Professional Documents

Culture Documents

Gear Pitch Relation Tech - Specs

Uploaded by

Mahesh Deivasiga Mani DOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gear Pitch Relation Tech - Specs

Uploaded by

Mahesh Deivasiga Mani DCopyright:

Available Formats

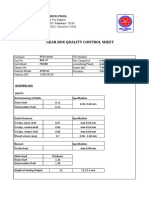

LINN

GEAR

COMPANY

SPUR GEAR HUB STYLES

A TYPE

SOLID

B TYPE

SOLID OR WELDED

WEB TYPE

WELDED

Stock Spur Gears are cut to allow backlash as listed below when mounted on standard center distances. They can be expected to

operate as satisfactory replacements for any make of standard commercial gears or in new installations with standard mountings.

20 D.P.

16 D.P.

12 D.P.

10 D.P.

8 D.P.

6 D.P.

.003"

.003"

.004"

.004"

.005"

.007"

5

4

3

2 1/2

2

1 3/4

D.P.

D.P.

D.P.

D.P.

D.P.

D.P.

.008"

.010"

.013"

.016"

.020"

.023"

1 1/2"

3/4"

1"

1 1/4"

1 1/2"

1 3/4"

D.P.

C.P.

C.P.

C.P.

C.P.

C.P.

.027"

.010"

.013"

.016"

.020"

.023"

TABLE OF TOOTH PARTS

DIAMETRAL PITCH

Relation between Diametral Pitch and Circular Pitch, with corresponding Tooth Dimensions

Diametral

Pitch

1/2

3/4

1

1

1

1

2

2

2

2

3

3

4

5

6

7

8

9

1/4

1/2

3/4

1/4

1/2

3/4

1/2

Circular

Pitch

6.2832"

4.1888

3.1416

2.5133

2.0944

1.7952

1.5708

1.3963

1.2566

1.1424

1.0472

.8976

.7854

.6283

.5236

.4488

.3927

.3491

Thickness

of Tooth On

Pitch Line

3.1416"

2.0944

1.5708

1.2566

1.0472

.8976

.7854

.6981

.6283

.5712

.5236

.4488

.3927

.3142

.2618

.2244

.1963

.1745

Whole

Depth

4.3142"

2.8761

2.1571

1.7257

1.4381

1.2326

1.0785

.9587

.8628

.7844

.7190

.6163

.5393

.4314

.3595

.3081

.2696

.2397

Dedendum

Addendum

Diametral

Pitch

Circular

Pitch

Thickness

of Tooth On

Pitch Line

Whole

Depth

Dedendum

Addendum

2.3142"

1.5428

1.1571

.9257

.7714

.6612

.5785

.5143

.4628

.4208

.3857

.3306

.2893

.2314

.1928

.1653

.1446

.1286

2.0000"

1.3333

1.0000

.8000

.6666

.5714

.5000

.4444

.4000

.3636

.3333

.2857

.2500

.2000

.1666

.1429

.1250

.1111

10

11

12

14

16

18

20

22

24

26

28

30

32

36

40

48

60

.3142

.2856

.2618

.2244

.1963

.1745

.1571

.1428

.1309

.1208

.1122

.1047

.0982

.0873

.0785

.0654

.0524

.1571

.1428

.1309

.1122

.0982

.0873

.0785

.0714

.0654

.0604

.0561

.0524

.0491

.0436

.0393

.0327

.0262

.2157

.1961

.1798

.1541

.1348

.1198

.1079

.0980

.0898

.0829

.0770

.0719

.0674

.0599

.0539

.0449

.0360

.1157

.1052

.0964

.0826

.0723

.0643

.0579

.0526

.0482

.0445

.0413

.0386

.0362

.0321

.0289

.0241

.0193

.1000

.0909

.0833

.0714

.0625

.0555

.0500

.0455

.0417

.0385

.0357

.0333

.0312

.0278

.0250

.0208

.0166

To obtain the size of a diametral pitch not given in the table divide the corresponding part of 1 diametral pitch by the pitch required.

