Professional Documents

Culture Documents

Variable Speed Pumping

Uploaded by

MONACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Variable Speed Pumping

Uploaded by

MONACopyright:

Available Formats

4

Tech Talk contd

Model 3500 to separate air properly for removal I Level control and speed control operate in through the degas system, the pump must concert operate at or above a minimum speed. When the pump operates below its minimum speed, the air This method involves again setting a range is not adequately separated and the pump for the control valve to operate such as 40 to performance deteriorates. This results in loss of 70% open. As the control valve modulates to level control and pump operation becomes control level, the pump speed also changes to unstable and erratic. To prevent this from respond to the level control valve position. occurring, the control scheme must take this into This typically involves a linear speed account. Several control schemes have been used relationship to the valve position. At the for medium consistency pumps with success. minimum speed the valve is open at the Each allows the pump to vary its speed but also minimum of 40% and the maximum speed incorporates a control valve for those situations corresponds to the maximum valve opening. when the pump speed is at or near the minimum. The control schemes described below Again, when the valve opening is less than are normally done through a DCS with a speed 40% in this case the pump speed remains at signal sent to the PS200 drive. The pump the minimum RPM until the valve opens protection features and inherent benefit of a above the 40% point. This control scheme variable speed drive result in an overall can be done with the variable set point economical package. option of PS200. Examples of control schemes used: I Level control valve is primary level control device with variable speed secondary This method incorporates a control range for the opening of the valve for example from 55 to 65% open. When the valve opening becomes less than the lower value (55%) the pump speed is reduced. When the valve opening becomes greater than the upper value (65%), the pump speed increases. In both cases the valve position then moves back into the target range. Should the valve opening continue to decrease and the pump speed decreases to the minimum speed, then the pump speed stays at the minimum and the control valve assumes full control for level. I Speed Control to maintain a fixed valve opening This scheme does not occur often but may be used in long pipelines or for booster pump (series) operation. In this situation the valve position is the parameter being controlled. The valve position becomes the set point and the pump speed is varied to maintain the set valve position. Combining the Model 3500 with a PumpSmart drive provides the type of operating flexibility often desired in pulp mills or bleach plants, pump protection features and the reliability required for these critical services in the Pulp & Paper Industry. I

Model 3500 medium consistency pump Installation.

permitted standpipe level control throughout a wide range of operating conditions without upsets due to high level alarms and trip out of related equipment. The efforts of the operators were focused on the training and start up of the new equipment and process for this mill. The second installation involved a Model 3500 pumping to a HD storage tower with a long pipe run to the tower. A range of production rates was desired which translates into a range of flow rates for the pump. An additional requirement for the future was a 10% additional production rate. Meeting the current production rate variations and having the capability to meet the future increase of 10% was satisfied by the use of the PumpSmart drive. The PS200 drive allowed the pump to operate at speeds above synchronous 1800 RPM when necessary. For this service, production rate ranges for the current requirements were from 900 BDSTPD to 1300 BDSTPD. At 12% consistency, this gives a flow range of 1250 GPM to 1800 GPM. The drive size is 500 HP . As the mill shifted production requirements between the different rates, HP savings as much as 75 HP result. Pump protection features similar to the first example were also invoked in this application as well. Additional capabilities include low flow torque protection. This can signal an alarm when the standpipe level has dropped to a very low level and air may be pulled into the system. This large influx of air can result in severe pipeline vibration if the root cause is not corrected. The nature of the Model 3500 medium consistency pump makes a variable speed application somewhat different from a conventional centrifugal pump. In order for the

