Professional Documents

Culture Documents

Project Standards and Specifications Pneumatic Test Specification Rev01

Uploaded by

hiyeonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Standards and Specifications Pneumatic Test Specification Rev01

Uploaded by

hiyeonCopyright:

Available Formats

Page : 1 of 9

KLM Technology Group

Project Engineering Standard

Rev: 01 April 2011

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

SPECIFICATION FOR PNEUMATIC TEST (PROJECT STANDARDS AND SPECIFICATIONS)

TABLE OF CONTENT

SCOPE REFERENCES DEFINITIONS AND TERMINOLOGY UNITS PNEUMATIC TESTING Circuit Monitoring and Checking Exclusions TEST MEDIUM TEST PRESSURE BLINDS FOR PRESSURE TEST TEST PACK PREPARATION General Test Pack Limits Test Pack Format Test Pack Approvals and Distribution Field Revision Request (FRR) TESTING PREPARATIONS PNEUMATIC TEST PROCEDURE REPORTS AND TEST RECORDS SAFETY General

2 2 2 3 3 3 4 4 4 4 5 5 5 5 6 6 6 7 8 8 8

KLM Technology Group

Project Engineering Standard

SPECIFICATION FOR PNEUMATIC TEST (PROJECT STANDARDS AND SPECIFICATIONS)

Page 2 of 9

Rev: 01

April 2011

SCOPE This Project Standard and Specification prescribes minimum requirements on pneumatic test procedure and acceptance criteria of piping works. REFERENCES Throughout this Standard the following dated and undated standards/codes are referred to. These referenced documents shall, to the extent specified herein, form a part of this standard. For dated references, the edition cited applies. The applicability of changes in dated references that occur after the cited date shall be mutually agreed upon by the Company and the Vendor. For undated references, the latest edition of the referenced documents (including any supplements and amendments) applies. 1. ASME B31.3 Process Piping 2. ASME SECTION IX Welding and Brazing Qualifications 3. ASME SECTION XIII Div 2, AT-502 DEFINITIONS AND TERMINOLOGY Category D fluid service (per ASME B31.3) A fluid service in which all the following apply: - The fluid hanged is nonflammable, nontoxic, and not damaging to human tissues. - The design gauge pressure does not exceed 10.35 bar. - The design temperature is between -29C and 186. Category M fluid service (per ASME B31.3) A toxic fluid service in which exposure to very small quantities of the fluid in the environment can produce serious irreversible harm to persons on breathing or bodily contact, even when prompt restorative measures are taken. Damaging to human tissues (per ASME B31.3) A fluid which, under expected operating conditions, can harm skin, eyes, or exposed mucous membranes so that irreversible damage may be done unless prompt restorative measures are taken. Design pressure The pressure of each component in a piping system which is not less than the pressure at the most severe condition of coincident internal or external pressure (minimum or maximum) expected during service.

KLM Technology Group

Project Engineering Standard

SPECIFICATION FOR PNEUMATIC TEST (PROJECT STANDARDS AND SPECIFICATIONS)

Page 3 of 9

Rev: 01

April 2011

Test pressure The pressure does not exceed stress intensity of yield strength of each component in a piping system at test temperature and should not be lower than design pressure. UNITS This Standard is based on International System of Units (SI) except where otherwise specified. However, nominal sizes of piping component shall be in accordance with inch system. PNEUMATIC TESTING Circuit Monitoring and Checking For pneumatic testing of circuits, access to the area of the test shall be limited to only the personnel directly involved in the test or personnel involved in the inspection and monitoring. During the pressure test the total circuit shall be inspected and tested for any leaks. If any leaks are found on flanged, threaded, plugged or welded joints the system pressure shall be totally released prior to any rectification work starting. Disciplinary action shall be taken against any individual and/or supervisor authorizing and/or undertaking work on the pressurized system. For flanged joint testing during pneumatic testing of circuits the flange joints shall be hermetically sealed by means of adhesive paper tape and a pinhole made in the tape to permit easy detection of leaks. The following equipment and components shall not be included in the system, and this equipment shall be isolated from the test section. a. Rotating equipment such as pumps, compressors and turbines. b. Safety valves rupture discs, flame arrestor, and stream traps. c. Pressure vessels with sophisticated internals. d. Equipment and piping lined with refractoriness. e. Storage tanks. f. Filters, if filter element(s) is not dismantled. g. Heat exchangers of which tube sheets and internals have been designed for differential pressure between tube side and shell side. h. Instrument such as control valves, pressure gages, level gages, and flow meter. (Excluding thermocouples)

KLM Technology Group

Project Engineering Standard

SPECIFICATION FOR PNEUMATIC TEST (PROJECT STANDARDS AND SPECIFICATIONS)