LINN

GEAR

COMPANY

TABLE OF TOOTH PARTS

CIRCULAR PITCH

Relation between Diametral Pitch and Circular Pitch, with corresponding Tooth Dimensions

Circular

Pitch

Diametral

Pitch

Thickness

of Tooth On

Pitch Line

Whole

Depth

Dedendum

Addendum

2

"

1 7/8 "

1 3/4 "

1 5/8 "

1 1/2 "

1 7/16 "

1 3/8 "

1 5/6 "

1 1/4 "

1 3/16 "

1 1/8 "

1 1/16 "

1

"

15/16 "

7/8 "

13/16 "

3/4 "

11/16 "

1.5708

1.6755

1.7952

1.9333

2.0944

2.1855

2.2848

2.3936

2.5133

2.6465

2.7925

2.9568

3.1416

3.3510

3.5904

3.8666

4.1888

4.5696

1.0000"

.9375

.8750

.8125

.7500

.7187

.6875

.6562

.6250

.5937

.5625

.5312

.5000

.4687

.4375

.4062

.3750

.3437

1.3732"

1.2874

1.2016

1.1158

1.0299

.9870

.9441

.9012

.8583

.8156

.7724

.7295

.6866

.6437

.6007

.5579

.5150

.4720

.7366"

.6906

.6445

.5985

.5525

.5294

.5064

.4837

.4604

.4374

.4143

.3913

.3683

.3453

.3223

.2993

.2762

.2532

.6366"

.5968

.5570

.5173

.4775

.4576

.4377

.4178

.3979

.3780

.3581

.3382

.3183

.2984

.2785

.2586

.2387

.2189

Circular

Pitch

Diametral

Pitch

Thickness

of Tooth On

Pitch Line

Whole

Depth

Dedendum

Addendum

5/8

9/16

1/2

7/16

2/5

3/8

1/3

5/16

1/4

1/5

3/16

1/6

1/7

1/8

1/9

1/10

1/16

1/20

5.0265

5.5851

6.2832

7.1808

7.8540

8.3776

9.4248

10.0531

12.5664

15.7080

16.7552

18.8496

21.9911

25.1327

28.2743

31.4159

50.2655

62.8318

.3125

.2812

.2500

.2187

.2000

.1875

.1666

.1562

.1250

.1000

.0937

.0833

.0714

.0625

.0555

.0500

.0312

.0250

.4291

.3862

.3433

.3003

.2746

.2575

.2287

.2146

.1716

.1373

.1287

.1144

.0981

.0858

.0763

.0687

.0429

.0343

.2301

.2071

.1842

.1611

.1473

.1381

.1228

.1151

.0921

.0737

.0690

.0614

.0526

.0460

.0409

.0368

.0230

.0184

.1989

.1790

.1592

.1393

.1273

.1194

.1061

.0995

.0796

.0637

.0592

.0531

.0455

.0398

.0354

.0318

.0199

.0159

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

To obtain the size of any part of a circular pitch not given in the table, multiply the corresponding part of 1" pitch by the pitch required.

TABLE OF TOOTH PARTS METRIC PITCH (MODULE)

Relation between Metric Pitch, Diametral Pitch and Circular Pitch, with Corresponding Tooth Dimensions

Module

Diametral

Pitch

Circular

Pitch

(Inches)

Thickness

On Pitch

Line

(Inches)

Whole

Depth

(Inches)

Dedendum

(Inches)

Addendum

(Inches)

Module

Diametral

Pitch

Circular

Pitch

(Inches)

Thickness

On Pitch

Line

(Inches)

Whole

Depth

(Inches)

1/2

3/4

50.800

33.867

25.400

20.320

16.933

14.514

12.700

11.288

10.160

9.236

8.466

7.257

6.350

.0618

.0927

.1236

.1546

.1855

.2164

.2473

.2783

.3092

.3401

.3710

.4329

.4947

.0309

.0464

.0618

.0773

.0928

.1082

.1237

.1392

.1546

.1701

.1855

.2165

.2474

.0425

.0637

.0849

.1062

.1274

.1486

.1699

.1911

.2123

.2336

.2548

.2972

.3397

.0228

.0342

.0456

.0569

.0683

.0797

.0911

.1025

.1139

.1253

.1367

.1594

.1822

.0197

.0295

.0394

.0492

.0591

.0689

.0787

.0886

.0984

.1083

.1181

.1378

.1575

4 1/2

5

5 1/2

6

7

8

9

10

11

12

14

16

18

5.644

5.080

4.618

4.233

3.628

3.175

2.822

2.540

2.309

2.117

1.814

1.587

1.411

.5566

.6184

.6802

.7421

.8659

.9894

1.1132

1.2368

1.3605

1.4839

1.7318

1.9795

2.2263

.2783

.3092

.3402

.3710

.4329

.4947

.5566

.6184

.6803

.7420

.8659

.9898

1.1132

.3822

.4246

.4671

.5096

.5946

.6794

.7644

.8493

.9342

1.0189

1.1891

1.3592

1.5354

1

1

1

1

2

2

2

2

3

3

4

1/4

1/2

3/4

1/4

1/2

3/4

1/2

The Metric Module is the Pitch Diameter in Millimeters divided by the number of teeth in the gear.