Variable Speed Pumping: Myths and Legends

Overcoming Perceived Barriers to Implementation

By Mike Pemberton PumpSmart Performance Services Therefore, even the lover of myth is in a sense a philosopher; for myth is composed of wonders Aristotle In common language, a myth is a fiction something that is untrue. A legend is a story from the past about a subject that was, or is believed to have been, historical. So, myths and legends encompass beliefs that may or may not be true. And legends are often so embellished that it is hard to discern how much of the story is factually true. When considering the application a variable frequency drive (VFD) for centrifugal pump

control, one often encounters myths and legends. How much is fiction and how much is fact. Today, it is increasingly important to sort through the misinformation in order to realize the significant benefits through application of this technology. Traditionally, a fixed-speed pump and control valve has been used to regulate process flow. Even though VFD technology has grown rapidly in acceptance, the technology and benefits are often poorly understood. As such, there is uncertainty surrounding its use for pump control. There are any number of reasons for this confusion including: I Lack of knowledge about the hydraulic performance between fixed and variable speed pump control I Lack of knowledge concerning control and failure modes, especially for mission critical applications I Perception that a VFD is always more expensive than a control valve

Tech Talk contd

I Concerns about the reliability of the electronics platform Many of these concerns stems from bad experiences before VFD technology matured. These legacy issues can be put into perspective by relating them to the evolution of PC technology. The cost of low voltage VF drives continues to drop while reliability and functionality increase. As a result, VFD technology has become a highly-reliable, cost-effective alternative to using fixed-speed pumping systems. There are compound benefits through implementation. These include energy and maintenance savings, pump and process reliability improvements, better process control and less fugitive emissions. Also, on new projects, VFD application can reduce overall capital cost by eliminating valves and starters plus the associated wiring and pneumatic lines. In many cases, smaller pumps with lower horsepower motors can be used. In terms of piping, smaller diameters often suffice and by-pass lines can be eliminated. Scope of Opportunity It is estimated that 20% of all electrical power is used to drive industrial pumps. Around 20% to 50% of the power consumed can be saved through variable speed operation. Opportunities to improve pump performance are often overlooked for the following reasons: I Low awareness of motor energy-efficient technologies I Financial and operational benefits are often not well understood I The Initial capital cost to employ motor-efficient technology may be higher (purchasing decisions are typically made on first-cost) I Energy-saving projects are often ranked below other process-related capital expenditures How Does the VFD Works A variable frequency drive (VFD) is an electrical system (i.e. inverter) used to control AC motor speed and torque. It provides a continuous range of process speeds compared to a discrete speed control device such as multiple-speed motors or gearboxes. Industry has standardized on the IGBT (Insulated Gate Bi-polar Transistor) based PWM (Pulse Width Modulated) design. A VFD controls motor speed by varying the frequency supplied to the motor. The drive also regulates the output voltage in proportion to the output frequency to provide a relatively constant ratio of voltage to frequency (V/Hz), as required by the characteristics of the AC motor

to produce torque. In closed-loop control, a change in process demand is compensated by a change in power and frequency supplied to the motor, and thus a change in motor speed. Latest VFD Improvements I Microprocessor controllers eliminate analog, potentiometer-based speed adjustments with precise digital control capability. I Advanced circuitry to detect motor rotor position by sampling power at the terminals, which keeps power waveforms clean and sinusoidal while minimizing power losses. I Soft-start capabilities with higher starting torques at lower speeds I Built-in power factor correction and short-circuit protection. I Digital bus communication to the DCS, PLC or CMMS for transmiting real-time information on equipment health. I Radio Frequency Interference (RFI) filters to protect process equipment Application Issues and Benefits It is widely recognized that the VFD can introduce harmonic distortion of voltage supplies caused by the non-sinusoidal currents drawn during the power conversion process inside the drive converters. Because of the fast switching frequency of the IGBT drive and impedance mismatching between the motor and transmission lines, a reflective wave occurs which results in spikes that are sometimes two to three times rated bus voltage. These occur on every pulse of the output and travel unevenly through the coils of the motor. The following are considerations in addressing this issue: I Induction motors used with inverters to supply adjustable frequency power should include inverter grade insulation. I Inverters produce steep fronted voltage spikes which can damage the stator winding insulation. I Part 31 of NEMA MG-1 requires the insulation of inverter duty motors to be capable of handling 1600 V spikes for supply voltages up to 600 volts. I Most standard induction motors meet this requirement, but always consult with the motor supplier if there is a question on suitability for inverter duty. I Use inverter duty motor power cables with a continuous corrugated armor sheath; i.e., provides low impedance to high frequency. I When the distance between the drive and the motor exceeds the recommended lead length, added protection is required, i.e., add a line reactor at the drive and RFI filter at the motor. It is important to specify the technical performance of the VFD and make sure that

