Professional Documents

Culture Documents

Multifunctionality Selection Criteria in The Dynamic Thermorheological Characterization of Solid-Like Polymer Materials. I. Pmma in Tensile Condtions

Uploaded by

htopaven4340Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multifunctionality Selection Criteria in The Dynamic Thermorheological Characterization of Solid-Like Polymer Materials. I. Pmma in Tensile Condtions

Uploaded by

htopaven4340Copyright:

Available Formats

SISOM 2007 and Homagial Session of the Commission of Acoustics, Bucharest 29-31 May

MULTIFUNCTIONALITY SELECTION CRITERIA IN THE DYNAMIC

THERMORHEOLOGICAL CHARACTERIZATION OF SOLID-LIKE POLYMER

MATERIALS. I. PMMA IN TENSILE CONDTIONS

Horia PAVEN*, Mariana CRISTEA**, Bogdan C. SIMIONESCU**

*ICECHIM - National Research and Development Institute of Research for Chemistry and Petrochemistry, Bucharest;

email: htopaven@netscape.net

**Petru Poni - Institute of Macromolecular Chemistry, Iassy.

The expose is a tentative towards a meaningful comprehensive evaluation of the potential

multifunctionality from the view point of thermorheological behaviour by means of dynamic

mechanical analysis. Experimental data obtained for PMMA in tensile conditions using a stress controlled system working at constant heating rate and multiple oscillation frequencies mode,

including the storage and loss moduli as well as the loss factor, are further processed in order to

complete the self contained set of characteristic dual modulus/compliance quantities both in

temperature and frequency descriptions.

Key words: multifunctionality,thermorheology, dynamic behaviour, PMMA..

1. INTRODUCTION

Realistic identification of the secure range of functionality variables in case of polymer materials needs

both the improvement of phenomenological approaches as well as the use of advanced experimental

equipment, the requirement being of outmost relevance rather when new generation hybrid systems are in

view [1], [2].

The rheological behaviour of many materials, especially of polymer-like ones, shows a high sensivity

from the standpoint of temperature, time, frequency, pressure, etc., the separate and cumulate effects

requiring the possibility to ensure a programmable control of variables, e.g., dynamic strain-(or stress-)

controlled excitation conditions at constant rate heating and different frequencies, or a frequency scaning and

different temperatures [3]-[9].

Accordingly, the full set of rheodynamic quantities, including for strain()-controlled conditions, the

primary quantities - the storage, M ( ) , loss, M ( ) , and absolute modulus, | M * ( ) | , as well as the

( ) , loss, J M ( ) , and

corresponding loss factor, M ( ) , - and the secondary ones - the storage, J M

absolute compliance, | J ( ) | , as well as the corresponding loss factor, J M ( ) , and in case of stress()*

controlled state, the primary quantities - the storage, J ( ) , loss, J ( ) , and absolute compliance,

| J * ( ) | , as well as the corresponding loss factor, J ( ) , - and the secondary ones - the storage, M J ( ) ,

loss, M J ( ) , and absolute compliance, | M J ( ) | , as well as the corresponding loss factor, J M ( ) , are

*

to be taken into account.

2. RESULTS AND DISCUSSION

Dynamic mechanical thermal analysis was conducted on Perkin Elmer Diamond DMA with the tensile

mode of deformation. The controlled temperature was from 15 to 190C with a constant heating ramp of

65

Multifunctionality selection criteria in the dynamic thermorheological characterization of solid-like polymer materials

2C/min. The active dimensions of a standard PMMA sample were 20.00 x 8.03 x 0.23 mm. The working

frequencies were 0.5; 1.0; 2.0;5.0; 10.0 Hz.

It is noteworthy to point out that while many available DMA instruments operate in a slow isothermal

step mode when performing frequency multiplexing experiments, with a lot of difficulties from the

standpoint of data collection, in case of employed system, owing to real-time FT technology and Synthetic

Oscillation (SO) mode, a complex sine stress which contains five simultaneous frequencies is applied to the

sample. Then, the resulting complex strain and stress sine waves are deconvoluted, and operated to compute

the different quantitative dynamic viscoelastic quantities [4]-[7], the shortcoming of only one discrete

frequency sequentially applied at a time in traditional systems being overcomed in case of SO mode option

when the sample is subjected to all five frequencies simultaneously.

The storage quantities (e.g., M ( , T ) and J ( , T ) ) are directly and inversely proportional,

respectively, to the recoverable component of energy of strain- and stress-controlled processes, respectively,

while the loss quantities (e.g., M ( , T ) and J ( , T ) ) relates to the corresponding dissipation

components. Furthermore, the absolute quantities (e.g., | M * ( , T ) | and | J * ( , T ) | )) l are measures of

overall dynamic rigidity

and compliance, respectively, whereas the

M ( , T ) = tan M ( , T )

M ( , T ) = tan M ( , T ) giving the loss factor in both considered cases appear to be rather an index of

viscoelasticity issued as a direct consequence of the lag between the dynamic stress and strain.

