Professional Documents

Culture Documents

Kershaw Scorpion RS64 DL Ramp

Uploaded by

camelia_pirjan57760 ratings0% found this document useful (0 votes)

70 views3 pagesKershaw Scorpion RS64 DL Ramp

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKershaw Scorpion RS64 DL Ramp

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

70 views3 pagesKershaw Scorpion RS64 DL Ramp

Uploaded by

camelia_pirjan5776Kershaw Scorpion RS64 DL Ramp

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

MOW Equipment Manufacturing

Kershaw Scorpion RS64 DL Ramp

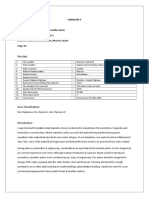

The Kershaw RS64 Ramp is a roll-up loading ramp that can be used to load all work equipment that is normally transported on a flat car. It can load both rail bound and rubber tired machines. Rubber tired and most rail bound machines can climb the 7% slope with ease. A winch is provided for disabled machines or machines that do not have sufficient traction to climb the ramp slope. One man can extend or retract the ramp in less than 5 minutes using a remote pushbutton control.

Deploy and retract sequence is all fully automatic with stage timing controlled by sequencing valves and cams. The operator simply holds down the deploy or retract button through the complete sequence. When retracted and stored for travel, the Scorpion fits within C plate clearance dimensions. Optional bridging bar systems are available to allow movement from one flat car to another. The coupler is retained to allow transportation in train formation. A self-contained diesel power plant drives hydraulic pumps to provide power for the hydraulic cylinders and winch. The engine is housed in a lockable enclosure with controls and instrumentation. A hydraulic tank and diesel fuel tank share a lockable enclosure with easy access for maintenance and service. Fluid levels are easily checked by observing the sight glass tubes. The ramp can be installed on a customer provided flat car or can be provided complete with car. The deck and frame must be of welded construction. Most machines have no problem climbing the 7% slope to load on the Scorpion. A

hydraulic winch is provided for machines that cannot load under their own power. 10650 Hwy. 80 East Montgomery, AL 36117 800-633-5766 ProgressRail.com

MOW Equipment Manufacturing

10650 Hwy. 80 East Montgomery, AL 36117

800-633-5766 ProgressRail.com

MOW Equipment Manufacturing

Kershaw Scorpion RS64 DL Ramp

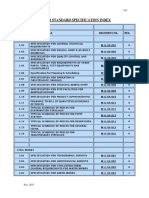

Weight: The ramp adds 13,000 pounds (5900 kg) to the weight of a flat car. Construction: Welded from tubular steel. Tread bearing areas are made from wear resistant steel. Engine: Air cooled diesel Deutz F2L2011 30 hp (22.4 KW) @3000rpm. Winch: Equipped with 5/8 (16 mm) inch wire rope. Retrieval speeds: 12 (3.66 m) feet per minute/high speed; 7 (2.13 m) feet per minute/low speed. Maximum tension: 20,000 pounds (9072 kg). Hydraulic System: A gear pump is driven directly by the engine providing hydraulic power to the ramp control circuit. Filters protect the ramp circuits from contamination. A pendant with pushbuttons is used to energize a solenoid directional valve that cycles the ramp. Electrical System: 12 volt dc negative ground. Maintained by an engine driven 40 amp alternator. Equipped with a special coiled plate 56 amp hour battery. Color coded and numbered wiring. Loading Capacity: The ramp can support 40,000 pounds (18144 kg) per axle on rail bound machines and 30,000 pounds (13608 kg) per axle on rubber tired machines. Capacities: Fuel: 11.5 gal. (43.5 l), Hydraulic: 25 gal. (94.6 l). Options: Adjustable wheel chocks, turnbuckle tie downs, bridging bar systems to allow movement of machines from one flat car to another.

Because of Kershaws continuous desire to improve products, specifications and design are subject to change at any time and without notice and without incurring any obligation to incorporate these changes in previous models. Illustrations and photographs may include optional equipment and may not include standard equipment.

