Professional Documents

Culture Documents

38 Design of Flat Belt Drives

Uploaded by

PRASAD326Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

38 Design of Flat Belt Drives

Uploaded by

PRASAD326Copyright:

Available Formats

Module

13

Belt drives

Version 2 ME , IIT Kharagpur

Lesson

2

Design of Flat Belt

drives

Version 2 ME , IIT Kharagpur

Instructional Objectives:

At the end of this lesson, the students should be able to understand:

• Features of flat belt drives

• Flat belt materials

• Flat belt stresses and its specifications

• Types of design factors

• A sample design procedure.

13.2.1 Flat belt drives

Flat belts drives can be used for large amount of power transmission and there is

no upper limit of distance between the two pulleys. Belt conveyer system is one

such example. These drives are efficient at high speeds and they offer quite

running. A typical flat belt drive with idler pulley is shown in Fig. 13.2.1. Idler

pulleys are used to guide a flat belt in various manners, but do not contribute to

power transmission. A view of the flat belt cross section is also shown in the

figure.

Idler pulley

b

t

Flat belt cross-section

Fig.13.2.1 Belt drive with idler

The flat belts are marketed in the form of coils. Flat belts are available for a wide

range of width, thickness, weight and material. Depending upon the requirement

one has to cut the required belt length from the coil and join the ends together.

The fixing of the joint must be done properly because the belt normally gets

snapped from the improper joints. The best way is to use a cemented belt from

the factory itself or with care one can join these belts with various types of clips

that are available in the market.

Version 2 ME , IIT Kharagpur

13.2.2 Belt Material

Leather

Oak tanned or chrome tanned.

Rubber

Canvas or cotton duck impregnated with rubber. For greater tensile strength, the

rubber belts are reinforced with steel cords or nylon cords.

Plastics

Thin plastic sheets with rubber layers

Fabric

Canvas or woven cotton ducks

The belt thickness can be built up with a number of layers. The number of layers

is known as ply.

The belt material is chosen depending on the use and application. Leather oak

tanned belts and rubber belts are the most commonly used but the plastic belts

have a very good strength almost twice the strength of leather belt. Fabric belts

are used for temporary or short period operations.

13.2.3 Typical Belt drive specifications

Belts are specified on the following parameters

Material

The decision of the material to be used depends on the type of service.

No. of ply and Thickness

Ply is the number of layers as indicated earlier. Therefore, the number of ply is

decided depending upon the belt tensile strength required for a given power

transmission.

Maximum belt stress per unit width

The belts are subjected to tensile load only. Therefore, the allowable tensile load

depends on the allowable stress on the belt and its cross sectional area. It is

customary to provide the belt stress value for a given belt thickness and per unit

belt width. Hence, a designer has to select a belt thickness and then calculate

the required belt width. Otherwise, one can calculate the belt cross sectional area

and then adjust the belt thickness and the width from the standards.

Version 2 ME , IIT Kharagpur

The maximum belt stress is also dependent on the belt speed. Hence, the

maximum belt stress (for a given belt thickness and per unit belt width) is

provided either for different belt speeds or for a specified speed.

Density of Belt material

Density of Belt material is provided as, per unit length per unit cross section.

Density of Belt material is required to calculate the centrifugal force on the belt.

Coefficient of friction of the belt material

Coefficient of friction for a pair of belt material and pulley material is provided in

design data book.

13.2.4 Modification of Belt stress

When Maximum belt stress/ unit width is given for a specified speed, a speed

correction factor ( CSPD ) is required to modify the belt stress when the drive is

operating at a speed other than the specified one.

When angle of wrap is less than 1800 :

The maximum stress values are given for an angle of wrap is 180ο for both the

pulleys, ie, pulleys are of same diameter. Reduction of belt stress is to be

considered for angle of wrap less than 180ο. . The belt stress is to be reduced by

3% for each ten degree lesser angle of wrap or as specified in a handbook. For

e.g., if the angle of wrap is 160ο , then the belt stress is to be reduced by 6%.

This factor is given as CW.

13.2.5 Design considerations for flat belt drives

Transmission ratio of flat belt drives is normally limited to 1:5

Centre distance is dependent on the available space. In the case of flat belt

drives there is not much limitation of centre distance. Generally the centre

distance is taken as more than twice the sum of the pulley diameters. If the

centre distance is too small then rapid flexing of the belt takes place and some

amount of belt life will be lost.