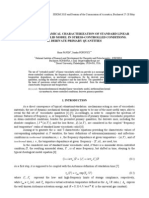

The dependence of the full set of rheodynamic quantities vs. temperature at different frequencies

(Figure 1), is presented on the basis of primary data - the storage and loss modulus as well as the

corresponding loss factor. The essential trends show, at given frequency, D , a monoton decrease with the

rise of temperature in case of

M (D , T ) and | M * ( D , T ) | , and a similar monoton, but increase, for

J (D , T ) and | J * ( D , T ) | . Furthermore, at given frequencies, distinct peaks corresponding to well defined

dynamic relaxation/relaxation or mixed processes, are observed in the increasing sequence - M ( D , T ) ,

M (D , T ) , J (D , T ) . Moreover, as result of the increase of control frequency, higher values in the former

case or shifts of the peaks towards higher temperatures in the later one, are observed.

In virtue of these results, a lot of functionality criteria may be defined in terms of differences and ratios

of characteristic temperatures (Table 1), as well by using the dynamic Arrhenius-like apparent activation

energies for typical rheodynamic relaxation/retardation or mixed processes (Figure 2).

Conversely, the dependence of the complete set of rheodynamic quantities vs. frequency at different

temperatures (Fig. 3), reveals distinctive trends, too. Thus, temperature-controlled effects, indicate, at given

temperature, TD , in case of M ( , TD ) and | M * ( , TD ) | nonlinear rise with increase of frequency, the

positions of TD -curves being in an ascending order, whereas a similar monoton, but decreasing with rise of

frequency, for J ( , TD ) and | J * ( , TD ) | , are present. Moreover, in case of available frequency range,

different loss rheodynamic quantities point out dissimilar tendencies - for E ( , TD ) , T TE , an increase,

and, for T TE , an inversion of relative positions of frequency controlled curves ; for tan D , T Ttan D ,

approximately constant values, and, for T Ttan D , decrease, with higher values; for J , T TJ , an

approximately constant value, and, for T TJ , a decrease, with higher values.

Horia PAVEN, Mariana CRISTEA, Bogdan C. SIMIONESCU

a.1-E1(T)

66

a.2-E1(T)

4.50E+09

1.00E+10

4.00E+09

3.50E+09

1.00E+09

f=0.5Hz

2.50E+09

f=1.0Hz

f=2.0Hz

2.00E+09

f=5.0Hz

E1[Pa]

E1[Pa]

3.00E+09

f=0.5Hz

f=1.0Hz

1.00E+08

f=2.0Hz

f=5.0Hz

f=10.0Hz

f=10.0Hz

1.50E+09

1.00E+07

1.00E+09

5.01E+08

1.00E+06

1.00E+06

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

T[C]

]T[C

b.1-E2(T)

b.2-E2(T)

3.50E+08

1.00E+09

3.00E+08

1.00E+08

2.00E+08

f=0.5Hz

f=1.0Hz

f=2.0Hz

1.50E+08

f=5.0Hz

E2[Pa]

E2[Pa]

2.50E+08

f=0.5Hz

f=1.0Hz

1.00E+07

f=2.0Hz

f=5.0Hz

f=10.0Hz

f=10.0Hz

1.00E+08

1.00E+06

5.00E+07

1.00E+05

0.00E+00

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

T[C]

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

]T[C

c.1-|E*|(T)

c.2-|E*|(T)

4.50E+09

1.00E+10

4.00E+09

1.00E+09

1.00E+08

3.50E+09

1.00E+07

3.00E+09

1.00E+06

f=1.0Hz

f=2.0Hz

f=5.0Hz

2.00E+09

|E*|[Pa]

|E*|[Pa]

f=0.5Hz

2.50E+09

f=0.5Hz

f=1.0Hz

1.00E+05

f=2.0Hz

f=5.0Hz

1.00E+04

f=10.0Hz

1.50E+09

f=10.0Hz

1.00E+03

1.00E+09

1.00E+02

5.00E+08

1.00E+01

0.00E+00

1.00E+00

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

T[C]

T[C]

d.2-tanDELTA(T)

d.1-tanDELTA(T)

1.00E+01

2.00E+00

1.80E+00

1.60E+00

1.40E+00

f=0.5Hz

f=1.0Hz

1.00E+00

f=2.0Hz

f=5.0Hz

8.00E-01

f=10.0Hz

tanDELTA

tanDELTA

1.00E+00

1.20E+00

6.00E-01

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

f=0.5Hz

f=1.0Hz

f=2.0Hz

f=5.0Hz

f=10.0Hz

1.00E-01

4.00E-01

2.00E-01

0.00E+00

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

1.00E-02

]T[C

T[C]

e.2-J1(T)

e.1-J1(T)

1.00E-06

6.00E-07

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

5.00E-07

1.00E-07

f=0.5Hz

f=1.0Hz

3.00E-07

f=2.0Hz

f=5.0Hz

f=10.0Hz

J1 [1/ P a ]

J1[1/P a]

4.00E-07

f=0.5Hz

f=1.0Hz

f=2.0Hz

f=5.0Hz

f=10.0

1.00E-08

2.00E-07

1.00E-09

1.00E-07

0.00E+00

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

1.00E-10

]T[C

T[C]

f.2-J2(T)

f.1-J2(T)

