Professional Documents

Culture Documents

Fasttech / IGNITION TIMING

Uploaded by

Joda_sanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fasttech / IGNITION TIMING

Uploaded by

Joda_sanCopyright:

Available Formats

fasttech / TECH / IGNITION TIMING /

fasttech

MAKING

BEFORE STARTING

The rst rule of working on cars and using tools of any kind is dont ever skimp on decent protection. Goggles, gloves, ear defenders, masks and a set of overalls should be in your garage. Use them. When using power tools, protective gear is essential grinders and welders can make a real mess of your soft skin and bone if you get it wrong. Never work under a car without supporting it using axle stands. A car falling on you is not something youll be laughing about down the pub.

ADVANCES

Think advancing your engines timing is a quick and easy way to go faster? Think again. Heres what you should know before you have a go.

INTAKE

COMPRESSION

IGNITION

EXHAUST

WE at Motorsport

had a car in

Developments recently that was pinking really badly. It transpired that the owner had advanced the timing as far as he could, as his mate told him that would make it as fast as it could be! This got me thinking that maybe an article on spark timing and its purpose would be interesting, and maybe save some of you from destroying your engines. So here we go...

SPARK ADVANCE

Words: Stewart Sanderson

Spark advance (or ignition timing as its more commonly known) is the term used to describe the point in the engine cycle that the spark is generated at the spark plug in the engines cylinder. This point is referenced against the pistons position in the cylinder at the time of ignition. As an example, if we were to re the spark plug at the exact time the piston is at 20 degrees before it reaches the top of the cylinder, we would call this ignition timing 20 degrees before top dead centre (TDC). This spark happens at an almost innitely variable point in the engines cycle depending on many different factors. Understanding some of those factors is the main reason for this

feature, so as always, lets take you back to basics and I will try to explain some of the basic factors affecting the point at which we require the spark to happen. Once you have a basic understanding of this, we can then move on to the more complex variables that affect the timing of the spark. Most petrol engines work on what is known as the four-stroke principle (see diag. above). The four strokes are: induction (the sucking in of the air); compression (the compression of the air); ignition (the ignition of the fuel and the power created); and exhaust (the release of the spent gas into the exhaust system so we can start again and rell it). The stroke we are interested in here is the ignition/power stroke and more specically, what actually happens both before and after we initiate the combustion with a spark from our spark plug. Incidentally, these four strokes are often easy to remember as, suck, squeeze, bang, blow. You can be sure that most of the blokes reading this will

Piston heights are one way of determining compression ratio, which in turn affects compression level (see text)

smile and remember it forever now. I certainly did!

COMPRESSION

So, our inlet valve opens and the piston heads downwards, creating a partial vacuum and drawing in air just like a syringe. The intake valve then closes, sealing the cylinder completely as the piston moves back upwards and compresses the mixture into a space much smaller than it initially lled. This compression level is determined by our compression ratio for example, an 8:1 engine will compress the mixture into a space eight times smaller than it originally lled. And a 500cc cylinder will compress that 500cc of air/fuel mixture into a space around 62cc in size. Once FAST FORD SEPTEMBER 2006

0103

0 1 0 2 SEPTEMBER 2006 FAST FORD

fasttech / TECH / IGNITION TIMING /

INLET VALVE CLOSED EXHAUST VALVE CLOSED PISTON IS FORCED DOWN BY EXPANDING GASES SPARK PLUG

than normal, carrying more latent heat that was unused for power creation on the power stroke. PCP arriving a little too early has the potential to be far more damaging. If the peak pressure wave arrives with the piston still on its way up the bore or slightly past TDC, it will try to force it to go back down, wasting energy trying to compress the piston and con rod and naturally robbing us of important torque. If PCP happens much too early it can be really bad and destroy things. Just imagine this scenario: we have the force of the road wheels, the transmission, the other cylinders power strokes and the crankshaft and ywheel inertia all forcing the con rod and piston up the bore in a particular cylinder, and a huge pressure wave of combusting fuel and oxygen forcing the piston back down! The results, as you can probably imagine can be catastrophic and terminal for the engine. Holed and molten pistons are the normal outcome of this scenario as the massive pressures lead onto articial ignition of the fuel known as detonation or knock; this knock can act as a thermal lance and literally melt the alloy piston away... start the fuel burning earlier than that. So lets take an educated guess and re the spark at around 20 degrees BTDC (before top dead centre). This gives us 35 degrees of crankshaft rotation for our mixture to ignite, start propagating and ultimately reach the point of peak expansion rate while at our desired crankshaft position, which we will take as 15 degrees ATDC. Its worth bearing in mind the kind of speeds we are talking about here: 3000 rpm is 50 full engine rotations per second. And we are dealing here with only 35 degrees of one solitary turn. It is all happening incredibly fast. After initial initiation of the spark, it normally takes between 2 and 15 degrees for our mixture to react with an exothermal process and start to raise the cylinder pressure above the compression line at which it would be with no combustion. This time delay is known as the delay period. From here the ame front propagates rapidly outwards, ultimately reaching the PCP and then ending a few degrees after this. Lets presume that this ignition point was perfect for our particular scenario and we reached PCP at 15 degrees. Why cant we just set the spark timing gure to 20 degrees BTDC and have done with it? Well, thats where it gets complicated and we have to start looking at the variables that affect just how fast the mixture burns, and of course how much time we have to deliver our burning fuel to achieve PCP in the correct place. Lets look at the various factors that inuence our spark timing. 3000, as the piston is travelling at half the speed. We can also assume twice as much at 6000 rpm as the piston is travelling at twice the speed. So we now have 10 degrees at 1500 rpm, 20 degrees at 3000 rpm and 40 degrees at 6000 rpm. If you are following me so far, then congratulations, you are starting to understand and plot your very rst advance curve for a fourstroke petrol engine! set-up and mapped for 98 RON will normally result in molten pistons and open wallet surgery.