Depending on the driving and driven shaft speeds, pulley diameters are to be

calculated and selected from available standard sizes.

Belt speed is recommended to be within 15-25 m/s.

A belt drive is designed based on the design power, which is the modified

required power. The modification factor is called the service factor. The service

Version 2 ME , IIT Kharagpur

factor depends on hours of running, type of shock load expected and nature of

duty.

Hence,

Design Power (P dcs) = service factor (C sev )* Required Power (P)

(13.2.1)

Csev = 1.1 to 1.8 for light to heavy shock.

From the basic equations for belt drive, it can be shown that,

⎛ ⎞

( ) ⎝ e

1

Pdes = bt σ '− ρv 2 ⎜ 1 − μα ⎟v

⎠

(13.2.2)

where, σ′ = σ max × CSPD × CW

Finally, the calculated belt length is normally kept 1% short to account for correct

initial tension.

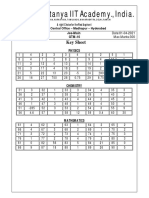

Sample Problem

Design a flat belt drive for the following data:

Drive: AC motor, operating speed is 1440 rpm and operates for over 10 hours. The

equipment driven is a compressor, which runs at 900 rpm and the required power

transmission is 20 kW.

Solution

Let us consider the belt speed to be 20 m/s, which is within the recommended range.

The given speed ratio = 1440/900 =1.6

Let the belt material be leather, which is quite common.

Now,

Version 2 ME , IIT Kharagpur

π× d s × 1440

20 =

60 × 1000

∴ dS = 265.3 mm

∴ d L = 1.6 × 265.3 = 424.5mm

From the standard sizes available, dS=280 mm and dL= 450 mm.

Recalculated speed ratio.

d L 450

= = 1.607 ≈ 1.61

dS 280

Therefore, the choice of both the pulley diameters is acceptable.

Center dis tan ce, C > 2(d L + d L )

∴ C > 1460mm

Hence, let C ≈ 1500 mm ( it is assumed that space is available )

Considering an open belt drive, the belt length,

π 1

= (d L + dS )+ 2C + (d L − dS )

2

L o

2 4C

π 1

(4 5 0 )+ (4 5 0 )

2

= + 280 3000 + − 280 ≈ 4151m m

2 6000

As a guideline, to take into consideration the initial tension, the belt length is

shortened by 1%. Hence, the required belt length,

LO = 4110 mm.

D e te r m in a tio n o f a n g le o f w ra p

d − ds

β = s in −1 ( L ) = 3 .2 5 0

2C

α L = 1 8 0 + 2 β = 1 8 6 .5 0 = 3 .2 6 ra d

α S = 1 8 0 − 2 β = 1 7 3 .5 0 = 3 .0 3 r a d

For the leather belt, the co-efficient of friction, μ may be taken as 0.4.

In this design, both the pulley materials are assumed to be the same, hence,

angle of wrap for the smaller pulley being lower, smaller pulley governs the

design and the angle of wrap is 3.03 radian.

Version 2 ME , IIT Kharagpur

Design power, Pdes = service factor (Csev ) × required power (P)

= 1.3 × 20 kW = 26 kW

The value 1.3 is selected from design data book for the given service condition.

For the design stress in the belt, σ′ = σ max × CSPD × CW

However, design stress, σ′ , for leather belt may be considered as 2 MPa.

Similarly, density of leather belt is 1000 kg/m3.

⎛ 1 ⎞

( )

Pdes = bt σ '− ρv 2 ⎜1 − μα ⎟ v

⎝ e ⎠

103 × 202 1

26×103 = bt(2 − 6

)(1 − ) × 20

10 3.36

bt = 1156.78 mm 2

Let us choose standard belt thickness, t =6.5 mm

Therefore standard belt width, b = 180mm

A leather belt of 6.5 mm thickness, 180 mm width and 4110 mm length will

satisfy the design conditions.

Questions and answers

Q1. Name some of the common flat belt materials.

A1. Leather, rubber, plastics and fabrics are some of the common flat belt

materials.

Q2. What is the correction factors used to modify belt maximum stress?

A2. Correction factor for speed and angle of wrap are used to modify the belt

maximum stress. This correction is required because stress value is given

for a specified drive speed and angle of wrap of 1800. Therefore, when a

drive has different speed than the specified and angle of wrap is also

different from 1800 , then above mentioned corrections are required.

Version 2 ME , IIT Kharagpur

Q3. What is the recommended center distance and belt speed for a flat belt

drive?

