Professional Documents

Culture Documents

Generic Risk Assessment

Uploaded by

morgojoyoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Generic Risk Assessment

Uploaded by

morgojoyoCopyright:

Available Formats

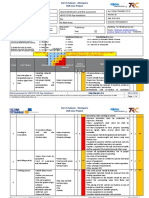

GENERIC RISK ASSESSMENT

Risk to Person Prior to Control Measure (High/ Medium/ Low) Overall Level of Residual Risk After Implementation of Control Measures (High/ Medium/ Low) LOW

Identification of Significant Hazards

Person at Risk

Control Measures

Use of Scaffold 1. Fall from platform. 2. Falls of material from platforms. 3. Collapse of scaffold. 4. Overloading.

Personel injuries (Worker/personels who work on the platform & at the ground)

HIGH

1. Guard rails and toe boards must be fiited where persons can fall more than 2m. 2. Tower scaffold will be erected, altered or dismalted by trained operatives in accordance with manufactures's specification. 3. The safe working load will be displayed on the structure which will not be exceeded.

Excavations 5. Collaps of unsupported excavations. 6. Falling into unfenced excavations. 7. Materials or equipment/ plant falling into excavations. 8. Struck by excavator. 9. Cutting into underground electricity cables.

Personel injuries, personesl who have activity in/around excavation area.

HIGH

1. Identified location of underground services & fencing of overhead power lines. 2. Planned provision and use of trench support equipment. 3. Adequate fencing or covering for excavations and excavations back filled as soon as practicable. 4. Materials to be stock piled clear of the excavation 1.5m from the edge of the excavation. 5. Safety helmets to be worn by all operatives working in the excavation or close to excavations. 6. Only correct and tested lifting equipment to be used. 7. Excavators and other plant to be operated by trained, certified and authorized operators.

LOW

Identification of Significant Hazards

Person at Risk

Risk to Person Prior to Control Measure (High/ Medium/ Low)

Control Measures

Overall Level of Residual Risk After Implementation of Control Measures (High/ Medium/ Low) MEDIUM

Working in Confined Spaces 10. Working atmosphere toxic, Personel who work at explosive or deficient in confine space area. Oxygen. 11. In rush of liquid gasses or solids. 12. Exposure to disease bearing organisms. 13. Evacuation of sick or injured person.

HIGH

1. Atmosphere to be tested before entry. 2. Atmosphere to be constantly monitored during work. 3. Work Permit System applied. 4. All access points for effluent or process materials to be locked off or sealed. 5. Rescue equipment to be provided and all workers to wear safety harness, helmets and protective clothing. 6. Workers to be warned of health risk specific to mtheir task and be provide with written information on these risks, to present to their Doctor in the event of illness.

Working Near Buried Services 14. Contact with underground Electric shock - to power cables causing danger personel to persons. Rupturing of gas pipes 15. leading to leaks, fire or explosion. Rupturing of water pipes 16. causing flooding and damage. Cutting of underground 17. telecomunications and interrupting services. Rupturing of drains, sewers, 18. culverts etc., causing health hazards.

HIGH

1. Prior to commencement of excavations all public and local untilities will be requested to provide information of services in the ground in proposed work area. 2. Where services are believed to be present, steps will be taken to establish exact position and routes which will b eidentified and marked. 3. Any damage to burried services must be reported to the appropriate utility immidiately. 4. If an electricity cable is struck, everyone should b ekept clear of the area until made safe. 5. If a gas pipe is ruptured, persons in the area should be excavated and steps taken to prevent ignition of gas.

LOW

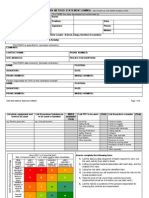

Identification of Significant Hazards

Person at Risk

Risk to Person Prior to Control Measure (High/ Medium/ Low)

Control Measures

Overall Level of Residual Risk After Implementation of Control Measures (High/ Medium/ Low) LOW

Crane Operations 19. Crane overturning - ground unsuitable, overloading, etc. Arcing or contact with 20. overhead cables or other obstructions. Materials falling during 21. lifting operations. Failure of lifting gear or 22. equipment.