fasttech

PETROL\AIR MIXTURE BURNS IN COMBUSTION CHAMBER

CHARGE DENSITY

FUEL MIXTURE

CONNECTING ROD CRANK SHAFT

The ignition/power stroke

compressed to this immense level, our mixture of fuel and air becomes extremely volatile and a single spark from the spark plug will initiate the combustion of it and release the energy from the mixture, forcing our piston smoothly back down the bore and producing our next stroke the power stroke. created when the crankshaft is at an advantageous angle. That angle is normally between 10 and 20 degrees after the piston has reached TDC. This gives the maximum leverage effect possible at the crankshaft and generates the maximum torque. The pressure we are talking about here is known as the peak cylinder pressure (PCP). Getting PCP point wrong will result in one of two things: if we achieve Peak Cylinder Pressure too late then we have missed the point of peak leverage on the crankshaft and lose a little torque as a result. Also, we will transfer less combustion heat into the water jacket around the cylinder head, thus potentially running the engine hotter. Another by-product of late PCP is our exhaust gas is somewhat hotter due to the burn cycle continuing further down the bore

CYLINDER PRESSURE

Simple enough to understand so far, I hope? OK, lets proceed. One of the most common misunderstandings is that the fuel, once ignited, simply explodes and forces the piston down! Nothing could be further from the truth and if that were the case your engine would be destroyed in seconds. To generate maximum pressure on the piston crown, we need to ensure that maximum point of expansion of the hot gases is

TIMINGS RIGHT

The petrol mixture and composition itself will affect the spark timing quite considerably. Petrol will burn quite easily when mixed with air at ratios between 10:1 and 20:1. In most engines we typically use between 11 and 16:1. All these mixtures have a slightly different burn rate and thus a different advance requirement. Most petrols burn fastest in the 12-13:1 range, which is of course the reason why peak power is found at this particular air/fuel ratio. It is also worth noting that the higher octane the fuel, generally speaking the slower it actually burns, so adding that ultra-high octane fuel to your engine that is not setup for it will normally cost you a few horsepower, and in reverse, running 95 RON fuel in your engine thats

This is largely related to the load the engine is under, but basically, the more air we cram into the cylinder, the denser the air/fuel mixture becomes and the less advance it requires due to its increasing burn speed. As a very simple example, the density of the air fuel mixture in the cylinder at idle will be far less than it would be at, say, 25 psi and 4000 rpm. The charge density in the cylinder normally relates very well to the torque graph, with peak torque also being peak air/fuel density ignited in the cylinder, and thus requiring the least spark advance of all due to its immense burn speed.

Colder air/fuel mixture burns faster and requires less advance

DISTRIBUTION

CHARGE TEMP

The temp of the mixture in the cylinder has a dramatic effect on burn speed and spark requirement of that particular combustion event. A cold and dense mixture normally burns at a very different rate to a hotter and potentially less dense one. Sometimes, hotter mixtures can burn even faster than cold, requiring more retard. Its a complex subject that cannot be covered fully here.

It is very important that the engine is designed in such a way as the air fuel molecules in the compressed charge end up in a uniform state. The charge present between the spark plugs electrodes at the time of ignition must be of an easily combustible composition, meaning somewhere between 10 and 20:1. Ideally the charge present throughout the combustion chamber should be a similar composition and evenly distributed, so as to allow smooth propagation

of the ame front at a controlled rate once the burn is initiated. Sudden rich or lean pockets of mixture can have dramatically negative effects on power output and engine health.