1.00E+00

1.60E-07

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

1

1

1

1

2

2

2

2

2

2

1.00E-01 0

1.40E-07

1.00E-02

1.20E-07

1.00E-03

1.00E-04

f=0.5Hz

f=1.0Hz

8.00E-08

f=2.0Hz

f=5.0Hz

f=10.0Hz

6.00E-08

J2[1/Pa]

J2[1/Pa]

1.00E-07

f=0.5Hz

1.00E-05

f=1.0Hz

f=2.0Hz

1.00E-06

f=5.0Hz

f=10.0Hz

1.00E-07

4.00E-08

1.00E-08

2.00E-08

1.00E-09

1.00E-10

0.00E+00

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

1.00E-11

]T[C

T[C]

g.1-|J*|(T)

g.2-|J*|(T)

6.00E-07

1.00E+00

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

1.00E-01

5.00E-07

1.00E-02

1.00E-03

f=0.5Hz

f=1.0Hz

3.00E-07

f=2.0Hz

f=5.0Hz

f=10.0Hz

2.00E-07

|J*|[1/Pa]

]J*|[1/Pa|

4.00E-07

1.00E-04

f=0.5Hz

f=1.0Hz

1.00E-05

f=2.0Hz

f=5.0Hz

f=10.0Hz

1.00E-06

1.00E-07

1.00E-07

1.00E-08

1.00E-09

0.00E+00

0.00E+0 2.00E+0 4.00E+0 6.00E+0 8.00E+0 1.00E+0 1.20E+0 1.40E+0 1.60E+0 1.80E+0 2.00E+0

0

1

1

1

1

2

2

2

2

2

2

]T[C

1.00E-10

T[C]

Figure 1. Rheodynamic quantities vs. temperature at different frequencies.

Multifunctionality selection criteria in the dynamic thermorheological characterization of solid-like polymer materials

67

Table 1. Maxima of rheodynamic quantities, corresponding temperatures, ratios and differences.

f

E2m

TE2m

[Hz]

[MPa]

[K]

0.5

220.19

217.74

219.8

221.1

222.9

392.24

392.56

392.96

394.16

394.67

2

5

10

1.747

1.701

1.685

1.65

1.631

TtanDm

J2m

TJ2m

[K]

[1/MPa]

[K]

404.51

406.69

408.72

412.33

415.64

0.139

0.14

0.14

0.139

0.14

421.17

423.64

429.02

435.4

438.23

TtanDm

TJ2m

TtanDm

TJ2m

/

/

TE2m TtanDm TE2m TtanDm

[K]

[K]

1.0313

1.036

1.0401

1.0461

1.0531

1.0412

1.0417

1.0497

1.056

1.0543

12.27

14.13

15.76

18.17

20.97

f(1/T)

3

2.5

2

y = -174375x + 444.13

r2 = 0.9677

1.5

LN{f[Hz]}

tanDm

E2

tanD

J2

Linear (E2)

Linear (tanD)

Linear (J2)

y = -45333x + 111.48

r2 = 0.9923

1

y = -30698x + 72.256

r2 = 0.9835

0.5

0

2.25E-03

2.30E-03

2.35E-03

2.40E-03

2.45E-03

2.50E-03

2.55E-03

-0.5

-1

1/T[K]

Figure 2. Dynamic Arrhenius plots.

Table 2. E2, tanD and J2 Arrhenius - like apparent activation

energies

Frequency

ratio

f1/f05

f2/f1

f5/f2

f10/f5

f10/f1

Aver. val.

Activation energy [kJ/mole]

E2

tanD

J2

2772.958

2222.439

983.2930

1757.810

1405.670

1455

434.882

471.877

355.637

298.38

361.562

374

416.287

194.682

223.043

388.543

243.595

258

2.60E-03

16.66

16.95

20.3

23.07

22.59

Horia PAVEN, Mariana CRISTEA, Bogdan C. SIMIONESCU

a.1- E1(f)

68

a.2- E1(f)

4.50E+03

1.00E+04

4.00E+03

3.50E+03

1.00E+03

2.50E+03

T=25C

T=50C

T=75C

2.00E+03

T=100C

T=125C

E1[MPa]

E1[MPa]

3.00E+03

T=25C

T=50C

T=75C

T=100C

1.00E+02

T=125C

1.50E+03

1.00E+01

1.00E+03

5.00E+02

0.00E+00

0.00E+00

2.00E+00

4.00E+00

6.00E+00

8.00E+00

1.00E+01

1.20E+01

1.00E+00

1.00E+00

1.00E-01

f[Hz]

f[Hz]

b.1- E2(f)

b.2- E2(f)

3.50E+02

1.00E+01

1.00E+03

3.00E+02

2.50E+02

1.50E+02

T=25C

T=50C

T=75C

T=100C

E2[MPa]

E2[MPa]