A3. The recommendations are; the center distance should be greater than twice

the sum of pulley diameters and the belt speed range should be within 15-

25 m/s.

References

1. V.Maleev and James B. Hartman , Machine Design, CBS Publishers And

Distributors.3rd Edition. 1983.

2. J.E Shigley and C.R Mischke , Mechanical Engineering Design , McGraw

Hill Publication, 5th Edition. 1989.

3. M.F Spotts, Design of Machine Elements, Prentice Hall India Pvt. Limited,

6th Edition, 1991.

4. Khurmi, R.S. and Gupta J.K., Text book on Machine Design, Eurasia

Publishing House, New Delhi.

5. Sharma, C.S. and Purohit Kamalesh, Design of Machine Elements,

Prentice Hall of India, New Delhi, 2003.

Version 2 ME , IIT Kharagpur

You might also like

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Materials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985From EverandMaterials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985J. V. BeeNo ratings yet

- Key(s) For Shaft-Hub ConnectionDocument6 pagesKey(s) For Shaft-Hub Connectionmet-calcNo ratings yet

- Plain Bearings Made From Engineering PlasticsDocument44 pagesPlain Bearings Made From Engineering PlasticsJani LahdelmaNo ratings yet

- 15 572 H - 653cvccDocument54 pages15 572 H - 653cvccJaime ArreolaNo ratings yet

- The Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaFrom EverandThe Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaD M R TaplinNo ratings yet

- Chapter4analysis of Clamping ForceDocument10 pagesChapter4analysis of Clamping ForceMohammad umarNo ratings yet

- Shaft Clamp ElsDocument20 pagesShaft Clamp ElsAlejandro Fabián MoreyraNo ratings yet

- Govt Tool Room Training Centre Bangalore Diploma SyllabusDocument14 pagesGovt Tool Room Training Centre Bangalore Diploma SyllabusAryanNo ratings yet

- Getting Start SolidPlant 2012Document27 pagesGetting Start SolidPlant 2012dmartinctNo ratings yet

- Revised Curriculum for Diploma of Associate Engineer in Mechanical TechnologyDocument116 pagesRevised Curriculum for Diploma of Associate Engineer in Mechanical TechnologyFaiz Ur RehmanNo ratings yet

- Solving Engineering Problems with SolidWorks Flow Simulation 2009Document80 pagesSolving Engineering Problems with SolidWorks Flow Simulation 2009Olafl0No ratings yet

- Modelling FRP and Plastic Piping in AutopipeDocument1 pageModelling FRP and Plastic Piping in AutopipehgscanavinoNo ratings yet

- PIPES AND FITTINGS CATALOGUEDocument44 pagesPIPES AND FITTINGS CATALOGUEANV100% (1)

- MechanicsMaterials2MadhukarVable PDFDocument595 pagesMechanicsMaterials2MadhukarVable PDFkabbirhossainNo ratings yet

- Gear and Gear TrainDocument21 pagesGear and Gear Trainm_er100No ratings yet

- TDS - M SeriesDocument8 pagesTDS - M SeriesDevang A Panchal100% (1)

- SKF Linear BushDocument60 pagesSKF Linear BushAwdhesh Singh Bhadoriya100% (1)

- Caepipe: Tutorial For Modeling and Results Review Problem 2Document93 pagesCaepipe: Tutorial For Modeling and Results Review Problem 2FRANCISCONo ratings yet

- Mitsu 14 TECHNICAL DATA PDFDocument52 pagesMitsu 14 TECHNICAL DATA PDFMohan PreethNo ratings yet

- Manual Solve ElecDocument28 pagesManual Solve ElecHenry HcNo ratings yet

- Innovative Vibration Learning System PDFDocument16 pagesInnovative Vibration Learning System PDFCristian Alfonso Tibabisco JamaicaNo ratings yet

- Dimensioning and TolerancingDocument22 pagesDimensioning and TolerancingArnobNo ratings yet

- Drawing ParametersDocument9 pagesDrawing ParametersGraham MooreNo ratings yet

- Combined Operations: Fundamentals of Tool Design, Sixth Edition Chapter 1: General Tool DesignDocument1 pageCombined Operations: Fundamentals of Tool Design, Sixth Edition Chapter 1: General Tool DesignKusaal KusasiNo ratings yet

- Polybel 2 MufDocument25 pagesPolybel 2 MufSanel TucakovicNo ratings yet

- Technical Drawing With Engineering Graphics - (732-735)Document4 pagesTechnical Drawing With Engineering Graphics - (732-735)mont21No ratings yet