10650 Hwy. 80 East Montgomery, AL 36117

800-633-5766 ProgressRail.com

You might also like

- Car Progression SystemsDocument12 pagesCar Progression SystemsEduardo LopesNo ratings yet

- Kershaw 12-12BridgeCraneDocument3 pagesKershaw 12-12BridgeCranecamelia_pirjan5776No ratings yet

- Guide to Choosing the Right Power Take-Off and Hydraulic PumpDocument22 pagesGuide to Choosing the Right Power Take-Off and Hydraulic Pumpdeepakg9100% (1)

- NCK Orion HC80 Spec Book BWDocument28 pagesNCK Orion HC80 Spec Book BWNitin PatelNo ratings yet

- MOW Equipment Manufacturing: Kershaw 12-12 Tie CraneDocument3 pagesMOW Equipment Manufacturing: Kershaw 12-12 Tie Cranecamelia_pirjan5776No ratings yet

- Pullmaster BrochureDocument16 pagesPullmaster BrochureHEMANTKHERANo ratings yet

- Lantec LH Series Hoists CatalogDocument16 pagesLantec LH Series Hoists CatalogAnonymous 1qAH6CKC100% (1)

- 216 BrochureDocument12 pages216 Brochureleotiger123No ratings yet

- Spart: Under Floor MountedDocument4 pagesSpart: Under Floor MountedVijay AnandNo ratings yet

- TÜLOMSAfi Company Profile and Locomotive IntroDocument13 pagesTÜLOMSAfi Company Profile and Locomotive IntroDesirulez NetNo ratings yet

- Car JackDocument9 pagesCar Jackdeepak GuptaNo ratings yet

- Bushman TransferCarsDocument4 pagesBushman TransferCarsJulio AcNo ratings yet

- Hydrostatic Transmission For Shunting LocomotivesDocument16 pagesHydrostatic Transmission For Shunting LocomotivesDIPAK VINAYAK SHIRBHATENo ratings yet

- WorldSeriesTRTrolley SC H1029 1002Document2 pagesWorldSeriesTRTrolley SC H1029 1002GogyNo ratings yet

- Dynawinch Industries LTD Catalog1Document105 pagesDynawinch Industries LTD Catalog1casda73100% (1)

- Top DriveDocument451 pagesTop DriveAlejita Riveros92% (12)

- Top DriveDocument4 pagesTop DriveJorge FreireNo ratings yet

- Wagon Tippler With Side Arm ChargerDocument4 pagesWagon Tippler With Side Arm ChargerMRITUNJAYNo ratings yet

- Top Drive Brochure PDFDocument6 pagesTop Drive Brochure PDFaldino020203100% (1)

- Dock Lifts: Heavy DutyDocument2 pagesDock Lifts: Heavy DutyAja YlNo ratings yet

- JCB 214eDocument8 pagesJCB 214epankituna54870% (1)

- Lecture II-Agricultural Operations and MachineryDocument131 pagesLecture II-Agricultural Operations and MachineryChileshe SimonNo ratings yet

- 3 Series Front LoadersDocument11 pages3 Series Front Loadersmithis3781No ratings yet

- B&D ManufacuringDocument20 pagesB&D ManufacuringRodolfoMarínNo ratings yet

- All Wheel Steer Loader SpecsDocument6 pagesAll Wheel Steer Loader Specsreddevil0023100% (1)

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentRiki PrasetyoNo ratings yet

- Man-size tractor delivers more power and usefulness for less costDocument14 pagesMan-size tractor delivers more power and usefulness for less costrwesseldykNo ratings yet

- Versatile 4WD 350 550Document20 pagesVersatile 4WD 350 550Ana Valentina Peila PantojaNo ratings yet

- t340-1xl - Truck CraneDocument12 pagest340-1xl - Truck CraneMegame BakiNo ratings yet

- Underground Mining Loader: Engine Operating SpecificationsDocument20 pagesUnderground Mining Loader: Engine Operating SpecificationsJames PaitooNo ratings yet