CHARGE DILUTION

Any exhaust gasses left over from the last exhaust stroke will dilute the fresh charge and slow down burn rates. The main culprit of this waste gas being left over is the camshaft timing. Excessive overlap can result in large amounts of exhaust gas

Get Peak Cylinder Pressure wrong and you could end up with a holed piston

OK, so we now know that we want to have our PCP between 10-20 degrees after TDC and we know that too early or too late is bad for our engine and/or performance. So all we need to know now, is what affects the burn and how we get it to peak at the required place with our well-timed spark. Before you can understand spark advance requirements, you must understand a little about the fuel mixture and what happens when we initiate combustion of it. The rst point to understand is that our fuel and air mixture will take a particular time to actually ignite and burn after the spark has been initiated (this time is almost innitely variable, but that comes later). The second point to understand is that our engine is also travelling at a certain speed (revolutions per minute) and that this speed must be accounted for when planning our spark. For now, lets imagine our engine is running at 3000 rpm. It should be fairly obvious to the majority of you that to achieve our cylinder pressure peak somewhere between 10 and 20 degrees after the piston hits TDC, we must actually

Skimming the cylinder head raises the compression and makes the mixture burn faster, requiring more retarded ignition

ENGINE SPEED

The rst and indeed main reason we need to adjust our point of spark is the fact our engine doesnt rotate at a set speed. In the example above I have used 3000 rpm and shown that we needed 20 degrees of advance to get the PCP in the correct place. Presuming that our engine speed has doubled to 6000 rpm. What will happen if we initiate the combustion at the same place as we did earlier, 20 degrees BTDC? Yes, thats right, our piston will have gone way past our ideal 15 deg ATDC due to the fact the piston itself is travelling at twice the speed it was earlier but our propagating mixtures ame front is travelling at the same rate as it was at 3000 rpm (this example assumes an identical volumetric efciency at the two engine speeds). Based on this, its reasonable to assume that we need half as much advance at 1500 rpm as we do at FAST FORD SEPTEMBER 2006

0105

0 1 0 4 SEPTEMBER 2006 FAST FORD

fasttech / TECH / IGNITION TIMING /

DETONATION KNOCK

Detonation or knock is dened as a form of combustion which involves an energy release which is far too fast. This release gives rise to massive temperatures and cylinder pressures. Normally detonation is an explosion of a part of the fuel mixture not currently involved in the normal propagation process.

Fitting a larger turbo can affect the spark advance almost everywhere in the load and rev range

FLAME PROPAGATION

Propagation is the correct term for the way your air fuel mixture actually burns. It is far more like a wave than an explosion with the mixture burning smoothly from its point of ignition outwards, rather like the ripple that is produced if you throw a pebble into a nice still pond.

being present when the exhaust valve nally closes. Exhaust back pressure also has a huge effect, the higher the back pressure is, the harder it is to ow the gas out of the cylinder on the exhaust stroke. This is one of the reasons a larger turbocharger increases volumetric efciency so much as explained in the June 2006 issue. So there you have it. Hopefully youll now have some idea of not only what spark advance actually is, but also what sort of things govern the gure required, and why it is almost innitely variable. One last subject worth covering is the common things people do that affect spark advance requirements without them knowing it.

HEAD SKIMMING

The most common thing of all is probably having the head skimmed. Skimming the head, block or both raises the compression and instantly increases the amount that the air/fuel charge is compressed, generally making it burn faster, thus requiring more retard. Go too far and uncontrollable detonation/ knock will be your only reward as the fuel is compressed to the point it auto ignites.

ensure your chip is matched to your new turbo or a meltdown could be imminent!

CAM PROFILES

band around, and thus the spark requirements. Advancing your cam will often require a spark retard at high engine revs, and vice versa.

Advancing cam timing often requires a spark retard at high revs

ADDING A LARGER TURBO

Again, the volumetric efciency of the engine is altered quite dramatically with new cams just like it is with a larger or smaller turbocharger. A camshaft prole that shifts more air and makes more power will have a different spark advance requirement both on and off its power band.

ENGINE CHECKS

NEXT MONTH

CAMSHAFTS: What they do, how to time them and what different timing does.

This has a large effect on the volumetric efciency of the engine, especially if it has a larger turbine housing, and thus can affect the spark advance almost everywhere in the load and rev range. Always

0 1 0 6 SEPTEMBER 2006 FAST FORD

CAM TIMING

Simple cam timing adjustment is not quite as bad as new cam proles but remember that moving the cam timing moves the engines power

The moral of the story is simple; when you have added a new go faster part or made an adjustment to any of the mentioned settings you must always check the engine not only for correct fuelling, but also for any engine damaging detonation/knock. Obviously I would recommend you leave all setting and adjustment work to an experienced professional with the correct equipment to do so. Take care out there.