- Valves 2Document105 pagesValves 2sierthinNo ratings yet

- Solid Element Formulation OverviewDocument36 pagesSolid Element Formulation OverviewasdqwexNo ratings yet

- Riveted and Welded Joint DesignDocument28 pagesRiveted and Welded Joint DesignChandan Singh100% (1)

- Astm A227Document5 pagesAstm A227Diganta KonerNo ratings yet

- Longitudinal Pin For Shaft-Hub ConnectionDocument6 pagesLongitudinal Pin For Shaft-Hub Connectionmet-calcNo ratings yet

- Knuckle Joints DesignDocument10 pagesKnuckle Joints DesignKvrd Prasad100% (1)

- AMO Absolute Encoder CatalogDocument36 pagesAMO Absolute Encoder CatalogElectromateNo ratings yet

- Autodesk Inventor 2010Document798 pagesAutodesk Inventor 2010koriom@live.com.au100% (1)

- By ASCENT For Review Only and Reuse Strictly Forbidden.: Autodesk Inventor 2016 For Experienced 3D CAD UsersDocument76 pagesBy ASCENT For Review Only and Reuse Strictly Forbidden.: Autodesk Inventor 2016 For Experienced 3D CAD UsersOmar VelandiaNo ratings yet

- 353 35435 ME357 2011 4 2 1 Sheet MD2Document10 pages353 35435 ME357 2011 4 2 1 Sheet MD2adel nabhanNo ratings yet

- Part Design PDFDocument244 pagesPart Design PDFOstromafNo ratings yet

- ME-311 Machine Design - Lecture 3Document27 pagesME-311 Machine Design - Lecture 3Muhammad Zun Nooren BangashNo ratings yet

- Development of Design Charts For Bolts Preloaded Up To The Plastic RangeDocument3 pagesDevelopment of Design Charts For Bolts Preloaded Up To The Plastic RangeGüneş DilberNo ratings yet

- A583 - Stainless Steel - Grade 416 (UNS S41600)Document4 pagesA583 - Stainless Steel - Grade 416 (UNS S41600)Dv Maria PradhikaNo ratings yet

- Research Paper Optimization of Shaft Design Under Fatigue Loading Using Goodman MethodDocument5 pagesResearch Paper Optimization of Shaft Design Under Fatigue Loading Using Goodman MethodIshwar PatilNo ratings yet

- DIN 17022-5 - Heat Treating of Ferrous Materials PDFDocument13 pagesDIN 17022-5 - Heat Treating of Ferrous Materials PDFFelipe FernandesNo ratings yet

- Work Bench VerificationDocument220 pagesWork Bench Verificationchkarthiksai0% (1)

- 002-Introduction To Continuum Mechanics-Vector and Tensor Calculus F. Barthold J. Stieghan p278Document146 pages002-Introduction To Continuum Mechanics-Vector and Tensor Calculus F. Barthold J. Stieghan p278Ariff ThayoobNo ratings yet

- Claw Pole Forging ProcessDocument8 pagesClaw Pole Forging ProcessBhagat SinghNo ratings yet

- NAAMS Locating PinsDocument64 pagesNAAMS Locating PinsAlex RGNo ratings yet

- COSMOS FloWorks (Introducing) PDFDocument292 pagesCOSMOS FloWorks (Introducing) PDFIngelit SacNo ratings yet

- Part and Assembly Modeling: With Solidworks 2014Document123 pagesPart and Assembly Modeling: With Solidworks 2014Tâm NguyễnNo ratings yet

- Chapter 9 Geometric Dimensioning & Tolerancing (GD&T) : FPOLR-52332Document12 pagesChapter 9 Geometric Dimensioning & Tolerancing (GD&T) : FPOLR-52332Jackie HwangNo ratings yet

- Water Hammer Production and Design Measures in Piping SystemsDocument16 pagesWater Hammer Production and Design Measures in Piping SystemsSivashankar DhanarajNo ratings yet

- Size MI N (In) Size MA X (In) Abrev Short Word Details Component SDocument16 pagesSize MI N (In) Size MA X (In) Abrev Short Word Details Component SAnthony InostrozaNo ratings yet

- Inventor spline data calculation under 40 charsDocument3 pagesInventor spline data calculation under 40 charsUfuk KılıçNo ratings yet