- 900 Cgs 11Document8 pages900 Cgs 11Mayko DreschNo ratings yet

- 950F IiDocument20 pages950F Iidico65583% (6)

- 50 MT Crawler CraneDocument42 pages50 MT Crawler CraneramyaNo ratings yet

- Agrotrac 610 and 620 Tractor Specs and Features6 / 5,9116 / 5,911Turbo intercooledTurbo intercooled140/103163/120Document12 pagesAgrotrac 610 and 620 Tractor Specs and Features6 / 5,9116 / 5,911Turbo intercooledTurbo intercooled140/103163/120Andreea BoacaraNo ratings yet

- LSV 800 Brochure FinalDocument8 pagesLSV 800 Brochure FinalForklift Systems IncorporatedNo ratings yet

- Overhead CraneDocument2 pagesOverhead CraneCepXNo ratings yet

- Synchronous Motors Selection Guide KM - SG - 000183 - en-USDocument24 pagesSynchronous Motors Selection Guide KM - SG - 000183 - en-USJuan Francisco Marin MendiolaNo ratings yet

- RH340Document8 pagesRH340ericNo ratings yet

- Skid Steer LoadersDocument16 pagesSkid Steer LoadersJuan Jose100% (1)

- Vertical Transportation SystemDocument14 pagesVertical Transportation Systempassionpropel100% (3)

- DumperDocument17 pagesDumperRamabhadran Sundaram100% (1)

- 1000 MaxtrackDocument6 pages1000 MaxtrackJaimeAguilar0% (1)

- Yale 3000Document2 pagesYale 3000VitorMelloNo ratings yet

- Scoop R1600 6yd3Document20 pagesScoop R1600 6yd3Mario Silva Zea0% (1)

- Scoop R1600 6yd3Document20 pagesScoop R1600 6yd3Mario Silva Zea0% (1)

- 750 gallon fuel and service trailer with DEF deliveryDocument12 pages750 gallon fuel and service trailer with DEF deliveryWes StandleyNo ratings yet

- Cat 950 HDocument20 pagesCat 950 Hstefan_barabas4760100% (1)

- HYDRAULIC EXCAVATOR 385B (Excavadora Hidraulica)Document32 pagesHYDRAULIC EXCAVATOR 385B (Excavadora Hidraulica)Christian Kari100% (1)

- Marine Active Heave Compensation Drive TechnologiesDocument6 pagesMarine Active Heave Compensation Drive TechnologiesbrunosamaeianNo ratings yet

- HT 740 - HT 747 1Document4 pagesHT 740 - HT 747 1zzkerNo ratings yet

- Overrunning and Backstopping Clutches For Mining ApplicationsDocument56 pagesOverrunning and Backstopping Clutches For Mining Applicationspumpisrb100% (1)

- RR-B Propulsion 0612 Singlepages LR10 250512 Tcm92-8664Document28 pagesRR-B Propulsion 0612 Singlepages LR10 250512 Tcm92-8664dondo1004No ratings yet

- Hypro-Marine Catalogue 2020 LR-1 2Document62 pagesHypro-Marine Catalogue 2020 LR-1 2Warapot WongsiriNo ratings yet

- Volvo power take-offs guide for trucksDocument22 pagesVolvo power take-offs guide for trucksjamesNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972From EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (3)

- RICS APC Candidate Guide Europe - Russia - CIS - Aug 2015 - WEBDocument23 pagesRICS APC Candidate Guide Europe - Russia - CIS - Aug 2015 - WEBcamelia_pirjan5776No ratings yet

- Specialist Assessment Applicant GuideDocument13 pagesSpecialist Assessment Applicant Guidecamelia_pirjan5776No ratings yet

- Responsibilities CR PD Pms RM SL CD PDLS: Embedding Risk ManagementDocument3 pagesResponsibilities CR PD Pms RM SL CD PDLS: Embedding Risk Managementcamelia_pirjan5776No ratings yet

