Professional Documents

Culture Documents

Mathematical Model of Once Through MSF

Uploaded by

Tino UmbarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathematical Model of Once Through MSF

Uploaded by

Tino UmbarCopyright:

Available Formats

J.

Mathematical Model of Once Through MSF

The advantages are:

- obtain quick design data

- evaluate system performance

Based on the following assumptions:

- Constant and equal specific heat for all liquid streams, Cp.

- Temperature drop per stage for the flashing brine equal to temperature drop per stage

for the feed seawater.

- The latent heat of vaporization in each stage is assumed equal to the average

value for the process.

- Effects of the non-condensable gases have negligible effect on the heat

transfer process.

- Non-equilibrium losses on the stage energy balance are negligible.

The simplified model includes the following elements:

1. Overall material balance

The overall material balance equations is given by

Mf=Md + Mb (1)

Where M is the mass flow rate and the subscript b, d, and defines the brine,distillate,

and feed.

The overall salt balance is given by

XfMf=XbMb (2)

Where X is the salt concentration. Equation (2) assumes that the distillate is salt free.

2. Stages and Condensers Temperature Profiles

The temperature distribution in the MSF-OT system is defined in terms of four

temperatures; *the temperatures of the steam= Ts

*top brine temperature=To

*the brine leaving the last stage=Tn

*the feed seawater=Tf

. The temperature drop per stage, T, is obtained from the relation

T = (To-Tn)/n (3)

the temperature of stage i

Ti = To - i T (4)

Ti = ti

so, the condenser temperature in stage i

ti = T f + ( n - ( i - l ) ) t (5)

3. Stage Material and Salt Balance

D1 = y Mf

D1 =the amount of flashing vapor formed in the first stage

Mf = the feed seawater flow rate

y= the specific ratio of sensible heat and latent heat and is equal to

y = Cp T/ av (6)

Cp =the specific heat capacity

av= the average latent heat calculated at the average temperature

Tav=(To + Tn)/2 (7)

The general formula for Di is

Di = Mf y (l-y)

(i-l)

(8)

The general form for the total summation of the distillate formed in all stages, Md,

which is given by

Md = M f ( l - ( l - y )

n

) (9)

The flow rate of the brine stream leaving stage (i) is given by

B i = M f -

=

i

k

k

D

1

(10)

The salt concentration in the brine stream leaving stage i is given by

Xi = Mf Xf / Bi (11)

The flow rate of the heating steam, Ms,

Ms s = Mf Cp (To-t1)

Ms = Mf Cp(To-t1)/ s (12)

4. Brine Heater and Condensers Heat Transfer Area

The brine heater area is given by

Ab = Ms s /(Ub(LMTD)b) (13)

Where LMTD is given by

(LMTD)b=((Ts-To)-(Ts-t1))/ln((Ts-To)/(Ts-t1)) (14)

and Ub is given by

Ub=1.7194+3.2063 x l0

-3

Ts+1.5971xl0

-5

(Ts)

2

- 1.9918x l0

-7

(Ts)

3

(15)

The heat transfer area for the condenser in each stage is assumed equal. Therefore, the

calculated heat transfer area for the first stage is used to obtain the total heat transfer

area in the plant. The condenser heat transfer area in the first stage is obtained from

Ac = Mf Cp(t1-t2)/(Uc(LMTD)c) (16)

Where

Uc= 1.7194 + 3.2063x10

-3

Tv

1

+ 1.5971x 10

-5

Tv

1

2

- l.99l8x 10

-7

Tv

1

3

(17)

Tv

1

= T1 BPE

1

NEA

1

- Td

1

(18)

B = 6.71 + 6.34xl0

-2

(T1)+9.74xl0

-5

(T1)

2

10

-3

C = 22.238 + 9.59x10

-3

( T I ) + 9.42x10

-5

(T1)

2

)10

-8

X1 = Mf Xf / B1

Substituting the values of B and C in the BPE correlation gives

BPE1=X1 (B + (X1)(C))l0

-3

NEA1 = (0.9784)