- 41 Rolling Contact BearingsDocument11 pages41 Rolling Contact BearingsPRASAD326100% (3)

- 29 Welded Joints Types and UsesDocument10 pages29 Welded Joints Types and UsesPRASAD326100% (1)

- Block Diagram of Intel 8086Document5 pagesBlock Diagram of Intel 8086Ritesh SinghNo ratings yet

- 17 Power Screw Drives and Their EfficiencyDocument15 pages17 Power Screw Drives and Their EfficiencyPRASAD326100% (2)

- 27 Riveted Joints Types and UsesDocument11 pages27 Riveted Joints Types and UsesPRASAD326100% (1)

- 33 Design of Eccentrically Loaded Welded JointsDocument10 pages33 Design of Eccentrically Loaded Welded JointsPRASAD326No ratings yet

- 37 Introduction To Belt DrivesDocument12 pages37 Introduction To Belt DrivesPRASAD326100% (11)

- Bearing-Study Material Mechanical Engg-1Document14 pagesBearing-Study Material Mechanical Engg-1anishiitdNo ratings yet

- 39 Design of V - Belt DrivesDocument10 pages39 Design of V - Belt DrivesPRASAD326100% (6)

- 32 Design of Eccentrically Loaded Bolted or Riveted JointsDocument10 pages32 Design of Eccentrically Loaded Bolted or Riveted JointsPRASAD326100% (3)

- 35 Design of Shoe BrakesDocument10 pages35 Design of Shoe BrakesPRASAD326100% (1)

- 26 Design Principles For Thick CylindersDocument20 pages26 Design Principles For Thick CylindersPRASAD326No ratings yet

- 36 Design of Band and Disc BrakesDocument10 pages36 Design of Band and Disc BrakesPRASAD326100% (2)

- 34 Design of Joints With Variable LoadingDocument8 pages34 Design of Joints With Variable LoadingPRASAD326100% (1)

- 31 Design of Adhesive JointsDocument8 pages31 Design of Adhesive JointsPRASAD326100% (1)

- 30 Design of Welded JointsDocument8 pages30 Design of Welded JointsPRASAD326No ratings yet

- 22 Shaft and Its Design Based On StrengthDocument11 pages22 Shaft and Its Design Based On StrengthPRASAD326100% (4)

- 25 Thick Cylinders Stresses Due To Internal and External PressuresDocument14 pages25 Thick Cylinders Stresses Due To Internal and External PressuresPRASAD326100% (4)

- 23 Shaft and Its Design Based On StrengthDocument9 pages23 Shaft and Its Design Based On StrengthPRASAD326No ratings yet

- 21 Design of Leaf SpringsDocument10 pages21 Design of Leaf SpringsPRASAD326100% (1)

- 28 Design of Riveted JointsDocument9 pages28 Design of Riveted JointsPRASAD326100% (1)

- Thin CylinderDocument10 pagesThin Cylinderarunnical100% (3)

- 20 Design of Helical Springs For Variable LoadDocument16 pages20 Design of Helical Springs For Variable LoadPRASAD326No ratings yet

- 19 Introduction To Design of Helical SpringsDocument12 pages19 Introduction To Design of Helical SpringsPRASAD326100% (3)

- 18 Design of Power ScrewsDocument14 pages18 Design of Power ScrewsPRASAD326100% (2)

- Pin Bush Coupling DesignDocument15 pagesPin Bush Coupling Designyogwani79No ratings yet

- 15 Introduction, Types and UsesDocument12 pages15 Introduction, Types and UsesPRASAD326100% (1)

- 13 Threaded FastenersDocument7 pages13 Threaded FastenersPRASAD326No ratings yet

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- National University of Engineering Statistics Qualified PracticeDocument6 pagesNational University of Engineering Statistics Qualified PracticeAlvaro Gabriel Culqui MontoyaNo ratings yet

- Automata and Quantum ComputingDocument34 pagesAutomata and Quantum ComputingJorge LeandroNo ratings yet

- Stability Analysis-Control SystemDocument29 pagesStability Analysis-Control SystemNanmaran RajendiranNo ratings yet

- 2 Cutsets Cut Vertices and The Line GraphsDocument78 pages2 Cutsets Cut Vertices and The Line GraphsVishnu Vardhan0% (1)

- Assessment in Learning 1 LoriMarDocument45 pagesAssessment in Learning 1 LoriMarSalonga Christalyn Mae F.100% (1)