Deden- Addendum

dum

(Inches) (Inches)

.2050

.2278

.2506

.2734

.3189

.3644

.4100

.4556

.5011

.5466

.6379

.7291

.8267

.1772

.1969

.2165

.2362

.2756

.3150

.3544

.3937

.4331

.4724

.5513

.6301

.7086

LINN

GEAR

COMPANY

DIAMETRAL PITCH

Diametral Pitch is the Number of Teeth Per Inch of the Pitch Diameter

FOR SPUR GEARS ONLY

To Get

Diametral

Knowing

The Circular Pitch

Pitch

Rule

To Get

Knowing

Rule

Divide 3.1416 by the Circular

Outside

The Pitch Dia. and

Divide the No. of Teeth plus 2

Pitch

Diameter

the Number of Teeth

by the quotient of No. of Teeth

The Pitch Diameter

Divide Number of Teeth by

and the No. of Teeth

Pitch Diameter

The Number of Teeth

divided by the Pitch Dia.

Multiply the Number of

The Outside Dia. and

Divide Number of Teeth plus

and Addendum

teeth plus 2 by Addendum

Multiply Pitch Diameter by

the No. of Teeth

2 by Outside Diameter

Pitch

The No. of Teeth and

Divide Number of Teeth by

Number

The Pitch Dia. and

Diameter

the Diametral Pitch

the Diametral Pitch

of Teeth

the Diametral Pitch

the Diametral Pitch

The No. of Teeth

Divide the product of Outside

The Outside Dia.

Multiply Outside Dia. by the

and the Diametral Pitch

Diametral Pitch and subtract 2

and Outside Dia.

Diameter and Number of

Teeth by No. of Teeth plus 2

Thickness

The Diametral Pitch

of Tooth

The Outside Dia. and

Subtract from the Outside Dia.

the Diametral Pitch

the quotient of 2 divided by

the Diametral Pitch

Addendum and

Multiply Addendum by the

Number of Teeth

Number of Teeth

Addendum

The Diametral Pitch

Root

The Diametral Pitch

Working

The No. of Teeth and

Divide Number of Teeth plus 2

Whole

Diameter

the Diametral Pitch

by the Diametral Pitch

Depth

Clearance

Add to the Pitch Diameter

the quotient of 2 divided

Divide 1.157 by the

Diametral Pitch

Outside

the Diametral Pitch

Divide 1 by the Diametral

Pitch

The Diametral Pitch

Depth

The Pitch Dia. and

Divide 1.5708 by the

Diametral Pitch

Divide 2 by the Diametral

Pitch

The Diametral Pitch

Divide 2.157 by the

The Diametral Pitch

Divide .157 by the Diametral

Thickness of Tooth

Divide Thickness of Tooth at

Diametral Pitch

Pitch

by the Diametral Pitch

pitch line by 10

CIRCULAR PITCH

Circular Pitch is the Distance from the Center of One Tooth to the Center of the Next Tooth at the Pitch Line

FOR SPUR GEARS ONLY

To Get

Circular

Knowing

The Diametral Pitch

Pitch

The Pitch Dia. and

Rule

To Get

Knowing

Divide 3.1416 by the

Outside

The Pitch Dia. and

Diametral Pitch

Diameter

the Circular Pitch

Divide Pitch Dia. by the product

Rule

Add to the Pitch Diameter

the product of the Circular

Pitch and .6366

the No. of Teeth

of .3183 and No. of Teeth

The No. of Teeth and

Multiply Addendum by

The Outside Dia. and

Divide Outside Dia. by the

the Addendum

Number of Teeth plus 2

the No. of Teeth

product of .3183 and

Number

The Pitch Diameter

Divide the Product of

Number of Teeth plus 2

of Teeth

and the Circular Pitch

Pitch Diameter and 3.1416

The Circular Pitch

One-half the Circular Pitch

Pitch

The No. of Teeth and

The continued product of

Diameter

the Circular Pitch

the Number of Teeth, the

Thickness

by the Circular Pitch

Circular Pitch and .3183

of Tooth

The No. of Teeth and

Divide the product of No. of

Addendum

The Circular Pitch

Multiply the Circular Pitch

the Outside Dia.

