Professional Documents

Culture Documents

Final

Uploaded by

Anuanuksya AnuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final

Uploaded by

Anuanuksya AnuCopyright:

Available Formats

FAKULTI PENDIDIKAN DAN BAHASA SEMESTER SEPTEMBER 2012

OUMH2203 ENGLISH FOR WORKPLACE COMMUNICATION

NAMA NO. MATRIKULASI NO. KAD PENGENALAN NO. TELEFON E-MEL

: NEELA A/P MYLVAGANAM : 730324-10-5752002 : 730324-10-5752 : 016 - 3740724 : neesha_916@oum.edu.my

PUSAT PEMBELAJARAN : SHAH ALAM LEARNING CENTRE

To Mr. Siau the managing director a) (Introduction) Sir, I as an occupational health manager in the company, posses the responsibilities of informing up to date informations pertaining to the safety measures both to the workers and the company as well. In accordance to that , I was annoyed to discover that in the Material and Handling Department ,operates were simply ignoring the safety regulation which would cause a major damage to the welfare of the factory workers. There are about more than 860 workers working in our factory . It is our responsibility to provide them proper safety methods to save their life. Anything may happen if we fail to find out a quicker remedial action. It was very much annoyed to see that the workers especially those in the material and handling department hesitates safety methods and are not bothered about it I as an occupational health manager at the said department propose the following actions to be taken as soon as possible. 1.Make an advisory committee immediately to find out the problem faced. 2.Inform the operators the dos and donts in case of neglecting safety method. 3.Introduce new safety devises to replace old and unusable devices. 4.Transfer irresponsible operators to other department. b) (Body) I identified the following problems in our factory which seems to be severe and needs an immediate action.

Problem :1 Hesitating to wear helmets. It is one of our factorys regulation that all the operators should wear helmets in order to protect themselves from the danger of any heavy things knocking their head . I also would like to forward to your acknowledge that one of our staffs had a major injury on his head last year and was admitted in the hospital on a severe condition. The visitors from the National Health Department had also produced a wearing statement to our company on this matter dated 2.09.2011.This has been informed to all the operators earlier through circulars on the 4th October 2011. Yet the action taken did not produce good result. Our factory would have to be answerable in case of any miserable happening in future because such matters are seriously taken in consideration by the national health department officers. I had attend an introductory meeting held on 12 October last year which was organized by National Health Department(NHD) at Langkawi .The safety method has been the main topic of the meeting discussed deeply .Out of which the following conclusions are made as an advise to all factory managements. a) All the workers and operators or even staffs should be provided with helmets which are certified by SIRIM: b) The company becomes solely responsible for any major problems faced in case of neglecting to obey safety methods. c) The company has to bear the playing of computation charged thereafter. Bearing all these ups and downs in mind we had to make a quicker move in this matter. Possible remedies are as follows: I. II. Advise the operators to wear the helmets throughout the day while working. Produce letters of warning to all the operators working in our company who hesitates to wear safety helmets.

III.

Acknowledge them the benefits of wearing helmets.

Such actions suggested above will safe both the operators and the managing department from trouble. Problem:2 Smoking at the prohibitted areas. Another problem that annoyed me was operators smoking at the prohibited areas .The operators know that it is highly dangerous to smoke at such areas where highly flammable chemicals are kept. Yet they ignore safeties and do things that are prohibited. Wordings in big red letter were kept in all the necessary places as warnings such as NO SMOKING .There has been an incident last month where one of our factorys guard room was totally destroyed. This was the cause of some irresponsible workers who threw the unfinished part of his cigarette in the room. The workers was sacked immediately in twenty-four hours time for haring caused a major loss to our factory .Although the operator in the Material and Handling Department aware of the danger ahead yet they seems to be not bothering anymore. Possible safety methods suggested are the follows. I. The operators working in the Material and Handling Department should be checked turrerly by the guards before entering the factory premises. II. In case of finding where operators caught on sport keeping cigarettes packets and match boxes should be informed to the authorities concerned immediately. III. IV. After giving a third warning the said person should be sacked. Investigate officers should go around the said premises every one hour to watch workers who smokes working hours V. Workers must acknowledged of the major problems caused by smoking both to personal and health condition as well as the safetiness of the factory Remedies actions suggested as above would be of much beneficial to our factory.

Problem: 3 Operators do not wear gloves: Hesitating to wear gloves is also seems to be a problem faced among operators. As they are dealing with materials which are connected with electrical and electronics substances it is very much important and needy to wear gloves recommended by the management. The high cost that the factory has to bear on buying high rated gloves has to be taken in consideration. The SALMA GLOVES ENTERPRISE is supplying high grade gloves to our factory every month and the factory has to spend a major proportion on buying gloves .But the operators seems to be bare handed while working and the gloves are scattered here and there. After some interviews with some of our operators, I come to know that they prevent using gloves because of the following reasons a. Their hands sweat and they find it uneasy to work. b. Sometime it is slippery and couldnt finish their jobs in time. c. They find free without gloves. These are the reasons receive from the operators. The operators are not aware of the problem that they may face if they dont use gloves. The following reasons are bared in mind for the importants given in wearing gloves. 1. The operators are dealing with things such as:

a. Sharp wires b. Scissors c. Very sharp cutters d. Chemicals e. Gums 2. The machines they use may cause cuts on their hands.