1.00E+02

T=25C

T=50C

T=75C

T=100C

2.00E+02

T=125C

T=125C

1.00E+01

1.00E+02

5.00E+01

0.00E+00

0.00E+00

2.00E+00

4.00E+00

6.00E+00

8.00E+00

1.00E+01

1.20E+01

1.00E+00

1.00E+00

1.00E-01

f[Hz]

1.00E+01

f[Hz]

c.1- |E*|(f)

c.2- |E*|(f)

4.50E+03

1.00E+04

4.00E+03

3.50E+03

1.00E+03

T=25C

T=50C

T=75C

T=100C

T=125C

2.50E+03

2.00E+03

|E*|[MPa]

|E*|[MPa]

3.00E+03

T=25C

T=50C

T=75C

T=100C

T=125C

1.00E+02

1.50E+03

1.00E+01

1.00E+03

5.00E+02

0.00E+00

0.00E+00

2.00E+00

4.00E+00

6.00E+00

8.00E+00

1.00E+01

1.20E+01

1.00E+00

1.00E+00

1.00E-01

f[Hz]

d.2- tanDELTA(f)

1.20E+00

1.20E+00

1.00E+00

1.00E+00

8.00E-01

T=25C

T=50C

T=75C

T=100C

T=125C

6.00E-01

tanDELTA

tanDELTA

8.00E-01

T=25C

T=50C

T=75C

6.00E-01

T=100C

T=125C

4.00E-01

4.00E-01

2.00E-01

0.00E+00

0.00E+00

1.00E+01

f[Hz]

d.1- tanDELTA(f)

2.00E-01

2.00E+00

4.00E+00

6.00E+00

8.00E+00

1.00E+01

1.20E+01

0.00E+00

1.00E+00

1.00E-01

f[Hz]

1.00E+01

f[Hz]

e.1- J1(f)

e.2- J1(f)

1.00E+00

0.00E+00

5.00E-03

2.00E+00

4.00E+00

6.00E+00

8.00E+00

1.00E+01

1.20E+01

4.50E-03

4.00E-03

1.00E-01

J1[1/MPa]

3.00E-03

2.50E-03

T=25C

T=50C

T=75C

2.00E-03

T=100C

T=125C

J1[1/MPa]

3.50E-03

T=25C

T=50C

T=75C

T=100C

T=125C

1.00E-02

1.50E-03

1.00E-03

1.00E-03

5.00E-04

0.00E+00

0.00E+00

2.00E+00

4.00E+00

6.00E+00

8.00E+00

1.00E+01

1.20E+01

1.00E-04

f[Hz]

f[Hz]

f.2- J2(f)

f.1- J2(f)

6.00E-03

1.00E-01

1.00E+00

1.00E+00

1.00E+01

5.00E-03

1.00E-01

T=25C

T=50C

T=75C

3.00E-03

T=100C

T=125C

1.00E-02

T=25C

T=50C

T=75C

T=100C

T=125C

J2[1/MPa]

J2[1/MPa]

4.00E-03

1.00E-03

2.00E-03

1.00E-03

0.00E+00

0.00E+00

1.00E-04

2.00E+00

4.00E+00

6.00E+00

8.00E+00

1.00E+01

1.20E+01

1.00E-05

f[Hz]

f[Hz]

g.2- |J*|(f)

g.1- |J*|(f)

8.00E-03

1.00E-01

1.00E+00

1.00E+00

1.00E+01

7.00E-03

6.00E-03

1.00E-01

T=25C

T=50C

T=75C

4.00E-03

T=100C

T=125C

|J*|[1/MPa]

|J*|[1/MPa]

5.00E-03

1.00E-02

3.00E-03

T=25C

T=50C

T=75C

T=100C

T=125C

2.00E-03

1.00E-03

1.00E-03

0.00E+00

0.00E+00

2.00E+00

4.00E+00

6.00E+00

f[Hz]

8.00E+00

1.00E+01

1.20E+01

1.00E-04

f[Hz]

Figure 3. Rheodynamic quantities vs. frequency at different temperatures.

69

Multifunctionality selection criteria in the dynamic thermorheological characterization of solid-like polymer materials

At the end, further criteria of evaluating intrinsic multifunctionality from the view point of potential

of polymeric material within the realm of linear viscoelastic behaviour may be considered both the frequency

and/or temperature Cole-Cole patterns of rheodynamic quantities (Figure 5).

E2(E1)

tanDELTA(E1)

3.50E+08

2.00E+00

1.80E+00

3.00E+08

1.60E+00

1.40E+00

f=0.5Hz

2.00E+08

f=1.0Hz

f=2.0Hz

f=5.0Hz

1.50E+08

tanDELTA

E2[Pa]

2.50E+08

f=10.0Hz

1.20E+00

f=0.5Hz

f=1.0Hz

1.00E+00

f=2.0Hz

f=5.0Hz

8.00E-01

f=10.0Hz

6.00E-01

1.00E+08

4.00E-01

5.00E+07

2.00E-01

0.00E+00

0.00E+00

0.00E+00 5.00E+08 1.00E+09 1.50E+09 2.00E+09 2.50E+09 3.00E+09 3.50E+09 4.00E+09 4.50E+09

0.00E+0 5.00E+0 1.00E+0 1.50E+0 2.00E+0 2.50E+0 3.00E+0 3.50E+0 4.00E+0 4.50E+0 5.00E+0

0

7

8

8

8

8

8

8

8

8

8

]E1 [Pa

]E1[Pa

J2(J1)

tanDELTA(J1)