proper electrical practices are followed during installation. It is equally important to realize these technical issues are well understood and can be successfully mitigated. Often, the concerns over these potential side effects has slowed acceptance of the technology. While this concern is valid, the technical issues can be addressed. The economic benefits are too compelling to delay implementation. Energy Savings Potential Energy savings are possible with VFD control due to the affinity laws that govern the operation of centrifugal pumps. Compared with throttling valves and bypass systems, speed reduction provides significant energy savings at partial load. The reduction of speed provides: I Flow (Q) reduction according to a linear function I Head (H) reduction according to a quadratic function I Power (P) reduction according to a cubic function

Graph 1: Affinity Laws in Action

Medium vs. Low Voltage Motors It is common practice in industrial plants to switch from low voltage to medium voltage motors above 200 Horsepower. The primary reason for switching to medium voltage is to reduce the amperage required to start and continuously operating fixed-speed motors. For example, the full load amps for a medium voltage 200 Hp TEFC motor @ 1180 rpm is four or more times less than an equivalent low voltage motor. VFD pump control often results in operation at 50 75% of full-speed to deliver the same flow rate. Subsequently, the horsepower and associated current draw is significantly reduced. For example, a low voltage 200 Hp TEFC motor at 60% of full speed requires about 30% of full load power. Therefore, the amp draw required for variable speed pumping at partial load is typically only one or two greater than is required for a medium voltage motor at full speed.

continued on page 6

Tech Talk contd

In addition, the VFD has a soft-starter built in to prevent over-current and over-torque conditions on start-up. The inherent soft-start capability avoids pressure spikes (water hammer) and reduces pipe fracture. Repeated pressure spikes can reduce the lifetime of the pumping system.

Graph 2: Reliability Issues vs. BEP

standard VFD with embedded algorithms to monitor the pumps health and to provide protection from process upsets. The operating manual is written in easy to understand language with the pump operator in mind. The intelligence is only enabled if you choose to do so. Similar to a cell phone, there are many useful functions that are only employed if and when needed. Conclusion In spite of the operating and economic benefits, there are many hurdles to implementing VFD technology. Among these constraints is the lack of awareness among plant engineering, operating and maintenance staffs of this approach for pump control. The myths and legends surrounding VFD technology and its application further exacerbate the situation. There is one overriding issue to understand. Pump and valve performance can make or break your bottom line. For the most part, the enormous cost of inefficient pump operation and valve throttling goes unnoticed. Its time to sort thorough the myths and legends surrounding variable speed pumping in order to reveal its wonders and transforming power. I

Reliability Savings Potential Variable speed operation contributes to reliability improvements by allowing the pump to operate at slower speeds, near the best efficiency point (BEP) with a 25% trimmed impeller. Operation more than +/- 10% away form the pumps BEP significantly lowers its reliability. Although often overlooked, the excess energy in fixed-speed systems is being dissipated into the infrastructure and can lower equipment life. This energy may transmute into vibration that can damage the pumping system including the pipes, instruments and valves. Intelligent Pumps In recent years automation suppliers have introduced smart instruments and valves.