- Crane operator - Rigger - Signal Man - Helper - Supervisor

HIGH

1. Craning operations will be supervised by a competent person other than crane driver. 2. Appropriate test certificates in respect of appliance and lifting gear will be examined and copies retained on site. 3. Driver of crane will hold a certificate of competence to drive (copy to be on site) and responsible for daily maintenance and completion of records. 4. Surface from which mobile crane is to operate will be prepared and checked to ensure stability. 5. Under no circumstances will appliance safe working load be exceeded. 6. All overhead electric cables will be identified. 7. Site Management is responsible for the safe operation of cranes NOT the crane driver. 1. Excavator will only be driven by trained competent operatives over the age 18 years, who are horlders of certificate of competence, copy of which will be retained with site records. 2. An excavator driver will be responsible for ensuring machine is not misused, is property maintained in accordance with manufacture's instructions and reporting of defects. 3. Excavators must not operate within 6m of overhead power cables when boom is fully extended. 4. Before excavation ground survey will be made to locate any underground services and prevent damage or injury.

Use of Excavators 23. Machine overturning. - Operator 24. Materials or equipment - Member of public & falling from machine. workmen 25. Members of public or workmen being endangered by machine operation. Machine arching with or 26. coming into contact with overhead cables or underground services.

HIGH

LOW

Identification of Significant Hazards

Person at Risk

Risk to Person Prior to Control Measure (High/ Medium/ Low)

Control Measures

Overall Level of Residual Risk After Implementation of Control Measures (High/ Medium/ Low) LOW

Pilling Operations 27. Contact with underground services. 28. Arcing or contact with overhead cables. 29. Overturning of pilling rig. 30. Materials or equipment falling from pilling rig. 31. Falls from pilling rig. 32. Overturning of plant associated with pilling.

- Operator - Workmen

HIGH

1. Survey will be conducted of area to be pilled to locate underground services, location of which will be marked, warning notices posted and necessary barries erected. 2. All hazards, which could affect stability of pilling rig, will be identified, e.g. ground conditions, cellars etc. and necessary precautions taken. 3. Method Statement will be prepared in writing and made available. 4. All lifting appliances and gear must have appropriate certificates of test, copies of which will be retained at side level. 5. All operatives will wear safety helmets and use safety harness if necessary.

Welding 33. Fire and explosives. 34. Burns. 35. Eye Injuries and Arc Eye . 36. Electric Shock. 37. Exposure to Fumes and Gases. 38. Exposure to heat. 39. Respiratory disease.

- Welder - Personel who work around wleding area

HIGH

1. Welding will only be carried out by trained operatives. 2. All cylinders used in welding should be kept and moved in trolleys or securely fastened in vertical position. 3. All equipment will b eused in accordance with manufacture's instructions and must be inspected before use to ensure it is safe. 4. Operatives will wear protective clothing and necessary eye, hearing and respiratory protection. 5. Area of work will be screened as necessary to protect others from welding hazards. 6. Fire Extinguisher will always be situated near work area.

LOW

Identification of Significant Hazards

Person at Risk

Risk to Person Prior to Control Measure (High/ Medium/ Low)

Control Measures

Overall Level of Residual Risk After Implementation of Control Measures (High/ Medium/ Low)

Demolition 40. Premature collapse of - Personel who work building or part of building. around demolition Damage to property area. 41. adjacent to site of demolition. Falls from the working place 42. or acces. Falls of materials. 43. Explosion, fire or 44. electrocution. Health hazards to operatives 45. and others e.g. Contaminants, asbestos, lead, dust etc.