Teeth and Outside Dia. by

No. of Teeth plus 2

Root

The Circular Pitch

Multiply the Circular Pitch

The Outside Dia. and

Subtract the product of the

Working

The Circular Pitch

Multiply the Circular Pitch

the Circular Pitch

Circular Pitch and .6366

Depth

from the Outside Dia.

Whole

Addendum and the

Multiply the No. of Teeth

Depth

Clearance

by .3183

by .3683

Number of Teeth

by the Addendum

Outside

The No. of Teeth and

The continued product of

Diameter

the Circular Pitch

the Number of Teeth plus 2,

the Circular Pitch and .3183

by .6366

The Circular Pitch

Multiply the Circular Pitch

by .6866

The Circular Pitch

Multiply the Circular Pitch

by .05

Thickness of Tooth

One-tenth the Thickness

of Tooth at Pitch Line

LINN

GEAR

COMPANY

MACHINE CUT SPROCKET TOLERANCES

SINGLE STRAND SPROCKET RIM THICKNESS

Pitch

Chain

Number

Sprocket

Thickness

Un-machined

Tolerance

Machined

Tolerance

1/4 "

3/8 "

1/2 "

25

35

41

.110"

.168"

.227"

+ .005 / - .021"

+ .006 / - .027"

+ .007 / - .032"

+ .000 / - .007"

+ .000 / - .008"

+ .000 / - .009"

1/2 "

5/8 "

3/4 "

40

50

60

.284"

.343"

.459"

+ .008 / - .035"

+ .009 / - .036"

+ .012 / - .036"

+ .000 / - .009"

+ .000 / - .010"

+ .000 / - .011"

1

"

1 1/4 "

1 1/2 "

80

100

120

.575"

.692"

.924"

+ .014 / - .040"

+ .017 / - .046"

+ .022 / - .057"

+ .000 / - .012"

+ .000 / - .014"

+ .000 / - .016"

1 3/4 "

2

"

2 1/4 "

140

160

180

.924"

1.156"

1.301"

+ .022 / - .057"

+ .027 / - .062"

+ .032 / - .068"

+ .000 / - .016"

+ .000 / - .019"

+ .000 / - .020"

2 1/2 "

3

"

200

240

1.389"

1.738"

+ .032 / - .072"

+ .050 / - .088"

+ .000 / - .021"

+ .000 / - .025"

SPROCKET ROOT DIAMETER

The Root or Bottom diameter tolerance is minus only and can be found by the following formula:

Tolerance Equals: [(.001 X Chain Pitch in Inches) + .003"] X Square Root of the No. of Teeth

FACE RUN-OUT

Maximum total face run-out is .0025" total indicator reading per inch of sprocket pitch diameter.

CONCENTRICITY

Maximum allowable pitch line eccentricity with relation to the bore is .001" total indicator reading per inch of

sprocket pitch diameter, with minimum tolerance of .006" at regular charges.

HUB DIAMETER AND LENGTH

Hub Diameter

Range

Hubs up to 3" Diameter

Over 3" to 4" Diameter

Over 4" to 6" Diameter

Hubs over 6" Diameter

Hub Diameter

Tolerance

+ 0"

+ 0"

+ 0"

+ 0"

- 1/32"

- 1/16"

- 1/16"

- 1/8"

Length Through Bore

Tolerance

+ 1/32"

+ 1/32"

+ 1/16"

+ 1/16"

- 1/32"

- 1/32"

- 1/16"

- 1/16"

DRILLED HOLES

Hole Diameter ..................................................................................................... + .010"

Radius from Center ............................................................................................. + .015"

Spacing .............................................................................................................. + .010"

- .000"

- .015"

- .010"

LINN

GEAR

COMPANY

MAXIMUM HUB DIAMETERS - INCHES

Pitch and Chain Number

No.