Page 4 of 9

Rev: 01

April 2011

Exclusions The followings are excluded from the testing requirements of this specification : a. Any package unit previously tested by the vendor in accordance with the applicable codes. b. Plumbing systems, which are tested in accordance with the applicable plumbing codes. c. Lines and systems which are open to the atmosphere such as drain, vents, open discharge of relief valve, and atmospheric sewers. TEST MEDIUM The gas used as test medium shall use the nonflammable and nontoxic gas such as N2 or inert gas, if not compressed air. TEST PRESSURE The test pressure shall be 110% of design pressure and according to test pressure. Equipment for testing should be have as following: - Air Compressor - Flexible hose - Calibrated Pressure gauge - Oil filter - Temporary piping set - N2 cylinder, if required - Safety valve Note: Safety valve required for pneumatic testing, rapid opening or pop action of over pressure, should be installed and connected with an adequate system of piping not containing valve which can isolate tested system. BLINDS FOR PRESSURE TEST 1. Plain test blanks shall be used with 3mm flat gaskets for blanking flat face, and raised face. Provide full face blanks and gaskets for Class 150 connections. However, where permanent operational blinds are installed, they may be used for pressure testing, provided they are rated the testing pressure. 2. Plate material, extra length bolts and gaskets, which are made at the Job Site could be used the testing.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- D.F.I. Helical Presentation 7Document68 pagesD.F.I. Helical Presentation 7hiyeonNo ratings yet

- Compressors IntroductionDocument12 pagesCompressors Introductionhiyeon100% (1)

- Perko-Helical Piles FlierDocument2 pagesPerko-Helical Piles FlierhiyeonNo ratings yet

- Lateral Capacity of Helix PiersDocument8 pagesLateral Capacity of Helix PiershiyeonNo ratings yet

- Chemical Engineering - Plant Engineering 2 Ideal Gas - RevisionDocument4 pagesChemical Engineering - Plant Engineering 2 Ideal Gas - RevisionhiyeonNo ratings yet

- Storage Tanks and SilosDocument9 pagesStorage Tanks and SiloshiyeonNo ratings yet

- Corrosion of Helix PiersDocument7 pagesCorrosion of Helix PiershiyeonNo ratings yet

- Chemical Engineering - Plant Engineering 2 Power RequirementDocument2 pagesChemical Engineering - Plant Engineering 2 Power RequirementhiyeonNo ratings yet

- The Design of Natural Gas PipelinesDocument7 pagesThe Design of Natural Gas PipelineshiyeonNo ratings yet

- 8042306Document99 pages8042306Darshan KashiNo ratings yet

- IS 4995 (Part 2) 1974Document25 pagesIS 4995 (Part 2) 1974Nagaraju ChintaNo ratings yet

- PT Concrete Storage StructuresDocument51 pagesPT Concrete Storage StructurescavnqnNo ratings yet

- NG. Compressor StationDocument12 pagesNG. Compressor StationBrian MayNo ratings yet

- EC201 (Rev) Tcm92 22934kompressDocument12 pagesEC201 (Rev) Tcm92 22934kompressJoe GoparNo ratings yet

- 11gas LiftDocument18 pages11gas LifthiyeonNo ratings yet

- 10 Transient Two-Phase Flow: Objectives: Quantitative Insights Into Transient Mechanisms and PhenomenaDocument6 pages10 Transient Two-Phase Flow: Objectives: Quantitative Insights Into Transient Mechanisms and PhenomenahiyeonNo ratings yet

- Calculations in Natural Gas CourseDocument6 pagesCalculations in Natural Gas CourseHilmi ScpgzNo ratings yet

- Gas Composition Examples TransportDocument1 pageGas Composition Examples TransporthiyeonNo ratings yet

- Gas Composition ExamplesDocument1 pageGas Composition ExampleshiyeonNo ratings yet

- Cd5796 Emma OlgaDocument26 pagesCd5796 Emma OlgahiyeonNo ratings yet

- Appendix T Route Selection MatrixDocument9 pagesAppendix T Route Selection MatrixhiyeonNo ratings yet

- 9 MultiphaseDocument26 pages9 MultiphaseAshrafNamamuTeratasNo ratings yet

- 8.1 Physical Properties of The Gas: 8.1.1 Pressure and VolumeDocument16 pages8.1 Physical Properties of The Gas: 8.1.1 Pressure and VolumehiyeonNo ratings yet

- Addendum Part 3Document16 pagesAddendum Part 3hiyeonNo ratings yet

- Beregninger Gass Z-FaktorDocument8 pagesBeregninger Gass Z-FaktorhiyeonNo ratings yet

- Vol2 Appendix QDocument314 pagesVol2 Appendix QhiyeonNo ratings yet

- 03 COR 25 1MDR0470 Route Selection C Butler FINALDocument17 pages03 COR 25 1MDR0470 Route Selection C Butler FINALhiyeonNo ratings yet

- Landfall Valve Installation: Sru Wad Dac Onb AyDocument1 pageLandfall Valve Installation: Sru Wad Dac Onb AyhiyeonNo ratings yet