CONTACT

Motorsport Developments 01253 508400 www.remapping.co.uk

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Micro Armour The Game-WWII 2nd Edition (Full Color)Document0 pagesMicro Armour The Game-WWII 2nd Edition (Full Color)burrob31100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 1 - Vampire - Gehenna - The Final NightDocument374 pages1 - Vampire - Gehenna - The Final NightKevin33% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Pimsleur - German I - BookletDocument30 pagesPimsleur - German I - BookletElena Popesco50% (4)

- Reloading Guide: For Centerfire CartridgesDocument64 pagesReloading Guide: For Centerfire CartridgesDansmc2No ratings yet

- UP04We 03 Water Spray SystemsDocument4 pagesUP04We 03 Water Spray SystemsDucVikingNo ratings yet

- Cause & Effect PDFDocument1 pageCause & Effect PDFDnyaneshwar100% (4)

- Fire Protection For Gas TurbinesDocument48 pagesFire Protection For Gas Turbinesralph1949No ratings yet

- The Building Regulations 2000Document159 pagesThe Building Regulations 2000Rahul SasidharanNo ratings yet

- Guideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire StructDocument92 pagesGuideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire StructLeung LiangNo ratings yet

- Dust ExplosionDocument26 pagesDust ExplosionShambhu Saran SinghNo ratings yet

- Intelligent Transportation SystemsDocument58 pagesIntelligent Transportation SystemsJoda_sanNo ratings yet

- Aircraft Fueling BAA HEATHROW Operational Safety InstructionDocument6 pagesAircraft Fueling BAA HEATHROW Operational Safety Instructionsinglebiker77No ratings yet

- FAF270 TechDocument3 pagesFAF270 TechfrodarturNo ratings yet

- Fasttech / BOOST CONTROLDocument3 pagesFasttech / BOOST CONTROLJoda_sanNo ratings yet

- Off The MapDocument3 pagesOff The Maprgajewski_4No ratings yet

- Fasttech TURBOCHARGERSDocument3 pagesFasttech TURBOCHARGERSJoda_sanNo ratings yet

- TOYOTA's Approaches To ITSDocument12 pagesTOYOTA's Approaches To ITSJoda_sanNo ratings yet

- SMT6 Windows Operations ManualDocument32 pagesSMT6 Windows Operations ManualSyazwan MustafaNo ratings yet

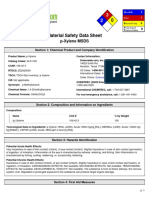

- Msds P XyleneDocument6 pagesMsds P XylenePriska Dewi AnjarsariNo ratings yet

- Frequently Asked Questions For DBA 3Document4 pagesFrequently Asked Questions For DBA 3Alexander VrakatselisNo ratings yet

- 2.3.1 Section H - Ergency Preparedness and Incident Management PlanDocument44 pages2.3.1 Section H - Ergency Preparedness and Incident Management PlanSyed AmjadNo ratings yet

- Erma EMP 35 Submachine Gun (Germany)Document2 pagesErma EMP 35 Submachine Gun (Germany)blowmeasshole191150% (2)

- Flame Sensor: Instruction ManualDocument6 pagesFlame Sensor: Instruction ManualMihai MecaNo ratings yet

- Active Incident Resource Summary: Link LinkDocument9 pagesActive Incident Resource Summary: Link LinkElizabeth Parsons100% (1)

- Naga College Foundation College of Criminal Justice EducationDocument5 pagesNaga College Foundation College of Criminal Justice EducationRalph CelesteNo ratings yet

- Fibaroll As Insulation ProtectionDocument3 pagesFibaroll As Insulation Protection최우혁No ratings yet

- Sop Hazmat Response PlanDocument20 pagesSop Hazmat Response PlanChristian MakandeNo ratings yet

- Chemistry Lab Safety ActivityDocument3 pagesChemistry Lab Safety Activityapi-293292389No ratings yet

- Excavation Emergency Response PlanDocument1 pageExcavation Emergency Response PlanUmesh BaralNo ratings yet

- Graph Theory - Group 9Document12 pagesGraph Theory - Group 9Daniel PielagoNo ratings yet

- 9232471Document96 pages9232471catfishhhNo ratings yet

- 05a Chapter 5Document4 pages05a Chapter 5Gan Chin PhangNo ratings yet

- West Valley FaultDocument13 pagesWest Valley FaultMark John Paul CablingNo ratings yet

- Total Spells For Fate CoreDocument4 pagesTotal Spells For Fate CoreJosh SalyersNo ratings yet

- MSDSDocument15 pagesMSDSMIshra05bholaNo ratings yet

- CH 09Document43 pagesCH 09Maktoum AlkaabiNo ratings yet

- Larry Niven - A Relic of The EmpireDocument13 pagesLarry Niven - A Relic of The EmpirelordporticoNo ratings yet

- Explosibility TestingDocument3 pagesExplosibility Testingfawmer61No ratings yet