Teeth

3/8

35

1/2

41

1/2

40

5/8

50

3/4

60

1

80

1 1/4

100

1 1/2

120

1 3/4

140

2

160

2 1/4

180

2 1/2

200

3

240

6

7

8

9

.24

.38

.50

.62

.42

.59

.77

.93

.33

.50

.67

.84

.42

.64

.84

1.06

.52

.77

1.03

1.28

.70

1.05

1.38

1.72

.88

1.31

1.73

2.15

1.06

1.58

2.08

2.59

1.25

1.84

2.44

3.03

1.42

2.11

2.80

3.46

1.61

2.39

3.14

3.89

1.80

2.66

3.50

4.34

2.16

3.19

4.20

5.21

10

11

12

13

.75

.87

.99

1.12

1.10

1.26

1.43

1.59

1.01

1.17

1.34

1.50

1.27

1.47

1.68

1.88

1.53

1.77

2.02

2.26

2.05

2.37

2.70

3.03

2.57

2.98

3.38

3.79

3.09

3.58

4.07

4.56

3.60

4.18

4.75

5.32

4.12

4.78

5.43

6.08

4.64

5.38

6.11

6.84

5.16

5.98

6.80

7.61

6.20

7.19

8.17

9.14

14

15

16

17

1.24

1.36

1.48

1.60

1.75

1.91

2.07

2.23

1.66

1.82

1.98

2.14

2.08

2.28

2.49

2.69

2.51

2.75

2.99

3.23

3.35

3.67

4.00

4.32

4.20

4.60

5.00

5.41

5.04

5.53

6.01

6.49

5.89

6.45

7.02

7.58

6.73

7.38

8.02

8.67

7.58

8.30

9.03

9.75

8.42

9.23

10.04

10.84

10.11

11.08

12.05

13.02

18

19

20

21

1.72

1.84

1.96

2.08

2.39

2.56

2.72

2.88

2.30

2.47

2.63

2.79

2.89

3.09

3.29

3.49

3.47

3.71

3.95

4.19

4.64

4.96

5.28

5.60

5.81

6.21

6.61

7.01

6.98

7.46

7.94

8.42

8.14

8.71

9.27

9.83

9.31

9.95

10.60

11.24

10.47

11.20

11.92

12.64

11.65

12.45

13.25

14.06

13.98

14.95

15.91

16.87

22

23

24

25

2.20

2.32

2.44

2.56

3.04

3.20

3.36

3.52

2.95

3.11

3.27

3.43

3.69

3.89

4.09

4.29

4.44

4.68

4.92

5.16

5.92

6.24

6.56

6.88

7.41

7.81

8.21

8.61

8.90

9.38

9.86

10.34

10.39

10.95

11.51

12.07

11.88

12.52

13.16

13.80

13.36

14.08

14.80

15.52

14.86

15.66

16.46

17.26

17.84

18.80

18.76

20.72

26

27

28

29

2.68

2.80

2.92

3.04

3.68

3.84

4.00

4.16

3.59

3.75

3.91

4.07

4.49

4.69

4.89

5.09

5.40

5.64

5.88

6.12

7.20

7.52

7.84

8.16

9.01

9.41

9.81

10.21

10.82

11.30

11.78

12.26

12.63

13.19

13.75

14.31

14.44

15.08

15.72

16.36

16.25

16.97

17.69

18.41

18.06

18.86

19.66

20.46

21.68

22.64

23.59

24.55

30

31

32

3.16

3.28

3.39

4.32

4.47

4.64

4.23

4.38

4.55

5.29

5.48

5.69

6.35

6.59

6.83

8.48

8.80

9.11

10.61

11.00

11.41

12.74

13.22

13.69

14.87

15.42

15.98

17.00

17.62

18.27

19.13

19.84

20.56

21.26

22.05

22.84

25.51

26.47

27.42

Pitch and Chain Number

No. of

1" Pitch

Effective

Teeth

2040

2042

1 1/4" Pitch

1 1/2" Pitch

2" Pitch

2 1/2" Pitch

3" Pitch

2050

2052

2060

2062

2080

2082

2100

2102

2120

2122

6

6 1/2

7

7 1/2

1.20

1.38

1.55

1.72

1.20

....

1.55

....

1.51

1.73

1.94

2.15

1.51

...

1.94

...

1.82

2.08

2.34

2.59

1.82

....

2.34

....

2.43

2.78

3.12

3.46

2.43

....

3.12

....

3.05

3.48

3.91

4.34

3.05

....

3.91

....

3.67

4.19

4.70

5.21

3.67

...

4.70

...

8

8 1/2

9

9 1/2

1.88

2.05

2.22

2.38

1.88

....