To

(15.7378)

H1

(1.3777)

Vb x 10-6

And

(LMTD)c = (Tv

1

- t1)-( Tv

1

- t2))/ln((Tv

1

- t1)/(Tv

1

- t2)) (19)

In the above equations

(BPE) =the boiling point elevation

(NEA)=the nonequilibrium allowance

(Tv) =the condensing vapor temperature

(Td) = the drop in the demister

(Uc) =the condenser overall heat transfer coefficient

transfer area for all condensers and the brine heater

A = Ab + n Ac (20)

5. Stage Dimensions

Calculations of the stage dimensions include the gate height, the height of the

brine pool, the stage width, and the stage length. The length of all stages is set equal

to the length of the last stage and the width of all stages is set equal to the width of the

first stage. The height of the brine pool must be higher than the gate height. The gate

height (GH) is obtained in terms of

the stage pressure drop= (P)

the brine density =( b)

the weir friction coefficient= (Cd)

the stage width= (W)

feed flow rate =(Mf). For stage i the gate height is

( ) ( ) W C Pi Dj Mf GHi

d bi

i

j

/ 2

) 5 . 0 (

1

1

A

|

|

.

|

\

|

=

=

(21)

The brine pool height is set higher than the gate height by 0.2 m.

Hi = 0.2 + GHi (22)

Where

Pi = Pi-P

i+l

W = Mf/Vb (23)

Pi and Pi+1=the pressures in stages i and i+1

Vb =the brine mass velocity per chamber width

The length of the last stage is

L= Dn/( vn Vvn W) (24)

the vapor flow rate=Dn

the vapor density= vn

the vapor allowable velocity=Vvn

the stage width=W

The cross section area for each stage, As, is then calculated

As = L W (25)

6. Performance Parameters

The system performance parameters are defined by

the thermal performance ratio= PR

the specific heat transfer area=sA

The performance ratio is the defined as the amount of distillate product produced per

unit mass of the heating steam. This is

PR = Md/Mg (26)

The specific heat transfer area is defined by

sA = (Ab + n Ac)/Md (27)

K. Problem and Solution

Fig.1. Multistage flash desalination once through process.

Fig. 2. Schematics of model variables in brine heater

- Problem:

An MSF system with 24 stages is used to produce 7.2 MGD of product water. The

following specifications are made to obtain the system design parameters and performance

characteristics:

- Feed seawater temperature, Tf = 25

0

C.

- Steam temperature, Ts = 116

0

C(

s=

2222.33 kJ/kg).

- Top brine temperature, To = 106

0

C.

- Brine temperature in the last stage, Tn = 40

0

C.

- Heat capacity of liquid streams, Cp = 4.18 kJ/kg

0

C.

- Salinity of feed seawater, Xf = 42000 ppm.

- Vapor velocity in the last stage, Vv

24

= 6 m/s

- Brine mass flow rate per stage width, Vb= 180 kg/ms.

- Weir friction coefficient, Cd = 0.5

-Vapor density (

v

23

)=

-T average=73

0

C,

av is equal to 2330.1 kJ/k9

- The temperature drop in the demister (Td) is assumed negligible

Determine the flow rates, stage dimensions,heat transfer area, and performance parameters of

the MSF system

- Solution:

a. Flow rate

1. Md

the product volume flow rate is converted to mass rate

in SI units, this is necessary for solution of the energy balance equations. The

distillate flow rate in kg/s is

|

.

|

\

|

|

|

.

|

\

|

|

|

.

|

\

|

|

|

.

|

\

|

|

.

|

\

|

|

|

.

|

\

|

|

.

|

\

|

|

|

.

|

\

|

|

.

|

\

|

=

3

3

3

6

10

96 . 219

1

3600 24

1

10 2 . 7

m

kg

G

m

s

d

MG

G

d

MG

Md

Md = 378.8 kg/s

2. Mf

The temperature drop is

T=t = (To-Tn)/n

= (106 - 40)/24

= 2.75

0

C

T average=73

0

C,

av is equal to 2330.1 kJ/k

y = Cp T/ av

= (4.18)(2.75)/2330.1

= 4.933x10

-3

The feed flow rate

Mf = M d / ( l - ( l - y )

n

)

= 378.8/(1 - (1 - 4.933x10

-3

)

24

)

= 3384.8 kg/s

3. Mb

The flow rate of the blow-down brine is then obtained from the overall balance

Mb = Mf-Md

= 3384.8 - 378.8

=3006 kg/s

4. Ms

The temperatures of the seawater leaving the condensers in the first calculated.

