Professional Documents

Culture Documents

Methodology For Increase The Rating of Overhead Lines

Uploaded by

Hariprasad gantyalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Methodology For Increase The Rating of Overhead Lines

Uploaded by

Hariprasad gantyalaCopyright:

Available Formats

2005 IEEE. Personal use of this material is permitted.

Permission from IEEE must be obtained for all other uses, in any current or future media, including reprinting/republishing this material for advertising or promotional purposes, creating new collective works, for resale or redistribution to servers or lists, or reuse of any copyrighted component of this work in other works.

Methods for Increasing the Rating of Overhead Lines

I. Albizu, A. J. Mazn, I. Zamora

AbstractAt the present time, there is great pressure to increase the power flow in existing right of ways using existing infrastructure as far as possible. In this paper, the diverse options for increasing the rating of overhead lines are presented and analyzed. By means of a comparative study, their advantages and drawbacks are highlighted. In addition, the factors that determine the choice of the method are analyzed. Index Termsoverhead line, ampacity, thermal rating, upgrading, uprating.

I. INTRODUCTION HE power flow in electrical lines has increased considerably in recent times. There are several reasons for this increase. Firstly, the technological growth and the increase of the quality-of-life have led to a growing demand for electrical power. Secondly, the deregulation of the electrical generation and the consequent changes on generation connected to the transmission system has caused major changes in the power flows across transmission lines. In addition, embedded generation connected directly to the distribution network impacts on the power flow across the distribution system. As a result of the increased power flow, some lines can be close to its ampacity limit. As defined in [1], the ampacity or thermal rating is that current which will meet the design, security and safety criteria of a particular line on which the conductor is used. An excessive conductor temperature may give rise to an excessive elongation of the conductor with consequent dangerous reduction of the clearances to ground. In addition it also could produce annealing and high temperature creep of the conductor and a decrease of the capability of compression joints. All these effects caused by an excessive current could put public safety at risk. In order to cope with this problem new lines could be installed. However, the high population density, the intensive use of land and the increasing rejection of new electrical installations determine that a small amount of space is available to be dedicated to electrical lines. As a consequence, legislations ruling the construction of overhead lines establish a great number of previous steps such as permissions, public presentation of the project, rights for the presentation of allegations, etc. Hence, the elapsed time since the need for the

installation of a line arises until the line is finally commissioned can easily be a decade or longer. Therefore, there is great pressure to increase the power flow in existing right of ways using existing infrastructure as far as possible. Traditionally, the upgrading of the line has been used in order to increase the line rating. The upgrading involves increasing the line voltage or the number of conductors. The main drawback of these methods is the need to strengthen the towers. For this reason, methods without the need to strengthen the towers that allow to increase line power flow securely and safely, close to its ampacity limit, have been developed. Among these methods, probabilistic methods and real time monitoring can be found. Another option is to increase the ampacity of the line by conductor replacement. The new conductor needs to have better properties, such as lower sagtemperature relation. In this paper, the diverse options for increasing the rating of overhead lines are presented and analyzed. By means of a comparative study, their advantages and drawbacks are highlighted. II. UPGRADING OF OVERHEAD LINES Upgrading strategies of overhead lines are divided into two types of methods for increasing the rating: Increase of ampacity Increase of voltage The rating increase by the increase of ampacity does not affect the line voltage. The value that is increased is the line maximum current, without decreasing safety. Traditionally, the increase in current has been achieved increasing the conductor section by the increase of the number of conductors per phase. The rating increase by the increase of voltage is based on the line rated voltage increase. This method allows a considerable rating increase. A. Increase of Conductor Section The increase of conductor section reduces the electrical resistance. As a consequence, for a certain current value, the heat dissipated due to Joule effect is reduced. In other words, in order to dissipate the same amount of heat, it is needed a

I. Albizu, A. J. Mazn and I. Zamora are with the Department of Electrical Engineering, The University of the Basque Country, Bilbao (e-mail:

higher current value. Hence, the ampacity is increased. In order to increase the conductor section it can be replaced by another of larger section. However, the usual solution is to increase the number of conductors per phase. Examples of the increase of the conductor section are described in [2,3]. These examples correspond to different countries such as Germany [2] and Spain [3] and are shown in Table I.

TABLE I CASES OF INCREASE OF CONDUCTOR SECTION Case S1 [2] S2 [3] Voltage (kV) 380 132 Original Conductor 2 ACSR 560/50 1 ACSR Hen New Conductor 4 ACSR 265/35 2 ACSR Hawk

forces increase a 13 % and for this reason new angle profiles are installed for complete tower legs. 3) Foundation Reinforcement The foundation requires also to be checked due to the increase of forces. Both in case S1 and S2, the foundations need to be reinforced. In the case S2 a calculation method is used to estimate the reinforcement need. In the case S1, the foundations are physically tested to achieve better results. B. Increase of Line Voltage If the current value of a line is close to the ampacity limit, the increase of line voltage reduces the current value for the same transmitted power. Hence, the margin with respect to the ampacity limit is increased. However, the cost of the voltage increase is high. The electrical isolation has to be increased and the towers and foundations need to be reinforced. Besides the changes in the line, the substation equipment also has to be adapted to the higher voltage. For this reason, the increase of rating by the increase of voltage has to be analyzed exhaustively in order to determine its feasibility [4]. Examples of application of increase of line voltage are described in [2,5,6]. These examples correspond to different countries such as USA [5,6] and Germany [2] and are shown in Table III. When the line voltage is increased, it is usual to increase the conductor section as well, in order to achieve a larger increase of rating. This can be observed in the cases shown in Table III.