2.22

....

2.36

2.57

2.80

2.99

2.36

...

2.78

...

2.84

3.09

3.34

3.59

2.84

....

3.34

....

3.80

4.13

4.47

4.80

3.80

....

4.46

....

4.76

5.17

5.59

6.00

4.75

....

5.59

....

5.71

6.21

6.71

7.24

5.71

...

6.71

...

10

10 1/2

11

11 1/2

2.55

2.71

2.88

3.04

2.55

....

2.88

....

3.19

3.40

3.60

3.81

3.19

...

3.60

...

3.84

4.08

4.33

4.57

3.84

....

4.33

....

5.13

5.45

5.78

6.11

5.12

....

5.78

....

6.41

6.83

7.23

7.64

6.41

....

7.23

....

7.71

8.20

8.69

9.18

7.70

...

8.69

...

12

12 1/2

13

13 1/2

3.20

3.36

3.53

3.69

3.20

....

3.52

....

4.04

4.21

4.42

4.62

4.01

...

4.42

...

4.82

5.06

5.31

5.55

4.82

....

5.30

....

6.43

6.76

7.08

7.41

6.43

....

7.08

....

8.05

8.46

8.86

9.27

8.05

....

8.85

....

9.67

10.15

10.64

11.13

9.66

...

10.64

...

14

14 1/2

15

3.85

4.01

4.17

3.84

....

4.15

4.82

5.02

5.23

4.82

...

5.23

5.79

6.03

6.28

5.79

....

6.28

7.73

8.06

8.38

7.73

....

8.38

9.67

10.08

10.48

9.64

....

10.43

11.61

12.10

12.58

11.61

...

12.58

LINN

GEAR

COMPANY

STANDARD KEYWAY

and SET SCREW DIMENSIONS - INCHES

SHAFT

DIAMETER

KEYWAY

WIDTH X DEPTH

SET SCREW

DIAMETER

SHAFT

DIAMETER

1/2 -

9/16

1/8

1/16

1/4

5/16 -

3 3/4

5/8 -

7/8

3/16 X

3/32

1/4

3 13/16 -

4 1/2

15/16 - 1 1/4

1/4

KEYWAY

WIDTH X DEPTH

7/8

SET SCREW

DIAMETER

7/16

3/4

1/2

3/4

1/8

5/16

9/16 -

5 1/2

1 1/4

5/8

5/16 - 1 3/8

5/16 X

5/32

5/16

9/16 -

6 1/2

1 1/2

3/4

7/16 - 1 3/4

3/8

3/16

3/8

9/16 -

7 1/2

1 3/4

7/8

1 13/16 - 2 1/4

1/2

1/4

1/2

9/16 -

8 15/16

5/16 - 2 3/4

5/8

5/16

5/8

2 1/2

1 1/4

2 13/16 - 3 1/4

3/4

3/8

3/4

- 10 15/16

3/4

WHEN KEYWAYS AND/OR SETSCREWS ARE ORDERED, BUT EXACT SPECIFICATIONS NOT INDICATED,

THE FOLLOWING PRACTICES WILL BE FOLLOWED.

Keyways are not located in line with sprocket or gear teeth unless requested. There is no additional charge for cutting in line but it

should be understood that perfect alignment cannot be accomplished by normal shop methods. Because of variations in shafting,

keystock and bore dimensions and the placement of keyways in shaft and bore, shaft misalignment or eccentricity or a combination

of all of these, tooth alignment closer than + or - 0 45' should not be anticipated from this method. Variations exceeding this amount

are possible even when care is taken in all areas. For applications requiring particularly close alignment, we can supply adjustable

hubs that allow one sprocket or gear to be rotated to match the other after installation on the shaft.

Keyways will be cut to the dimensions in the above table. Tapered keyways will be tapered 1/8" per foot - standard depth at deep end.

Tapered keyways will be furnished with deep end on hub side of sprockets or gears with hub on one side only. If thickness of hub

remaining over standard depth keyway is deemed inadequate, keyways will be cut shallow. Keys are not furnished except on order

and at additional cost.

When one set screw is ordered, it is normally over the keyway. However, if the hub thickness remaining over the keyway is less than

the diameter of a standard set screw it will be placed at 90. When 2 set screws are ordered they are normally placed 1 over the key

and 1 at 90. If hub thickness over a standard depth keyway is less than the diameter of a standard set screw, they will be placed at

90 and 180 to the keyway. Set screws are furnished.