This is

t1 = Tf+n t

= 25 + (24) (2.75)

= 91

0

C

The steam flow rate is

Ms = Mf Cp(To-t1)/ s

= (3384.8) (4.18) (106 - 91)/(2222.33)

= 95.49 kg/s

b. Stage Dimensions

1. The width of the stage (W)

W = Mf/Vb

= 3384.8/180

= 18.8 m

2. The stage length (L)

D

24

= 14.9 kg/s (from the appendix)

L = Dn/(

v

24

Vv

24

W)

= 14.9/((0.0512)(6)(18.8))

= 2.58 m

3. GH1

The temperatures of the first and second stages, T1 and T2, where

T1 = To - T

= 106-2.75

= 103.25

o

C

T2 = T1 - T

= 103.25-2.75

= 100.5

o

C

The brine density in the first stage is 1002.413 kg/m

3

, which is obtained from the

correlation given the appendix at a salinity of 42208 ppm and a temperature of 103.25

C. The pressures of the first and second stage are obtained from the saturation

pressure correlations, where, at T1 = 103.25

0

C, P1= 113.72 kPa, and at T2 = 100.5

0

C, P2 = 103.23 kPa. The resulting gate height in the first stage, GH1

GH1 = Mf (2 b

1

P1)

(-0.5)

/(Cd W)

=(3384.8)((2)(1002.413)(113.72-103.23)xl0

3

)

(-0.5)

/(0.5)(18.8)

= 0.078 m

It should be noted that the pressure drop in the above equation is in Pa and not

kPa. The corresponding brine pool height is obtained by simply adding 0.2 m to

the value of GH1, or

H1 = 0.278 m

c. Heat Transfer Areas

1. The heat transfer area for the brine heater (Ab)

Requires calculations of the logarithmic mean temperature difference (LMTD)b

and the overall heat transfer coefficient. The value of (LMTD)b is

(LMTD)b = (t1 - To)/ln((Ts - To)/(Ts t1))

= (91 - 106)/ln((116 - 106)/(116 - 91))

= 16.37

0

C

The overall heat transfer coefficient is

Ub = 1.7194 + 3.2063x10

-3

Ts + 1.5971x10

-5

(Ts)

2

- 1.9918xl0

-7

(Ts)

3

= 1.7194 + 3.2063x10

-3

(116) + 1.5971x10

-5

(116)

2

- 1.9918x10

-7

(116)

3

= 2 kW/m

2

o

C

The brine heater area, Ab

Ab = Ms s/Ub(LMTD)b)

= (95.49)(2222.33)/((2)(16.37))

=6481.68 m

2

2. The condenser area (Ac)

Determined for the first stage. This requires calculations of the vapor

condensation temperature (Tv

1

) the logarithmic mean temperature difference

(LMTD)c, and the overall heat transfer coefficient, Uc.

Tv

1

= T1 BPE1 NEA1 - T

d1

*The boiling point(BPE1)

D1 = y Mf

= (4.933xl0

-3

)(3384.8)

= 16.697 kg/s

B1 = Mf-D1

= 3384.8 - 16.697

= 3368.1 kg/s

X1 = Mf Xf/B1

= (3384.8)(42000)/3368.1

= 42208 ppm

The values of B and C in the correlation for the boiling point elevation are

B = (6.71 + 6.34xl0

-2

(T1)+9.74xl0

-5

(T1)

2

10

-3

= (6.71 + 6.34xl0

-2

(l03.25)+ 9.74xl0

-5

^(l03.25)