TABLE III CASES OF INCREASE OF LINE VOLTAGE

Case V1 [5] V2 [6] V3 [6] V4 [6] V5 [6] V6 [2] V7 [2] Original Voltage (kV) 115 115 230 230 230 220 220 New Voltage (kV) 230 230 345 345 500 380 380 Original Conductor 1 ACSR 266,8 kcmil 26/7 1 ACSR 954 kcmil 54/7 1 ACSR 1272 kcmil 45/7 1 ACSR 1272 kcmil 45/7 2 ACSR 240/40 2 ACSR 240/40 New Conductor 1 ACSR 795 kcmil 24/7 The same 2 ACSR 1272 kcmil 45/7 2 ACSR 1272 kcmil 45/7 3 ACSR/TW 1565 kcmil 36/7 3 ACSR 340/30 3 ACSR 340/30

In Table II, the rating increase and the saving with respect to the investment in a new line are shown.

TABLE II RATING INCREASE AND SAVING WITH RESPECT TO A NEW LINE Case S1 [2] S2 [3] Rating Increase (%) 31 100 Saving with respect to a New Line (%) 53 -

The conductor replacement results in some changes in the insulators, the towers and the foundations. The insulators have to be adapted to the new conductor configuration. The increase in section results in an weight increase. For this reason, the mechanical requirement of the towers is increased and it is usual the need for tower and foundation reinforcement. 1) Insulators When the number of conductors is increased, the bundle swinging increased and the existing horizontal distances may not be enough to guarantee the safety. If it is necessary to respect the right-of-way and it is not possible to increase horizontal distances, a system that limits the lateral swinging is used. This is the case of example S1, where an asymmetric V-type insulator is installed in order to limit the lateral swinging of the new quad bundle conductor. 2) Tower Reinforcement The increase of the mechanical requirement of the towers forces to the analysis of their capacity. In case that the capacity of the tower is exceeded it has to be reinforced. If the reinforcement is not enough, the tower is replaced. In the case S2, the lattice towers need to be reinforced. The bracing of the lower diaphragms is carried out to prevent the steel members from buckling. In the suspension towers, double angle members are installed in the legs of the lower panel. In the angle and tension towers, double angle members are installed for complete tower legs and some diagonal members are replaced in the upper part of the body. In a similar way, in the case S1, the lattice towers are reinforced. The compression

In Table IV, the rating increase and the saving with respect to the investment in a new line are shown.

TABLE IV RATING INCREASE AND SAVING WITH RESPECT TO A NEW LINE Case V2 [6] V3 [6] V4 [6] V5 [6] V6 [2] V7 [2] Rating Increase (%) 217 200 Saving with respect to a New Line (%) 40 45 45 50 32 42

iepalfli@bi.ehu.es, iepmasaj@bi.ehu.es, iepzabei@bi.ehu.es)

1) Insulators Due to the increase of line voltage, the electrical isolation has to be increased. The use of longer insulators reduce the vertical distance between conductors and ground. In order to compensate this effect, the conductor connection point can be raised (cases V1, V2, V5), or the conductor tension can be increased. In order to raise the conductor connection point some changes in the structure are needed. The increase of conductor tension increases the forces in the tower and the foundations. In addition, due to the increases in voltage and isolator length, the distances between phases and between phases and tower may be not enough to guarantee the safety. For this reason, in cases V2-V6, I-strut or V-string isolators are used in order to limit conductor movement. 2) Tower Reinforcement The increase of the mechanical requirement of the towers forces to the analysis of their capacity. In case that the capacity of the tower is exceeded it has to be reinforced. If the reinforcement is not enough, the tower is replaced. In case V1, the top of the wooden tower structure, the X-braces and the tower base have been reinforced. In case V2, some suspension towers have been replaced by new ones and other ones have been replaced by tension towers. In addition, more tension towers have been installed to reinforce the line. In case V4, the number of legs of the lattice tower has been increased to six legs. Besides, some angle and tension towers have been replaced. In case V5, the towers also have been reinforced and some angle and tension towers have been replaced as well. 3) Foundation Reinforcement The foundation requires also to be checked due to the increase of forces. In case V5 most of the foundation have been replaced by new ones. In case V6, the foundations have been reinforced. 4) Electrical Field Another inconvenience of the voltage increase is related to the increase of electrical field and the risk of corona effect. The electrical field and corona noise values must comply with the existing regulations. The increase of the number of conductors of the conductor bundle helps to achieve this objective. III. MAXIMIZING LINE CURRENT In order to meet the design, security and safety criteria, the line current should be below the ampacity limit. The ampacity is a certain current that will result in the maximum allowable conductor temperature being reached. As defined in [1], the maximum allowable conductor temperature is the highest conductor temperature at which an overhead power line can be safely operated. This limit is usually caused by clearance limits and not by annealing. The temperature limit due to clearance limit is known as templating temperature. Once the maximum allowable conductor temperature is determined, the current that will result in this temperature value will depend on weather conditions such as wind speed and direction, ambient temperature and solar radiation. Therefore, the

