Professional Documents

Culture Documents

Coating - Wikipedia, The Free Encyclopedia

Uploaded by

didodido_67Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coating - Wikipedia, The Free Encyclopedia

Uploaded by

didodido_67Copyright:

Available Formats

Coating

From Wikipedia, the free encyclopedia

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate. In many cases coatings are applied to improve surface properties of the substrate, such as appearance, adhesion, wetability, corrosion resistance, wear resistance, and scratch resistance. Some new coatings formulated using nanotechnology promise to create long-term surface protection.[1] In other cases, in particular in printing processes and semiconductor device fabrication (where the substrate is a wafer), the coating forms an essential part of the finished product. Coating and printing processes involve the application of a thin film of functional material to a substrate, such as paper, fabric, film, foil, or sheet stock. This article discusses what is frequently termed "roll-to-roll" or "web-based" coating. A roll of substrate, when wound through the coating machine, is typically called a web. Coatings may be applied as liquids, gases or solids. Coatings can be measured and tested for proper opacity and film thickness by using a drawdown card.

Contents

1 Functions 2 Coating processes 2.1 Chemical vapor deposition 2.2 Physical vapor deposition 2.3 Chemical and electrochemical techniques 2.4 Spraying 2.5 Optical coatings 2.6 Other 2.7 Roll-to-roll coatings 3 Standards 4 See also 5 References

Functions

Printing (text or decoration) such as on paper, fabric, and flexible packaging. As used in the converting industry. Self adhesive properties such as for tape, labels, and packaging Melt-adhesive properties such as for vacuum seal and heat seal applications "Release" coatings such as the liner of a double-sided tape or vinyl stickers Low surface energy coatings to act as a non-stick surface Optical properties such as tint, color, anti-reflection, and holographics Photo-sensitivity such as for photographic film and paper Electronic properties such as passivity or conduction as with flexible circuits Magnetic properties such as for magnetic media like cassette tapes and floppy disks Water-resistant or waterproof coatings, such as for fabrics or paper, or on wood surfaces such as outdoor furniture, patio decks, yacht hulls, and decks Scent properties such as scratch and sniff stickers and labels

Coating processes

Coating processes are classified as follows:

Chemical vapor deposition

Main article: Chemical vapor deposition Metalorganic vapour phase epitaxy Electrostatic spray assisted vapour deposition (ESAVD)

Physical vapor deposition

Main article: Physical vapor deposition Cathodic arc deposition Electron beam physical vapor deposition (EBPVD) Ion plating Ion beam assisted deposition (IBAD) Magnetron sputtering Pulsed laser deposition Sputter deposition Vacuum deposition Vacuum evaporation, evaporation (deposition)

Chemical and electrochemical techniques

Anodising Conversion coating Anodizing Chromate conversion coating Plasma electrolytic oxidation Phosphate (coating) Ion beam mixing Pickled and oiled, a type of plate steel coating Plating Electroless plating

Electroplating Sol-gel

Spraying

High velocity oxygen fuel (HVOF) Plasma spraying Thermal spraying Plasma transferred wire arc thermal spraying

Optical coatings

Main article: optical coating Antireflection coating, to reduce reflection A mirror coating to enhance it

Other

Dip-coating Epitaxy (vapor phase, liquid phase) Vitreous enamel Paint Enamel paint Silicate mineral paint Polymer coatings, such as Teflon Powder coating or Powder slurry coating Fusion bonded epoxy coating (FBE coating) Molecular beam epitaxy Sheradizing Spin coating Paper coating Industrial coating

Roll-to-roll coatings

Common roll-to-roll coating processes include: Air knife coating Anilox coater Curtain Coating Single and Multilayer Slide Coating Flexo coater Gap Coating Gravure coating Hot Melt coating Immersion (dip) coating Knife-over-roll coating Metering rod (Meyer bar) coating Reverse Roll coating Roller coater Rotary screen Silk Screen coater Slot Die (Extrusion) coating[2] The main coating and varnishes for the printing industry include: Overprint varnish Water based coating Acrylic based Solvent based Aqueous coating UV Coating - curing (chemistry)

Standards

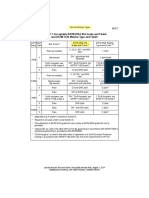

ISO 1461 Hot dip galvanized coatings on fabricated iron and steel articlesSpecifications and test methods ISO 4042 FastenersElectroplated coatings ISO 10683 FastenersNon-electrolytically applied zinc flake coatings ISO 10684 FastenersHot dip galvanized coatings ISO 12944 Paints and varnishesCorrosion protection of steel structures by protective paint systemsPart 6: Laboratory performance test methods