- Conversions UnitsDocument1 pageConversions UnitshiyeonNo ratings yet

- Calculations in Natural Gas CourseDocument6 pagesCalculations in Natural Gas CourseHilmi ScpgzNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Pressure Test of The DBB ValveDocument3 pagesThe Pressure Test of The DBB ValvevaliullahNo ratings yet

- ANNEXURE - III - Typical Data Sheet For Orifice PlatesDocument1 pageANNEXURE - III - Typical Data Sheet For Orifice Platesmanoj262400/2No ratings yet

- Fluid Mechanic.151 200Document50 pagesFluid Mechanic.151 200Shanmuga Ramanan100% (2)

- Bernoulli Equation ExperimentDocument1 pageBernoulli Equation ExperimentMohamed GdNo ratings yet

- Houttuin TT BrochureDocument8 pagesHouttuin TT BrochureAswin Lorenso Gultom NamoralotungNo ratings yet

- 6-44-0007 Steam Tracing PDFDocument18 pages6-44-0007 Steam Tracing PDFdgkmurtiNo ratings yet

- Package Blower 1 July 2019Document32 pagesPackage Blower 1 July 2019Vivek KapadiaNo ratings yet

- Series & Parallel Pump TestDocument22 pagesSeries & Parallel Pump TestIkhwan Z.100% (23)

- Heavy Duty Control ValveDocument7 pagesHeavy Duty Control Valveamer_arauf100% (1)

- Surface Team-Sob CTFDocument25 pagesSurface Team-Sob CTFVikas KumarNo ratings yet

- HEX - 300D - With Tier III Engines - SERV7107 - Sect 3 - TextDocument23 pagesHEX - 300D - With Tier III Engines - SERV7107 - Sect 3 - TextsergeyNo ratings yet

- Gl1.Z Complex - Sonatrach: Process Operating ManualDocument8 pagesGl1.Z Complex - Sonatrach: Process Operating ManualSofiane HalimiNo ratings yet

- Drill+Stem+Testing+Tools+-+DST SLBDocument13 pagesDrill+Stem+Testing+Tools+-+DST SLBMahrouz MadoNo ratings yet

- Classification of Pumps and TurbinesDocument12 pagesClassification of Pumps and TurbinesKarim SayedNo ratings yet

- Mercer Valve 9100 Relief Valve Flanged AEDocument16 pagesMercer Valve 9100 Relief Valve Flanged AEChristopher Kenneth ChoaNo ratings yet

- ﺮﻴﺷ تﻻآ) يروﺎﻤﺳ Plug Valves (: Email: sepehrtech-co@istt.irDocument5 pagesﺮﻴﺷ تﻻآ) يروﺎﻤﺳ Plug Valves (: Email: sepehrtech-co@istt.irMASOUDNo ratings yet

- Herbert Metzendorff & Co. KGDocument3 pagesHerbert Metzendorff & Co. KGbeu catalin0% (2)

- Eska ValveDocument34 pagesEska Valveariel_mira12345No ratings yet

- Zr190kce TFDDocument9 pagesZr190kce TFDnaser712No ratings yet

- Online Piping and Caesar Course SyllabusDocument10 pagesOnline Piping and Caesar Course Syllabusm 418No ratings yet

- Art of The Pid-Aiche-Rbt11-15-19Document94 pagesArt of The Pid-Aiche-Rbt11-15-19Yacine MokhtariNo ratings yet

- Compresso CONTROL - TPG Rev1Document36 pagesCompresso CONTROL - TPG Rev1Karmal Rajan100% (1)

- Tesco HCS 750 Troubleshooting Guide PDFDocument86 pagesTesco HCS 750 Troubleshooting Guide PDFLuther MoletaNo ratings yet

- Hot Water Storage Tank 2500L - HorizontalDocument1 pageHot Water Storage Tank 2500L - HorizontalZal RizalNo ratings yet

- Pressure DropDocument36 pagesPressure DropdesignselvaNo ratings yet

- تقارير العملي 201906672Document30 pagesتقارير العملي 201906672حسن كميت hassankomeit lNo ratings yet

- 502 CAC-Unit IIIDocument22 pages502 CAC-Unit IIIGauri ShindeNo ratings yet

- Jet Pumps and EjectorsDocument7 pagesJet Pumps and EjectorsRajesh NimmakayalaNo ratings yet

- Surge Analysis Program Version 2 - Training Program - January 2005Document4 pagesSurge Analysis Program Version 2 - Training Program - January 2005Suhas NatuNo ratings yet

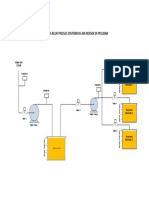

- Gambar Alur Proses Distribusi Air Bersih Di Poliban: Intake Dari PdamDocument1 pageGambar Alur Proses Distribusi Air Bersih Di Poliban: Intake Dari Pdamhendra setiawanNo ratings yet