All alteration charges are for standard bore sizes in increments of 1/16" with standard tolerances. Non-standard bore, keyway or set

screw sizes, tapered bores, splines, multiple keyways or specific location of keyways, pin holes or other variations from normal

practice are subject to extra charge.

BORE AND KEYWAY TOLERANCES

The standard tolerances listed below have proved satisfactory in use throughout the industry for many years and will be maintained

on all standard commercial sprockets and gears. Should specific applications require closer tolerances, they can be supplied at

reasonable extra cost. However, care should be taken not to specify tolerances which are less than the standard listed, when not

actually required, in order to avoid unnecessary extra charges.

BORE TOLERANCE

Bores up to 2" Diameter ............................................................................

Over 2" to 3" Diameter ..............................................................................

Over 3" to 4" Diameter ..............................................................................

Bores over 4" Diameter .............................................................................

+.002"

+.003"

+.004"

+.005"

-.000"

-.000"

-.000"

-.000"

KEYWAY TOLERANCE

Width of Keyway - Straight or Tapered ...................................................... +.002" -.002"

Depth of Keyway - Straight ........................................................................ +.010" -.000"

Depth of Keyway - Tapered ....................................................................... +.000" -.010"

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Alto High Performance CatalogDocument48 pagesAlto High Performance CatalogEvs SrhNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ZF TransmisionDocument20 pagesZF Transmisionchikoo49950% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Power Train SOTA RENR5124 PDFDocument132 pagesPower Train SOTA RENR5124 PDFHerrera Salazar VisnuNo ratings yet

- 1995-2002 VW Derby Polo - 5 Speed Manual Gearbox 02J DSF DTA EKU EKV EKW EWY EWZ EXADocument227 pages1995-2002 VW Derby Polo - 5 Speed Manual Gearbox 02J DSF DTA EKU EKV EKW EWY EWZ EXARogelio Orozco Salas100% (1)

- BaldorDocument12 pagesBaldorRavi KumarNo ratings yet

- Description of The Fault Codes For ERGO-Control EST37: ZF FRIEDRICHSHAFEN AktiengesellschaftDocument57 pagesDescription of The Fault Codes For ERGO-Control EST37: ZF FRIEDRICHSHAFEN AktiengesellschaftmorusNo ratings yet

- BB502 Xd07aen E1Document50 pagesBB502 Xd07aen E1ARTMehr Eng. GroupNo ratings yet

- Useful Data On Plastic Injection MouldingDocument71 pagesUseful Data On Plastic Injection MouldingMahesh Deivasiga Mani D100% (2)

- NPE Prodn Record Analysis 2012-13-01Document195 pagesNPE Prodn Record Analysis 2012-13-01Mahesh Deivasiga Mani DNo ratings yet

- General Exemption Central Excise TariffDocument7 pagesGeneral Exemption Central Excise TariffSameer HusainNo ratings yet

- Counterboring Speeds and FeedsDocument1 pageCounterboring Speeds and FeedsMahesh Deivasiga Mani DNo ratings yet

- Sphere FormulasDocument3 pagesSphere FormulasMahesh Deivasiga Mani DNo ratings yet

- 3D Modeling Auto CAD 2007Document29 pages3D Modeling Auto CAD 2007Siryo SoNo ratings yet

- Blow Moulding Processing Manual: Dupont Engineering PolymersDocument24 pagesBlow Moulding Processing Manual: Dupont Engineering PolymersSandeep LeeNo ratings yet

- Milling Speeds and FeedsDocument1 pageMilling Speeds and FeedsMahesh Deivasiga Mani DNo ratings yet

- Counterboring Speeds and FeedsDocument1 pageCounterboring Speeds and FeedsMahesh Deivasiga Mani DNo ratings yet

- Plastic Gear Moulding Design GuideDocument27 pagesPlastic Gear Moulding Design GuideMahesh Deivasiga Mani DNo ratings yet

- Screw - Design of Screws, Fasteners and PowerDocument39 pagesScrew - Design of Screws, Fasteners and PowerAljen MojeNo ratings yet

- MTC CircuitDocument1 pageMTC CircuitMahesh Deivasiga Mani DNo ratings yet

- Dual Temperature Controller. If Needed If Needed) D-Te.C O/pDocument1 pageDual Temperature Controller. If Needed If Needed) D-Te.C O/pMahesh Deivasiga Mani DNo ratings yet