2

)10

-3

= 0.0143

C = (22.238 + 9.59x10

-3

( T I ) + 9.42x10

-5

(T1)

2

)10

-8

= (22.238 + 9.59xl0

-3

(l03.25)+ 9.42xl0

-5

(l03.25)2)10

-8

= 2.423x10

-7

Substituting the values of B and C in the BPE correlation gives

BPE1=X1 (B + (X1)(C))l0

-3

= 42208 (0.0143 + (42208) (2.423x10

-7

))l0

-3

= 1.035

0

C

*The non-equilibrium allowance (NEA1)

H1=0.278m

NEA1 = (0.9784)

To

(15.7378)

H1

(1.3777)

Vb x 10-6

= (0.9784)

(106)

(l5.7378)

(0.278)

(1.3777)

(180 x 10-6)

= 0.213

o

C

Therefore, the vapor temperature in the first is

Tv

1

= T1 BPE1 NEA1- Td1

= 103.25-1.035-0.213-0

= 102.002 oC

The vapor temperature, Tv1 , is used to calculate Uc and (LMTD)c, where

t1=91

0

C

t2 = t1 - t

= 91-2.75

= 88.25

0

C

(LMTD)c = (t2-t1)/ln((Tv-t1)/(Tv-t2))

= (2.75)/ln((102.002-91)/(102.002-88.25))

= 12.32

o

C

Uc = 1.7194 + 3.2063x10

-3

Tv

1

+ 1.5971x10

-5

(Tv

1

)

2

- 1.9918xl0

-7

(Tv

1

)

3

= 1.7194 + 3.2063x10

-3

(101.207) + 1.5971x10

-5

(101.207)

2

- 1.9918x10

-7

(101.207)

3

= 2 kW/m

2

o

C

Ac=Mf Cp (t2-t1)/(Uc(LMTD)c)

= ((3384.8) (4.18) (2.75))/((2) (12.32))

= 1579 m

2

The total heat transfer area is obtained from

A = Ab + n Ac

= 6481.68 + (24) (1579)

= 44377.7 m

2

d. Performance Parameters

1. Performance Ratio (PR)

PR = Md/Ms

= 378.8/95.49

= 3.96

2. The specific heat transfer area

sA = A/Md

= (44377.7)/378.8

= 117.2 m

2

/(kg/s)

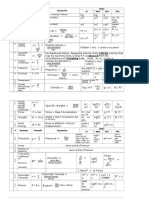

Solution Summary

Flow Rates

Md = 378.8 kg/s

Mb = 3006 kg/s

Mf = 3384.8 kg/s

Ms = 95.49 kg/s

Stage Dimensions

W= 18.8 m

L = 2.56 m

GH1 = 0.078 m

H1 = 0.278 m

Heat Transfer Areas

Ab = 6481.68 m

2

Ac = 1579 m

2

A = 44377.7 m

2

Performance Parameters

PR = 3.96

sA= 117.2 m

2

/(kg/s)

Stage Profiles

The MSF-OT simplified model is used to calculate the temperature and

concentration profiles for the 24 stages. The calculations also include the brine

and distillate flow rate, the gate height and the brine level in each stage. In the

following table, the flow rates are in kg/s, the temperature in

0

C, the salinity in

ppm, and the height in m.