Pump suppliers now offer a smart pump, i.e. a standard VFD with embedded pump intelligence. This advent represents the next logical step in the evolution of intelligent field devices. With the growing use of digital field buses to communicate between smart devices and process control system, equipment health can be sent to asset management software in real-time. An intelligent pump can be seamlessly integrated into the process control system architecture. The perception may exist that a VFD with pump intelligence is highly customized and complicated to implement and use. Yet, the opposite is true. An intelligent pump is a

Personnel Moves

Marketing Appointments Announced John Manna, Vice President of Global Marketing, announced the promotion of two marketing executives to key positions in his organization. David E. Flinton was elevated to the position of Product Dave Flinton Marketing Manager for the Seneca Falls Operations and Erik Torseke has been appointed Director of Performance Solutions. Flinton joined ITT A-C Pump in 1997 and has held several positions of increased responsibility including Double Suction Product Manager and Water & Wastewater Industry Marketing Manager. Dave holds a Bachelors Degree in Mechanical Engineering from Worcester Polytechnic Institute and an MBA from the Simon School at University of Rochester. John Manna stated, To improve our global marketing coordination and effectiveness, I am consolidating the Seneca Falls based product marketing organizations. Dave will be developing and leading this important organization. Manna continued, As we continue to develop products that incorporate new-age technologies, it is important to have one person focused on planning and implementing successful development and launch strategies. Erik Torseke will lead these exciting new projects, positioning ITT and its brands as the technology leaders. Torseke joined ITT Goulds last year after many years of experience with ABB as a project manager, sales & marketing manager, general manager and senior marketing and business development Erik Torseke manager. He brings with him a wealth of experience and knowledge. A graduate of Uppsala University in Sweden, Torseke holds a Bachelors Degree in Industrial Marketing and also a technology degree in Mechanical Engineering. Jose Gutierrez has been appointed Marketing & Engineering Manager for Goulds Vertical Pump Operation in City of Industry, California. Jose graduated from the National University of Jose Gutierrez Mexico with a Bachelors Degree in Mechanical Engineering. He also holds a MS in Hydraulics and an MBA from the Tecnologico of Monterrey. He comes to us with more than 20 years of Engineering and Management experience. Jose has also worked many years in other capacities such as Quality, Engineering, Customer Service and Product Development. He spent 17 years working at Flowserve, Mexico, manufacturing vertical, cantilever, boiler feed, and multistage pumps for the petroleum, power, water and general Industry. In 2000, he was transferred to Flowserve Vernon, CA where he held the position of Engineering and Technical Services Manager for commercial and nuclear products. In addition, he was nominated as Lead of Between Bearing Products for the Americas. Joses years of experience will make him a valuable asset in helping to service the needs of our Vertical Pump customers. I

You might also like

- Thomas Calculus 11th (Textbook + Solutions)Document140 pagesThomas Calculus 11th (Textbook + Solutions)Sendhilkumar Alalasundaram76% (33)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- 022 Instrumentation & Electronics (JAA ATPL Theory)Document733 pages022 Instrumentation & Electronics (JAA ATPL Theory)Wd Shaant100% (1)

- Condensate Water RecoveryDocument4 pagesCondensate Water RecoveryTy Smith100% (2)

- Perkins 1500Document2 pagesPerkins 1500Andry HikariNo ratings yet

- Fulltext01 PDFDocument64 pagesFulltext01 PDFdexiNo ratings yet

- Central Battery Systems ExplainedDocument26 pagesCentral Battery Systems ExplainedHassan FarazNo ratings yet

- Control Valve SourcebookDocument5 pagesControl Valve Sourcebookpneuma110No ratings yet

- Jan 2018 - Data Center Continuous (DCC) Ratings - A Comparison of DCC Ratings, IsO Definitions and Uptime RequirementsDocument4 pagesJan 2018 - Data Center Continuous (DCC) Ratings - A Comparison of DCC Ratings, IsO Definitions and Uptime RequirementsAngan KitaNo ratings yet

- Electrical Power System Fundamentals for Non-Electrical EngineersDocument42 pagesElectrical Power System Fundamentals for Non-Electrical EngineersMoeed IqbalNo ratings yet

- ALA 1 Chapter 9 - Fluid DynamicsDocument9 pagesALA 1 Chapter 9 - Fluid Dynamicsphoenix eastwoodNo ratings yet