ampacity is not a constant value as it depends on weather conditions. Traditionally, the ampacity or thermal rating is calculated using deterministic assumptions of high ambient temperature, full solar radiation and a low wind speed. This condition is defined as the worst weather case. However, since this weather condition occurs only rarely, the line is capable of carrying a higher current nearly all of the time. In other words, when the line current equals the static thermal rating, the line temperature will be below the maximum allowable temperature. For this reason, methods to increase the line current above the static thermal rating but below the actual ampacity have been developed. Some methods are based on statistical studies of weather data and load profiles in order to evaluate the probability of exceeding the ampacity value. Other methods calculate the real time ampacity by means of real time measurement of actual line temperature, tension or sag. A. Deterministic Method Taking into account the maximum allowable conductor temperature, the deterministic method calculates the line rating making assumptions of the wind direction, wind speed, ambient temperature and solar radiation. The ambient conditions to be used were determined in the sixties or seventies based on what was considered conservative at that time. No risk analysis was carried out. The calculations usually follow the CIGRE Standard method [7] or the closely related IEEE Standard [8]. Ratings are calculated using deterministic assumptions of full solar radiation, high ambient temperature and low wind speed. Most utilities assume wind speeds of 0.5-0.6 m/s. Some utilities, have recently increased the wind speed assumption to 0.9-1.2 m/s in order to increase the rating. This is often done without assessing the associated risk and as a consequence the temperature can go above the maximum allowable conductor temperature for short periods of time. Hence, annealing may occur on the line conductors and security clearance may be exceeded. B. Probabilistic Method Taking into account the actual weather conditions prevalent in the geographical area of the line, probabilistic methods determine, for a given current value, either the amount of time the maximum allowable conductor temperature will be exceeded or the risk of an unsafe condition arising. Some of these methods are described in [9]. Examples of application of probabilistic methods are shown in [10-12]. These examples correspond to different countries such as United Kingdom [10], USA [11], and Italy [12]. Results show that the probabilistic thermal rating is higher than the static thermal rating. Furthermore, the risk taken is controlled. The methods based on the amount of time the maximum temperature is exceeded determine the distribution of the ampacity, taking into account the distribution of the weather conditions during a period of time and the value of the

maximum allowable conductor temperature. The percentage of acceptable exceedence is defined and the probabilistic thermal rating obtained. A comprehensive example of this method is shown in [10]. In [11] this method has been applied for the determination of the probabilistic thermal rating for high voltage transmission lines. Choosing an exceedence of 1 % and changing the wind assumptions, an increase of around 15 % over the deterministic rate has been obtained. The methods based on the risk of an unsafe condition calculates the probability of risk for a given current value. The current value is changed until the probability value obtained equals the chosen value. In [12] a risk of 3.510-5 is adopted in order to obtain the probabilistic thermal rating. C. Real Time Monitoring Real time monitoring allows line operation close to the ampacity limit [13]. The use of real time monitoring can increase the thermal rating on an average of 10 %. Methods based on weather measurements [14] or conductor temperature monitoring [15,16] have been used. However, due to the uncertainties of these methods, modern methods are based on either tension [17,18] or sag [19] measurements. Examples that correspond to different countries, such as Spain [14], USA [15,17-19], Japan [16], New Zealand [17,18] and Denmark [18] are shown. 1) Weather Measurement This method uses weather and current measurements to calculate the conductor temperature. This temperature is used to determine the conductor sag value or it is compared with the maximum allowable temperature. The weather stations monitor the weather at a particular point. But the wind speed varies along the line, depending on the terrain and the sheltering objects. Hence, this methods give errors in sections remote from the weather station. Furthermore, when the wind speed is slow (critical condition), wind speed and direction measurements are inaccurate. The best results are obtained from ultrasonic anemometers. Another source of error is related to the uncertainties in the sag/temperature relationship. 2) Conductor Temperature Measurement Conductor temperature measurements are carried out by clamp-on sensors that transmit the data via radio. If the wind condition change along the line, the temperature in each section is different. Hence, the temperature should be measured in multiple locations in order to determine an average temperature. Anyway, as it has been mentioned, there is a source of error related to the uncertainties in the sag/temperature relationship. 3) Tension Measurement The tension is usually measured using a load cell in the strain assembly. The data are transmitted by cable or radio. The load cell is at ground potential. As there is a close relation between tension and sag, the tension measurement is a good indicator of the actual clearance. For this reason it is widely used by many utilities.

4) Sag Measurement The objective of the real time monitoring is to maintain the line above the security clearance. If it is possible to measure the sag directly, the errors associated to simplified assumptions are removed. A method of conductor position measurement has been proposed recently based on differential GPS (DGPS) technology [19]. It measures conductor position within 17 cm with 70 % confidence level. IV. INCREASE OF CONDUCTOR TEMPLATING TEMPERATURE The simplest way of increasing the ampacity of overhead lines is to increase the conductor templating temperature, that is to say, the maximum temperature related to the clearance to ground or crossings. This increase takes into account the capability of the conductor and its fittings to accommodate the higher temperature. In order to increase the clearance to ground, the height of the line can be increased with some minor physical modifications [20]. The techniques to increase the height of the line include re-tensioning the conductors or replacing the insulator strings. Another possibility is to increase tower height but this is an expensive option. As an example, in South Africa a 400 kV line of 50 C have been increased to 85 C with a rating increase of 60 % [20]. The cost was 5 % of the investment in new line. In the UK, ACSR lines of 50 C have been increased to 75 C with a rating increase of nearly 25 % [21]. V. REPLACEMENT BY LOW SAG CONDUCTOR Replacing the existing conductor by high-temperature lowsag conductors a considerable uprating is obtained without the need for strengthening the supports. With these conductors, the sag increases more slowly when the conductor temperature increases. Hence, for the same sag limit, they allow higher conductor templating temperature. The higher templating temperature allows a higher thermal rating. There are several types of conductors available (G(Z)TACSR, ACSS(/TW), (Z)TACIR, etc). Examples of uprating with G(Z)TACSR [22-24], ZTACIR [22] and ACSS/TW [25] show the validity of this method. In UK, the replacement by GZTACSR resulted in an increase of 130 % in a 400 kV line [23]. In Spain, the replacement by GTACSR results in an increase of 70 % in a 132 kV line [24]. In USA, the replacement by ACSS/TW could result in an increase of 70 % in a 138 kV line [25]. VI. CHOOSING BETWEEN THE DIFFERENT OPTIONS Choosing an appropriate method for uprating is a complicated process and the optimum choice varies from project to project [26]. Several factors have to be taken into account in order to choose the appropriate method. The condition of the existing assets, the characteristic of the rating constrain, the budgetary and time constraints and the availability of outages are factors that determine the method.