2.00E+00

1.60E-07

1.80E+00

1.40E-07

1.60E+00

1.20E-07

1.40E+00

f=0.5Hz

f=1.0Hz

8.00E-08

f=2.0Hz

f=5.0Hz

f=10.0Hz

6.00E-08

1.20E+00

tanDELTA

J2[1/Pa]

1.00E-07

f=0.5Hz

f=1.0Hz

1.00E+00

f=2.0Hz

f=5.0Hz

f=10.0

8.00E-01

6.00E-01

4.00E-08

4.00E-01

2.00E-08

2.00E-01

0.00E+00

0.00E+00

0.00E+00

1.00E-07

2.00E-07

3.00E-07

4.00E-07

5.00E-07

6.00E-07

0.00E+00

1.00E-07

2.00E-07

3.00E-07

4.00E-07

5.00E-07

6.00E-07

]E1[Pa

J1[1/Pa]

Figure 5. Temperature Cole - Cole patterns.

4. CONCLUSIONS

The versatility of the used DMA system enables a comprehensive characterization of viscoelastic

behaviour versus temperature and frequency, respectively, for complete sets of modulus- and compliancelike quantities substantiated as proper indicators of rheodynamic multifunctionality.

The considered storage and especially rheodynamic loss quantities represent key measures of dynamic

relaxation/retardation and mixed processes, accounting for the outstanding potential of polymeric materials

generated at different levels of structural architecture.

REFERENCES

1. MEZGER ,T. G., The Rheology Handbook, Vincentz Network, Hannover, 2006.

2. SPERLING, L. H., Introduction to Polymer Science, Wiley, 2006.

3. PAVEN, H., Private communication, ICM-PP, Iassy, 1 March 2007.

4. MENARD, K., Dynamic Mechanical Analysis, CRC Press, Boca Raton, 1999.

5. MENARD, K., Basic DMA: Part 1-How DMA works, Perkin Elmer, AN 90, 2002.

6. MENARD, K., Basic DMA: Part 2- Thermoplastic Transitions and Properties, Perkin Elmer, AN 91, 2002.

7. MENARD, K., Basic DMA: Part 3- Frequency effects in Materials, Perkin Elmer, AN 92, 2002.

You might also like

- Explicit Analytical Relations For Stress-Controlled Rheodynamical Quantities in The Case of Zener-Arrhenius ModelDocument4 pagesExplicit Analytical Relations For Stress-Controlled Rheodynamical Quantities in The Case of Zener-Arrhenius Modelhtopaven4340No ratings yet

- Explicit Analytical Relations For Strain-ControlledDocument4 pagesExplicit Analytical Relations For Strain-Controlledhtopaven4340No ratings yet

- A Three-Dimensional Description of Shape Memory Alloy Thermomechanical BehaviorDocument10 pagesA Three-Dimensional Description of Shape Memory Alloy Thermomechanical BehaviorManolo GipielaNo ratings yet

- 1999 - Vyazovkin - Model Free and Model Fitting Approaches To Kinetic Analysis of Isothermal and Nonisothermal DataDocument16 pages1999 - Vyazovkin - Model Free and Model Fitting Approaches To Kinetic Analysis of Isothermal and Nonisothermal Datarafael_nicolay9196No ratings yet

- Sma Um ManualDocument26 pagesSma Um Manualletter_ashish4444No ratings yet

- Density, Temp, VolDocument11 pagesDensity, Temp, VolAli AhamdNo ratings yet

- Accumulated Discretization Error. The Local and Global Discretization Errors Are Identical For The First TimeDocument18 pagesAccumulated Discretization Error. The Local and Global Discretization Errors Are Identical For The First TimeEmaan W KaNo ratings yet

- Press (1972)Document6 pagesPress (1972)cbisogninNo ratings yet

- Dynamic Mechanical Analysis: Effects of Transport on Polymeric Adhesive RelaxationDocument69 pagesDynamic Mechanical Analysis: Effects of Transport on Polymeric Adhesive RelaxationMiruna PetriaNo ratings yet

- Estimating Bivariate Integer-Valued Moving Average Models With The Generalized Method of MomentsDocument4 pagesEstimating Bivariate Integer-Valued Moving Average Models With The Generalized Method of MomentsimmsilvamNo ratings yet

- Short Communications: Journal of Thermal Analysis, Vol 25 (1982) 593 - 596Document4 pagesShort Communications: Journal of Thermal Analysis, Vol 25 (1982) 593 - 596Kamel IbrahimNo ratings yet

- Kissinger Kinetic Analysis of Data Obtained Under Different Heating SchedulesDocument7 pagesKissinger Kinetic Analysis of Data Obtained Under Different Heating SchedulesJohn TorrezNo ratings yet