HIGH

1. Adjacent property, building or part of building to be demolished will be surveyed and a report, in writing, prepared as to findings. 2. A detailed Method Statement will be prepared and submitted for approval of management before work commences to cover mathod of demolition, access, protection of workforce and members of public, arrangements for making safe gas, electric supplies, methods for dealing with flammable or other hazardous materials, dist suppression, transport and disposal of waste, and Health & Welfare arrangements. 3. A competent person will be appointed to supervise work.

LOW

Work Creating Excessive Noise 46. Damage to hearing. Person who work near 47. Nuisance to local residents. operation of heavy equipment (excavator, crane etc.)

MEDIUM

1. Noise will be reduced to lowest level possible and where persons are exposed to noise at or above first action level or peak action level. Assessment will be made by a competent person and action taken in accordance with reagulations to protect both operatives and members of public.

LOW

Identification of Significant Hazards

Person at Risk

Risk to Person Prior to Control Measure (High/ Medium/ Low)

Control Measures

Overall Level of Residual Risk After Implementation of Control Measures (High/ Medium/ Low) LOW

Use of Ladders 48. Falls from ladders. 49. Ladders collapsing.

Personel who work using ladders (civil, mechanical).

HIGH

1. Suitable ladders only will be permitted to be used and must be free from defect. 2. Ladders will carry an identification mark and be inspected before use and by a competent person every 3 months. 3. Ladders will be set on firm level base, at angle of 75 degree at the top where practicable, by lashing on both stiles, or if not possible 'footed' or lashed at the bottom and prevented from sagging and swaying. 4. Ladders will not be misused. 5. Only one person will be on a ladder at any time. 6. Both hands must be free for holding a ladder. 7. Heavy loads must not be carried either ascending or descending ladders. 8. Oparatives, working from a ladder, must not over reach.

Erection of Structures in Steel and Concrete 50. Falls from ladders. Erection team 51. Falls of material from height. Structural collapse. 52. Lifting appliances 53. overturning. Arcing, contact or damage to 54. overhead and underground services.

HIGH

1. SURVEY OF SITE TO BE CONDUCTED to determine condition of ground and safe routes of access for vehicular traffic, location of any overhead and underground services, proximity of other buildings and members of public, anticipated activities of other contractors and any suspected contamination. 2. METHOD STATEMENT TO BE PREPARED in logical planned sequence of action. Statement to include details of structure and person responsible for supervision, vehicular access to and from site, delivery squence, storage, of appliance and gear requirements, crane siting (plan), preparation of hard standing for crane, appointment of competent person to supervise lifting operations, slinging method to be used,

LOW

Identification of Significant Hazards

Person at Risk

Risk to Person Prior to Control Measure (High/ Medium/ Low)

Control Measures

Overall Level of Residual Risk After Implementation of Control Measures (High/ Medium/ Low)

detailed method of erection to ensure stability, means of access to the workplace (if practicable, Hydraulic Platform should be used). Access along beams and any other safety factors to considered e.g. restricted area, wearing harness and helmets etc. 3. Method statement to be checked and approved. 4. Erection of structure will be monitored. No deviation from Method Statement will be permitted without approval from client.

Portable Power Tools 55. Electric shock. Workmen team who 56. Hair or clothing becoming use portable tools to entangled in moving parts. perform their job. 57. Eye injuries from dust, swarf or other fragments. 58. Wrist and hand injuries, due to tool jamming or binding. Vibration with finger (note 59. reportable disease). Air lines becoming detached 60. or bursting due to damage.

MEDIUM

1. All power feeds, electrical, pneumatic or hydraulic, to be to Safety Standard and maintained in good condition. 2. Loose clothing and long hair to be kept clear of mowing parts of power tools. 3. Eye protection to be worn at all times where there is a reasonably foreseeable risk of eye injury. 4. Operatives to be trained in the correct use of power tools. 5. Tools producing high levels of vibration to have padded handle to reduce the risk of vibration with finger.

