PKMHaryo WNo ratings yet

- Mahle GrafalDocument273 pagesMahle GrafalErnesto CruzaltaNo ratings yet

- Eastern Visayas State University-Ormoc City CampusDocument3 pagesEastern Visayas State University-Ormoc City Campuskhellian villameroNo ratings yet

- High Voltage Engineering Ref ManualDocument147 pagesHigh Voltage Engineering Ref Manualzeus009100% (1)

- Ce2039 MSW NotesDocument659 pagesCe2039 MSW NotesMuthu Praveen SarwanNo ratings yet

- Saacke Steam Pressure Atomizer PDFDocument2 pagesSaacke Steam Pressure Atomizer PDFKhaled SaadnehNo ratings yet

- SERIES AC CIRCUIT PROBLEMSDocument4 pagesSERIES AC CIRCUIT PROBLEMSHubert Semeniano100% (1)

- Sensor Lect4Document23 pagesSensor Lect4morton1472No ratings yet

- PRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpDocument3 pagesPRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpSuman GhoshNo ratings yet

- Screw Compressors: Models: VEDocument42 pagesScrew Compressors: Models: VEVoştinar IoanNo ratings yet

- Ref - No.IM-B086-01: Operating Instructions Rechargeable ShaverDocument8 pagesRef - No.IM-B086-01: Operating Instructions Rechargeable ShaverrootermxNo ratings yet

- Aluminum Extrusions in Solar Power ApplicationsDocument4 pagesAluminum Extrusions in Solar Power ApplicationsСтанислав ПодольскийNo ratings yet

- PPR Techincal Data SheetDocument0 pagesPPR Techincal Data SheetKrish ChennaiNo ratings yet

- Igcse: Definitions & Concepts of ElectricityDocument4 pagesIgcse: Definitions & Concepts of ElectricityMusdq ChowdhuryNo ratings yet

- Electrical Machines DC Motor NewDocument27 pagesElectrical Machines DC Motor NewPranav MahadikNo ratings yet

- Equity Research Report On Bajaj Finserv LTD Authored By: Mohammad Reza PoyaDocument6 pagesEquity Research Report On Bajaj Finserv LTD Authored By: Mohammad Reza Poyashraddha anandNo ratings yet