If the existing assets are due for refurbishment within a short time, the upgrading of the line or the conductor replacement could be a good choice for the uprating. In the case of new assets, these options result in early asset write-off costs. In this case, real time monitoring or the increase of conductor templating temperature could be used as an alternative at the expense of a smaller uprating. With respect to the size of the uprating, the methods differ considerably. The increase of voltage level is the method that achieves the highest rating increase. The increase of the conductor section or the replacement by low sag conductors achieve considerable increases as well. The increase of conductor templating temperature is not always possible and the increase obtained is more modest. Finally, the real time monitoring or the probabilistic methods are the methods that give the lowest uprating. Furthermore, the dynamic methods depend on the weather conditions and the enhancements cannot be guaranteed at any specific time. The changes required for the uprating are related to the cost, the time and the outages needed. The increase of voltage level is the method that the most changes requires in the line. Hence, it is the most expensive solution and it takes long. The increase of the conductor section requires many changes in the line as well. The increase of conductor templating temperature requires minor modifications. The replacement by low sag conductors involves the replacement of the conductors but it has the advantage that no modification of the towers is needed. Finally, the real time monitoring and the probabilistic methods do not require modification in the line. However the real time monitoring needs monitoring equipment with its associated communications equipment and sometimes requires outages to install. VII. CONCLUSIONS Options for the increase of the rating of overhead lines have been presented. The upgrading of overhead lines by the increase of conductor section or line voltage has been described. Methods to maximize the current values of the existing lines taking into account weather conditions have been analyzed as well. Finally, methods of uprating the lines have been presented. One method is based on the increase of the conductor templating temperature. Another uprating method is based on the conductor replacement by low-sag conductors. In addition, the factors that determine the choice of the appropriate method have been analyzed. Many factors have to be taken into account in order to choose the appropriate method and the optimum choice varies from case to case. VIII. REFERENCES

[1] [2] Conductors for the Uprating of Overhead Lines, CIGR V2-12 Brochure (Ref. No. 244), 2004. F. Kiessling, D. Hussels, C. Juerdens, J. Ruhnau, Upgrading highvoltage lines to increase their capacity and mitigate environmental impacts, CIGRE Session, 22-208, Paris-France, 1998.

[3]

[4]

D. Sanchez, C. Alonso, Increase in transmission capacity in highvoltage power lines on the Levante (Eastern Spain) coastal path, CIGR Session, V2-206, Paris-France, 2004. D.F. Shankle, Incremental voltage uprating of transmission lines, IEEE Transactions on Power Apparatus and Systems, Vol.PAS-90, No. 4, pp. 1791-95, 1971.

[5]

[6] [7] [8] [9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20] [21]

[22]

[23]

[24]

M. Broschat, Transmission-line uprating 115 kV to 230 kV - Report on operating performance, IEEE Transactions on Power Apparatus and Systems, Vol. PAS-91, No. 2, pp. 545-48, 1972. J.G. Hanson, Upgrading transmission lines, IEEE PES T&D Conference, pp. 824-27, Dallas-USA, 1991. Thermal behaviour of overhead conductors, CIGR 22-12 Brochure (Ref. No. 207), 2002. IEEE Std 738-1993, IEEE Standard for Calculating the CurrentTemperature Relationship of Bare Overhead Conductors, 1993. Working Group SC 22-12 Cigr (Chairman R. Stephen). Probabilistic determination of conductor current ratings, ELECTRA, No. 164, pp. 103-17, 1996. C.F. Price, R.R. Gibbon, Statistical approach to thermal rating of overhead lines for power transmission and distribution, IEE Proceedings Pt C, Vol. 130, No. 5, pp. 245-56, 1983. F.R. McElvain, S.S. Mulnix, Statistically determined static thermal ratings of overhead high voltage transmission lines in the Rocky Mountain region, IEEE Transactions on Power Systems, Vol. 15, No. 2, pp. 899-902, 2000. B. Cauzillo, L. Paris, G. Pirovano, Ampacity assessment of overhead line conductors as a compromise between safety and deregulated market requirements, CIGR Session, 22-206, Paris-France, 2002. R. Stephen, Description of state of the art methods to determine thermal ratings of lines in real-time and their application in optimising power flow, CIGR Session, 22-304, Paris-France, 2000. F. Soto, D. Alvira, L. Martn, J. Latorre, J. Lumbreras, M. Wagensberg, Increasing the capacity of overhead lines in the 400 kV Spanish transmission network: real time thermal ratings, CIGR Session, 22211, Paris-France, 1998. S.D. Foss, S.H. Lin, H.R. Stillwell, R.A. Fernandes, Dynamic thermal line ratings. Part II. Conductor temperature sensor and laboratory field test evaluation, IEEE Transactions on Power Apparatus and Systems, Vol. 102, No. 6, pp. 1865-76, 1983. K. Adachi, T. Kumeda, K. Nagano, A method for expanding the current capacity of overhead transmission lines, CIGR Session, V2-209, ParisFrance, 2004. T.O. Seppa, H.W. Adams, D.A. Douglass, N. Coad, A. Edris, P. Olivier, F.R. Thrash, Use of on-line tension monitoring for real-time thermal ratings, ice loads and other environmental effects, CIGR Session, 22102, Paris-France, 1998. T.O. Seppa, S. Damsgaard-Mikelsen, M. Clements, R. Payne, N. Coad, Application of real time thermal ratings for optimizing transmission line investment and operating decisions, CIGR Session, 22-301, ParisFrance, 2000. C. Mensah-Bonsu, G.T. Heydt, Overhead transmission conductor sag: a novel measurement technique and the relation of sag to real time circuit ratings, Electric Power Components and Systems, Vol. 31, pp. 61-69, 2003. R. Stephen, D. Muftic, Determination of the thermal rating and uprating methods for existing lines, CIGR Session, 22-305, Paris-France, 2000. S. P. Hoffmann, A.M. Clark, The approach to thermal uprating of transmission lines in the UK, CIGR Session, V2-317, Paris-France, 2004. A. Kikuchi, R. Morimoto, K. Mito, Y. Kimura, A. Mikumo, Uprating of transmission capacity in Great Riyadh 132 KV T/L grid system by adopting small sag and thermal rate-up conductor, CIGRE Symposium Leningrad, S 33-91, 100-06, 1991. M. J. Tunstall, S. P. Hoffmann, N. S. Derbyshire, M. J. Pyke, Maximising the ratings of National Grids existing transmission lines using high temperature low sag conductor, CIGR Session, 22-202, Paris-France, 2000. I. Zamora, A.J. Mazon, P. Eguia, R. Criado, C. Alonso, J. Iglesias, J.R. Saenz, High-temperature conductors: a solution in the uprating of overhead transmission lines, IEEE Power Tech, Porto-Portugal, 2001.