LOW

Identification of Significant Hazards

Person at Risk

Risk to Person Prior to Control Measure (High/ Medium/ Low)

Control Measures

Overall Level of Residual Risk After Implementation of Control Measures (High/ Medium/ Low)

Use of Abrasive Wheel Machine 61. Operatives being injured by Personel use abrasive contact white or 'bursting' or wheel machine disintegration of wheel. (cutting, grinding etc.) Abbrasive particles causing 62. eye injuries. Damage to hearing from 63. exposure to noise. Health hazards arising from 64. exposure to dust and abrasive particles. HIGH 1. Abrasive wheel machines will only be used by trained competent operatives. 2. Suitable abrasive wheels will be selected for each work process. 3. Abrasive wheel machines will not be used unless suitable guards are fitted to contain fragments of bursting wheel. 4. Area in which machine is to be used will be clear and free of obstructions. 5. Noise will be reduced to lowest possible level and where action levels are likely to be reached, assessments will be conducted, information given to all persons likely to be affected, ear protection provided, which must be worn when required. 6. Where dust is likely to be a hazard to health, suitable Personal Protective Equipment (PPE) WILL BE PROVIDED AND WORN. LOW

Manual Handling 65. Operatives sustaining back Logistic man, workmen injury. (civil) 66. Operatives sustaining injury to limbs

MEDIUM

1. Where there is a risk of injury from the manual handling of materials, equipment etc. an assessment will be made in writing, detailing control measures, and operatives given instruction. 2. Conduct individual Manual handling risk assessment.

LOW

Prepared by:

HSE Coordinator

You might also like

- HSE PLAN Generic RA PDFDocument5 pagesHSE PLAN Generic RA PDFテレブリコ ジェファーソン100% (1)

- 002 Working at Height Risk AssessmentDocument4 pages002 Working at Height Risk Assessmentgangadharan000100% (14)

- Demolition Risk AssessmentDocument41 pagesDemolition Risk AssessmentVenkadesh Periathambi100% (3)

- Risk Assessment - Backfilling Around Foul Sewer and Storm Warter ManholesDocument6 pagesRisk Assessment - Backfilling Around Foul Sewer and Storm Warter Manholesloveson70950% (2)

- Excavation Risk Assessment KTPS - 8 PAGESDocument7 pagesExcavation Risk Assessment KTPS - 8 PAGESrajalingam100% (1)

- Activity Hazard AnalysisDocument4 pagesActivity Hazard AnalysisGerrard Singh100% (1)

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 pagesJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- Risk assessment for excavation worksDocument3 pagesRisk assessment for excavation worksYaser A. Al-Bustanji72% (18)

- RA, COSHH, MSDS Screed & Waterproofing PDFDocument27 pagesRA, COSHH, MSDS Screed & Waterproofing PDFテレブリコ ジェファーソン60% (5)

- Working at Height Risk AssessmentDocument7 pagesWorking at Height Risk AssessmentAshish100% (3)

- DSM-FRM-0001-27-0, HDPE PE-100 Pipe InstallationDocument4 pagesDSM-FRM-0001-27-0, HDPE PE-100 Pipe Installationkadir tanzaniaNo ratings yet

- Hyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectDocument4 pagesHyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectYounis Khan100% (1)

- Site Activities Risk AssessmentDocument50 pagesSite Activities Risk Assessmentjamie542393% (41)

- HSE TRA-04 Steel Reinforcement and Shuttering WorksDocument6 pagesHSE TRA-04 Steel Reinforcement and Shuttering WorksQusai Khalil Abu Awad100% (1)

- Construction Risk Assessments IndexDocument41 pagesConstruction Risk Assessments Indexmasoodae100% (4)

- SWP 002 - Risk AssessmentDocument23 pagesSWP 002 - Risk AssessmentAbhinavBanerjee100% (2)

- Risk Assessment for Pipe ErectionDocument6 pagesRisk Assessment for Pipe ErectionAzhar MushtaqNo ratings yet