Stage D D

B X T Tf GH H

1 16.70 16.70 3368.1 42208.2 103.25 91 0.078 0.278

2 16.61 33.31 3351.5 42417.5 100.5 88.25 0.081 0.281

3 16.53 49.84 3335.0 42627.7 97.75 85.5 0.084 0.284

4 16.45 66.30 3318.5 42839.1 95 82.75 0.087 0.287

5 16.37 82.67 3302.1 43051.4 92.25 80 0.09 0.29

6 16.29 98.96 3285.8 43264.9 89.5 77.25 0.094 0.294

7 16.21 115.16 3269.6 43479.3 86.75 74.5 0.097 0.297

8 16.13 131.29 3253.5 43694.9 84 71.75 0.101 0.301

9 16.05 147.34 3237.5 43911.5 81.25 69 0.105 0.305

10 15.97 163.31 3221.5 44129.2 78.5 66.25 0.11 0.31

11 15.89 179.21 3205.6 44348.0 75.75 63.5 0.114 0.314

12 15.81 195.02 3189.8 44567.8 73 60.75 0.119 0.319

13 15.74 210.75 3174.0 44788.8 70.25 58 0.124 0.324

14 15.66 226.41 3158.4 45010.8 67.5 55.25 0.13 0.33

15 15.58 241.99 3142.8 45233.9 64.75 52.5 0.136 0.336

16 15.50 257.50 3127.3 45458.2 62 49.75 0.143 0.343

17 15.43 272.92 3111.9 45683.5 59.25 47 0.15 0.35

18 15.35 288.27 3096.5 45910.0 56.5 44.25 0.157 0.357

19 15.28 303.55 3081.3 46137.6 53.75 41.5 0.165 0.365

20 15.20 318.75 3066.1 46366.3 51 38.75 0.175 0.375

21 15.12 333.87 3050.9 46596.2 48.25 36 0.185 0.385

22 15.05 348.92 3035.9 46827.2 45.5 33.25 0.197 0.397

23 14.98 363.90 3020.9 47059.3 42.75 30.5 0.211 0.411

24 14.90 378.80 3006.0 47292.6 40 27.75 0.211 0.411

You might also like

- 7D162B Pressure Drop For Double Pipe Heat Exchanger SiDocument4 pages7D162B Pressure Drop For Double Pipe Heat Exchanger SiparagmhamunkarNo ratings yet

- 11 MSF Engineering 1Document19 pages11 MSF Engineering 1Mohammed Al ShammeriNo ratings yet

- Design of LPG Refigeration System: 1. Copper TubesDocument20 pagesDesign of LPG Refigeration System: 1. Copper TubesJeevan Landge PatilNo ratings yet

- 4.4 Heat Ex ChangersDocument7 pages4.4 Heat Ex Changersmukesh kaushikNo ratings yet

- Class Notes 3Document9 pagesClass Notes 3Aitazaz HassanNo ratings yet

- Process Design of Total CondenserDocument5 pagesProcess Design of Total CondenserVivek VĩvĕNo ratings yet

- Multi ModeDocument73 pagesMulti ModeShalinee KavadiyaNo ratings yet

- Heat Exchangers: Effectiveness-NTU Method Chapter SectionsDocument15 pagesHeat Exchangers: Effectiveness-NTU Method Chapter SectionsrajindoNo ratings yet

- Modeling Chemical Processes Using MATLAB Homework Set #5 SolutionsDocument37 pagesModeling Chemical Processes Using MATLAB Homework Set #5 Solutionsmadithak100% (1)

- Problems 13 1 To 13 17Document39 pagesProblems 13 1 To 13 17Carlos Huete FelixNo ratings yet

- Heat Exchanger - Effectiveness - NTU MethodDocument15 pagesHeat Exchanger - Effectiveness - NTU MethodhendiyrNo ratings yet

- Asssigment of Heat and ThermoidynamicsDocument18 pagesAsssigment of Heat and ThermoidynamicsMobeen HayatNo ratings yet

- 5.6 Schedule of Electrical RequirementsDocument7 pages5.6 Schedule of Electrical RequirementsFaquruddin AliNo ratings yet

- NPTEL Chemical Engineering Design Rotary DryerDocument6 pagesNPTEL Chemical Engineering Design Rotary DryerganeshNo ratings yet

- Lecture 3: Design Consideration of DriersDocument6 pagesLecture 3: Design Consideration of DriersachalNo ratings yet

- Design of DryerDocument11 pagesDesign of DryerHARKULVINDER SINGHNo ratings yet

- Types of Heat Exchangers and Their Analysis Using Effectiveness-NTU MethodDocument16 pagesTypes of Heat Exchangers and Their Analysis Using Effectiveness-NTU MethodArun MohapatraNo ratings yet