- Usco PD V1 A1 22Document12 pagesUsco PD V1 A1 22baywatch80No ratings yet

- Danfoss AHU - 5Document16 pagesDanfoss AHU - 5J.P. PazaNo ratings yet

- Analysis of Air Conditioner Precision (PAC) Machine Using Overall Equipment Efectiveness (OEE) Method (Case Study at Data Center XYZ Company Jakarta)Document10 pagesAnalysis of Air Conditioner Precision (PAC) Machine Using Overall Equipment Efectiveness (OEE) Method (Case Study at Data Center XYZ Company Jakarta)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Design Gas LiftDocument5 pagesDesign Gas LiftRima Apriani JamilahNo ratings yet

- Understanding Pump Curves: Taco Radiant Made Easy Application Guide Technical DocumentsDocument4 pagesUnderstanding Pump Curves: Taco Radiant Made Easy Application Guide Technical DocumentsmohdnazirNo ratings yet

- Flow Measurement PDFDocument32 pagesFlow Measurement PDFmn_sundaraam100% (1)

- Pump EfficiencyDocument2 pagesPump EfficiencyRsn786No ratings yet

- Global Trend and Challenges to Internet Data Centre: High Energy Efficiency StrategiesDocument19 pagesGlobal Trend and Challenges to Internet Data Centre: High Energy Efficiency StrategiesYashveer TakooryNo ratings yet

- Intelligent Device Management Tutorial: CalibrationDocument16 pagesIntelligent Device Management Tutorial: Calibrationtrozn2812100% (1)

- Vertiv Ap Elevated Return Air Temperature - en - Asia 302442 0Document10 pagesVertiv Ap Elevated Return Air Temperature - en - Asia 302442 0YoYoRamezNo ratings yet

- Steam TheoryDocument44 pagesSteam TheoryProcess EngineerNo ratings yet

- Waste Heat Recovery Power GeneratorDocument20 pagesWaste Heat Recovery Power GeneratorPasquale Cutri100% (1)

- Smart TransmitterDocument53 pagesSmart TransmitterMuhammad FaizanNo ratings yet

- Distributed Pumping ConceptDocument52 pagesDistributed Pumping ConceptRichard Richard100% (1)

- Basics of Flow Measurement With The Orifice Flow MeterDocument14 pagesBasics of Flow Measurement With The Orifice Flow MeterBEN ADEGBULUNo ratings yet

- Pump Formulas - Imperial and SI Units: Pressure To HeadDocument9 pagesPump Formulas - Imperial and SI Units: Pressure To Headkesavaganesan58No ratings yet

- Design Considerations For Hydronic Pump System Design PDFDocument74 pagesDesign Considerations For Hydronic Pump System Design PDFFredie UnabiaNo ratings yet

- Petersenplgpckrcats PDFDocument112 pagesPetersenplgpckrcats PDFEdixon ZambranoNo ratings yet

- 1-HVAC Concepts and Fundamentals R1Document88 pages1-HVAC Concepts and Fundamentals R1Tony HuangNo ratings yet

- Orifice Assembly: Let The Restriction Do MeasurementDocument29 pagesOrifice Assembly: Let The Restriction Do MeasurementRajesh ViswanNo ratings yet

- Power+ A Parallel Redundant UPS - Uninterruptible Power SupplyDocument8 pagesPower+ A Parallel Redundant UPS - Uninterruptible Power SupplyGamatronicNo ratings yet

- Deluge ValveDocument3 pagesDeluge ValveFarhan AhmedNo ratings yet

- Industrial Instrumentation NotesDocument13 pagesIndustrial Instrumentation NotesArun RajeshNo ratings yet

- Hiway Gateway Specification and Technical Data: DetergantDocument6 pagesHiway Gateway Specification and Technical Data: Detergantthericksays7827No ratings yet