See also

Adhesion Tester Deposition Formulations Optically active additive, for inspection purposes after a coating operation Plastic film Printed electronics Seal (mechanical) Thermal barrier coating

Thin-film deposition

References

1. ^ "The Benefits of Nano Coatings" (http://www.nanoshell.co.uk/performance-coating-benefits) (in English). nanoShell Ltd. http://www.nanoshell.co.uk/performance-coating-benefits. Retrieved 3 January 2013. 2. ^ http://www.packaging-int.com/video/Slot-Curtain-Coating.html Slot die coating animations

Titanium and titanium alloys, edited by C. Leyens and M. Peters, Wiley-VCH, ISBN 3-527-30534-3, table 6.2: overview of several coating systems and fabriction processes for titanium alloys and titanium aluminides (amended) Coating Materials for Electronic Applications: Polymers, Processes, Reliability, Testing by James J. Licari; William Andrew Publishing, Elsevier, ISBN 0-8155-1492-1 Retrieved from "http://en.wikipedia.org/w/index.php?title=Coating&oldid=540350098" Categories: Coatings Corrosion Materials science Printing This page was last modified on 25 February 2013 at 20:28. Text is available under the Creative Commons Attribution-ShareAlike License; additional terms may apply. See Terms of Use for details. Wikipedia is a registered trademark of the Wikimedia Foundation, Inc., a non-profit organization.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bill of Materials - Hernandez ResidenceDocument5 pagesBill of Materials - Hernandez ResidenceVincent Jones KoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Building Material - PlasterDocument26 pagesBuilding Material - PlasterSaurav ShresthaNo ratings yet

- Vibration - Wikipedia, The Free EncyclopediaDocument7 pagesVibration - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- MBBR Tank Painting Cost EstimationDocument2 pagesMBBR Tank Painting Cost EstimationDiosdado Mingi Jr.No ratings yet

- Aircraft Painting and Finishing TechniquesDocument6 pagesAircraft Painting and Finishing TechniquesSarai ZúnigaNo ratings yet

- DGS 6600 010 Rev 2-48Document1 pageDGS 6600 010 Rev 2-48Mohamed NasifNo ratings yet

- Paint Problems Building Tech NotesDocument3 pagesPaint Problems Building Tech Notescorazon philNo ratings yet

- Reichhold: Coating Resins CatalogDocument35 pagesReichhold: Coating Resins CatalogAPEX SON100% (1)

- Vibration Isolation - Wikipedia, The Free EncyclopediaDocument5 pagesVibration Isolation - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Vibration Control - Wikipedia, The Free EncyclopediaDocument1 pageVibration Control - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Sealant - Wikipedia, The Free EncyclopediaDocument2 pagesSealant - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Shrink Wrap - Wikipedia, The Free EncyclopediaDocument2 pagesShrink Wrap - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Popular Cat Names - Wikipedia, The Free EncyclopediaDocument4 pagesPopular Cat Names - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Shock Absorber - Wikipedia, The Free EncyclopediaDocument3 pagesShock Absorber - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Snap Freezing - Wikipedia, The Free EncyclopediaDocument1 pageSnap Freezing - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Plate Theory - Wikipedia, The Free EncyclopediaDocument9 pagesPlate Theory - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Shock Mount - Wikipedia, The Free EncyclopediaDocument1 pageShock Mount - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Plastic Film - Wikipedia, The Free EncyclopediaDocument2 pagesPlastic Film - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Earthquake Resistant Structures - Wikipedia, The Free EncyclopediaDocument3 pagesEarthquake Resistant Structures - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Plastic - Wikipedia, The Free EncyclopediaDocument6 pagesPlastic - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Purine ListDocument9 pagesPurine Listdidodido_67No ratings yet

- Pressure Measurement - Wikipedia, The Free EncyclopediaDocument7 pagesPressure Measurement - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Kelvin - Wikipedia, The Free EncyclopediaDocument3 pagesKelvin - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Paint - Wikipedia, The Free EncyclopediaDocument5 pagesPaint - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Flash Freezing - Wikipedia, The Free EncyclopediaDocument1 pageFlash Freezing - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Geotechnical Engineering - Wikipedia, The Free EncyclopediaDocument8 pagesGeotechnical Engineering - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Glossary of Physics - Wikipedia, The Free EncyclopediaDocument13 pagesGlossary of Physics - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Blast Chilling - Wikipedia, The Free EncyclopediaDocument1 pageBlast Chilling - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Deformation (Engineering) - Wikipedia, The Free EncyclopediaDocument2 pagesDeformation (Engineering) - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Food Storage - Wikipedia, The Free EncyclopediaDocument1 pageFood Storage - Wikipedia, The Free Encyclopediadonodoni0008No ratings yet