- Experiment 5 HeatDocument21 pagesExperiment 5 HeatAzwan BaharinNo ratings yet

- Online Notebook Plate Heat Exchanger DesignDocument18 pagesOnline Notebook Plate Heat Exchanger DesignAditya JaniNo ratings yet

- Worked Problems Heat ExchangersDocument18 pagesWorked Problems Heat Exchangers521 Balaji ONo ratings yet

- AF84C8 Excel Template Prelim Double Pipe Heat Exchanger Design Us UnitsDocument8 pagesAF84C8 Excel Template Prelim Double Pipe Heat Exchanger Design Us Unitss111_sunilNo ratings yet

- Single Effect Evaporation (SEE) ProcessesDocument28 pagesSingle Effect Evaporation (SEE) ProcessesAl- Dhaheri0% (1)

- HT304 - Draft Report PDFDocument7 pagesHT304 - Draft Report PDFshashiNo ratings yet

- UopsDocument7 pagesUopsRecio RhonelNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument2 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAbhishek SinglaNo ratings yet

- Concentric Tube Water-Water Heat Exchanger Study UnitDocument12 pagesConcentric Tube Water-Water Heat Exchanger Study Unitseraj ibramemNo ratings yet

- Aph PRESENTATIONDocument42 pagesAph PRESENTATIONRajneesh VachaspatiNo ratings yet

- Chemical: List I List IIDocument6 pagesChemical: List I List IISudhanshu PandeyNo ratings yet

- Homework 24Document2 pagesHomework 24Alexis Nathán RuedaNo ratings yet

- Design of Air Pre Heater and Economizer: Submitted by J.Shanmuka Venkata Gopichand (101fa08133) L.SURYA TEJA (101FA08141)Document42 pagesDesign of Air Pre Heater and Economizer: Submitted by J.Shanmuka Venkata Gopichand (101fa08133) L.SURYA TEJA (101FA08141)Chien NguyenNo ratings yet

- Heat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Document15 pagesHeat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Joli SmithNo ratings yet

- Optimization of A Steam Boiler PDFDocument8 pagesOptimization of A Steam Boiler PDFSyifaprilia N0% (1)

- Answer For Mid ExamDocument7 pagesAnswer For Mid Examtedy yidegNo ratings yet

- HEAT EXCHANGER TITLEDocument10 pagesHEAT EXCHANGER TITLEKerem GönceNo ratings yet

- Heat Exchanger Design OptimizationDocument27 pagesHeat Exchanger Design OptimizationUsama AkramNo ratings yet

- Exam 2013 ExchangerDocument2 pagesExam 2013 ExchangernemoneoNo ratings yet

- Solution 6Document9 pagesSolution 6nesjokokNo ratings yet

- HEAT EXCHANGER TABLE OF CONTENTSDocument9 pagesHEAT EXCHANGER TABLE OF CONTENTSZeenat RanaNo ratings yet

- Chapter 7Document34 pagesChapter 7ShahrizatSmailKassimNo ratings yet

- Heat Exchanger Part 1 PDFDocument22 pagesHeat Exchanger Part 1 PDFRyu RyloNo ratings yet

- (Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingDocument32 pages(Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingLisa SeptidianaNo ratings yet

- Heat Chap13 032Document18 pagesHeat Chap13 032Kerem GönceNo ratings yet

- Design of Air Pre Heater and EconomizerDocument4 pagesDesign of Air Pre Heater and EconomizerRyan PerezNo ratings yet

- Simulation of A Multiple-Effect EvaporatorDocument36 pagesSimulation of A Multiple-Effect EvaporatorSamsouma SoumiaNo ratings yet

- Heat Transfer UNIT-8 Heat Exchangers:: Problem 50Document8 pagesHeat Transfer UNIT-8 Heat Exchangers:: Problem 50Miguel Angel Carranza OlveraNo ratings yet

- Aircraft Propulsion PDF FreeDocument23 pagesAircraft Propulsion PDF FreeSai ManiNo ratings yet