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Electric Hand Drill Risk AssessmentDocument4 pagesElectric Hand Drill Risk AssessmentTariq AkhtarNo ratings yet

- Excavation Risk Assessment SheetDocument3 pagesExcavation Risk Assessment SheetMuhammad Ibrahim93% (45)

- Hazard Identification and Risk Assessment FormDocument4 pagesHazard Identification and Risk Assessment FormAli Al-GhamghamNo ratings yet

- Risk Assessment For Sand Blasting PDFDocument8 pagesRisk Assessment For Sand Blasting PDFOvais FarooqNo ratings yet

- RISK ASSESSMENT FOR 10 VILLA CONSTRUCTIONDocument12 pagesRISK ASSESSMENT FOR 10 VILLA CONSTRUCTIONFrancis Enriquez Tan50% (6)

- 6-Steel Work Risk Assessment ReportDocument7 pages6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- Excavations: Job Safety AnalysisDocument5 pagesExcavations: Job Safety AnalysisJICKNo ratings yet

- HEALTH & SAFETY RISK ASSESSMENTDocument52 pagesHEALTH & SAFETY RISK ASSESSMENTmujahid113794% (36)

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 Forkliftoscar67% (3)

- Risk Assessment For HDB (14.12.12)Document9 pagesRisk Assessment For HDB (14.12.12)Saravanan SKNo ratings yet

- Risk Assessment Register: Prepared By: Toolpusher / Hse AdvisorDocument1 pageRisk Assessment Register: Prepared By: Toolpusher / Hse Advisorcmrig740% (1)

- Project Risk Assessment For Design and ConstructionDocument32 pagesProject Risk Assessment For Design and ConstructionAjas Aju100% (31)

- ConfinedSpace RiskAssessmentDocument9 pagesConfinedSpace RiskAssessmentrashid zaman100% (4)

- RISK ASSES-105-Erection of Steel Structure BuildinDocument4 pagesRISK ASSES-105-Erection of Steel Structure BuildinRochdi Bahiri75% (8)

- 7 Hand Held Power ToolsDocument4 pages7 Hand Held Power ToolsGilmar MonteiroNo ratings yet

- Job Safety Analysis Risk Assess Confined Spaces v2 250311 KPDocument9 pagesJob Safety Analysis Risk Assess Confined Spaces v2 250311 KPIkhwanul Hujiatna50% (2)

- Risk Assessment For General ActivitiesDocument25 pagesRisk Assessment For General Activitiesabou bakar67% (3)

- Manual Handling Assessment - RPS Floor SortingDocument5 pagesManual Handling Assessment - RPS Floor SortingBayu Aji S100% (1)

- Very Very Good Risk Assessment EnvironmentDocument8 pagesVery Very Good Risk Assessment EnvironmentSalley Bukhari100% (1)

- Task Specific Risk AssessmentDocument22 pagesTask Specific Risk Assessmentsimone92% (12)

- JSA for Night Work at Laydown AreaDocument2 pagesJSA for Night Work at Laydown Areagulryz84100% (9)

- OHS SWMS Form 005 ExcavationDocument8 pagesOHS SWMS Form 005 Excavationazlinaz100% (2)

- Risk Assessment - Concrete CastingDocument3 pagesRisk Assessment - Concrete Castingdnmule50% (2)

- Welding and Radiography Risk AssessmentDocument11 pagesWelding and Radiography Risk AssessmentAldrin75% (8)

- Grinding Equipment Risk AssessmentDocument3 pagesGrinding Equipment Risk Assessmentdroffilcz270% (1)

- Backfilling Risk AssessmentDocument3 pagesBackfilling Risk Assessmentgulryz84100% (1)

- Excavation Safety ProcedureDocument8 pagesExcavation Safety ProcedureJamilNo ratings yet

- Risk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONDocument6 pagesRisk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONnsadnanNo ratings yet