- International Journal of Fatigue analysis based on energy dissipationDocument14 pagesInternational Journal of Fatigue analysis based on energy dissipationEngels OchoaNo ratings yet

- Combustion Theory and Modelling: Please Scroll Down For ArticleDocument30 pagesCombustion Theory and Modelling: Please Scroll Down For ArticleEmilia PopescuNo ratings yet

- UserCom26 TA eDocument24 pagesUserCom26 TA ealitariq90No ratings yet

- A numerical analysis of Stefan problems foDocument10 pagesA numerical analysis of Stefan problems foLucas Santos de OliveiraNo ratings yet

- Effect of transient strain rate change on plastic flow behavior of low carbon steelDocument12 pagesEffect of transient strain rate change on plastic flow behavior of low carbon steelShivraman ThapliyalNo ratings yet

- Terence Mills: Skinning A Cat': Alternative Models of Representing Temperature Trends: An Editorial CommentDocument12 pagesTerence Mills: Skinning A Cat': Alternative Models of Representing Temperature Trends: An Editorial Commentsimon evansNo ratings yet

- Smoothing and Differentiation of Thermogravimetric Data of Biomass MaterialsDocument13 pagesSmoothing and Differentiation of Thermogravimetric Data of Biomass MaterialsPaula ANo ratings yet

- Comparison of Glass-Transition Temperatures For Epoxy Polymers Obtained by Methods of Thermal AnalysisDocument14 pagesComparison of Glass-Transition Temperatures For Epoxy Polymers Obtained by Methods of Thermal AnalysisPaulo UtargNo ratings yet

- Journal of Thermal StressesDocument20 pagesJournal of Thermal Stressesडॉ. कनिष्क शर्माNo ratings yet

- Artigo Importante 2Document67 pagesArtigo Importante 2Lucas SantosNo ratings yet

- Study of An EE Mechanism Using Double Potential Step TechniquesDocument11 pagesStudy of An EE Mechanism Using Double Potential Step Techniqueshide999No ratings yet

- Thermal Analysis 19 Feb 2023Document29 pagesThermal Analysis 19 Feb 2023eeman tariqNo ratings yet

- DTADocument14 pagesDTABalaji NagisettyNo ratings yet

- Dimensional Analysis and Hydraulic SimilarityDocument43 pagesDimensional Analysis and Hydraulic SimilarityTing Wee KietNo ratings yet

- Optimal Tuning of Tuned Mass Dampers for Seismic Response ReductionDocument9 pagesOptimal Tuning of Tuned Mass Dampers for Seismic Response ReductionbutelcanecNo ratings yet

- Brown Robertson PDFDocument8 pagesBrown Robertson PDFParth ShahNo ratings yet

- Simulation of Thermomechanical Behavior of Shape Memory Alloy Beams Using COMSOLDocument6 pagesSimulation of Thermomechanical Behavior of Shape Memory Alloy Beams Using COMSOLDEEPESH MEENANo ratings yet

- Magnetic Reconnection Controlled by External Current DriveDocument10 pagesMagnetic Reconnection Controlled by External Current DriveScriblazNo ratings yet

- Kinetic Model CompletenessDocument5 pagesKinetic Model CompletenessMukund KsNo ratings yet

- English 1Document13 pagesEnglish 1amin_127No ratings yet

- Estimation of Nonstationary HeterogeneousDocument12 pagesEstimation of Nonstationary HeterogeneousSeydou OumarouNo ratings yet

- Landau Phase-Field Model For Shape Memory AlloysDocument15 pagesLandau Phase-Field Model For Shape Memory AlloysPrevalisNo ratings yet

- Ter Mopar Magnetism oDocument2 pagesTer Mopar Magnetism oCecilia DécigaNo ratings yet

- 2018 ThermogravimetricAnalysisofPolymersBookChapter PDFDocument30 pages2018 ThermogravimetricAnalysisofPolymersBookChapter PDFA1234 AJEFNo ratings yet

- Simple Functions For Fast Calculations of Selected Thermodynamic Properties of The Ammonia-Water SystemDocument7 pagesSimple Functions For Fast Calculations of Selected Thermodynamic Properties of The Ammonia-Water SystemEngineer1987No ratings yet

- Reti01-Computer Simulation of Steel Quenching Process Using A Multi-Phase Transformation Model PDFDocument18 pagesReti01-Computer Simulation of Steel Quenching Process Using A Multi-Phase Transformation Model PDFRebekah PetersonNo ratings yet

- Chapter 6Document21 pagesChapter 6Shida ShidotNo ratings yet

- Dimensional Analysis TMDocument8 pagesDimensional Analysis TMDr.S.RamamurthyNo ratings yet

- Characterization and Modeling of The Fatigue Behavior of TPUDocument6 pagesCharacterization and Modeling of The Fatigue Behavior of TPUDeepak SharmaNo ratings yet

- Stress Singularities in Piezoelectric Multi-Material SystemsDocument10 pagesStress Singularities in Piezoelectric Multi-Material SystemsAnonymous wWOWz9UnWNo ratings yet