- RICS APC Requirements+Competencies 2016-17Document55 pagesRICS APC Requirements+Competencies 2016-17camelia_pirjan5776No ratings yet

- Procurement Routes Table 1 PDFDocument2 pagesProcurement Routes Table 1 PDFcamelia_pirjan5776No ratings yet

- Sub Clause 52Document1 pageSub Clause 52camelia_pirjan5776No ratings yet

- Enrolment Joining Supplementary Guide Europe Russia April 2015Document6 pagesEnrolment Joining Supplementary Guide Europe Russia April 2015camelia_pirjan5776No ratings yet

- Membership Assessment Requirements OverviewDocument1 pageMembership Assessment Requirements Overviewcamelia_pirjan5776No ratings yet

- RICS APC Pathway Guide - Built Infrastructure-Feb 2015-WEBDocument32 pagesRICS APC Pathway Guide - Built Infrastructure-Feb 2015-WEBcamelia_pirjan5776No ratings yet

- 38 6KribberAdzerDocument3 pages38 6KribberAdzercamelia_pirjan5776No ratings yet

- Variation Order Sub ClauseDocument1 pageVariation Order Sub Clausecamelia_pirjan5776No ratings yet

- Variation Order Sub ClauseDocument1 pageVariation Order Sub Clausecamelia_pirjan5776No ratings yet

- FormulasDocument1 pageFormulascamelia_pirjan5776No ratings yet

- Construction Law Handbook 2007 - ToCDocument56 pagesConstruction Law Handbook 2007 - ToCcamelia_pirjan57760% (1)

- HTC Telescopic BoomDocument28 pagesHTC Telescopic Boomcamelia_pirjan5776No ratings yet

- Sikadur-31 2-part epoxy adhesiveDocument4 pagesSikadur-31 2-part epoxy adhesivecamelia_pirjan5776No ratings yet

- JCB Loadall HiVizSpecDocument6 pagesJCB Loadall HiVizSpeccamelia_pirjan5776No ratings yet

- 46 6BallastRegulatorDocument3 pages46 6BallastRegulatorcamelia_pirjan5776No ratings yet

- Breitschwelle en PDFDocument12 pagesBreitschwelle en PDFcamelia_pirjan5776No ratings yet

- P. O. Box 244100 Montgomery, AL 36124 Telephone (334) 387-9100 Fax (334) 387-9375Document1 pageP. O. Box 244100 Montgomery, AL 36124 Telephone (334) 387-9100 Fax (334) 387-9375camelia_pirjan5776No ratings yet

- M318 HRRoadRailWheelExcavatorDocument3 pagesM318 HRRoadRailWheelExcavatorcamelia_pirjan5776No ratings yet

- P. O. Box 244100 Montgomery, AL 36124 Telephone (334) 387-9100 Fax (334) 387-9375Document1 pageP. O. Box 244100 Montgomery, AL 36124 Telephone (334) 387-9100 Fax (334) 387-9375camelia_pirjan5776No ratings yet

- 4600 Ballast RegulatorDocument3 pages4600 Ballast Regulatorcamelia_pirjan5776No ratings yet

- Rheda RXDocument6 pagesRheda RXcamelia_pirjan5776No ratings yet

- 46 2BallastRegulatorDocument3 pages46 2BallastRegulatorcamelia_pirjan5776No ratings yet

- Utilaje CFDocument1 pageUtilaje CFcamelia_pirjan5776No ratings yet

- ScarificatorDocument3 pagesScarificatorcamelia_pirjan5776No ratings yet

- 34 7HorizontalScarifierDocument3 pages34 7HorizontalScarifiercamelia_pirjan5776No ratings yet

- 32 10brushcutterDocument3 pages32 10brushcuttercamelia_pirjan5776No ratings yet

- GS-37 LcaDocument22 pagesGS-37 LcaGeny KucherNo ratings yet

- E PM 100Document29 pagesE PM 100masoudNo ratings yet

- Delta Ia-Mds Vfd-Ed Um en 20150910-1Document280 pagesDelta Ia-Mds Vfd-Ed Um en 20150910-1FahadNo ratings yet