6 [25] F.R. Thrash, ACSS/TW An improved conductor for upgrading existing lines or new construction, IEEE PES Summer Meeting, pp. 182-85, 2001. [26] R. Stephen, Description and evaluation of options relating to uprating of overhead transmission lines, CIGR Session, V2-201, Paris-France, 2004.

IX. BIOGRAPHIES

I. Albizu. He received his degree in Electrical, Electronic and Control Engineering from the University of Navarra in 1998. He received his MSc degree in Electronic Instrumentation Systems from the University of Manchester Institute of Science and Technology (UMIST) in 1999. Currently he is PhD student in the Department of Electrical Engineering at the University of the Basque Country. His fields of interest include the Uprating of Overhead Lines and the Diagnosis of Induction Machines. A. J. Mazn (M03). He received his Electrical Engineering and PhD degrees from the University of the Basque Country in 1990 and 1994 respectively. During 1992 he worked in Labein Research Laboratories. He is currently Associate Professor in the Department of Electrical Engineering at the University of the Basque Country. His research activities include the Electric Power Systems, Transients Simulation, Fault Analysis and Uprating of Overhead Lines. He is IEEE member. I. Zamora (M03). She received her Electrical Engineering and PhD degrees from the University of the Basque Country in 1989 and 1993. Currently, she is Associate Professor and Head in the Department of Electrical Engineering at the University of the Basque Country. Her research activities include the Electric Power Systems, Transients Simulation, Fault Analysis and Uprating of Overhead Lines. She is member of CIGRE and IEEE.

You might also like

- PTC 2005 4524481 PDFDocument6 pagesPTC 2005 4524481 PDFpedramNo ratings yet

- B2 103 2012Document9 pagesB2 103 2012Hugh EdwardsNo ratings yet

- Cigreb2 4Document4 pagesCigreb2 4Nguyễn Tăng LâmNo ratings yet

- Effect of Sag On Transmission LineDocument4 pagesEffect of Sag On Transmission LineMohan ManickamNo ratings yet

- Effect of Sag On TLDocument4 pagesEffect of Sag On TLsubashini_jaganathanNo ratings yet

- Electromagnetic Interference Issues of Power Electronics Systems With Wide Band Gap Semiconductor DevicesDocument6 pagesElectromagnetic Interference Issues of Power Electronics Systems With Wide Band Gap Semiconductor DevicesDinesh KumarNo ratings yet

- Bipolar AC-ACDocument15 pagesBipolar AC-ACBui DaiNo ratings yet

- Ultra Step-Up DC-DC Converter With Reduced Switch StressDocument10 pagesUltra Step-Up DC-DC Converter With Reduced Switch StressnimasalimNo ratings yet

- Energies: Analysis and Design of Three-Phase LLC Resonant Converter With Matrix TransformersDocument18 pagesEnergies: Analysis and Design of Three-Phase LLC Resonant Converter With Matrix Transformersabhijitkadam03No ratings yet

- Id 121Document10 pagesId 121Yjr Arun KumarNo ratings yet

- (SiC-En-2013-2) A Comparative Performance Study of An Interleaved Boost Converter Using Commercial Si and SiC Diodes For PV ApplicationsDocument11 pages(SiC-En-2013-2) A Comparative Performance Study of An Interleaved Boost Converter Using Commercial Si and SiC Diodes For PV Applicationsnuaa_qhhNo ratings yet

- Trends enDocument0 pagesTrends enmaxi_1987No ratings yet

- Transmission Line LoadabilityDocument6 pagesTransmission Line LoadabilityUsama AhmedNo ratings yet

- X International Symposium on Lightning ProtectionDocument20 pagesX International Symposium on Lightning ProtectionABRAHAMNo ratings yet

- Pub 1080Document6 pagesPub 1080Junaid YNo ratings yet

- Paper Judendorfer PackDocument7 pagesPaper Judendorfer PackRamesh EpiliNo ratings yet