- Heat Exchanger Design CalculationsDocument61 pagesHeat Exchanger Design CalculationsJohnJaye100% (7)

- 03C - Chapter 3 - Sec 3.6Document13 pages03C - Chapter 3 - Sec 3.6cmegmhiNo ratings yet

- MMME2007 Spring 2016-2017 SolutionsDocument15 pagesMMME2007 Spring 2016-2017 SolutionsJonathan AngNo ratings yet

- Process Modelling, Simulation and Control For Chemical Engineering. Solved Problems. Chapter 5: Simulation Ex-AmplesDocument12 pagesProcess Modelling, Simulation and Control For Chemical Engineering. Solved Problems. Chapter 5: Simulation Ex-AmplesJohn100% (2)

- Me 2204 Fluid Mechanics and Machinery LiDocument8 pagesMe 2204 Fluid Mechanics and Machinery LiSheryll de GuzmanNo ratings yet

- HT14 Lab Report AnalysisDocument9 pagesHT14 Lab Report AnalysisPasindu MalithNo ratings yet

- Gate Previous Year QuestionsDocument53 pagesGate Previous Year QuestionsPOOJA VERMANo ratings yet

- Bell Delaware Math Cad ExampleDocument8 pagesBell Delaware Math Cad ExampleMohammed A IsaNo ratings yet

- Solution Ch8Document15 pagesSolution Ch8Anonymous ou6LhnW6qv100% (2)

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Linguaphone Russian Coursebook 1990Document90 pagesLinguaphone Russian Coursebook 1990Tino Umbar0% (1)

- Norm and Tenorm in GermanDocument10 pagesNorm and Tenorm in GermanTino UmbarNo ratings yet

- Russian Verbs of MotionDocument81 pagesRussian Verbs of MotionJustina BandolNo ratings yet

- Cramer's Rule and Gauss Elimination ExplainedDocument34 pagesCramer's Rule and Gauss Elimination ExplainedTino UmbarNo ratings yet

- Production of sodium benzoateDocument21 pagesProduction of sodium benzoateTino UmbarNo ratings yet

- Brain Rules Chapter SummariesDocument13 pagesBrain Rules Chapter SummariesPear Press93% (15)

- 600MostCommonAE Idioms PDFDocument0 pages600MostCommonAE Idioms PDFwatashivnnNo ratings yet

- 12 Brain RulesDocument1 page12 Brain RulesZack ZawaniNo ratings yet

- Contoh Soal Dan Jawaban Transformasi LaplaceDocument3 pagesContoh Soal Dan Jawaban Transformasi LaplaceMiftah Farid100% (8)

- McCabe ThieleDocument37 pagesMcCabe Thielefumanchu@fastmail.fmNo ratings yet

- 12 Brain RulesDocument1 page12 Brain RulesZack ZawaniNo ratings yet

- Vapor-Liquid Equilibrium Data Set 3575Document2 pagesVapor-Liquid Equilibrium Data Set 3575Tino UmbarNo ratings yet

- Norton Ghost 15 User GuideDocument213 pagesNorton Ghost 15 User Guidefourseven2001No ratings yet

- Geiger MullerDocument13 pagesGeiger MullerTino UmbarNo ratings yet

- Physics of FluidsDocument41 pagesPhysics of FluidsSherwin PNo ratings yet

- Unit 1 - Ways Informatics Transforming Health CareDocument22 pagesUnit 1 - Ways Informatics Transforming Health CareRaquel MonsalveNo ratings yet

- Management Science NotesDocument13 pagesManagement Science NotesAndi Te'a Mari O. SimbalaNo ratings yet

- Cartridge Heaters0721Document48 pagesCartridge Heaters0721dominhdung263168No ratings yet

- Operator E-Jets News Rel 040Document12 pagesOperator E-Jets News Rel 040jivomirNo ratings yet

- ELT 1000 Y1-03-0259 Rev GDocument62 pagesELT 1000 Y1-03-0259 Rev GKumaraswamy RSNo ratings yet