- Omax Annual ReprtDocument78 pagesOmax Annual ReprtSalini RajamohanNo ratings yet

- Master Plan 2021Document172 pagesMaster Plan 2021Rajnish MishraNo ratings yet

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- Marine Chock InstallationDocument48 pagesMarine Chock InstallationSumeet SawantNo ratings yet

- Scope of Work Doc-Fire Hydrant SystemDocument2 pagesScope of Work Doc-Fire Hydrant SystemMauliNo ratings yet

- GROUP 1 - PetE 3306 - Final Requirement in Engineering EconomicsDocument12 pagesGROUP 1 - PetE 3306 - Final Requirement in Engineering Economicskevin alidoNo ratings yet

- 320, 320L Medicion de Presiones Bomba Hidraulica PDFDocument181 pages320, 320L Medicion de Presiones Bomba Hidraulica PDFrprim100% (2)

- Chapter 8 ObjectivesDocument3 pagesChapter 8 ObjectivesdaddlescoopNo ratings yet

- More power in less space with SMA SUNNY CENTRAL UPDocument4 pagesMore power in less space with SMA SUNNY CENTRAL UPBrahadeesh Perinkolam MuraliNo ratings yet

- All Terrain Vehicle Wiring PDFDocument3 pagesAll Terrain Vehicle Wiring PDFVINAY KUMARNo ratings yet

- Question Paper Code:: Reg. No.Document2 pagesQuestion Paper Code:: Reg. No.tamilarasi87thulasiNo ratings yet

- Seller'S Disclosure and Condition of Property Addendum (Residential)Document8 pagesSeller'S Disclosure and Condition of Property Addendum (Residential)Barbara BishopNo ratings yet

- SHD30 and SHD30-45 Models: (Standard)Document2 pagesSHD30 and SHD30-45 Models: (Standard)Roger TorrejonNo ratings yet

- Test 48Document9 pagesTest 48Thị VyNo ratings yet

- VS1-2 Manual PDFDocument284 pagesVS1-2 Manual PDFJorge InostrozaNo ratings yet

- India's Former President APJ Abdul Kalam on Leadership, Knowledge and Managing FailureDocument14 pagesIndia's Former President APJ Abdul Kalam on Leadership, Knowledge and Managing FailureHarsh TiwariNo ratings yet

- Dual Nature of Radiation and MatterDocument6 pagesDual Nature of Radiation and Mattersub100% (1)

- EMT2-hw4 - SolDocument6 pagesEMT2-hw4 - SolSuper SpecialNo ratings yet

- Ccu Sem (2010-05-05) PDFDocument181 pagesCcu Sem (2010-05-05) PDFBích Đỗ DanhNo ratings yet

- Ncert Summary Class 12th PhysicsDocument29 pagesNcert Summary Class 12th Physicsmeghraj.socialNo ratings yet

- Genie GTH 4013Document202 pagesGenie GTH 4013Sam Manutenção100% (2)

- Symmetry & Crystal StructuresDocument37 pagesSymmetry & Crystal StructuresNurnajihah Sukimi JiehaNo ratings yet

- KR AGILUS Hygienic Machine Fast Cleaning Food PharmaDocument2 pagesKR AGILUS Hygienic Machine Fast Cleaning Food PharmaValke Athletes HandcareNo ratings yet

- Futuro Continuo Afirmativo y NegativoDocument4 pagesFuturo Continuo Afirmativo y NegativoSkoNo ratings yet

- Deepwater Training Seminar Presented ToDocument36 pagesDeepwater Training Seminar Presented ToSergio Jesus MarquezNo ratings yet

- Krff302ess01 Tech Sheet - w10787422 - Rev CDocument10 pagesKrff302ess01 Tech Sheet - w10787422 - Rev CJesikaGomezSaavedraNo ratings yet

- Understanding ThermodynamicsDocument4 pagesUnderstanding Thermodynamicscory kurdapyaNo ratings yet