3. Some of the chemical used may spoil their nails of their hands. 4. Some of the nails and sharp needles, screwdrivers are very much harm full. After considering this entire problems the managing authorities has made it a must to wear gloves and this was implemented from the beginning. The following suggestions could bring changes: a. Advise the operators of the danger they may face by hesitating to wear gloves in their hands. b. Those managements may take deceplinery actions on operators who dont wear gloves. c. The management would not bear the cost of any injuries. d. operators without gloves will not be allowed to proceed their works. e. The management may take actions to sack their said operators who hesitates to wear gloves after tree warnings. A stern and strict action on operation neglecting safety regulation will bring changes. Problem: 4 Another big problem that I came across was negligence in wearing masks. The factory has amended the rule of wearing gloves and masks since the opening of factory .These safety moves were introduced for the safeties of the operators. But it is highly ridiculous to find out that the operators simply ignore because of ignorance. The management also provides the facilities of wearing masks bearing its costs. the masks were imported from a foreign company and are certified by the government. Using of masks during working hour is recommended because the workers sometimes have to deal with highly adorable chemicals. A continuous smelling of these chemicals may cause problems in breathing. There is a possibility to face problems in the defunctioning of the lungs. We had annalysed this earlier and come to a conclusion that wearing mask should be strictly followed. The data shows that event how wearing mask is highly recommended yet there are

workers who face problems in breathing. An analysis done last year shows that 53 workers had some chronical problem in breathing and were admitted in hospitals. Possible suggestions that could be implement: I. II. Operators not wearing masks must not be allowed to continue their job. Operator must be acknowledged about the high risk of health condition that they may face by not wearing the mask. III. They must also be acknowledged with the problems that the management may face if encountered by the NHD. The suggestion given above may help in overcoming the problem said above. Conclusions. Maintaining a factory is not a simple task . There are so many ups and downs where to operate each and every corner of the factory. In relation to that maintaining strict regulation on safety measures have also becomes an important factor that has to be handled carefully. Failing in implementing and preparing occupational and safety standard may end in facing though problem. Maintaining good safety method becomes impossible because of the ignorance of the workers .This is because; 2. The workers or operators are unaware of the high range of problems that would ruin totally the working systems of the factory both to the management and workers as well. 3. They dont understand that the government is very strict of health measurer that should be amended according to the act of Industries of Malaysia. 4. They take matters simple because lack of proper education.

Those factories which are dealing with .chemicals and electronic goods have to take major actions concerning safety measures. Wearing safety helmets, hand gloves, masks are among an important method that should be strictly followed .Smoking is not allowed too because it may cause damages to highly inflammable equipments and health.

There are thousands of factories throughout Malaysia and the complaints received each year about improper safetiness is also increasing highly day to day. Importances to safety must be in first place in every factory .An in accordance to that the government has to implement strict rules to all the factories. There are some modern methods of implements in factories to safeguards the workers. The management may have to bear an increase in cost in handling and implementing the methods by introducing new and safe devises .But this is must so that the benefits is shared both by the management and workers as well. Bearing all these in mind. I hope that as the managing director of the factory you would forward this matter to the authorities concerned. Thank you

REFERENCES

Abdul Aziz Hussin, 2000, Aspek Undang-Undang Tort Dalam Projek Pembinaan. Pulau Pinang: Penerbit Universiti Sains Malaysia.

Akta Keselamatan dan Kesihatan Pekerja, 1994.

Kementerian Sumber Manusia, 1975, Code of Conduct for Industrial Harmony. Maule, K. Expectation of the Principal Constractor Buletin NIOSH September, 1998 Module OUMH2203 English for workplace communication (2006),Open University Malaysia

Peraturan Kilang dan Jentera (Keselamatan, Kesihatan & Kebajikan), 1970.

Sidang Media 27 Ogos 2001, Y.A.B. Perdana Menteri.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Adidas InvoiceDocument1 pageAdidas InvoicePHARMA RESEARCH100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 233 2 V Example 13.23.: C B BC BCDocument9 pages233 2 V Example 13.23.: C B BC BCmuhammad haseebNo ratings yet

- Martinez v. Morfe - DigestDocument2 pagesMartinez v. Morfe - DigestMaria Angela Gaspar100% (1)

- C57.91-2011 Unlocked PDFDocument11 pagesC57.91-2011 Unlocked PDFHector CalderonNo ratings yet

- The Attorney-General of Israel v. EichmannDocument2 pagesThe Attorney-General of Israel v. EichmannJD Ballos100% (2)