- DC Power Transmission TechnologyDocument10 pagesDC Power Transmission TechnologyDrVikas Singh BhadoriaNo ratings yet

- Solid State Transformer-TechnologyReviewDocument5 pagesSolid State Transformer-TechnologyReviewvshalshethNo ratings yet

- Major Factors Affecting Cable AmpacityDocument6 pagesMajor Factors Affecting Cable AmpacityfvicunaeNo ratings yet

- DC Power Transmission TechnologyDocument15 pagesDC Power Transmission TechnologySal Excel60% (5)

- An Interleaved High Step-Up DC DC Converter-Based Three-Winding Coupled Inductors With Symmetrical StructureDocument11 pagesAn Interleaved High Step-Up DC DC Converter-Based Three-Winding Coupled Inductors With Symmetrical Structurewinkavi87No ratings yet

- Xuan - TPEL - A Quasi-Switched-Capacitor Resonant ConverterDocument22 pagesXuan - TPEL - A Quasi-Switched-Capacitor Resonant ConverterteomondoNo ratings yet

- Article CIGRE 22 - 206E PDFDocument6 pagesArticle CIGRE 22 - 206E PDFIsaac DiazNo ratings yet

- IEEE 34 Bus Intermittent Sources PDFDocument8 pagesIEEE 34 Bus Intermittent Sources PDFKancherla SameeraNo ratings yet

- Comparison Between GIS & AISDocument5 pagesComparison Between GIS & AISYaser Barrawaz100% (1)

- Corona Loss Measurements in Cage on UHV Bundle ConductorsDocument11 pagesCorona Loss Measurements in Cage on UHV Bundle ConductorsHarish ReddyNo ratings yet

- A Guide For Minimun Electrical Clearances For Standard Basic Insulation Levels PDFDocument6 pagesA Guide For Minimun Electrical Clearances For Standard Basic Insulation Levels PDFFrancisco Bustamante100% (1)

- Application of Line Surge Arresters to Reduce Lightning OutagesDocument7 pagesApplication of Line Surge Arresters to Reduce Lightning Outagessorry2qazNo ratings yet

- Considering Synchronous Generator Capability Curve Variations For Reactive Power MarketDocument6 pagesConsidering Synchronous Generator Capability Curve Variations For Reactive Power Markettatacps100% (1)

- Effects of Dynamic Reactive Compensation Arc Furnace Operation Characteristics and Its Economic BenefitsDocument6 pagesEffects of Dynamic Reactive Compensation Arc Furnace Operation Characteristics and Its Economic BenefitsAhmed Mohamed HassanNo ratings yet

- 11 180815ASwitched-CapacitorBidirectionalDCDCDocument12 pages11 180815ASwitched-CapacitorBidirectionalDCDCPatil MounicareddyNo ratings yet

- Electrical Engineering GuideDocument124 pagesElectrical Engineering GuidesselmtpdrNo ratings yet

- Efect of Sag On Transmission LineDocument4 pagesEfect of Sag On Transmission LineGabriel Barriga JaqueNo ratings yet

- Advantages of Heavy-Duty MAG WeldingDocument9 pagesAdvantages of Heavy-Duty MAG WeldingNaksalitNo ratings yet

- Cable Heating Effects Due To Harmonic Distortion in Electrical InstallationsDocument6 pagesCable Heating Effects Due To Harmonic Distortion in Electrical InstallationsMunindra GoswamiNo ratings yet

- Carburization Degree, Pyrolysis, Non-Destructive Techniques, Thermodynamics Calculation, Diffusion CalculationDocument10 pagesCarburization Degree, Pyrolysis, Non-Destructive Techniques, Thermodynamics Calculation, Diffusion CalculationJJNo ratings yet

- Modelling Voltage Sag Mitigation Using Dynamic Voltage Restorer and Analyzing Power Quality IssueDocument9 pagesModelling Voltage Sag Mitigation Using Dynamic Voltage Restorer and Analyzing Power Quality Issue1978ECRNo ratings yet

- Power System Term Paper 2Document13 pagesPower System Term Paper 2Durgesh jaiswal123No ratings yet

- Achieving Higher Ampacity of Busbars Through InterleavingDocument0 pagesAchieving Higher Ampacity of Busbars Through InterleavingtceterexNo ratings yet

- Design of Radial NetworkDocument22 pagesDesign of Radial NetworkAli Kaiser0% (1)

- DC Power Transmission Technology ExplainedDocument10 pagesDC Power Transmission Technology ExplainedHARE KRISHNANo ratings yet

- Cigre, 13 Years Test Experience With Short Circuit Withstand Capability of Large Power TransformersDocument7 pagesCigre, 13 Years Test Experience With Short Circuit Withstand Capability of Large Power TransformersMartin ButcherNo ratings yet

- Evaluation of Mathematical Models of Metal Oxide SurgeDocument4 pagesEvaluation of Mathematical Models of Metal Oxide Surgeadriasiq3068No ratings yet

- Tom Tat Luan An - Tieng Anh - V1Document32 pagesTom Tat Luan An - Tieng Anh - V1Hua Tran Phuong ThaoNo ratings yet

- A Lecture On Current LimiterDocument25 pagesA Lecture On Current LimiterLavanya VallbhareddyNo ratings yet

- Cigre, 13 Years Test Experience With Short Circuit Withstand Capability of Large Power TransformersDocument7 pagesCigre, 13 Years Test Experience With Short Circuit Withstand Capability of Large Power TransformersAnonymous YBOliZYNo ratings yet