- Heat Sealer - Wikipedia, The Free EncyclopediaDocument2 pagesHeat Sealer - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Damping - Wikipedia, The Free EncyclopediaDocument4 pagesDamping - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Bending of Plates - Wikipedia, The Free EncyclopediaDocument11 pagesBending of Plates - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Bending - Wikipedia, The Free EncyclopediaDocument6 pagesBending - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- Base Isolation - Wikipedia, The Free EncyclopediaDocument2 pagesBase Isolation - Wikipedia, The Free Encyclopediadonodoni0008No ratings yet

- Cat - Wikipedia, The Free EncyclopediaDocument13 pagesCat - Wikipedia, The Free Encyclopediadidodido_67No ratings yet

- 2019-10 Combo SW130 CopperJadeDocument2 pages2019-10 Combo SW130 CopperJadeVasiliy DyominNo ratings yet

- Ultra Petronne Interior Supply Corporation - Boards Price ListDocument1 pageUltra Petronne Interior Supply Corporation - Boards Price ListAlberto Dorupa50% (2)

- Oil Painting and Painting WorksDocument4 pagesOil Painting and Painting WorksdigvijayjagatapNo ratings yet

- RCSC Table 2.1 Nut and Washer TypesDocument1 pageRCSC Table 2.1 Nut and Washer TypesAdam JonesNo ratings yet

- Common Metal Surface Coating Methods ExplainedDocument10 pagesCommon Metal Surface Coating Methods ExplainedShristi Singh100% (1)

- Efficient Ship Maintenance with Brush and RollerDocument4 pagesEfficient Ship Maintenance with Brush and RollerTOLLAUT DESIGNNo ratings yet

- Specification 908 Anti-Graffiti - Approved Anti-Grafitti Coatings - 13Sept2016.RCN-D162358064Document1 pageSpecification 908 Anti-Graffiti - Approved Anti-Grafitti Coatings - 13Sept2016.RCN-D162358064K H V V MADUSHANKANo ratings yet

- Approved Tier - 2 SupplierDocument3 pagesApproved Tier - 2 SupplierMariyappanNo ratings yet

- Mto Iso R0Document77 pagesMto Iso R0sairam2234No ratings yet

- Aaum Residency - Apex UltimaDocument1 pageAaum Residency - Apex UltimaBhavin JaniNo ratings yet

- What Is A Paint PrimerDocument5 pagesWhat Is A Paint PrimerJaspreet singh nagpalNo ratings yet

- Jotafix System Brochure - tcm78 140617Document3 pagesJotafix System Brochure - tcm78 140617hdtucuNo ratings yet

- Painting Process Flow DiagramDocument1 pagePainting Process Flow DiagramMuthusamy Ayyanapillai0% (1)

- Protective Coating System According To ISO 12944-5: Technology To Rely OnDocument2 pagesProtective Coating System According To ISO 12944-5: Technology To Rely OnjayakumarNo ratings yet

- Nerolac PaintsDocument4 pagesNerolac PaintsNitin RaiNo ratings yet

- Hempel DeclarationofconformityDocument9 pagesHempel DeclarationofconformitySinisa Ćićo RuskicNo ratings yet

- A&B Official Pricelist 2019 - Parex - 1550567379Document2 pagesA&B Official Pricelist 2019 - Parex - 1550567379Daren TalanaNo ratings yet

- Complete Guide to Electroplating, Phosphating, Powder Coating and Metal FinishingDocument10 pagesComplete Guide to Electroplating, Phosphating, Powder Coating and Metal Finishingmiguelin9169No ratings yet

- Paint As A Building MaterialDocument32 pagesPaint As A Building MaterialJohn MorganNo ratings yet

- Harga SatuanDocument115 pagesHarga Satuanendi_putra_1No ratings yet

- Product CatalogDocument31 pagesProduct Catalogapi-309439120No ratings yet

- Paints and CoatingsDocument22 pagesPaints and CoatingsFatima LiaquatNo ratings yet

- DIY - Best Paint For Kitchen CabinetsDocument5 pagesDIY - Best Paint For Kitchen CabinetsJelaiNo ratings yet