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Activity Hazard AnalysisDocument43 pagesActivity Hazard AnalysisShawn James100% (4)

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatemahmoudmakladNo ratings yet

- Risk Assesment For Demolition of Factory Buildings at 14 Tuas Ave 1Document4 pagesRisk Assesment For Demolition of Factory Buildings at 14 Tuas Ave 1Yam Balaoing100% (1)

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- RISK ASSE 110 - Fire Fighting System - F03Document8 pagesRISK ASSE 110 - Fire Fighting System - F03Rochdi BahiriNo ratings yet

- Working at HeightDocument9 pagesWorking at Heightsixejo100% (6)

- Risk Assessment - Lifting OperationsDocument3 pagesRisk Assessment - Lifting Operationsdnmule100% (1)

- Consolidated International Contractor Risk AssessmentDocument45 pagesConsolidated International Contractor Risk Assessmentkumar100% (1)

- Temporary Fencing Risk AssessmentDocument7 pagesTemporary Fencing Risk AssessmentIrfan Prima AldiNo ratings yet

- JSA FORM SAFETY ANALYSISDocument13 pagesJSA FORM SAFETY ANALYSISPaulSwinbank100% (4)

- NCP - 22Document13 pagesNCP - 22chettriranjanNo ratings yet

- Water & Wastewater Treatment HSE PlanDocument16 pagesWater & Wastewater Treatment HSE Planmorgojoyo100% (1)

- EVI-EP-06-Environmental Practise For Using Company's VehicleDocument3 pagesEVI-EP-06-Environmental Practise For Using Company's VehiclemorgojoyoNo ratings yet

- EVI EP 05 Environmental Office PractiseDocument5 pagesEVI EP 05 Environmental Office PractisemorgojoyoNo ratings yet

- EVI EP 01 Environmental Management PlanDocument3 pagesEVI EP 01 Environmental Management PlanmorgojoyoNo ratings yet

- HSE BASIC PROCEDURESDocument66 pagesHSE BASIC PROCEDURESmorgojoyo100% (6)

- EVI-EP-04-Selection & Control of SubcontractorDocument4 pagesEVI-EP-04-Selection & Control of SubcontractormorgojoyoNo ratings yet

- EVI EP 02 Waste Management PlanDocument3 pagesEVI EP 02 Waste Management PlanmorgojoyoNo ratings yet

- WTP Improvement Lifting PlanDocument13 pagesWTP Improvement Lifting PlanmorgojoyoNo ratings yet

- Procedure of Lifting Material, Equipment & Tools-PE11-3025-DOC-M1100Document15 pagesProcedure of Lifting Material, Equipment & Tools-PE11-3025-DOC-M1100morgojoyoNo ratings yet

- PLTU KALTIM TELUK BALIKPAPAN 2X100 MW PROJECT HSE PLANDocument16 pagesPLTU KALTIM TELUK BALIKPAPAN 2X100 MW PROJECT HSE PLANmorgojoyoNo ratings yet

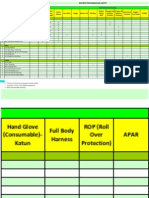

- LM HSE 001 001 Matrix Perlengkapan SafetyDocument2 pagesLM HSE 001 001 Matrix Perlengkapan SafetymorgojoyoNo ratings yet

- Analysis of Fatigue Fracture of Tank Wagon Railway Axles: Cosmin LocoveiDocument5 pagesAnalysis of Fatigue Fracture of Tank Wagon Railway Axles: Cosmin LocoveiZoser KalengayiNo ratings yet

- Bostik Seal N Flex One Plus TDS 05102021Document3 pagesBostik Seal N Flex One Plus TDS 05102021Pro. devNo ratings yet

- Matrox U110 TDS PDFDocument1 pageMatrox U110 TDS PDFrajanarenderNo ratings yet

- Roman Blacksmithing TechniquesDocument11 pagesRoman Blacksmithing TechniquesaoransayNo ratings yet