- 1e1: Engineering Mathematics I (5 Credits) LecturerDocument2 pages1e1: Engineering Mathematics I (5 Credits) LecturerlyonsvNo ratings yet

- Aircraft Radio SystemsDocument259 pagesAircraft Radio SystemsEdward Muriithi100% (2)

- PHAR 7633 Chapter 19 Multi-Compartment Pharmacokinetic ModelsDocument23 pagesPHAR 7633 Chapter 19 Multi-Compartment Pharmacokinetic ModelsBandameedi RamuNo ratings yet

- Mangaldan Distric Ii Pogo-Palua Elementary School: ND RDDocument3 pagesMangaldan Distric Ii Pogo-Palua Elementary School: ND RDFlordeliza Manaois RamosNo ratings yet

- Javascript - Domain Fundamentals AssignmentsDocument43 pagesJavascript - Domain Fundamentals AssignmentsSana Fathima SanaNo ratings yet

- Phy1 11 - 12 Q1 0603 PF FDDocument68 pagesPhy1 11 - 12 Q1 0603 PF FDhiroNo ratings yet

- Rr210501 Discrete Structures and Graph TheoryDocument6 pagesRr210501 Discrete Structures and Graph TheorySrinivasa Rao GNo ratings yet

- Chapter 3. Drag Force and Its CoefficientDocument47 pagesChapter 3. Drag Force and Its Coefficientsmyeganeh100% (1)

- Y V - J MVJ B - J ° - ) : 4.2. The Huron-Vidal (Hvo) ModelDocument8 pagesY V - J MVJ B - J ° - ) : 4.2. The Huron-Vidal (Hvo) ModelBruno Luiz Leite MartinsNo ratings yet

- Solving Problems by Searching: Artificial IntelligenceDocument43 pagesSolving Problems by Searching: Artificial IntelligenceDai TrongNo ratings yet

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument40 pagesDesign and Drawing of RC Structures: Dr. G.S.SureshvipinNo ratings yet

- Calculate area under curveDocument6 pagesCalculate area under curvePunit Singh SahniNo ratings yet

- Linear Slot Diffusers 1Document13 pagesLinear Slot Diffusers 1AlihassanNo ratings yet

- Predicting Gas Well Performance Including Non-Darcy Flow EffectsDocument8 pagesPredicting Gas Well Performance Including Non-Darcy Flow EffectsAndreco 210198No ratings yet

- MSC Mathematics 2014Document21 pagesMSC Mathematics 2014Muralikrishna SingamaneniNo ratings yet

- For Every Linear Programming Problem Whether Maximization or Minimization Has Associated With It Another Mirror Image Problem Based On Same DataDocument21 pagesFor Every Linear Programming Problem Whether Maximization or Minimization Has Associated With It Another Mirror Image Problem Based On Same DataAffu ShaikNo ratings yet

- Decimal Differentiation by Monica LenewayDocument6 pagesDecimal Differentiation by Monica Lenewaygoldenoj100% (4)

- Sajc 2010 Prelim Math p2Document6 pagesSajc 2010 Prelim Math p2lauyongyiNo ratings yet

- Wind Load On StructuesDocument14 pagesWind Load On StructuesNasri Ahmed mohammedNo ratings yet

- Mark Scheme (Results) January 2007: GCE Mathematics Statistics (6683)Document8 pagesMark Scheme (Results) January 2007: GCE Mathematics Statistics (6683)ashiqueNo ratings yet

- Structure Chap-7 Review ExDocument7 pagesStructure Chap-7 Review Exabenezer g/kirstosNo ratings yet

- 01-04-2021 SR - Super60 & All Jee-Main GTM-16 Key & Sol'sDocument12 pages01-04-2021 SR - Super60 & All Jee-Main GTM-16 Key & Sol'sGowri ShankarNo ratings yet

- Selection, Bubble, Insertion Sorts & Linear Binary Search ExplainedDocument5 pagesSelection, Bubble, Insertion Sorts & Linear Binary Search ExplainedAndrew MagdyNo ratings yet

- Patch Antenna Design Tutorial With CST Microwave - Electronics Engineering TutorialsDocument13 pagesPatch Antenna Design Tutorial With CST Microwave - Electronics Engineering TutorialsMuthuKumaranNo ratings yet

- Reconfigurable Computing (EN2911X, Fall07) : Lab 2 PresentationsDocument28 pagesReconfigurable Computing (EN2911X, Fall07) : Lab 2 PresentationsTom PerrinNo ratings yet