- CRANE BS&U Proportional Balancing GuideDocument37 pagesCRANE BS&U Proportional Balancing GuideAhmed MostafaNo ratings yet

- From Wikipedia, The Free EncyclopediaDocument6 pagesFrom Wikipedia, The Free Encyclopediapredic1No ratings yet

- Bending The RulesDocument2 pagesBending The RuleskikiuNo ratings yet

- Energy Efficient Building TechnologiesDocument41 pagesEnergy Efficient Building TechnologiesArundeep SinghNo ratings yet

- Energy Saving TipsDocument7 pagesEnergy Saving Tipsabhimanyu5001No ratings yet

- Scada Paper1Document8 pagesScada Paper1Edu EdyNo ratings yet

- Aspen Hysys Course W0orkDocument1 pageAspen Hysys Course W0orknwosu_dixonNo ratings yet

- Riesenberger J. and J. Koeller (2005) Commercial Laundry FacilitiesDocument30 pagesRiesenberger J. and J. Koeller (2005) Commercial Laundry FacilitiesTilakjiNo ratings yet

- Irrigation Pump VFD Energy Savings CalculationDocument15 pagesIrrigation Pump VFD Energy Savings CalculationRavindra Angal0% (1)

- Optimizing HVAC Water Pumping SystemsDocument49 pagesOptimizing HVAC Water Pumping SystemsVasanth KumarNo ratings yet

- Data Acquisition & SCADA SystemsDocument4 pagesData Acquisition & SCADA SystemsSneha MvNo ratings yet

- Energy Efficiency Tips for Facility ManagersDocument2 pagesEnergy Efficiency Tips for Facility ManagersRushikesh Uttamrao patilNo ratings yet

- Process Control SystemDocument8 pagesProcess Control SystemIno JohannisNo ratings yet

- Energy OptimizationDocument21 pagesEnergy OptimizationadnanNo ratings yet

- Chillers - CatalogDocument2 pagesChillers - Catalogdéborah_rosalesNo ratings yet

- Cooling Water Problems and SolutionsDocument56 pagesCooling Water Problems and SolutionsArselan Mustafa KhanNo ratings yet

- LT IDCBookextractDocument33 pagesLT IDCBookextractKurniawan SaputraNo ratings yet

- VSD Pumps Best PracticeDocument48 pagesVSD Pumps Best PracticebeechyNo ratings yet

- AIR SYSTEM BASICS: THE FUNDAMENTALSDocument11 pagesAIR SYSTEM BASICS: THE FUNDAMENTALSpbhat83No ratings yet

- 07Khp Water-Cooled Split Condensing Unit: InstallationDocument14 pages07Khp Water-Cooled Split Condensing Unit: InstallationAbel L. LopezNo ratings yet

- CFD Simulation For Charging and Discharging Process of Thermal Energy Storage System Using Phase Change MaterialDocument8 pagesCFD Simulation For Charging and Discharging Process of Thermal Energy Storage System Using Phase Change MaterialInnovative Research PublicationsNo ratings yet

- Evaporative Cooling SystemDocument8 pagesEvaporative Cooling SystemAshok KumarNo ratings yet

- Pump Control With Variable Frequency Drives - Case Study: Hitachi America, Ltd.Document4 pagesPump Control With Variable Frequency Drives - Case Study: Hitachi America, Ltd.Hitachi America, Ltd., Industrial Components and Equipment DivisionNo ratings yet

- To VFD or To FCVDocument7 pagesTo VFD or To FCVAmit SarkarNo ratings yet

- Efficient AC Drives: Yaskawa Electric America, IncDocument4 pagesEfficient AC Drives: Yaskawa Electric America, IncRajashekar LokamNo ratings yet

- #A-Direct VFD ConsiderationsDocument8 pages#A-Direct VFD ConsiderationsCyrix.OneNo ratings yet

- Main Steam Turbine Controls Retrofit ISA FinalDocument13 pagesMain Steam Turbine Controls Retrofit ISA Finalvankayalasurya100% (1)