- CJ70Document116 pagesCJ70FlexartNo ratings yet

- DS-0035 3W PM2L-3LLx-SD v1.6Document13 pagesDS-0035 3W PM2L-3LLx-SD v1.6Pavan KumarNo ratings yet

- SPC PDH /PP Project: General Safety Procedure For FRP PipingDocument10 pagesSPC PDH /PP Project: General Safety Procedure For FRP PipingAshish PattanaikNo ratings yet

- Carlson 904L Austenitic Stainless Steel: CategoriesDocument6 pagesCarlson 904L Austenitic Stainless Steel: CategoriesBagus PutraNo ratings yet

- Consul PDF 25777Document2 pagesConsul PDF 25777Eben OforiNo ratings yet

- 09 Samss 097Document8 pages09 Samss 097fariboy123100% (1)

- High Rate Solids Contact Clarifier HRSCCDocument4 pagesHigh Rate Solids Contact Clarifier HRSCCshambhurajesurywanshi1No ratings yet

- Thermo-Mechanical Treatment RebarDocument6 pagesThermo-Mechanical Treatment RebarMunna Bhai100% (1)

- Review of Literature On Steam AccumulatorDocument10 pagesReview of Literature On Steam Accumulatortamil vaananNo ratings yet

- Processing of Grease With PDFDocument92 pagesProcessing of Grease With PDFahmetNo ratings yet

- Kenmore 385.4052/janome LX200 Sewing Machine Instruction ManualDocument77 pagesKenmore 385.4052/janome LX200 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Reactive Polyglycol EthersDocument2 pagesReactive Polyglycol EthersJayNo ratings yet

- SP Tools - MaytoJuly2013Document24 pagesSP Tools - MaytoJuly2013Riverland Welding and Tool SuppliesNo ratings yet

- Saes B 008Document5 pagesSaes B 008Anonymous a4Jwz14WNo ratings yet

- AstmDocument3 pagesAstmMuhammad NaumanNo ratings yet

- VRV General Catalogue - Cooling Only 50Hz - APCVDT1613 (Low Res)Document96 pagesVRV General Catalogue - Cooling Only 50Hz - APCVDT1613 (Low Res)enduNo ratings yet

- Cast Iron: Cast Irons Are A Class of Ferrous Alloys WithDocument12 pagesCast Iron: Cast Irons Are A Class of Ferrous Alloys WithChandima K PriyamalNo ratings yet

- Awz 410Document2 pagesAwz 410vukelic79No ratings yet

- Isopentane Stabilization Facilities Operation GuideDocument10 pagesIsopentane Stabilization Facilities Operation GuideBrainer SanchezNo ratings yet

- Icold Committe On Cemented Materail Dams Rock-Filled Concrete DamsDocument123 pagesIcold Committe On Cemented Materail Dams Rock-Filled Concrete DamsMarcelo ProtzNo ratings yet

- Diagnostic Test in Science 7Document3 pagesDiagnostic Test in Science 7ma. melanie s. capawing75% (8)

- MSDS Accepta LTD Accepta 3543Document5 pagesMSDS Accepta LTD Accepta 3543mechzarNo ratings yet

- Thermal Expansion of Polytetrafluoroethylene (Teflon)Document4 pagesThermal Expansion of Polytetrafluoroethylene (Teflon)Josafat Cruz-PrietoNo ratings yet

- GRUNDFOS DATA BOOKLET FOR REWINDABLE SUBMERSIBLE MOTORSDocument50 pagesGRUNDFOS DATA BOOKLET FOR REWINDABLE SUBMERSIBLE MOTORSfrcarras11No ratings yet

- Fine Woodworking 028Document92 pagesFine Woodworking 028Buliga Alexandra Elena100% (2)

- Lean Production at Portakabin: HospitalsDocument4 pagesLean Production at Portakabin: HospitalsFLAVIUS222No ratings yet