- Ilmu BahasaDocument3 pagesIlmu BahasaAnuanuksya AnuNo ratings yet

- Ilmu BahasaDocument3 pagesIlmu BahasaAnuanuksya AnuNo ratings yet

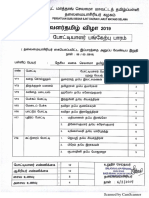

- Borang Valar Tamil Vizha 2019Document1 pageBorang Valar Tamil Vizha 2019Anuanuksya AnuNo ratings yet

- Kod Sek: ABD 6104 No. Tel: 05-8394858 Email: ABD6104@moe - Edu.myDocument1 pageKod Sek: ABD 6104 No. Tel: 05-8394858 Email: ABD6104@moe - Edu.myAnuanuksya AnuNo ratings yet

- GrammarDocument9 pagesGrammarAnuanuksya AnuNo ratings yet

- Jsu Bahasa Inggeris PemahamanDocument2 pagesJsu Bahasa Inggeris PemahamanAnuanuksya AnuNo ratings yet

- GrammarDocument9 pagesGrammarShalini KanganNo ratings yet

- Report On Workplace SafetyDocument18 pagesReport On Workplace SafetyAnuanuksya Anu100% (1)

- Hamparan ElektronikDocument1 pageHamparan ElektronikAnuanuksya AnuNo ratings yet

- Diognastik TestDocument2 pagesDiognastik TestAnuanuksya AnuNo ratings yet

- Monthly Exam PapersDocument5 pagesMonthly Exam PapersAnuanuksya AnuNo ratings yet

- BS en 10028-4-2017Document18 pagesBS en 10028-4-2017Ly KhoaNo ratings yet

- Direct Shear Test ReprtDocument4 pagesDirect Shear Test ReprtShivaraj SubramaniamNo ratings yet

- Case DigestsDocument12 pagesCase DigestsMiguel Anas Jr.100% (1)

- Holtz DeclinationDocument1 pageHoltz DeclinationCeleste KatzNo ratings yet

- Atp 2023 2024 AdvertDocument2 pagesAtp 2023 2024 AdvertDavid Lemayian SalatonNo ratings yet

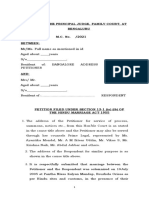

- Sample Divorce Petition DraftDocument41 pagesSample Divorce Petition DraftAyantika Mondal100% (1)

- NSTP Chapter 2Document5 pagesNSTP Chapter 2NicoleVideñaNo ratings yet

- A Project Management Approach: Sustaining SOX 404Document14 pagesA Project Management Approach: Sustaining SOX 404Rahul MongaNo ratings yet

- Legodesk - BFSIsDocument24 pagesLegodesk - BFSIsashishpadhyNo ratings yet

- Kill or Get KilledDocument440 pagesKill or Get Killedkonan7696% (28)

- Chair. Comm. On Appropriations: Jeann T. EcleDocument17 pagesChair. Comm. On Appropriations: Jeann T. EcleAida AntipoloNo ratings yet

- Balance Sheet of Tata Power Company: - in Rs. Cr.Document3 pagesBalance Sheet of Tata Power Company: - in Rs. Cr.ashishrajmakkarNo ratings yet

- Property 3Document16 pagesProperty 3japsondiceNo ratings yet

- Positive Role The Indian Youth Can Play in PoliticsDocument2 pagesPositive Role The Indian Youth Can Play in PoliticsArul ChamariaNo ratings yet

- TRU - Academic Schedule and Important Dates - 2023-2024Document1 pageTRU - Academic Schedule and Important Dates - 2023-2024Aravind KrishnaNo ratings yet

- 1098-T Copy B: Tuition StatementDocument2 pages1098-T Copy B: Tuition Statemented redfNo ratings yet

- Salary PDFDocument83 pagesSalary PDFGaurav BeniwalNo ratings yet

- 1.0 Background of The Study: Chapter OneDocument33 pages1.0 Background of The Study: Chapter Oneokewunmi Afeez olaideNo ratings yet

- Accountant Resume 14Document3 pagesAccountant Resume 14kelvin mkweshaNo ratings yet

- Human Rights Project, 2018Document25 pagesHuman Rights Project, 2018Vishal Jain100% (3)

- Misrecognition, Media and Discrimination? An Analysis of The Weaknesses and Potential of Anti-Discrimination Law in Addressing Discrimination Through Expressive MeansDocument9 pagesMisrecognition, Media and Discrimination? An Analysis of The Weaknesses and Potential of Anti-Discrimination Law in Addressing Discrimination Through Expressive MeansDr Steven McDermottNo ratings yet

- Deed of Sale of Motor VehicleDocument1 pageDeed of Sale of Motor VehicleJonah ReyesNo ratings yet

- Commonwealth Act 141 Powerpoint ReportDocument17 pagesCommonwealth Act 141 Powerpoint ReportVinz G. VizNo ratings yet

- OptiTrade For Oracle Apps - BrochureDocument10 pagesOptiTrade For Oracle Apps - Brochuremanoj1141No ratings yet

- Solution To Ch14 P13 Build A ModelDocument6 pagesSolution To Ch14 P13 Build A ModelALI HAIDERNo ratings yet