- Metering Pumps - A New DefinitionDocument3 pagesMetering Pumps - A New DefinitionMoises JonesNo ratings yet

- Separator Drain Traps - Eaton Corporation - FiltrationDocument2 pagesSeparator Drain Traps - Eaton Corporation - FiltrationMONANo ratings yet

- 66B Breathing AirDocument11 pages66B Breathing AirMONANo ratings yet

- Cursive 48 RefDocument1 pageCursive 48 RefMONANo ratings yet

- Cursive 36 RefDocument1 pageCursive 36 RefMONANo ratings yet

- Energy Saving in The Filtration and Drying of Compressed AirDocument31 pagesEnergy Saving in The Filtration and Drying of Compressed AirMONANo ratings yet

- 488109Document4 pages488109MONANo ratings yet

- Technical Data on Gas Liquid SeparatorsDocument4 pagesTechnical Data on Gas Liquid SeparatorsMONANo ratings yet

- Best Practices For Condensate Removal On Steam Lines - TLVDocument5 pagesBest Practices For Condensate Removal On Steam Lines - TLVMONANo ratings yet

- Installation Instructions - GeneralDocument4 pagesInstallation Instructions - GeneralMONANo ratings yet

- A032 035Document4 pagesA032 035MONANo ratings yet

- 66B Breathing AirDocument11 pages66B Breathing AirMONANo ratings yet

- Optimum Design of Reciprocating CompressorsDocument6 pagesOptimum Design of Reciprocating Compressors최승원No ratings yet

- Type DTL DryDocument6 pagesType DTL DryMONANo ratings yet

- ChromAccessories GCAcc GasPurifiersNTraps P268to275Document8 pagesChromAccessories GCAcc GasPurifiersNTraps P268to275MONANo ratings yet

- 20450Document8 pages20450MONANo ratings yet

- Compressed Air System Design ManualDocument26 pagesCompressed Air System Design ManualBadrul HishamNo ratings yet

- Chilled Water System Installation Operation Maintenance Manual 2811 15340Document36 pagesChilled Water System Installation Operation Maintenance Manual 2811 15340MONANo ratings yet

- 00620Document14 pages00620MONANo ratings yet

- Odwadniacz Plywakowy UNA 13 P (INS) (En)Document14 pagesOdwadniacz Plywakowy UNA 13 P (INS) (En)MONANo ratings yet

- Install Water Heater Indoors Away From FlammablesDocument28 pagesInstall Water Heater Indoors Away From FlammablesMONANo ratings yet

- Document Information Pages (List of NFPA Codes & Standards)Document16 pagesDocument Information Pages (List of NFPA Codes & Standards)MONANo ratings yet

- PVV 540 PumpDocument14 pagesPVV 540 PumpMONANo ratings yet

- Install Water Heater Indoors Away From FlammablesDocument28 pagesInstall Water Heater Indoors Away From FlammablesMONANo ratings yet

- Aspen Exchanger Design and Rating V7.3.2: Release NotesDocument42 pagesAspen Exchanger Design and Rating V7.3.2: Release NotesMONANo ratings yet

- Pump Different FluidsDocument5 pagesPump Different FluidsMONANo ratings yet

- Pump OperationsDocument1 pagePump OperationsMONANo ratings yet

- Tgifb 4Document20 pagesTgifb 4MONANo ratings yet

- TLV JA3 Air Drain TrapDocument2 pagesTLV JA3 Air Drain TrapMONANo ratings yet

- Maintenance Tips For Heat ExchangerDocument4 pagesMaintenance Tips For Heat ExchangerMONANo ratings yet

- Appendix 2CDocument159 pagesAppendix 2Crmm99rmm99No ratings yet

- IEGCDocument80 pagesIEGCMonika SharmaNo ratings yet

- 2600: The Hacker Quarterly (Volume 7, Number 1, Spring 1990)Document48 pages2600: The Hacker Quarterly (Volume 7, Number 1, Spring 1990)Ranko KohimeNo ratings yet