- 04073335Document9 pages04073335Bodhayan PrasadNo ratings yet

- Facts WhiteDocument5 pagesFacts WhiteAnurag BansalNo ratings yet

- IEEE 1584 - Changes To The Next Edition: Flash Hazard Calculations Was First Published in 2002. This Standard Was HighlyDocument4 pagesIEEE 1584 - Changes To The Next Edition: Flash Hazard Calculations Was First Published in 2002. This Standard Was HighlyJason Ruel ParaderoNo ratings yet

- Why busbar trunking systems are a space-saving and cost-effective electrical solutionDocument9 pagesWhy busbar trunking systems are a space-saving and cost-effective electrical solutionsabeerNo ratings yet

- Electrical Application Substation Design Guide PDFDocument405 pagesElectrical Application Substation Design Guide PDFHimdad TahirNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesNo ratings yet

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringFrom EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNo ratings yet

- RDLCDocument2 pagesRDLCHariprasad gantyalaNo ratings yet

- Oman Property Market Report 2019-2020Document40 pagesOman Property Market Report 2019-2020Hariprasad gantyalaNo ratings yet

- A Method of Definition of Life-Cycle Resources ofDocument6 pagesA Method of Definition of Life-Cycle Resources ofHariprasad gantyalaNo ratings yet

- Class 1 Shapes and Space - NotesDocument4 pagesClass 1 Shapes and Space - NotesHariprasad gantyalaNo ratings yet

- RSI-The Complete Guide-John HaydenDocument126 pagesRSI-The Complete Guide-John HaydenSyed Muhammad Shahbaz100% (8)

- Ifrs Acca - Dipifrs - Revision Kit 2019Document304 pagesIfrs Acca - Dipifrs - Revision Kit 2019Hariprasad gantyalaNo ratings yet

- IRENAinsight On Project Cost Webinar - RPGC in 2019 OverviewDocument61 pagesIRENAinsight On Project Cost Webinar - RPGC in 2019 OverviewHariprasad gantyalaNo ratings yet

- IFRS ACCA - DipIFRS - Revision Kit 2019Document304 pagesIFRS ACCA - DipIFRS - Revision Kit 2019Hariprasad gantyala0% (1)

- Large-Scale Solar PV Lcoe Comprehensive Breakdown MethodologyDocument20 pagesLarge-Scale Solar PV Lcoe Comprehensive Breakdown MethodologyHariprasad gantyalaNo ratings yet

- Nextracker + PV Tech TECHTALK Webinar SlidesDocument61 pagesNextracker + PV Tech TECHTALK Webinar SlidesHariprasad gantyalaNo ratings yet

- Leading The New Era of 600W+ Modules: Canadian Solar Hiku7 & Bihiku7 Technical White PaperDocument20 pagesLeading The New Era of 600W+ Modules: Canadian Solar Hiku7 & Bihiku7 Technical White PaperHariprasad gantyala100% (1)

- Class 1 - MATHS-NUMBERS 0 TO 9 WORKSHEET 4Document3 pagesClass 1 - MATHS-NUMBERS 0 TO 9 WORKSHEET 4Hariprasad gantyalaNo ratings yet

- NCSCM Campus Tender DocumentsDocument498 pagesNCSCM Campus Tender Documentssadi3013No ratings yet

- Pages From OmanObserver - 31!01!21Document1 pagePages From OmanObserver - 31!01!21Hariprasad gantyalaNo ratings yet

- Oman Custom Duty ScheduleDocument333 pagesOman Custom Duty ScheduleHariprasad gantyalaNo ratings yet

- Procedure Forissue NOC of PP by MoD Apr2014Document2 pagesProcedure Forissue NOC of PP by MoD Apr2014Hariprasad gantyalaNo ratings yet

- Pages From OmanObserver - 31!01!21Document1 pagePages From OmanObserver - 31!01!21Hariprasad gantyalaNo ratings yet

- IFC Harnessing+Energy+From+The+Sun - FinalDocument132 pagesIFC Harnessing+Energy+From+The+Sun - FinalHariprasad gantyalaNo ratings yet

- Construction Method StatementDocument29 pagesConstruction Method StatementHariprasad gantyalaNo ratings yet

- 13.pole Type Structure 1Document22 pages13.pole Type Structure 1Hariprasad gantyalaNo ratings yet

- Solar Street Light 4Document5 pagesSolar Street Light 4Mohammad MajdalawiNo ratings yet

- Transmission Monopole PDFDocument71 pagesTransmission Monopole PDFHariprasad gantyala100% (3)

- Private WMS From 20.06.2008 To 31.03.2012 DT 16.05.2017Document5 pagesPrivate WMS From 20.06.2008 To 31.03.2012 DT 16.05.2017Hariprasad gantyalaNo ratings yet

- Bbbbbbbbbbbbb: '≥Å∞Qæ∞ =¸Åo: N ##Flü«∞Éèí/Ïì~°‰Õω - »∞ N Uhõ¯# ™È=∞Ü«∂L N Z¢~ŢѨQæ - ». (Hõq¢'«Ü«∞O)Document37 pagesBbbbbbbbbbbbb: '≥Å∞Qæ∞ =¸Åo: N ##Flü«∞Éèí/Ïì~°‰Õω - »∞ N Uhõ¯# ™È=∞Ü«∂L N Z¢~ŢѨQæ - ». (Hõq¢'«Ü«∞O)sanagavarapuNo ratings yet

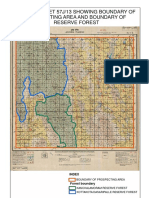

- SOI Toposheet 57J/13 with Prospecting Area & Forest BoundariesDocument1 pageSOI Toposheet 57J/13 with Prospecting Area & Forest BoundariesHariprasad gantyalaNo ratings yet