- AlgoDocument46 pagesAlgoJoseCastilhoNo ratings yet

- Science.abo4297 SmDocument37 pagesScience.abo4297 SmKen DarghiNo ratings yet

- Microwave Dimensional Measurements of Cylindrical Resonators For Primary Acoustic ThermometryDocument1 pageMicrowave Dimensional Measurements of Cylindrical Resonators For Primary Acoustic ThermometryNational Physical LaboratoryNo ratings yet

- Modulated-Temperature Thermomechanical Analysis: D. M. PriceDocument8 pagesModulated-Temperature Thermomechanical Analysis: D. M. PriceRizky EkoNo ratings yet

- Review of Methods For Estimating The Overpressure and Impulse Resulting From A Hydrogen Explosion in A Confined/Obstructed VolumeDocument12 pagesReview of Methods For Estimating The Overpressure and Impulse Resulting From A Hydrogen Explosion in A Confined/Obstructed VolumehsebillalNo ratings yet

- Finite Element/finite Volume Approaches With Adaptive Time Stepping Strategies For Transient Thermal ProblemsDocument19 pagesFinite Element/finite Volume Approaches With Adaptive Time Stepping Strategies For Transient Thermal Problemsprajjwal patidarNo ratings yet

- Innostock 2012 error analysisDocument20 pagesInnostock 2012 error analysisUoVT ManufacturingNo ratings yet

- Numvar: Table 135: ESOL - General Item and Component LabelsDocument4 pagesNumvar: Table 135: ESOL - General Item and Component Labelsicemage1991No ratings yet

- Fatigue Plane Prediction Using Variance and Damage MethodsDocument12 pagesFatigue Plane Prediction Using Variance and Damage MethodsAdemar CardosoNo ratings yet

- Martensitic Transformations in Shape-Memory Alloys. Successes and Failures of Thermal Analysis and CalorimetryDocument26 pagesMartensitic Transformations in Shape-Memory Alloys. Successes and Failures of Thermal Analysis and CalorimetrySrinivasan NarayananNo ratings yet

- Prediction of fatigue life in composite materials using thermoelastic stress analysisDocument8 pagesPrediction of fatigue life in composite materials using thermoelastic stress analysiskishorghatage89No ratings yet

- 2000PES Thermo AllDocument33 pages2000PES Thermo AllMoeenulHaqueNo ratings yet

- A Simple Method of Handling Thermomechanical Coupling For Temperature Computation in A Rolling TireDocument13 pagesA Simple Method of Handling Thermomechanical Coupling For Temperature Computation in A Rolling TiresiritapeNo ratings yet

- Methodology of Thermo-Oxidative Degradation of PolymersDocument19 pagesMethodology of Thermo-Oxidative Degradation of PolymersEvansChombaNo ratings yet

- Quantum Work Statistics With Initial CoherenceDocument16 pagesQuantum Work Statistics With Initial CoherenceCarlos GonzálezNo ratings yet

- Panel Vector Autoregression Models in RDocument49 pagesPanel Vector Autoregression Models in RFousséni ZINSONNINo ratings yet

- Treatise on Irreversible and Statistical Thermodynamics: An Introduction to Nonclassical ThermodynamicsFrom EverandTreatise on Irreversible and Statistical Thermodynamics: An Introduction to Nonclassical ThermodynamicsRating: 1 out of 5 stars1/5 (1)

- Spectral method for fatigue damage estimation with non-zero mean stressFrom EverandSpectral method for fatigue damage estimation with non-zero mean stressNo ratings yet

- Iupac Macro'83Document2 pagesIupac Macro'83htopaven4340No ratings yet

- HORI.I\ PA VEN SAr--~OR POPOVICS Reologia compozitelor polimericeDocument7 pagesHORI.I\ PA VEN SAr--~OR POPOVICS Reologia compozitelor polimericehtopaven4340No ratings yet