- Ejector Pin FormatDocument1 pageEjector Pin FormatMahesh Deivasiga Mani DNo ratings yet

- About SolarPower Discn.Document3 pagesAbout SolarPower Discn.Mahesh Deivasiga Mani DNo ratings yet

- Shrinkage Rate ExerciseDocument7 pagesShrinkage Rate Exercisemazhar79No ratings yet

- Shrinkage TableDocument6 pagesShrinkage TableMahesh Deivasiga Mani DNo ratings yet

- Transfer Case and Extension: A: RemovalDocument8 pagesTransfer Case and Extension: A: RemovalJeff PascoeNo ratings yet

- Interference: Design of Power Transmission SystemDocument5 pagesInterference: Design of Power Transmission SystemJai SharmaNo ratings yet

- General description of gear pumpsDocument28 pagesGeneral description of gear pumpsStefan RaduNo ratings yet

- ABB - Overhung LoadDocument3 pagesABB - Overhung LoaddrewtwitchNo ratings yet

- Unit 1 Clutch and Gearbox GuideDocument5 pagesUnit 1 Clutch and Gearbox GuideSathis Kumar67% (12)

- A1753230 30 Conveyor Parts Manual CON 203 23 J1349Document7 pagesA1753230 30 Conveyor Parts Manual CON 203 23 J1349waltergvNo ratings yet

- Presented By-Raghav Maheshwari Roll No.-124086Document20 pagesPresented By-Raghav Maheshwari Roll No.-124086RaghavMaheshwari100% (1)

- Unit Iii Hydromatic Drive: Fluid Coupling ConverterDocument44 pagesUnit Iii Hydromatic Drive: Fluid Coupling ConverterGuruLakshmiNo ratings yet

- Copia de Base para Creacion Articulos Sistemas 12-07-2017Document90 pagesCopia de Base para Creacion Articulos Sistemas 12-07-2017Camilo Andres Bonilla GonzalezNo ratings yet

- DSG Pinout - Passat PDFDocument5 pagesDSG Pinout - Passat PDFCaio EleuterioNo ratings yet

- Synchromesh Gearbox - Construction, Working Principle, Advantages, Disadvantages, and Applications (PDF)Document7 pagesSynchromesh Gearbox - Construction, Working Principle, Advantages, Disadvantages, and Applications (PDF)Kyle LabileNo ratings yet

- Replacing Jaw Clutches - Welcome To Combined Cycle Journal PDFDocument3 pagesReplacing Jaw Clutches - Welcome To Combined Cycle Journal PDFferayiNo ratings yet

- 205-02 Rear Drive Axle and Differential - Removal and Installation - Electronic Locking Differential ELD SolenoidDocument4 pages205-02 Rear Drive Axle and Differential - Removal and Installation - Electronic Locking Differential ELD SolenoidCARLOS LIMADANo ratings yet

- (2010 AND AFTER) : Mercedes-Benz (Eu) Atego Euro 5 375/950/970/972/974/975/976 ATEGO 1226 F Euro 5Document4 pages(2010 AND AFTER) : Mercedes-Benz (Eu) Atego Euro 5 375/950/970/972/974/975/976 ATEGO 1226 F Euro 5MoussaNo ratings yet

- Bevel Gear - Force Analysis of Bevel GearDocument16 pagesBevel Gear - Force Analysis of Bevel GearRohit GhulanavarNo ratings yet

- Gearing - ProblemsDocument7 pagesGearing - ProblemsmanuNo ratings yet

- NRB Tractor VehiclesDocument13 pagesNRB Tractor VehiclesmaheshmbelgaviNo ratings yet

- FWD 6 Speed: Ganzeboom Transmission Parts & Torque ConvertersDocument2 pagesFWD 6 Speed: Ganzeboom Transmission Parts & Torque ConvertersAlli YantiNo ratings yet

- Gear Box Quality Control Sheet: PT Indotruck UtamaDocument2 pagesGear Box Quality Control Sheet: PT Indotruck UtamaYasin Noer Huda PNo ratings yet

- Flat Belt TM2Document21 pagesFlat Belt TM2Abdi samad MohamedNo ratings yet

- TransmisionDocument303 pagesTransmisionzaka_czNo ratings yet

- 2021-2022 Technical Information v031 enDocument634 pages2021-2022 Technical Information v031 enValtessNo ratings yet