- Unit 4 Index Structures For Files: StructureDocument16 pagesUnit 4 Index Structures For Files: StructuregaardiNo ratings yet

- Midlands State University Library Department Course: Information Literacy Skills (Hcs135)Document7 pagesMidlands State University Library Department Course: Information Literacy Skills (Hcs135)Loveniah Yemurai MbakataNo ratings yet

- 4K HDR - What Is It, and What's The Different Between 8,10, and 12-Bit HDRDocument12 pages4K HDR - What Is It, and What's The Different Between 8,10, and 12-Bit HDRArkadiusz StrzeszewskiNo ratings yet

- LCPro SDDocument8 pagesLCPro SDAndrei IonNo ratings yet

- Lab Manual 15B17CI574 Artificial Intelligence Lab PDFDocument45 pagesLab Manual 15B17CI574 Artificial Intelligence Lab PDFAviral TanwarNo ratings yet

- Job Analysis: Patricia A. Meglich, PH.D., SPHR 2009Document38 pagesJob Analysis: Patricia A. Meglich, PH.D., SPHR 2009Rana MohamedNo ratings yet

- Gas Dynamics MCQsDocument6 pagesGas Dynamics MCQsprawinlNo ratings yet

- Saudi 7th Scientific ConferenceDocument383 pagesSaudi 7th Scientific ConferenceMairene0% (1)

- SD ContentsDocument18 pagesSD ContentsAnonymous gUjimJKNo ratings yet

- Top 20 Automation Testing Interview Questions and AnswersDocument36 pagesTop 20 Automation Testing Interview Questions and AnswersBilal Achernan100% (1)

- SMAC Actuators User ManualDocument52 pagesSMAC Actuators User ManualElectromateNo ratings yet

- T REC G.650.1 201210 S!Amd1!PDF EDocument16 pagesT REC G.650.1 201210 S!Amd1!PDF EVenâncio Ricardo MendonçaNo ratings yet

- (Advances in Experimental Medicine and Biology 1142) Qing Yang, Tamo Fukamizo - Targeting Chitin-Containing Organisms-Springer Singapore (2019)Document293 pages(Advances in Experimental Medicine and Biology 1142) Qing Yang, Tamo Fukamizo - Targeting Chitin-Containing Organisms-Springer Singapore (2019)La Ciencia de AlejoNo ratings yet

- LM340/LM78XX Series 3-Terminal Positive Regulators: General DescriptionDocument17 pagesLM340/LM78XX Series 3-Terminal Positive Regulators: General DescriptionAlexandru Gabriel HunaNo ratings yet

- PRODUCT SPEC TITLEDocument32 pagesPRODUCT SPEC TITLExvolcanoNo ratings yet

- BOEHME For Beginners-Gnosis Magazine-Fall1997 PDFDocument7 pagesBOEHME For Beginners-Gnosis Magazine-Fall1997 PDFgpmarquesNo ratings yet

- PVC Water Pumps PDFDocument26 pagesPVC Water Pumps PDFYulidar Wahyu RachmawanNo ratings yet

- Abis For GSM TelecommunicationsDocument2 pagesAbis For GSM TelecommunicationsUmar Abbas BabarNo ratings yet

- Plastic Ban LetterDocument5 pagesPlastic Ban LetterrkarlinNo ratings yet

- Cp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Document1 pageCp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Triana Rosma Fikriyati DinaNo ratings yet

- CaFSET (Antigua) Office Workbook - Sixth Edition - Programming Concepts Sample PagesDocument4 pagesCaFSET (Antigua) Office Workbook - Sixth Edition - Programming Concepts Sample PagescafsetNo ratings yet

- Chap # 14 (Electromagnetic Induction)Document6 pagesChap # 14 (Electromagnetic Induction)Tariq MahmoodNo ratings yet

- Microprocessors and MicrocontrollerDocument2 pagesMicroprocessors and MicrocontrollerKumar MukeshNo ratings yet

- Theory of ErrorsDocument43 pagesTheory of Errorsjaybh575No ratings yet