- MP2010 121Document5 pagesMP2010 121htopaven4340No ratings yet

- PDS 1994Document6 pagesPDS 1994htopaven4340No ratings yet

- Joam 2004Document4 pagesJoam 2004htopaven4340No ratings yet

- PB80Document4 pagesPB80htopaven4340No ratings yet

- Isr 2000Document3 pagesIsr 2000htopaven4340No ratings yet

- NASA Transl. 1974Document10 pagesNASA Transl. 1974htopaven4340No ratings yet

- Upbsb 2013Document14 pagesUpbsb 2013htopaven4340No ratings yet

- MP2011 176Document7 pagesMP2011 176htopaven4340No ratings yet

- PSS 1975Document14 pagesPSS 1975htopaven4340No ratings yet

- ECCM9 2kDocument10 pagesECCM9 2khtopaven4340No ratings yet

- Icr 84Document8 pagesIcr 84htopaven4340No ratings yet

- 2011 D19 XDocument8 pages2011 D19 Xhtopaven4340No ratings yet

- ICR13 2kDocument3 pagesICR13 2khtopaven4340No ratings yet

- RC 04Document15 pagesRC 04htopaven4340No ratings yet

- RC 05Document13 pagesRC 05htopaven4340No ratings yet

- MP2007 138Document6 pagesMP2007 138htopaven4340No ratings yet

- 2010D25Document5 pages2010D25htopaven4340No ratings yet

- 2012D33Document6 pages2012D33htopaven4340No ratings yet

- 2009D32Document5 pages2009D32htopaven4340No ratings yet

- 2012D32Document6 pages2012D32htopaven4340No ratings yet

- 2009D33Document5 pages2009D33htopaven4340No ratings yet

- 2004D27Document8 pages2004D27htopaven4340No ratings yet

- 2010D26Document5 pages2010D26htopaven4340No ratings yet

- 2004D26Document8 pages2004D26htopaven4340No ratings yet

- 2007D14Document8 pages2007D14htopaven4340No ratings yet

- Bentone LTDocument2 pagesBentone LTdamiendamNo ratings yet

- Heat Exchanger Design and Drawing FundamentalsDocument11 pagesHeat Exchanger Design and Drawing Fundamentalsjeevanantham 5846No ratings yet

- Boston Acoustic PDFDocument12 pagesBoston Acoustic PDFAdam StarkNo ratings yet

- Metaphors As Ammunition The Case of QueeDocument19 pagesMetaphors As Ammunition The Case of QueeMarijana DragašNo ratings yet

- ASSIGNMENTDocument10 pagesASSIGNMENTKoleen Lopez ÜNo ratings yet

- RESISTANCEDocument9 pagesRESISTANCERohit SahuNo ratings yet

- BC230XL Literature 12-11 SpreadslrDocument5 pagesBC230XL Literature 12-11 SpreadslrCiprian Petrule0% (1)

- Exogenous Driver Analysis Driver Relative GDP GrowthDocument107 pagesExogenous Driver Analysis Driver Relative GDP GrowthBhagya FoodsNo ratings yet

- Stats Set-1Document4 pagesStats Set-1Harsha KSNo ratings yet

- Mic ProjectDocument12 pagesMic Projectsarthakjoshi012No ratings yet

- Exercise Questions (Materials) .: BFT 112 Introduction To EngineeringDocument1 pageExercise Questions (Materials) .: BFT 112 Introduction To EngineeringSK DarsyanaaNo ratings yet

- Shotcreting in Australia 2010Document84 pagesShotcreting in Australia 2010Vedad TerzicNo ratings yet

- STPM Chemistry Topic 16 Haloalkanes Short Notes PDFDocument2 pagesSTPM Chemistry Topic 16 Haloalkanes Short Notes PDFbendanNo ratings yet

- Hypnotherapy GuideDocument48 pagesHypnotherapy Guides_e_bell100% (2)

- Service and Repair Instructions: Water & WastewaterDocument72 pagesService and Repair Instructions: Water & WastewaterLa Marina Mantenimiento100% (1)

- Medicinal Chemistry 1 - Drug MetabolismDocument39 pagesMedicinal Chemistry 1 - Drug MetabolismPark arimaNo ratings yet

- Briefing Paper No 4 CV Electrification 30 11 17 PDFDocument5 pagesBriefing Paper No 4 CV Electrification 30 11 17 PDFAlex WoodrowNo ratings yet

- Gas Exchange in Plants and AnimalsDocument7 pagesGas Exchange in Plants and AnimalsMarvin MelisNo ratings yet

- Psychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)Document48 pagesPsychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)sfrtr100% (1)

- Conflict and Factional Disputes - Siegel & BealsDocument12 pagesConflict and Factional Disputes - Siegel & BealsDanielNo ratings yet

- Equations 2Document8 pagesEquations 2Patrick ValdezNo ratings yet

- Sepuran® N Module 4": in NM /H at 7 Barg 25°CDocument2 pagesSepuran® N Module 4": in NM /H at 7 Barg 25°CsanjaigNo ratings yet

- Grade 9 Unit 1 - Part 1: Square RootsDocument20 pagesGrade 9 Unit 1 - Part 1: Square RootsWilson ZhangNo ratings yet

- General Guidelines For Design and Construction of Concrete Diaphram (Slurry) WallsDocument108 pagesGeneral Guidelines For Design and Construction of Concrete Diaphram (Slurry) WallsharleyNo ratings yet

- Chem Tech South 2013 - ConferenceDocument5 pagesChem Tech South 2013 - ConferenceAbirami PriyadharsiniNo ratings yet

- Alcon Capacitor AC Mp4aDocument6 pagesAlcon Capacitor AC Mp4aDAC Secretary EENo ratings yet

- Mast Bending Stress Calculation: Antenna 1Document6 pagesMast Bending Stress Calculation: Antenna 1Vinay KumarNo ratings yet

- Using Graphs To Display Data R 2-12 PDFDocument2 pagesUsing Graphs To Display Data R 2-12 PDFShafika AidaNo ratings yet

- Moisture ManagementDocument5 pagesMoisture ManagementSombis2011No ratings yet

- Contemporary Philippine Arts From The Regions: Quarter 3Document15 pagesContemporary Philippine Arts From The Regions: Quarter 3Ackie Inacay RosarioNo ratings yet