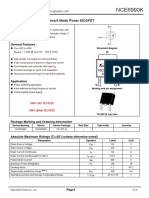

- NCE6990K: NCE N-Channel Enhancement Mode Power MOSFETDocument7 pagesNCE6990K: NCE N-Channel Enhancement Mode Power MOSFETpepenitoNo ratings yet

- 1 HPPDocument36 pages1 HPPAutomation WorksNo ratings yet

- R-30iA KAREL Operation Manual Reference (B-83144EN-1 01) PDFDocument510 pagesR-30iA KAREL Operation Manual Reference (B-83144EN-1 01) PDFfrederic190pNo ratings yet

- Manual Book Oriental MotorDocument4 pagesManual Book Oriental MotorPepi SupriatnaNo ratings yet

- As 60068.2.68-2003 Environmental Testing Tests - Test L - Dust and SandDocument8 pagesAs 60068.2.68-2003 Environmental Testing Tests - Test L - Dust and SandSAI Global - APAC50% (2)

- Mini Project of Paper BatteryDocument22 pagesMini Project of Paper BatteryvamsiNo ratings yet

- Inventory list of electronic equipment and accessoriesDocument2 pagesInventory list of electronic equipment and accessoriessmuralirajNo ratings yet

- Dse402mk11 Data SheetDocument2 pagesDse402mk11 Data Sheetgigo_dreamNo ratings yet

- Guidelines PHD Admission 20153Document8 pagesGuidelines PHD Admission 20153manish_chaturvedi_6No ratings yet

- Polyphase RectifierDocument4 pagesPolyphase RectifierGlenda Grageda100% (1)

- máy cắt sf6 abbDocument7 pagesmáy cắt sf6 abbQuảng Thành NamNo ratings yet

- IEEE STD ANSI-IEEE STD 1004-1987Document14 pagesIEEE STD ANSI-IEEE STD 1004-1987abdou samiNo ratings yet

- 1 Icol Trading Product ListDocument8 pages1 Icol Trading Product ListRichard RegidorNo ratings yet

- Passenger Lift: Type: Machine Room Gearless MachineDocument5 pagesPassenger Lift: Type: Machine Room Gearless Machineandri kustiawanNo ratings yet

- 2G CMDDocument3 pages2G CMDأبوعمر الفاروق عبدالرحمنNo ratings yet

- A 65nm CMOS Ultra Low Power and Low Noise 131M Front-End Transimpedance AmplifierDocument5 pagesA 65nm CMOS Ultra Low Power and Low Noise 131M Front-End Transimpedance AmplifierBerry KueteNo ratings yet

- Understanding and Testing The Negative-Sequence Directional ElementDocument12 pagesUnderstanding and Testing The Negative-Sequence Directional ElementJosé Miguel Ochoa AcerosNo ratings yet

- Gt5a604 PDFDocument19 pagesGt5a604 PDFArnaud BegueNo ratings yet

- Atv32 PDFDocument40 pagesAtv32 PDFRavi NegiNo ratings yet

- Lab Report Process (Repaired)Document16 pagesLab Report Process (Repaired)amirulNo ratings yet

- PLC Training ManualQ Series Basic Course (For GX Developer) EDocument374 pagesPLC Training ManualQ Series Basic Course (For GX Developer) EHamdan AbdurrahmanNo ratings yet

- Gs Ds Nanocom Ax100 33Document27 pagesGs Ds Nanocom Ax100 33Damas WangsaNo ratings yet

- Xii Derivation List-2023-24 2Document3 pagesXii Derivation List-2023-24 2prachurjyapadhiNo ratings yet

- Nota Padat Fizik F5 ElectronicDocument21 pagesNota Padat Fizik F5 Electronicslokkro100% (24)

- Operations ResearchDocument37 pagesOperations ResearchShashank BadkulNo ratings yet