- Guidelines for Defence Clearance of Wind ProjectsDocument3 pagesGuidelines for Defence Clearance of Wind ProjectsHariprasad gantyalaNo ratings yet

- Soi Toposheet 57J/13 Showing Boundary of Prospecting Area and Boundary of Reserve ForestDocument1 pageSoi Toposheet 57J/13 Showing Boundary of Prospecting Area and Boundary of Reserve ForestHariprasad gantyalaNo ratings yet

- Const PowerProjectDocument2 pagesConst PowerProjectHariprasad gantyalaNo ratings yet

- NOC Construction Helipad Greenfield AirfieldDocument15 pagesNOC Construction Helipad Greenfield Airfieldbansalaman1986No ratings yet

- ATMA Sample Question IDocument18 pagesATMA Sample Question IHariprasad gantyalaNo ratings yet

- Marmaray TPS Project Contract CR1Document60 pagesMarmaray TPS Project Contract CR1Ismet Hizyolu100% (1)

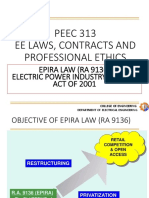

- Ra 9136Document117 pagesRa 9136Jan VegaNo ratings yet

- Lightning Surge Modeling of Ground ElectrodesDocument9 pagesLightning Surge Modeling of Ground ElectrodesAbraham MaravíNo ratings yet

- Ph203 CH23 WorksheetDocument5 pagesPh203 CH23 WorksheetEko Bambang SaputroNo ratings yet

- Principle Approach For Assessing Nordic Welfare Under Flow-Based MethodologyDocument31 pagesPrinciple Approach For Assessing Nordic Welfare Under Flow-Based MethodologylupoderiNo ratings yet

- 1 Letter-217 FOTE TrainingDocument2 pages1 Letter-217 FOTE TrainingFahimNo ratings yet

- 02 SALTRAN DNN Jenis Kondisi Saluran TransmisiDocument28 pages02 SALTRAN DNN Jenis Kondisi Saluran TransmisipradanaNo ratings yet

- REE Copy PDFDocument9 pagesREE Copy PDFJake ZozobradoNo ratings yet

- Inductive Interference Calculation On Imperfect Coated Pipelines Due To Nearby Faulted Parallel Transmission LinesDocument10 pagesInductive Interference Calculation On Imperfect Coated Pipelines Due To Nearby Faulted Parallel Transmission LinesgusNo ratings yet

- List of IEEE StandardsDocument224 pagesList of IEEE StandardsAbhay Kumar50% (2)

- Indian Power ScenarioDocument69 pagesIndian Power ScenarioManoj JhaNo ratings yet

- Modern Trends in Power TransmissionDocument13 pagesModern Trends in Power Transmissionhoney9daringNo ratings yet

- Technical Specification of PLCC: Wbsetcl Page - 1/26 Battery ChargerDocument26 pagesTechnical Specification of PLCC: Wbsetcl Page - 1/26 Battery ChargerpvenkyNo ratings yet

- Wireless Charging of Battery in Electrical Vehicle Using Solar Energy IJERTV9IS030436Document4 pagesWireless Charging of Battery in Electrical Vehicle Using Solar Energy IJERTV9IS030436vishal kambleNo ratings yet

- Tunisian Electric System ProjectDocument10 pagesTunisian Electric System ProjectAchref Ben MabroukNo ratings yet

- DE Ee1Document4 pagesDE Ee1Jj JumawanNo ratings yet

- Dynamic Modeling of Induction Motor Loads For Transient Voltage Stability StudiesDocument5 pagesDynamic Modeling of Induction Motor Loads For Transient Voltage Stability StudiesHashim KhanNo ratings yet

- Transmission Line Steady-State Operation and Stability LimitsDocument28 pagesTransmission Line Steady-State Operation and Stability LimitsSherry KhanNo ratings yet

- Press Release:: Page 1 of 2Document2 pagesPress Release:: Page 1 of 2muhammad aliNo ratings yet

- DTU DONG Ivan Arana Overvoltage ProtectionDocument31 pagesDTU DONG Ivan Arana Overvoltage Protectionbubo28No ratings yet

- TH ALL r3Document186 pagesTH ALL r3tamann2004No ratings yet

- Underground CablesDocument84 pagesUnderground Cableshaidarkukum5686100% (1)

- Short Circuit Analysis TRF and DG ModeDocument409 pagesShort Circuit Analysis TRF and DG ModeBalamurugan ArumugamNo ratings yet

- Power System Operation and Control NotesDocument130 pagesPower System Operation and Control NotesParimal PatelNo ratings yet

- Using High-Speed Grounding SwitchesDocument3 pagesUsing High-Speed Grounding SwitchesAnupam0103No ratings yet

- Before: Transmission Company LTDDocument33 pagesBefore: Transmission Company LTDSiddharth BhawsarNo ratings yet

- Section III: Symmetrical Fault in A Power System: Chapter 6: Short Circuit Studies - Symmetrical FaultsDocument3 pagesSection III: Symmetrical Fault in A Power System: Chapter 6: Short Circuit Studies - Symmetrical FaultsMichele OconnorNo ratings yet

- Substation Automation Solutions and ApplicationsDocument7 pagesSubstation Automation Solutions and ApplicationsWilson MondoNo ratings yet

- P",znerator: AnalysisDocument7 pagesP",znerator: AnalysismemohsNo ratings yet

- Ekspose PLN Litbang For HIDA-METIDocument34 pagesEkspose PLN Litbang For HIDA-METIYuliandra Syahrial NurdinNo ratings yet